With the old paint and primer stripped off, this is what I was looking at:

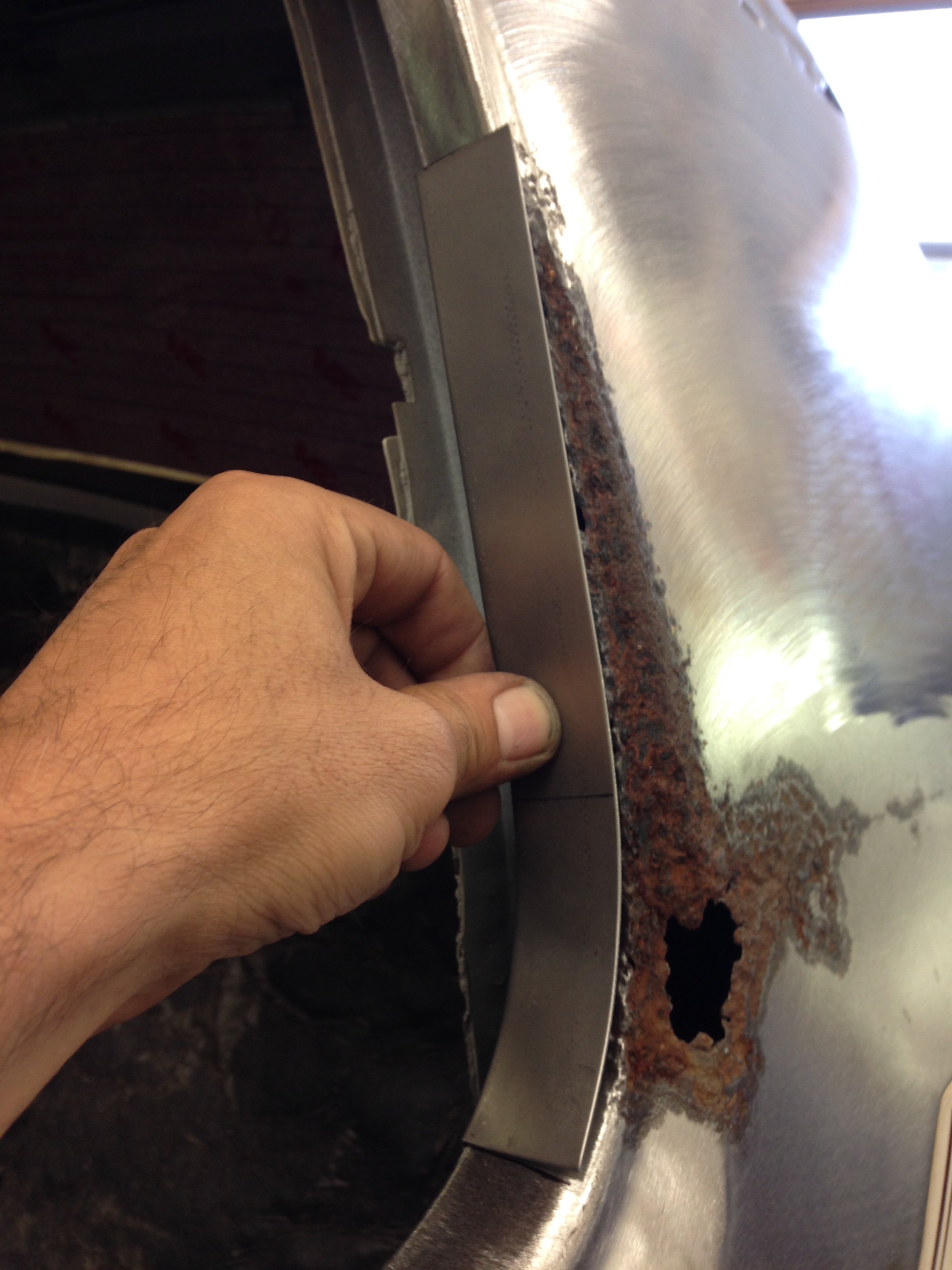

Doesn't look too bad, right? After a little grinding to the areas, things got a lot worse. The blistered and rusty areas are actually perforated through.

These pics are in progression, as I move front to back:

The last hole in the progression towards the rear I might be able to get away with grinding out bigger and welding up, as it's quite a ways away from the rest of the damaged areas, but most will require cutting out and welding in one or more patches.

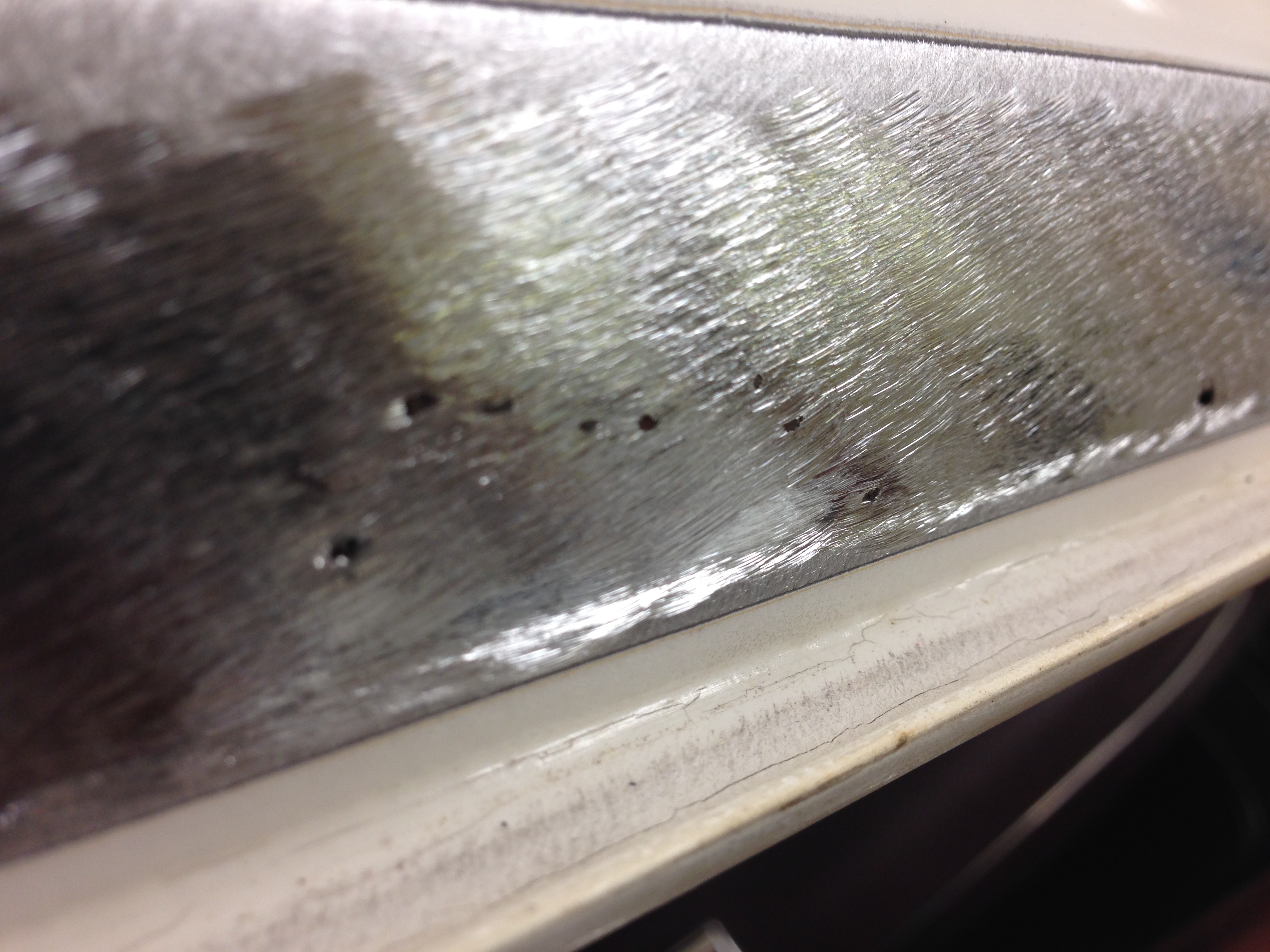

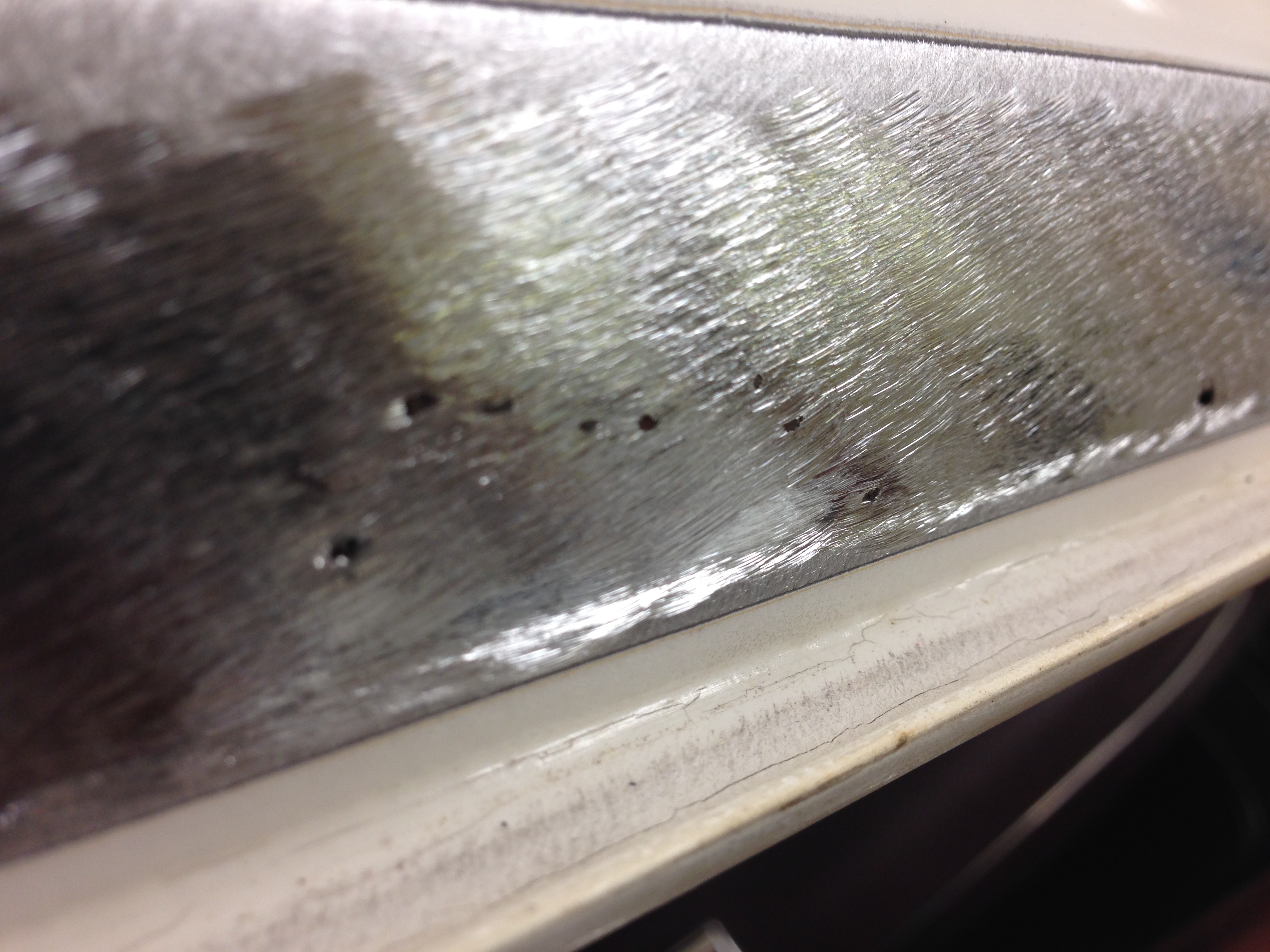

Especially this area. It's Swiss cheese, all these little pin holes tells me the backside is rotten, and no good:

The rear most hole:

It's about 6" away from the rest, I MIGHT be able to get away with trying to weld this one up. Not holding my breath tho.

It's really tough to get a good pic of it, but here's the entire affected area:

Oh well. Better to find it now, than once I'm in the middle of the filler and blocking work.

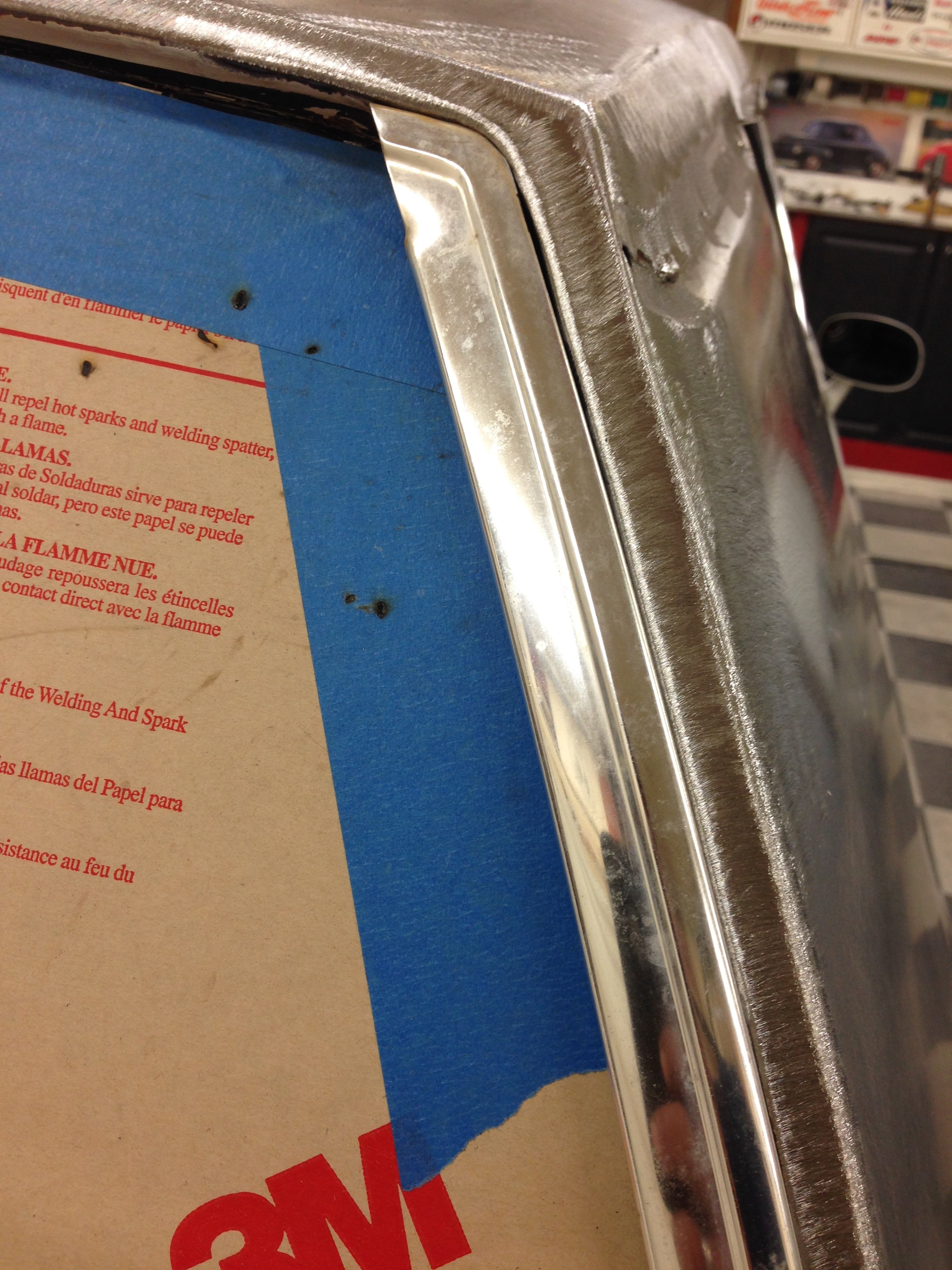

Earlier last week when I was stripping the paint and primer out of the quarter window opening, I found this little gem hiding below.

A nasty dent.

This area is covered and protected by the thick chrome quarter window trim, the only way it could've gotten there is if it left the assembly line that way!

No worries, I have the means to fix that right up!

😀

I broke out the UniSpotter (yes, I have a UniSpotter!), and welded a couple studs to the deepest part of the dent, and pulled it out.

Grand total time to fix it? About 5 minutes. Jeez, you think the factory could've at least spent that amount of time to fix it properly instead of just covering it up!

Anyways, here's the same area, after the dent was removed:

And that's all I got for now.

I'm officially on holidays all this week now, so I'll be logging some serious hours on the car over the next couple days.

Updates to follow as always!

Thanks for checking back everyone.

D.

Doesn't look too bad, right? After a little grinding to the areas, things got a lot worse. The blistered and rusty areas are actually perforated through.

These pics are in progression, as I move front to back:

The last hole in the progression towards the rear I might be able to get away with grinding out bigger and welding up, as it's quite a ways away from the rest of the damaged areas, but most will require cutting out and welding in one or more patches.

Especially this area. It's Swiss cheese, all these little pin holes tells me the backside is rotten, and no good:

The rear most hole:

It's about 6" away from the rest, I MIGHT be able to get away with trying to weld this one up. Not holding my breath tho.

It's really tough to get a good pic of it, but here's the entire affected area:

Oh well. Better to find it now, than once I'm in the middle of the filler and blocking work.

Earlier last week when I was stripping the paint and primer out of the quarter window opening, I found this little gem hiding below.

A nasty dent.

This area is covered and protected by the thick chrome quarter window trim, the only way it could've gotten there is if it left the assembly line that way!

No worries, I have the means to fix that right up!

😀

I broke out the UniSpotter (yes, I have a UniSpotter!), and welded a couple studs to the deepest part of the dent, and pulled it out.

Grand total time to fix it? About 5 minutes. Jeez, you think the factory could've at least spent that amount of time to fix it properly instead of just covering it up!

Anyways, here's the same area, after the dent was removed:

And that's all I got for now.

I'm officially on holidays all this week now, so I'll be logging some serious hours on the car over the next couple days.

Updates to follow as always!

Thanks for checking back everyone.

D.