Phew, it took a while, but I read through the whole thread up to now. All I can say is AMAZING! I can't wait to see the next installment!

BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Phew, it took a while, but I read through the whole thread up to now. All I can say is AMAZING! I can't wait to see the next installment!

Thank you very much! Always nice to see a new face on here, welcome aboard the thread.

Update coming tomorrow night, some teaser pics in the meantime...

D.

D.

Alrighty, time for that promised update.

Where to start? I guess we’ll start with a status report on the finger I decided to stick in a fan last week, it’s been 8 days since I got 5 stitches in it. I went to the doc after work tonight thinking he’d be pulling them, instead he informed me that I popped one stitch today, it’s infected, and now I get to be on a regimen of antibiotics and anti inflammatories. Oh, and the stitches gotta stay for another week yet.

Yay me.

Guess that’s what I get for still having to work with it.

Onto less depressing things, let’s talk about the headway I’ve made on the car.

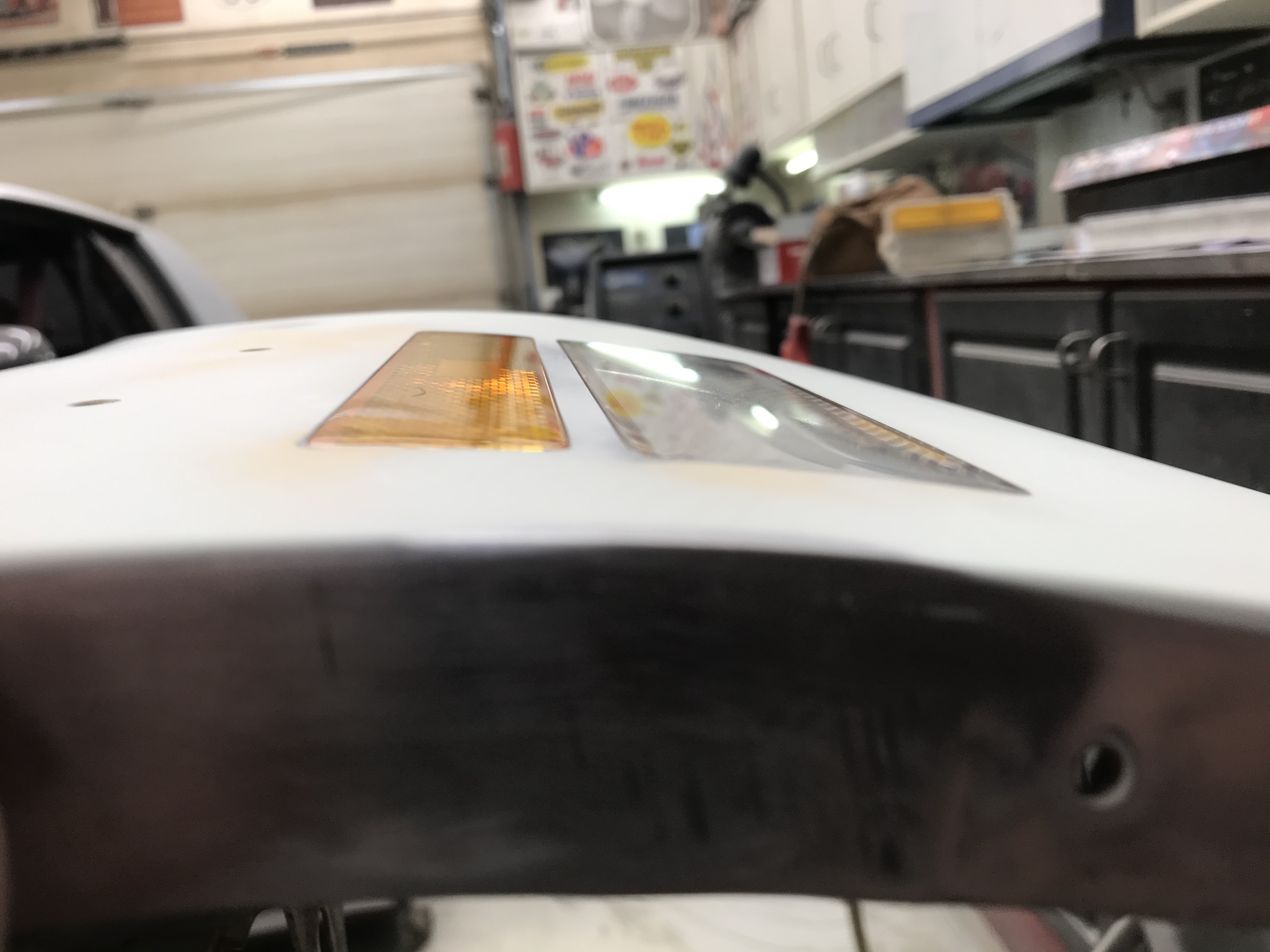

Y’all probably remember me posting this photo shortly after I got the holes cut for the flush mount marker light mod...

...however what I didn’t mention is that was just a quick and dirty mock up with the old original light. Although it’s not readily apparent, I found the original light had a large crack right through the middle of it once I had it out of the old chrome bezel.

This is where things get interesting.

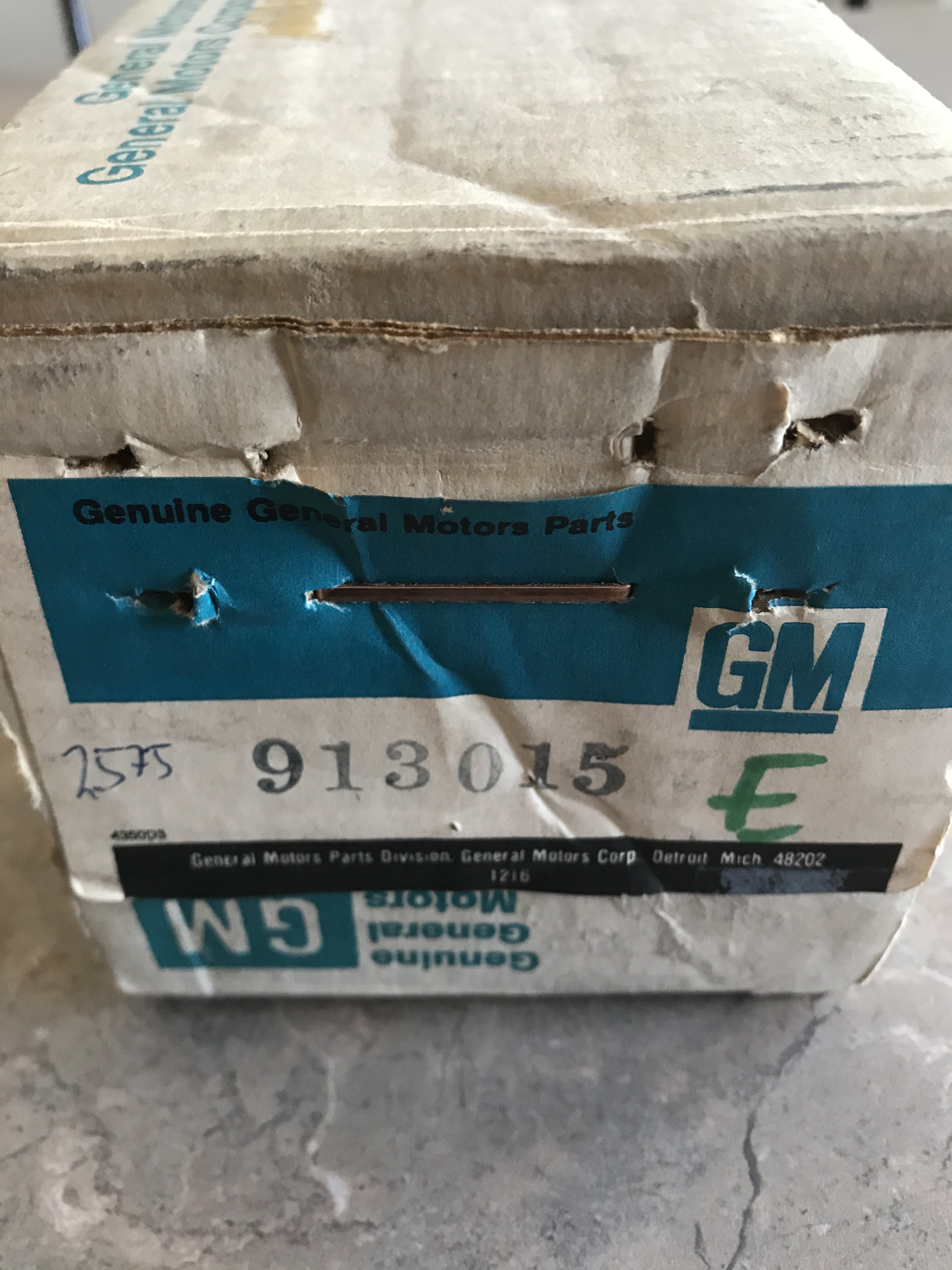

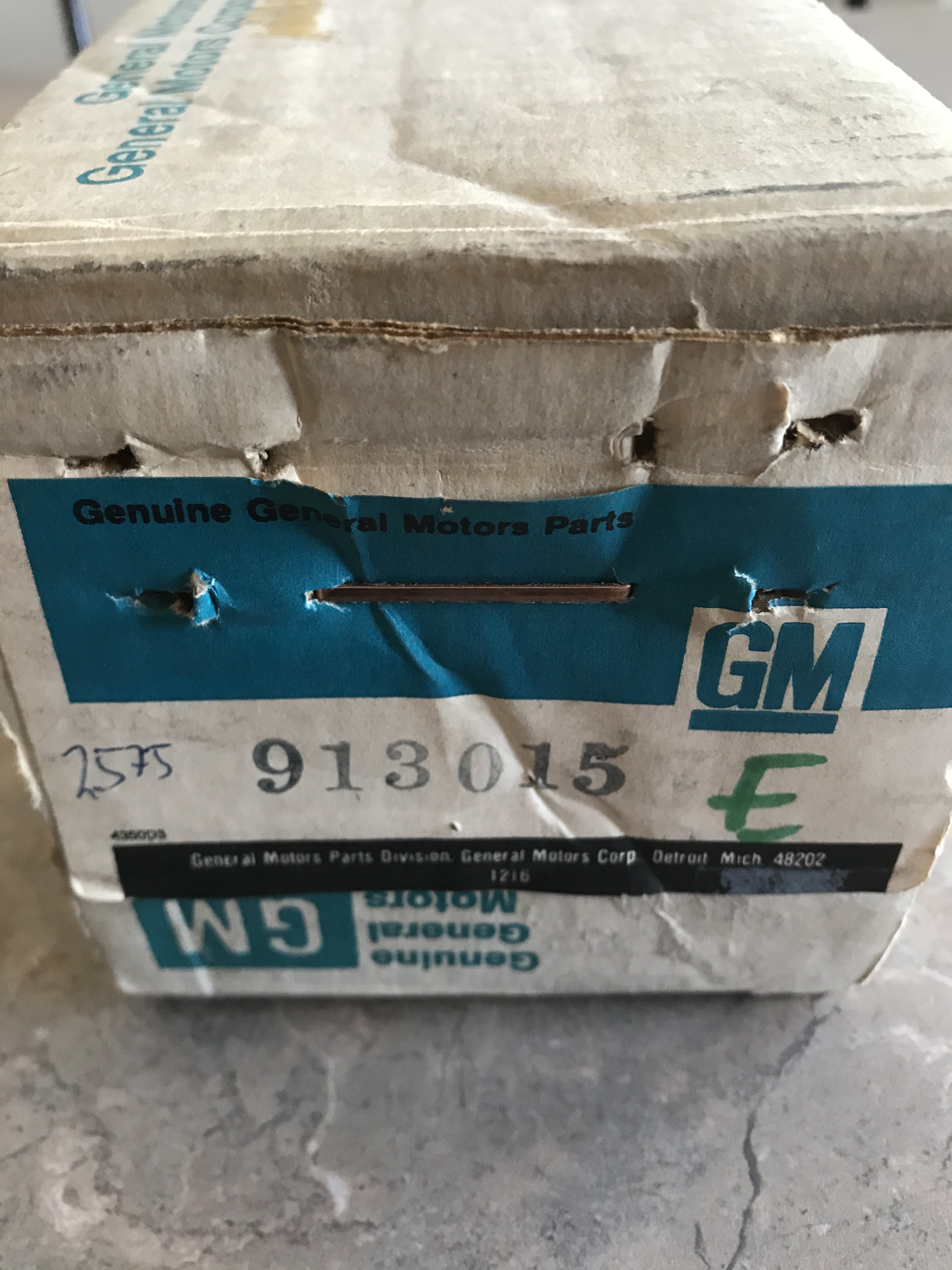

I had put up an ad in the wanted section here on the forum for a replacement thinking that someone would have a decent used one to offer. Instead, I got a series of PM’s from none other than our own Mr. 69HurstOlds, who, all of his own accord, and without verification from me, had gone ahead and purchased a NOS light that he had found for me on eBay. Simply because he knew I needed one, and that the seller wouldn’t ship to Canuckistan.

THAT, my friends, is going above and beyond. As if his thoughtfulness and risk wasn’t enough, once I confirmed that I’d OF COURSE be buying it from him, he volunteered to ship it to me on his own dime. Called it a “gift” and his contribution to my build.

Talk about blown away. I mean, people just don’t show acts of kindness like that in this day and age, do they?? Apparently so.

Mike, I again want to sincerely thank you from the bottom of my heart for your thoughtfulness and generosity. It was more than appreciated, and will not be forgotten.

THANK YOU!!!

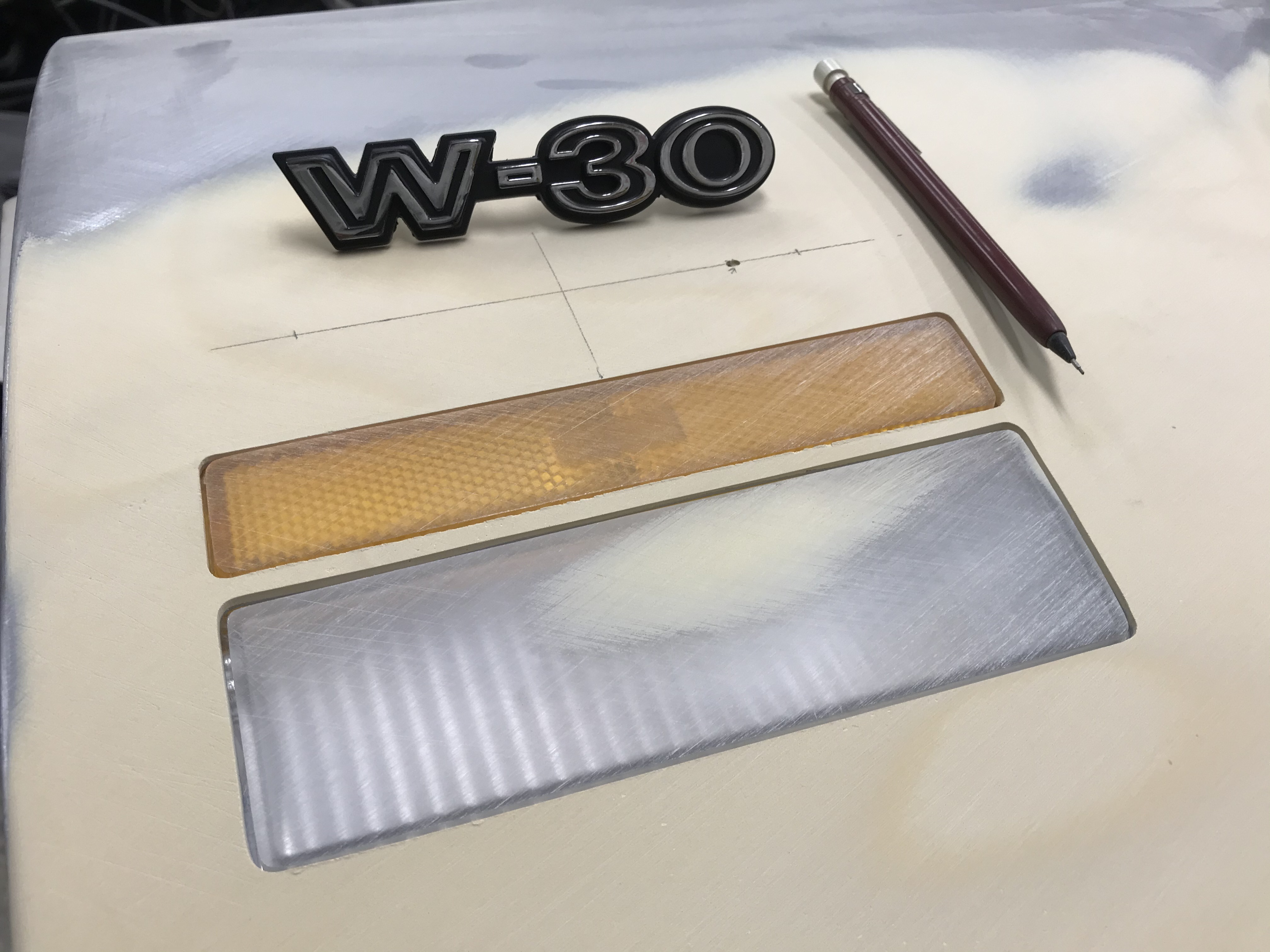

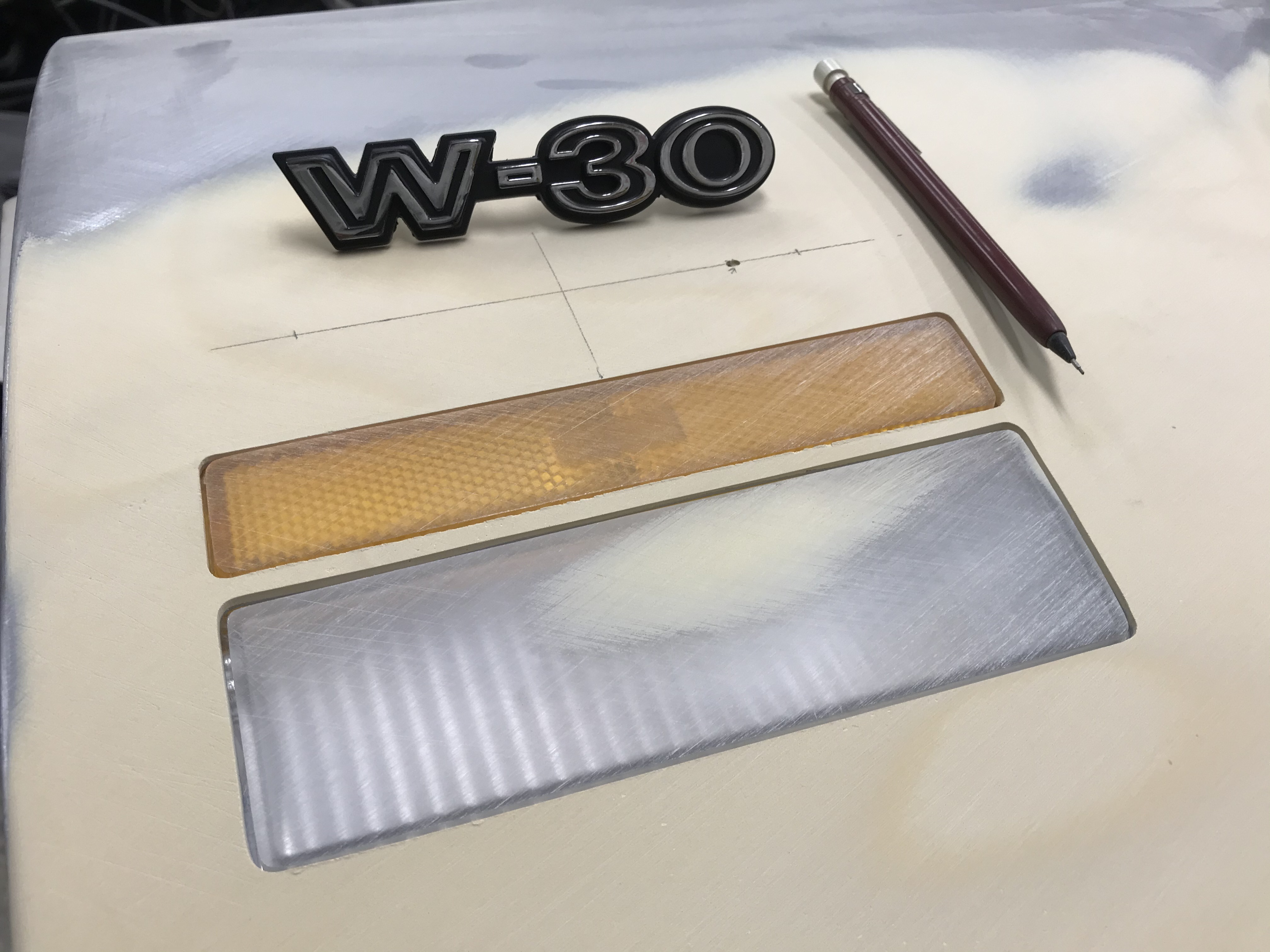

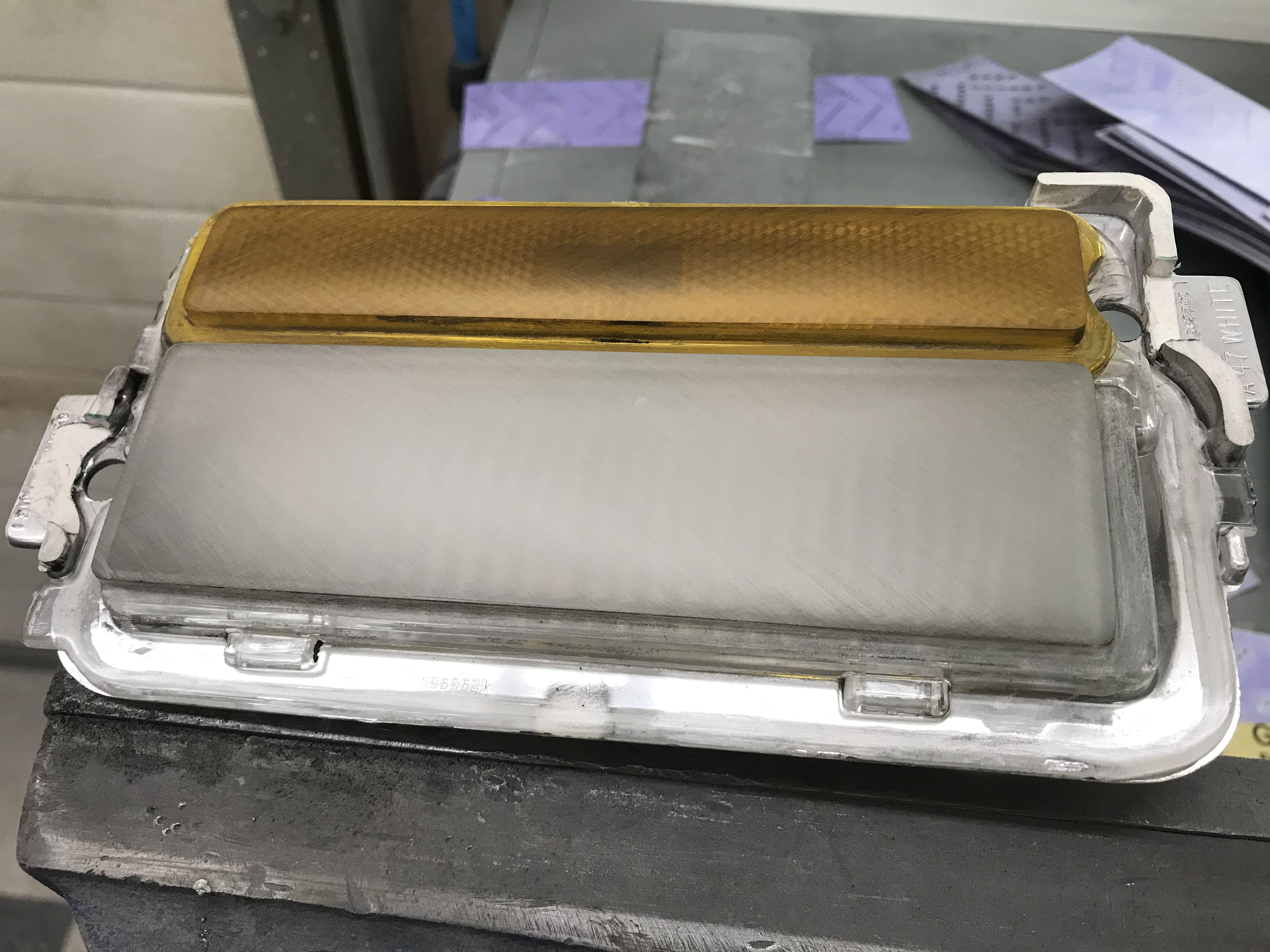

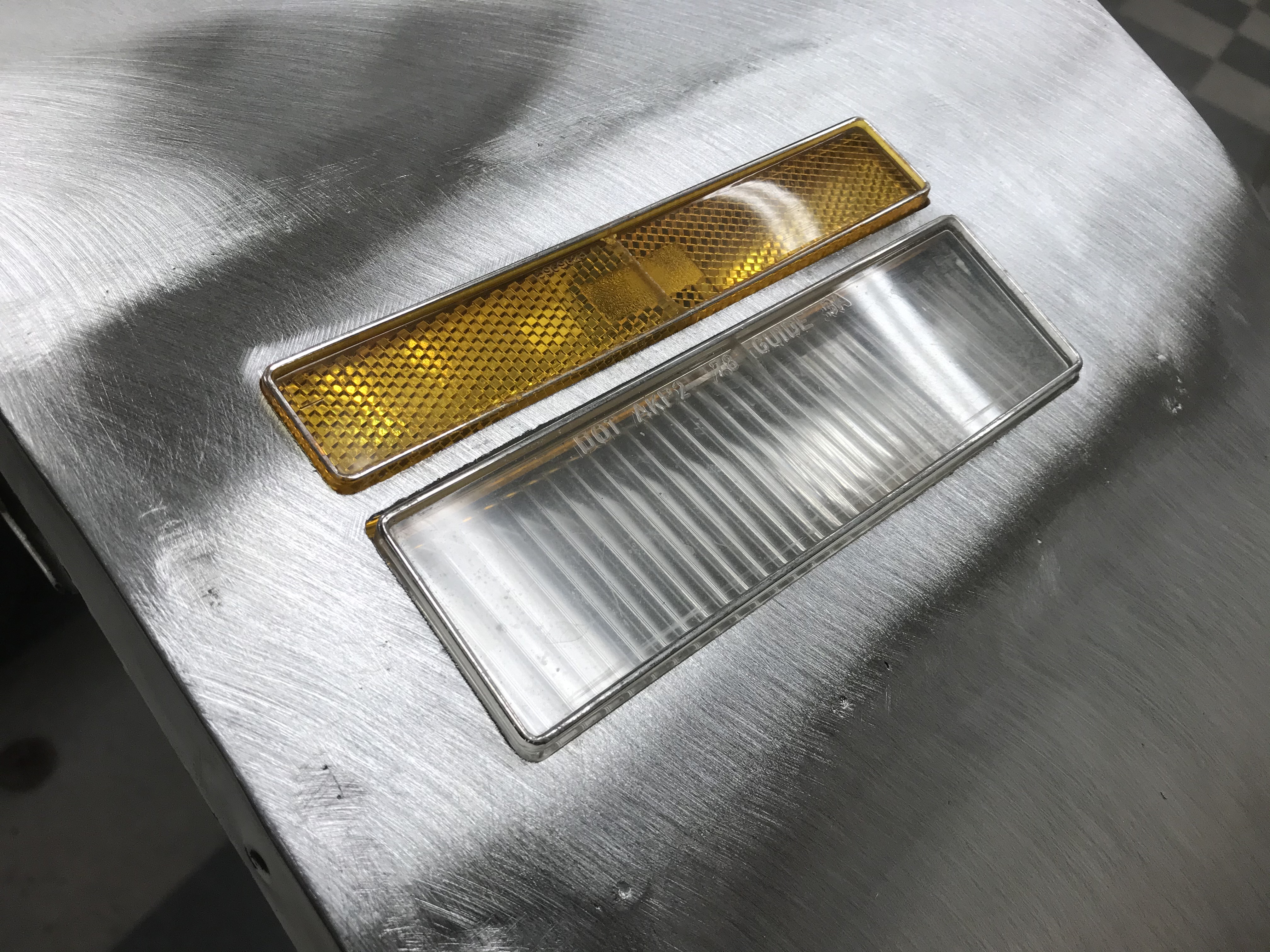

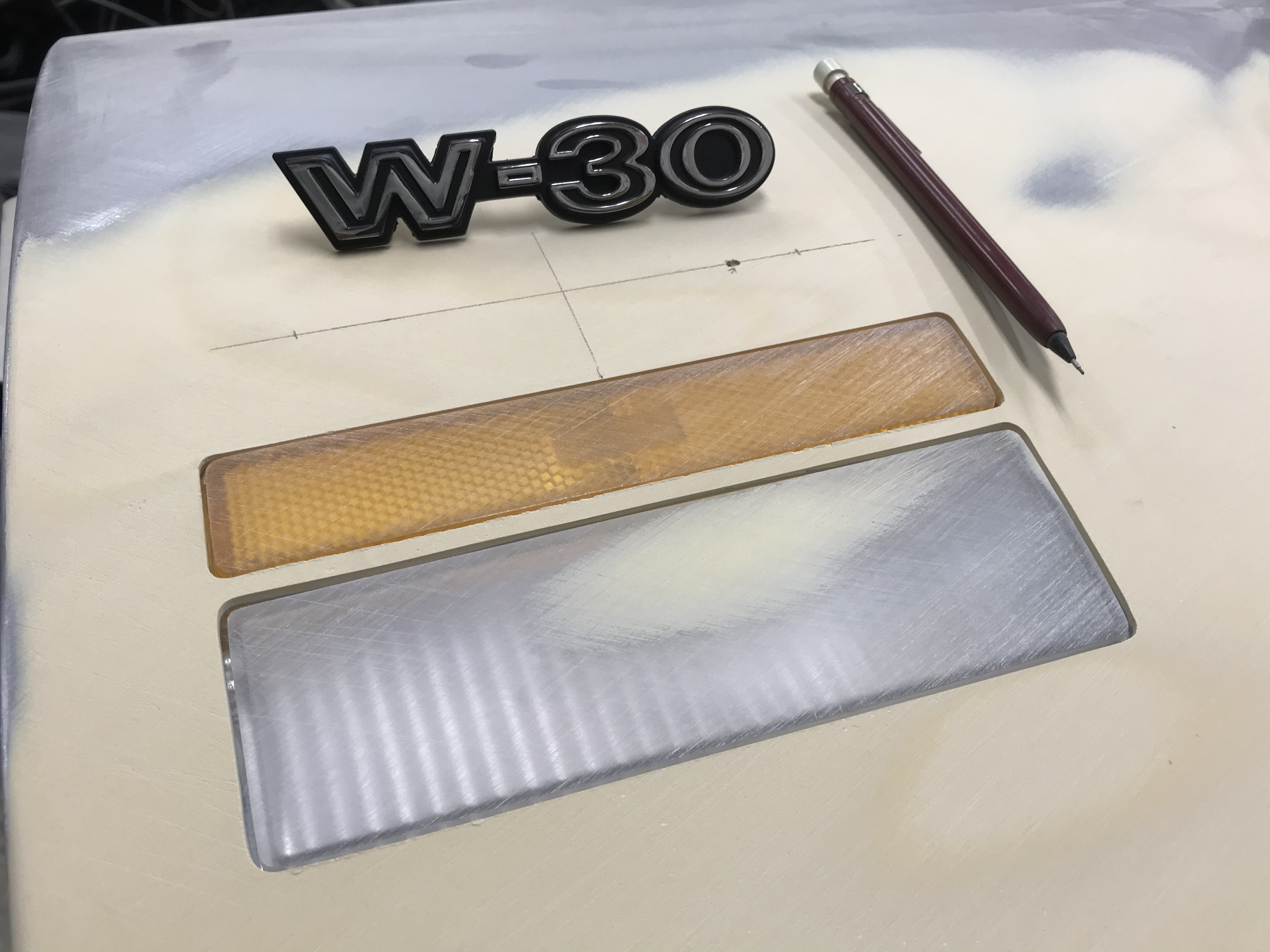

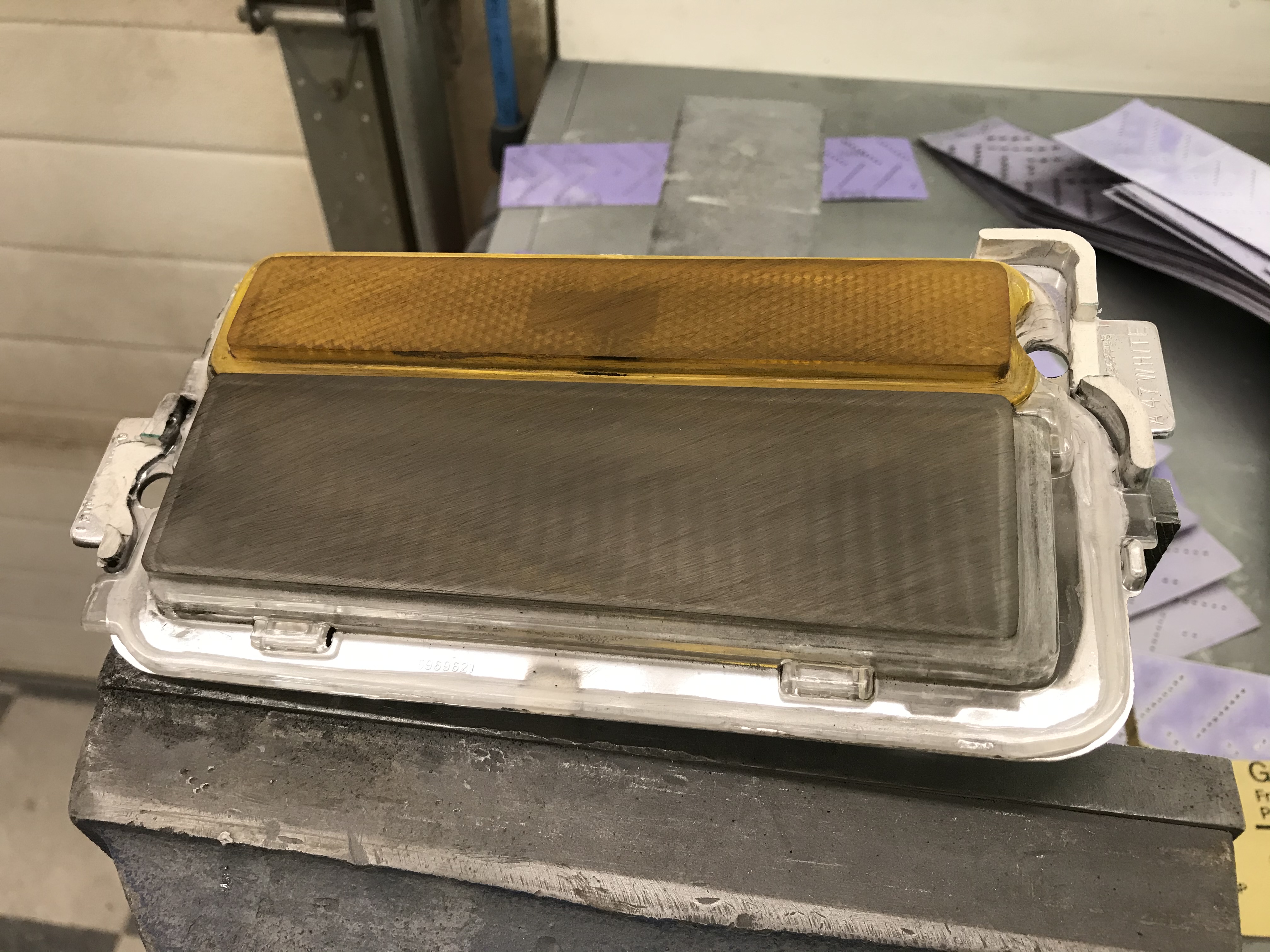

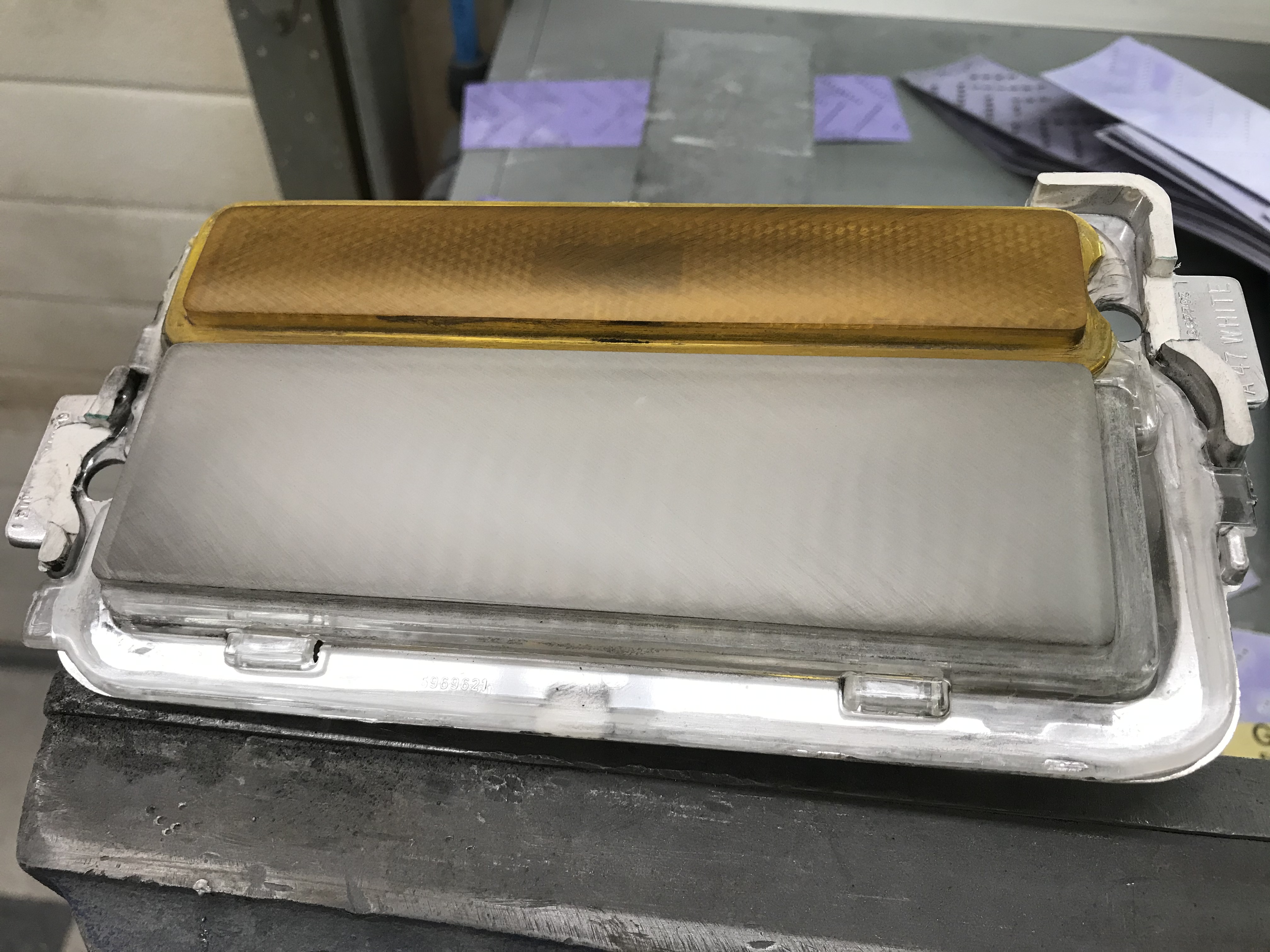

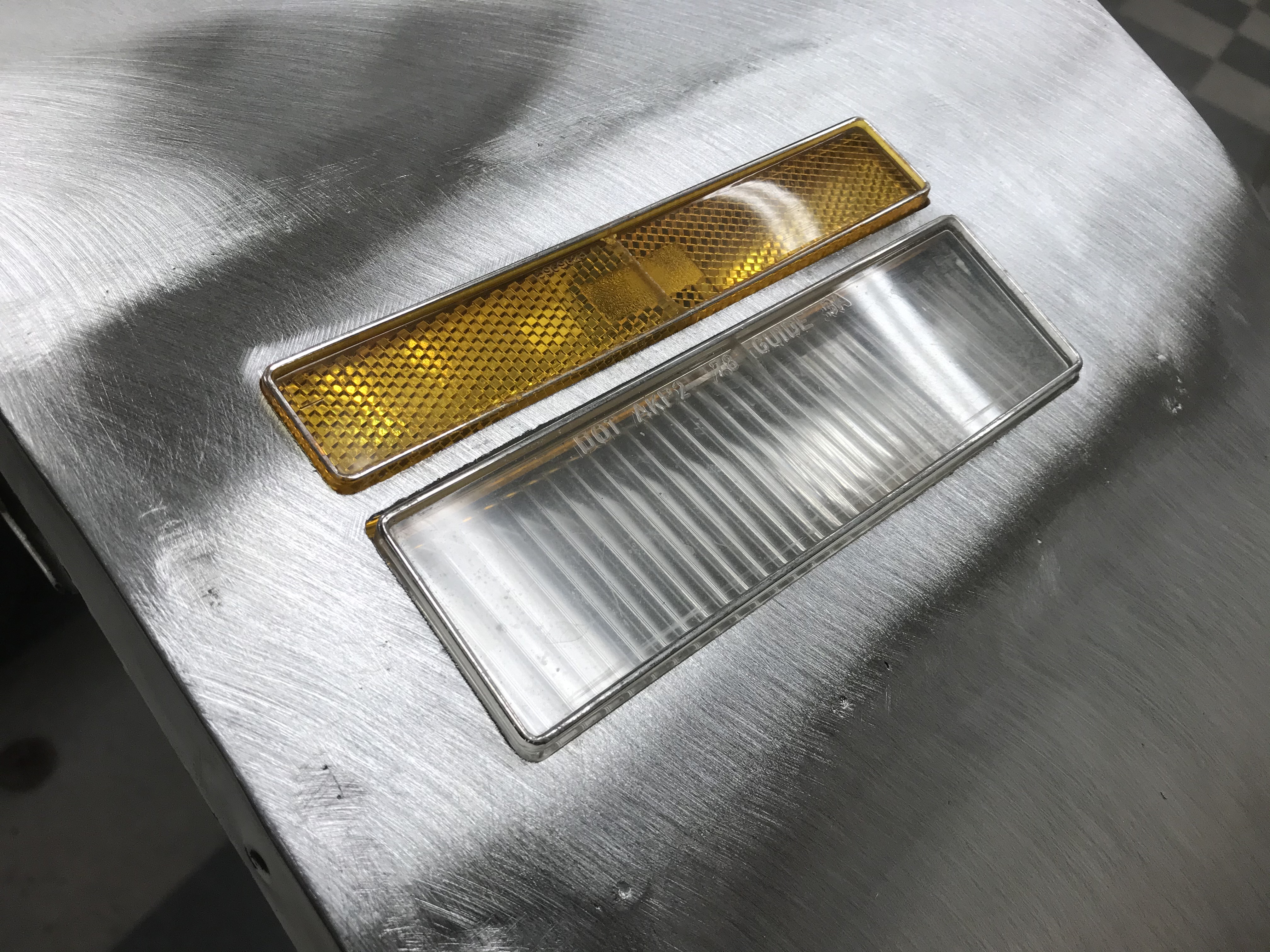

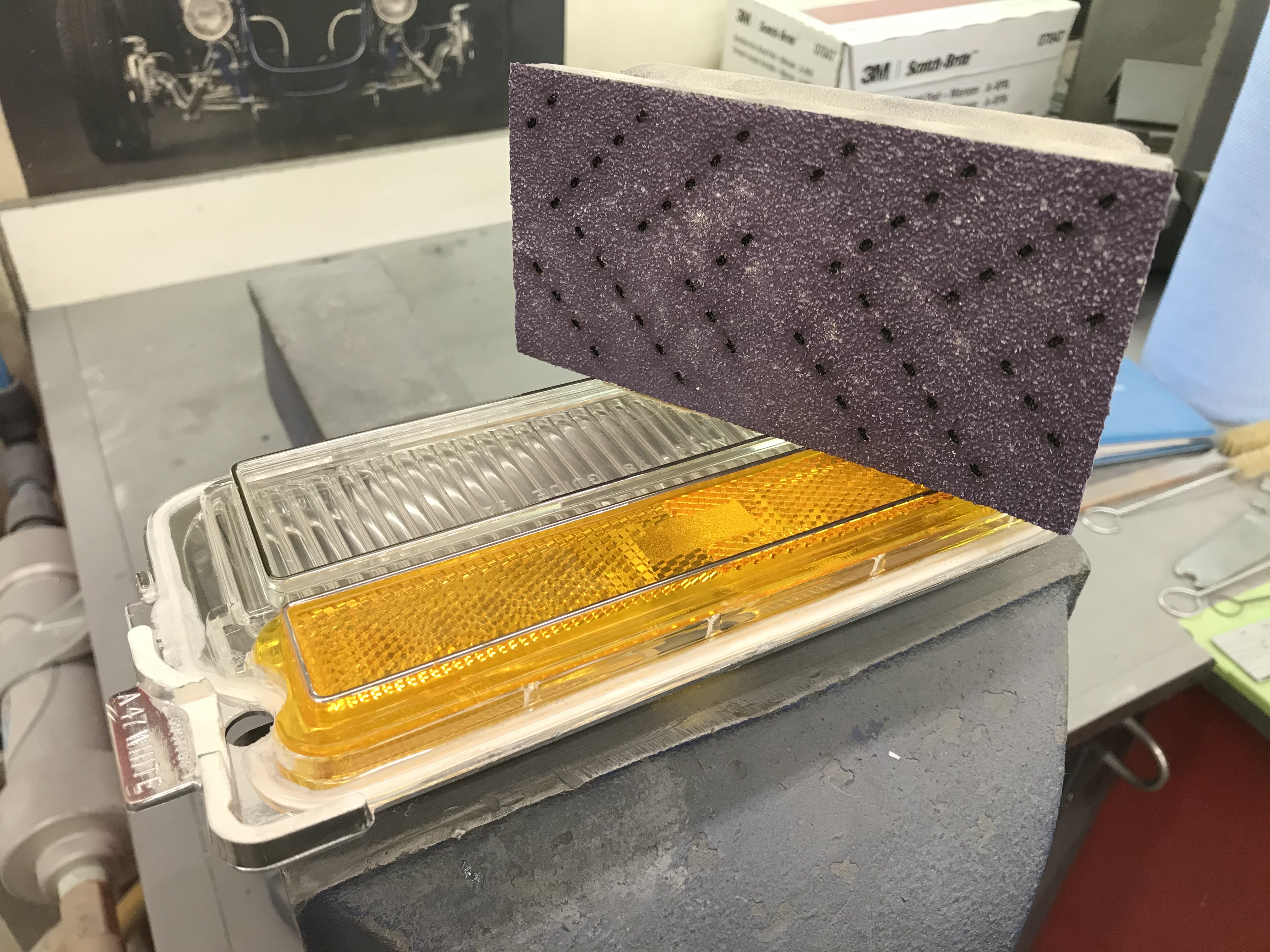

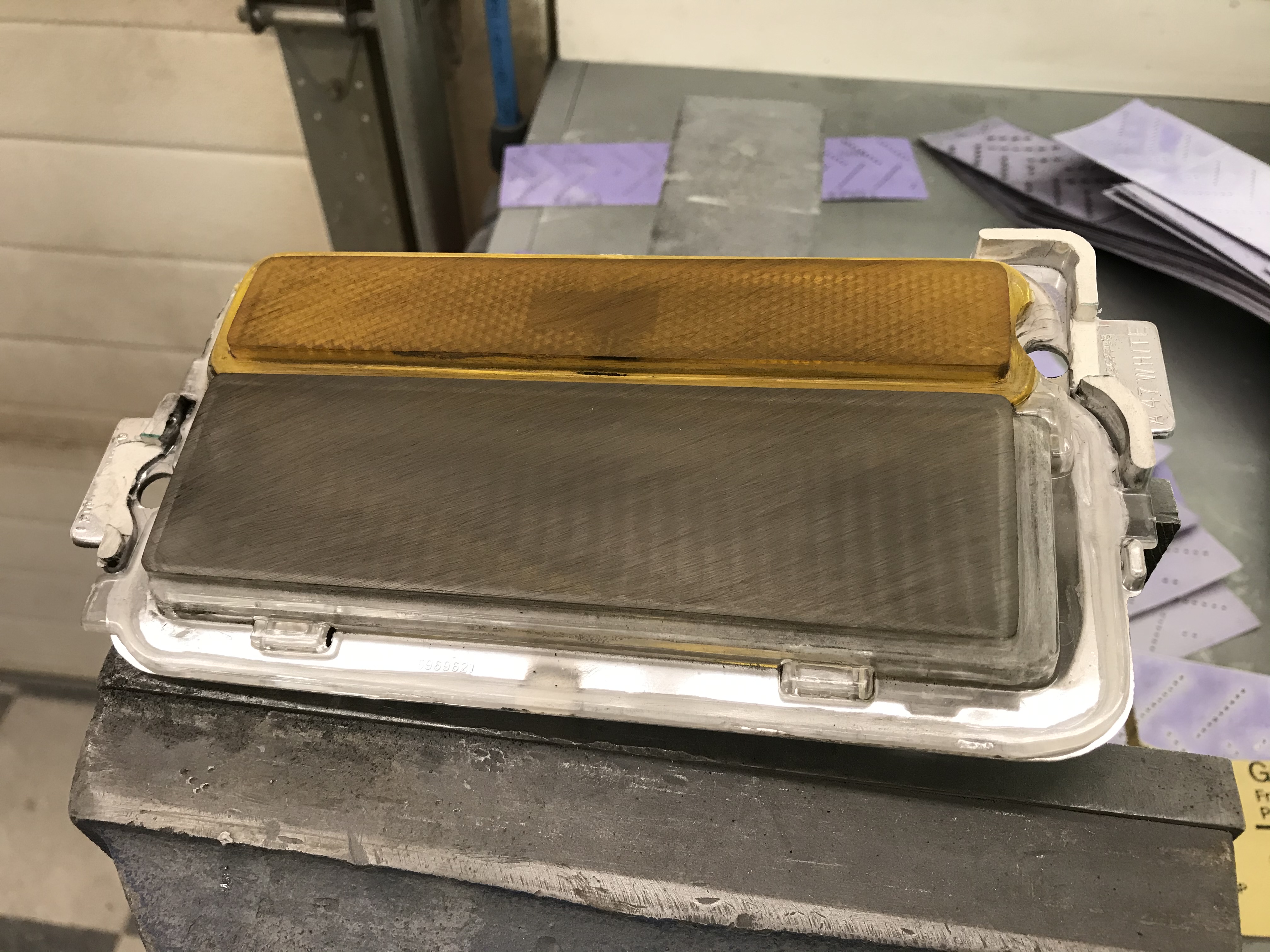

Here’s the old original light in the fender, along with the NOS light from him:

What a beautiful piece. I’ve never been fortunate enough to have anything NOS before, so this was an exceptional treat!

....Which makes it all that much harder to relate what I had to do to it next.

If you’re squeamish about seeing a vintage NOS part get violated, you may want to look away now. Seriously. It might make you wanna cry, I damn near did!

(Disclaimer: I warned Mike of what I was gonna do to this pristine part and got his blessing, so send your hate mail to [email protected])

Ok, if you’re still reading, you can’t say you haven’t been warned.

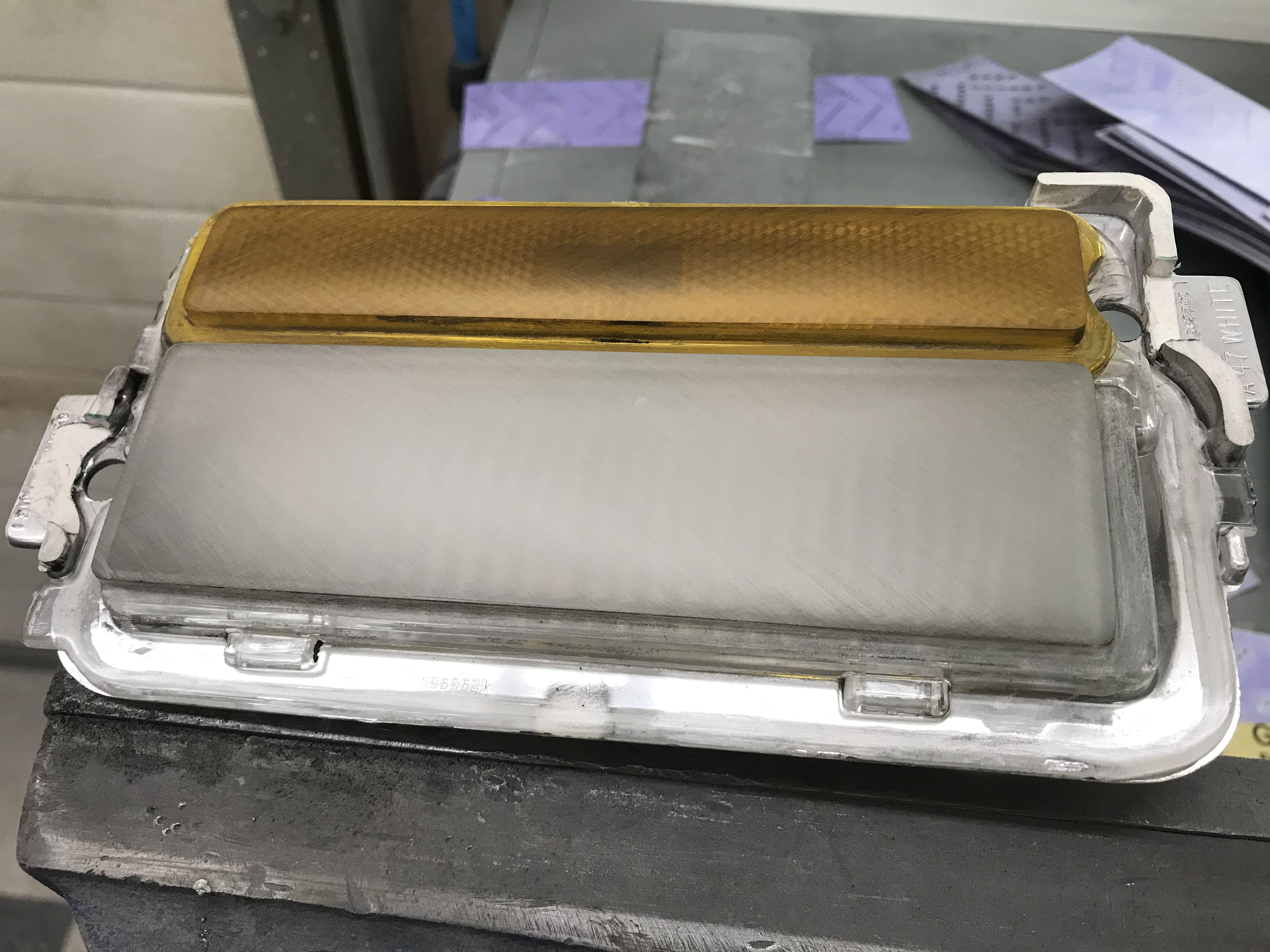

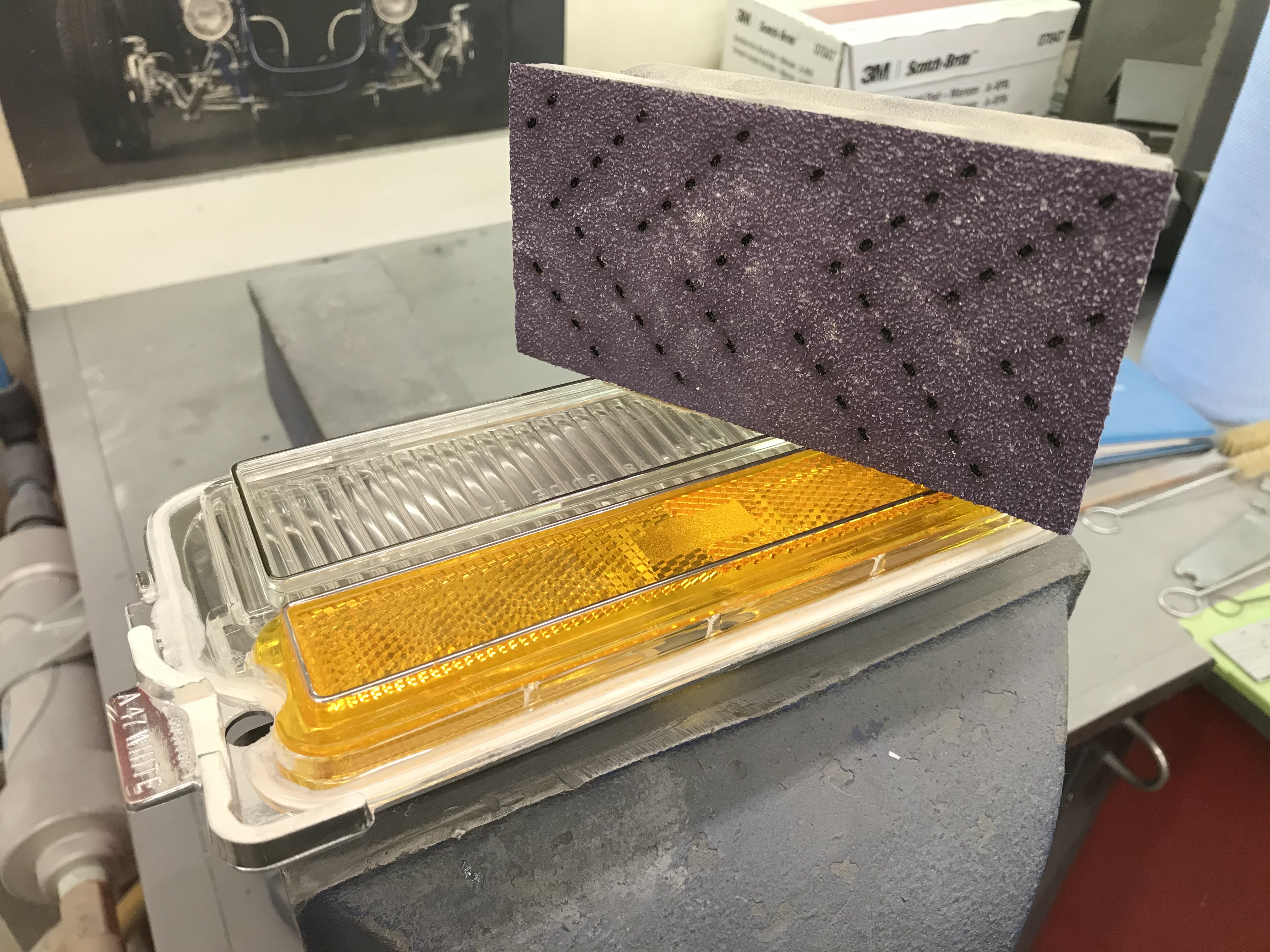

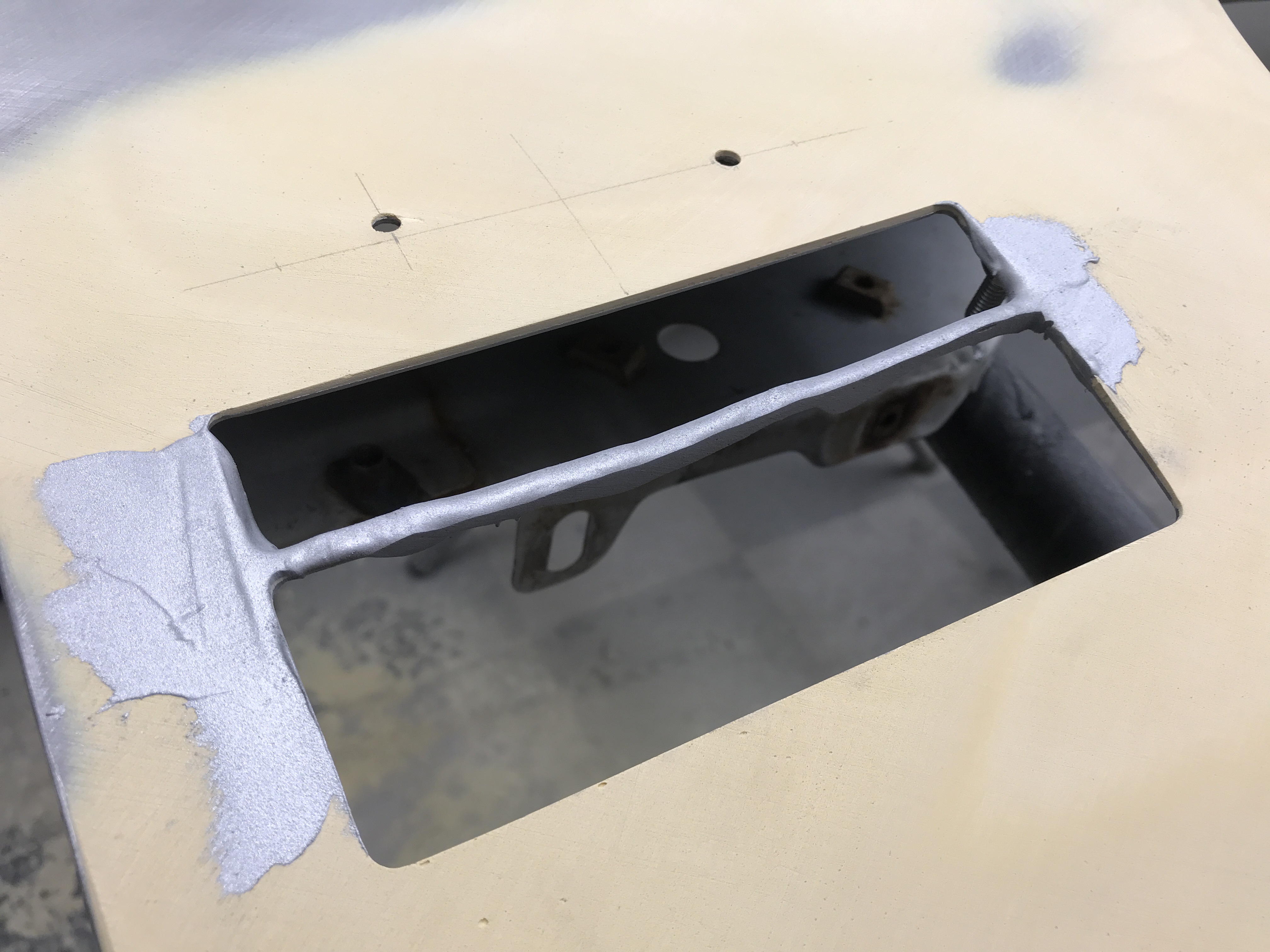

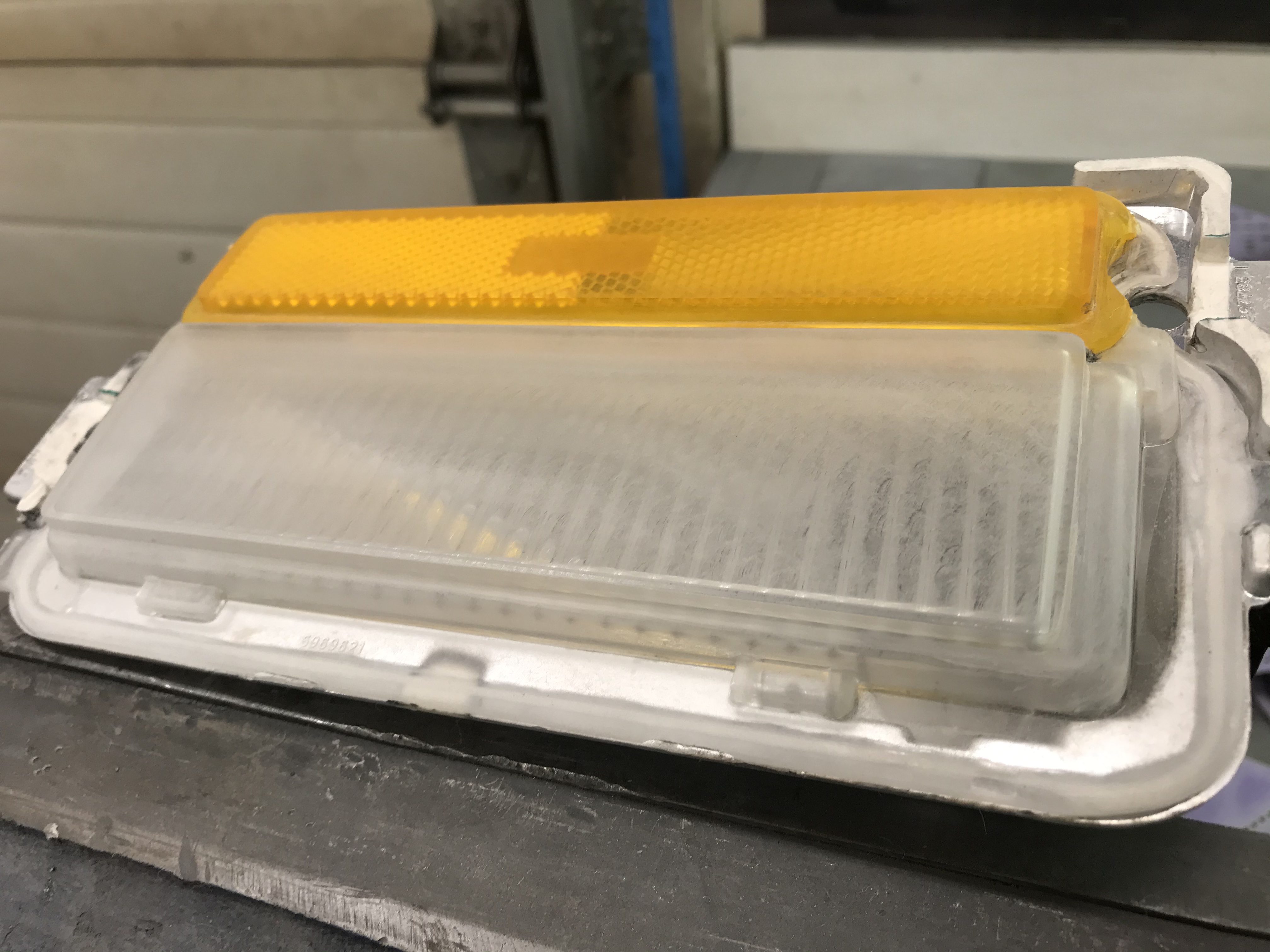

Yep, that’s a sanding block with a 40 grit strip on it. The lovely chrome lined raised edges had to get knocked down, and that meant going after it with the big guns. Once the edges had been levelled, it was time for a test fit:

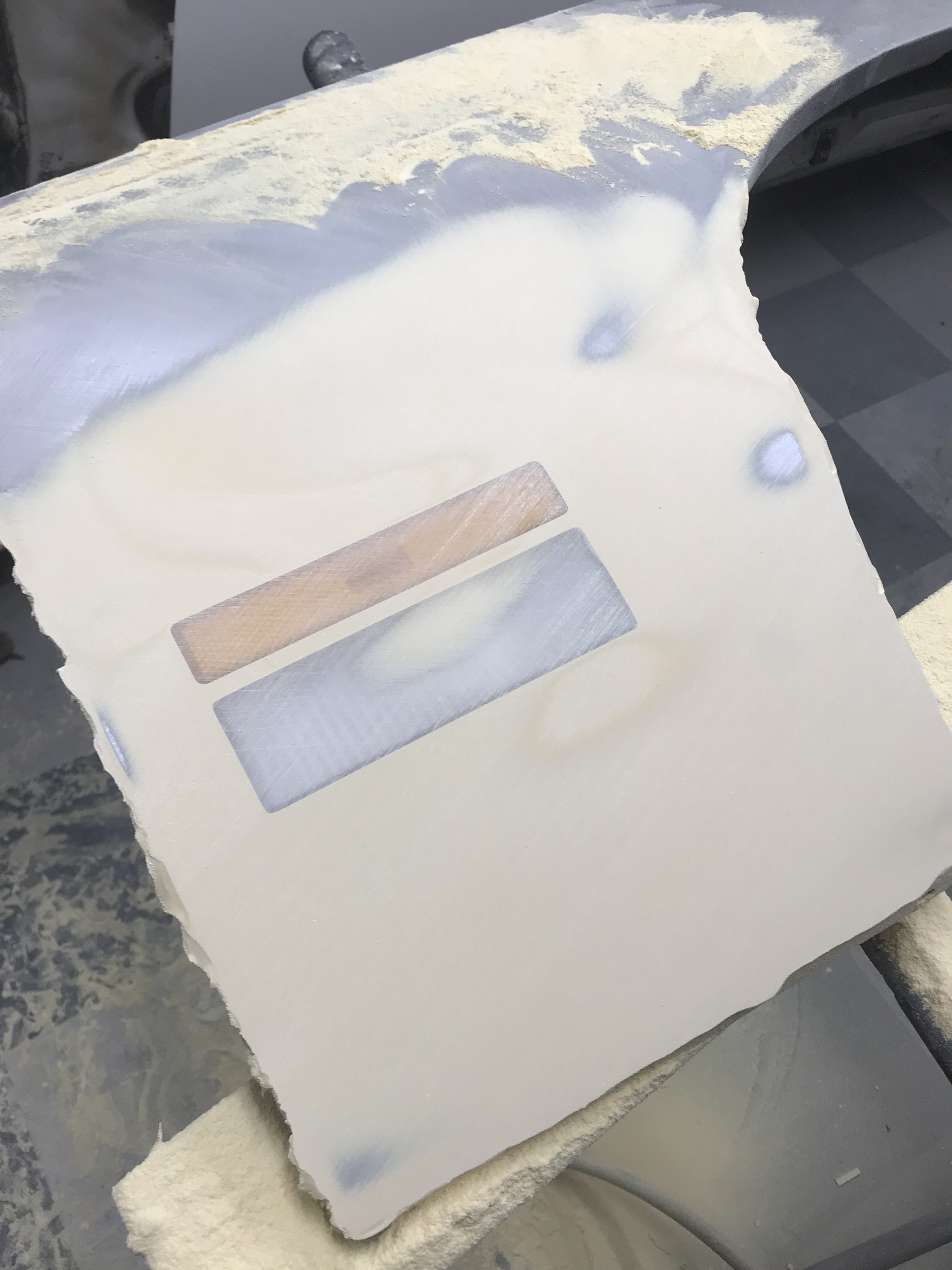

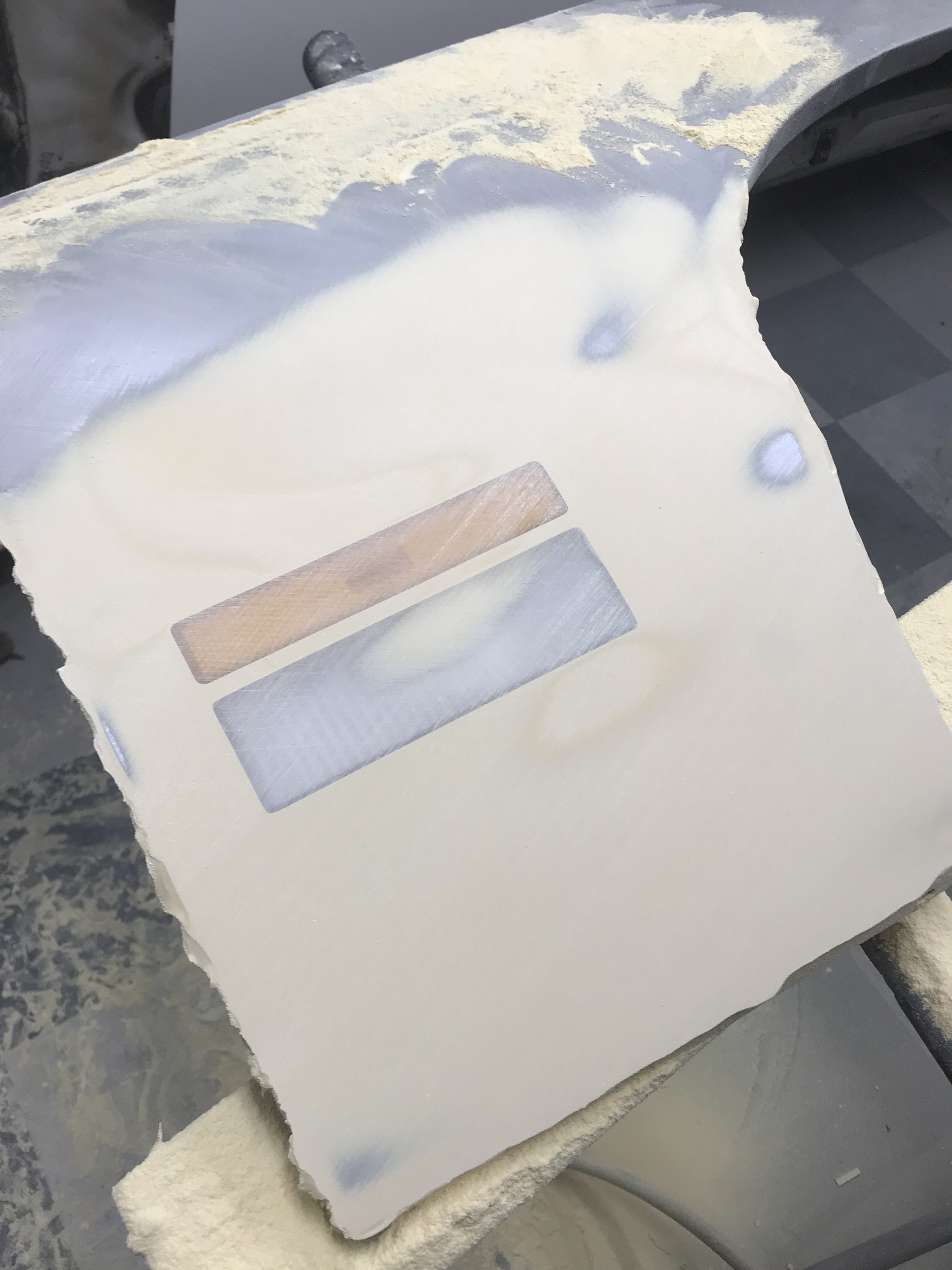

So far, so good. After shimming to get the required flush fitment, just like last year, I skimmed over the whole shoot n match with filler:

After several rounds of block sanding and adjusting the height, it was starting to get close:

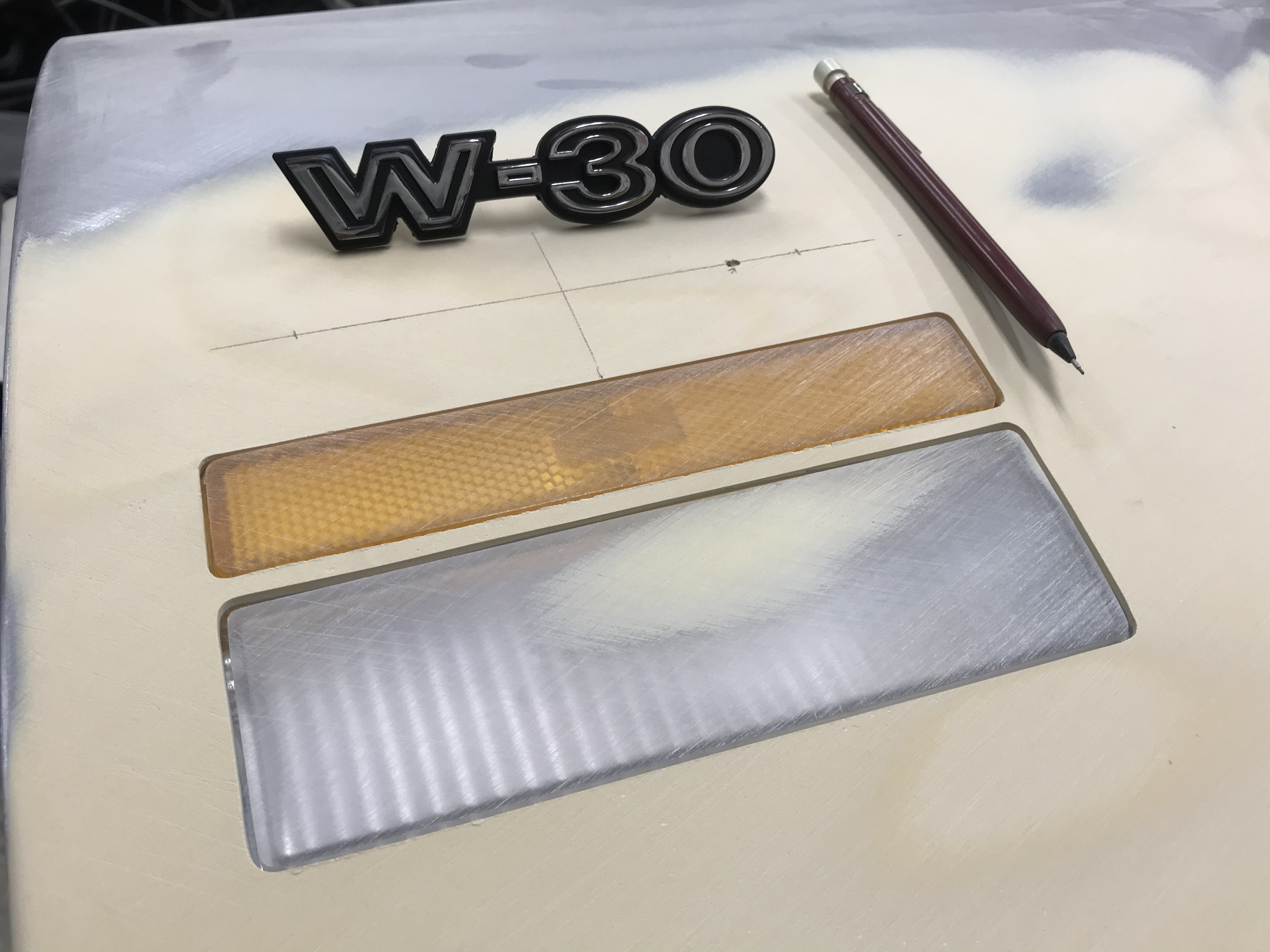

Time to add in the additional planned detail, the thanks go out to Turna for his contribution here too. Some sexy new W-30 emblems:

Now before y’all jump down my throat and yell “but D, that’s sacrilege, it’s not Olds powered or even a big block!!!”, it’s my retro take on the cheap vinyl W-30 decals that adorned the 1980 442 that my paint scheme is based on. So once again, you know where to address your hate mail.

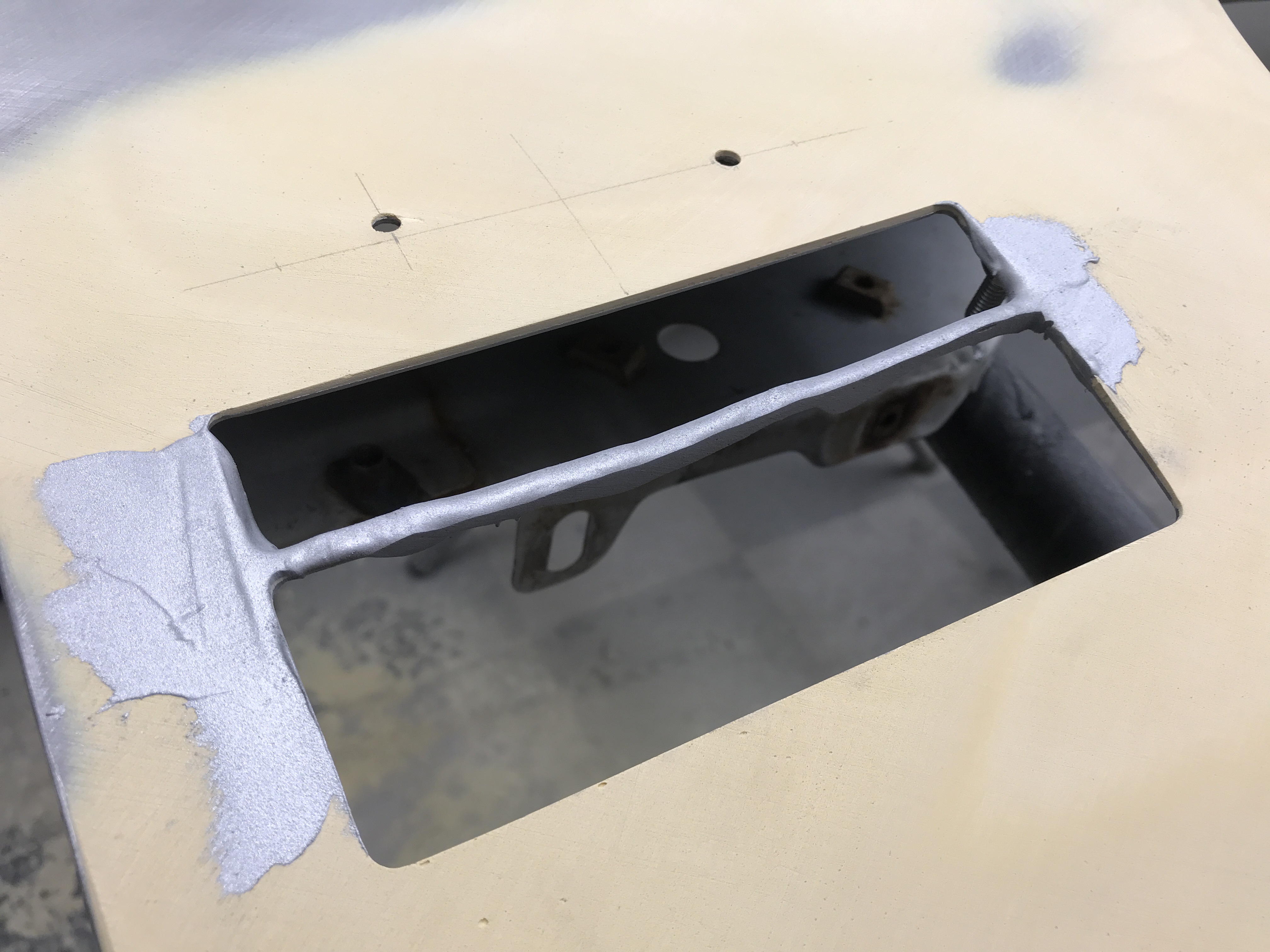

Back to the build. During one of the many test fits and mockups, the filler on the thin center divider between the lights became separated which required grinding the whole strip down to bare metal and rebuilding it. I decided to rebuild it the second time around with some All Metal filler which is a little more robust:

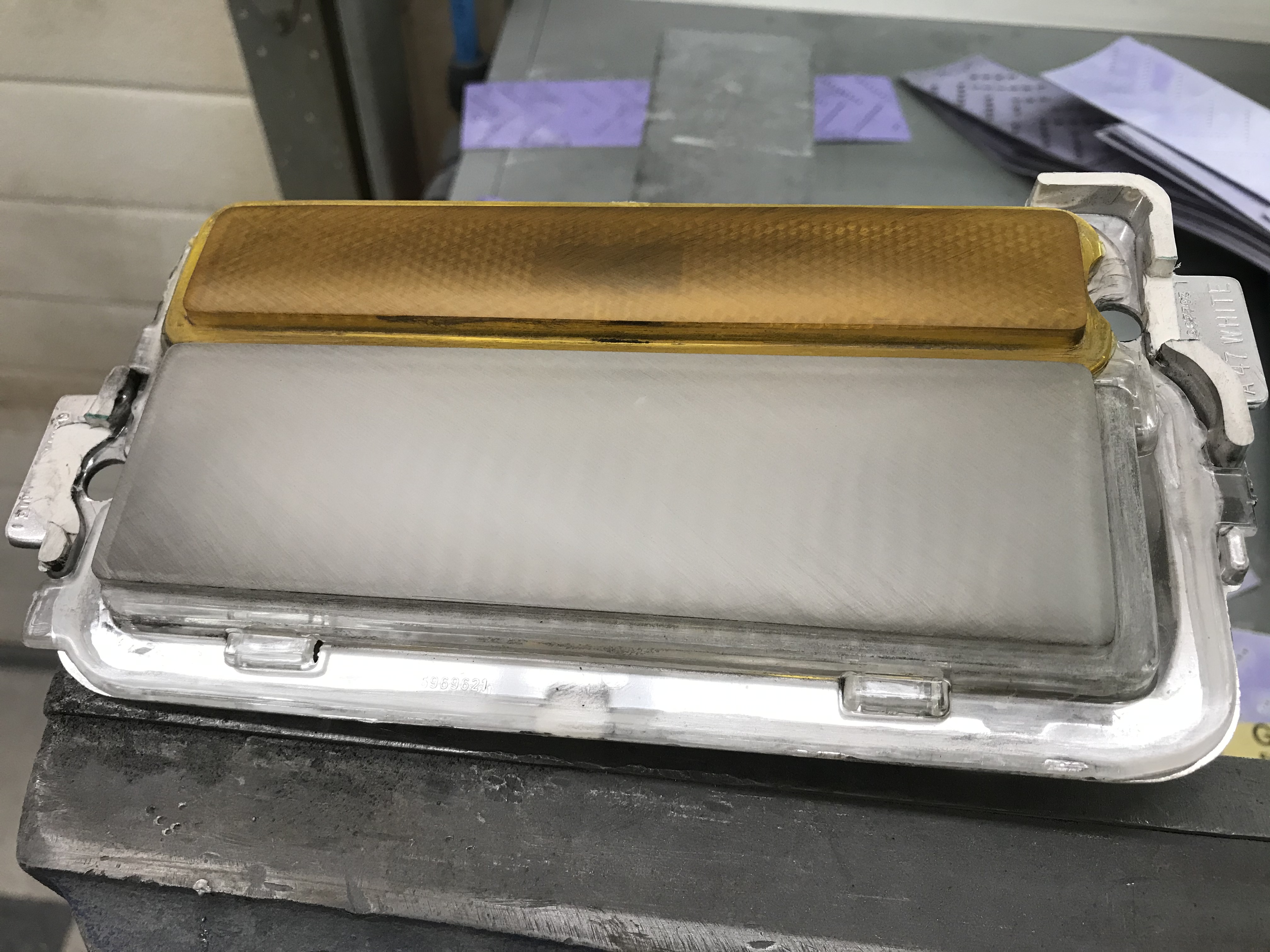

After the center divider was rebuilt, I could move on to restoring the finish on that poor light. It was dusted with some 3M dry guide coat, then the 80 grit marks were sanded out with 120:

The same procedure was repeated over and over again with 220, 320, and 400 grits dry.

Only halfway there, the rest of the sanding was done wet, with 600, 1000, 1500, and finally, 2000 grit.

Here’s the light now, finished in 2000 grit and ready for polishing:

Not so scary now eh?

😉

Tools of the trade:

A little polishing...

...and presto! Like no trauma ever happened to it.

Continued >>>

Where to start? I guess we’ll start with a status report on the finger I decided to stick in a fan last week, it’s been 8 days since I got 5 stitches in it. I went to the doc after work tonight thinking he’d be pulling them, instead he informed me that I popped one stitch today, it’s infected, and now I get to be on a regimen of antibiotics and anti inflammatories. Oh, and the stitches gotta stay for another week yet.

Yay me.

Guess that’s what I get for still having to work with it.

Onto less depressing things, let’s talk about the headway I’ve made on the car.

Y’all probably remember me posting this photo shortly after I got the holes cut for the flush mount marker light mod...

...however what I didn’t mention is that was just a quick and dirty mock up with the old original light. Although it’s not readily apparent, I found the original light had a large crack right through the middle of it once I had it out of the old chrome bezel.

This is where things get interesting.

I had put up an ad in the wanted section here on the forum for a replacement thinking that someone would have a decent used one to offer. Instead, I got a series of PM’s from none other than our own Mr. 69HurstOlds, who, all of his own accord, and without verification from me, had gone ahead and purchased a NOS light that he had found for me on eBay. Simply because he knew I needed one, and that the seller wouldn’t ship to Canuckistan.

THAT, my friends, is going above and beyond. As if his thoughtfulness and risk wasn’t enough, once I confirmed that I’d OF COURSE be buying it from him, he volunteered to ship it to me on his own dime. Called it a “gift” and his contribution to my build.

Talk about blown away. I mean, people just don’t show acts of kindness like that in this day and age, do they?? Apparently so.

Mike, I again want to sincerely thank you from the bottom of my heart for your thoughtfulness and generosity. It was more than appreciated, and will not be forgotten.

THANK YOU!!!

Here’s the old original light in the fender, along with the NOS light from him:

What a beautiful piece. I’ve never been fortunate enough to have anything NOS before, so this was an exceptional treat!

....Which makes it all that much harder to relate what I had to do to it next.

If you’re squeamish about seeing a vintage NOS part get violated, you may want to look away now. Seriously. It might make you wanna cry, I damn near did!

(Disclaimer: I warned Mike of what I was gonna do to this pristine part and got his blessing, so send your hate mail to [email protected])

Ok, if you’re still reading, you can’t say you haven’t been warned.

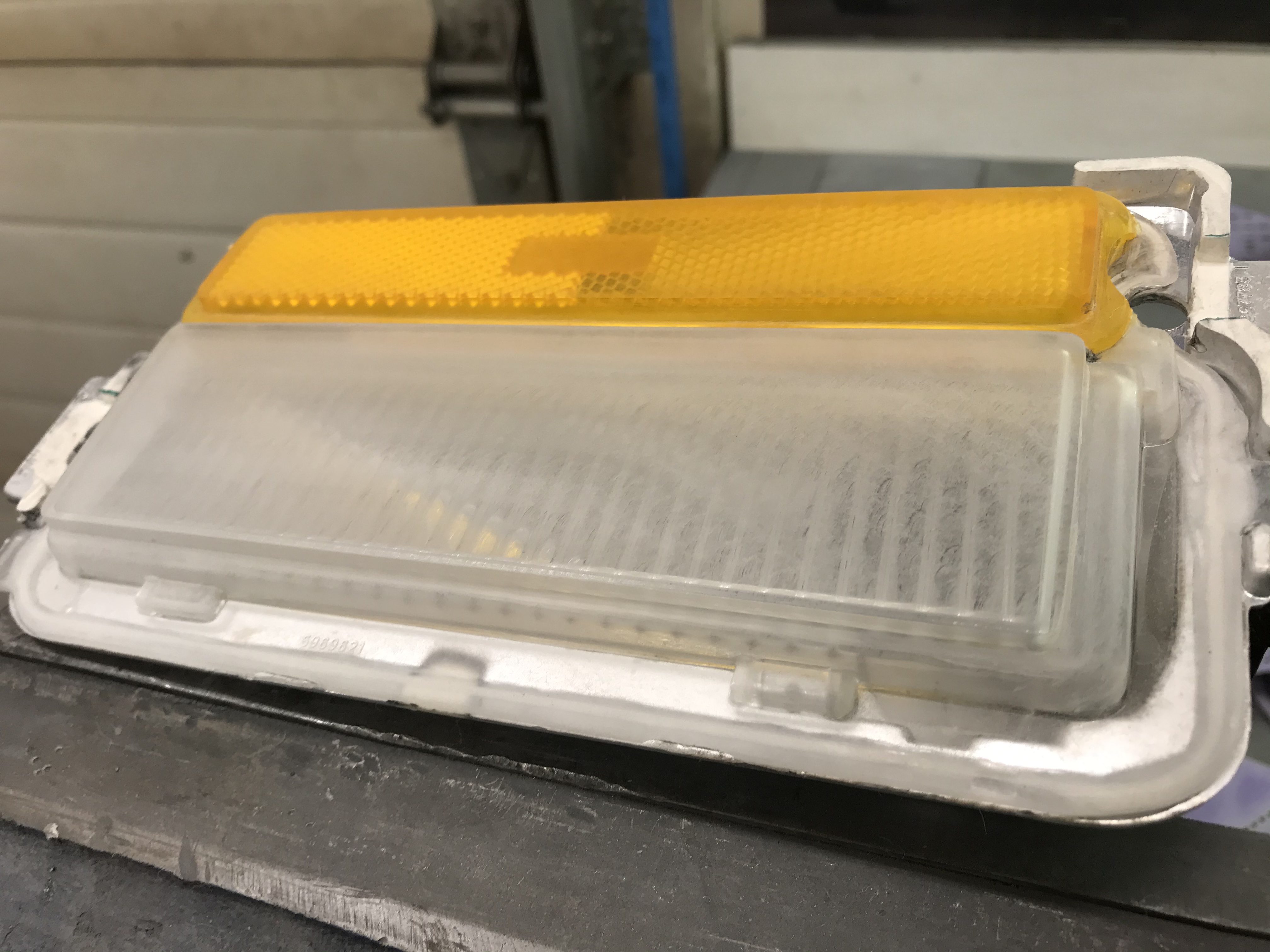

Yep, that’s a sanding block with a 40 grit strip on it. The lovely chrome lined raised edges had to get knocked down, and that meant going after it with the big guns. Once the edges had been levelled, it was time for a test fit:

So far, so good. After shimming to get the required flush fitment, just like last year, I skimmed over the whole shoot n match with filler:

After several rounds of block sanding and adjusting the height, it was starting to get close:

Time to add in the additional planned detail, the thanks go out to Turna for his contribution here too. Some sexy new W-30 emblems:

Now before y’all jump down my throat and yell “but D, that’s sacrilege, it’s not Olds powered or even a big block!!!”, it’s my retro take on the cheap vinyl W-30 decals that adorned the 1980 442 that my paint scheme is based on. So once again, you know where to address your hate mail.

Back to the build. During one of the many test fits and mockups, the filler on the thin center divider between the lights became separated which required grinding the whole strip down to bare metal and rebuilding it. I decided to rebuild it the second time around with some All Metal filler which is a little more robust:

After the center divider was rebuilt, I could move on to restoring the finish on that poor light. It was dusted with some 3M dry guide coat, then the 80 grit marks were sanded out with 120:

The same procedure was repeated over and over again with 220, 320, and 400 grits dry.

Only halfway there, the rest of the sanding was done wet, with 600, 1000, 1500, and finally, 2000 grit.

Here’s the light now, finished in 2000 grit and ready for polishing:

Not so scary now eh?

😉

Tools of the trade:

A little polishing...

...and presto! Like no trauma ever happened to it.

Continued >>>

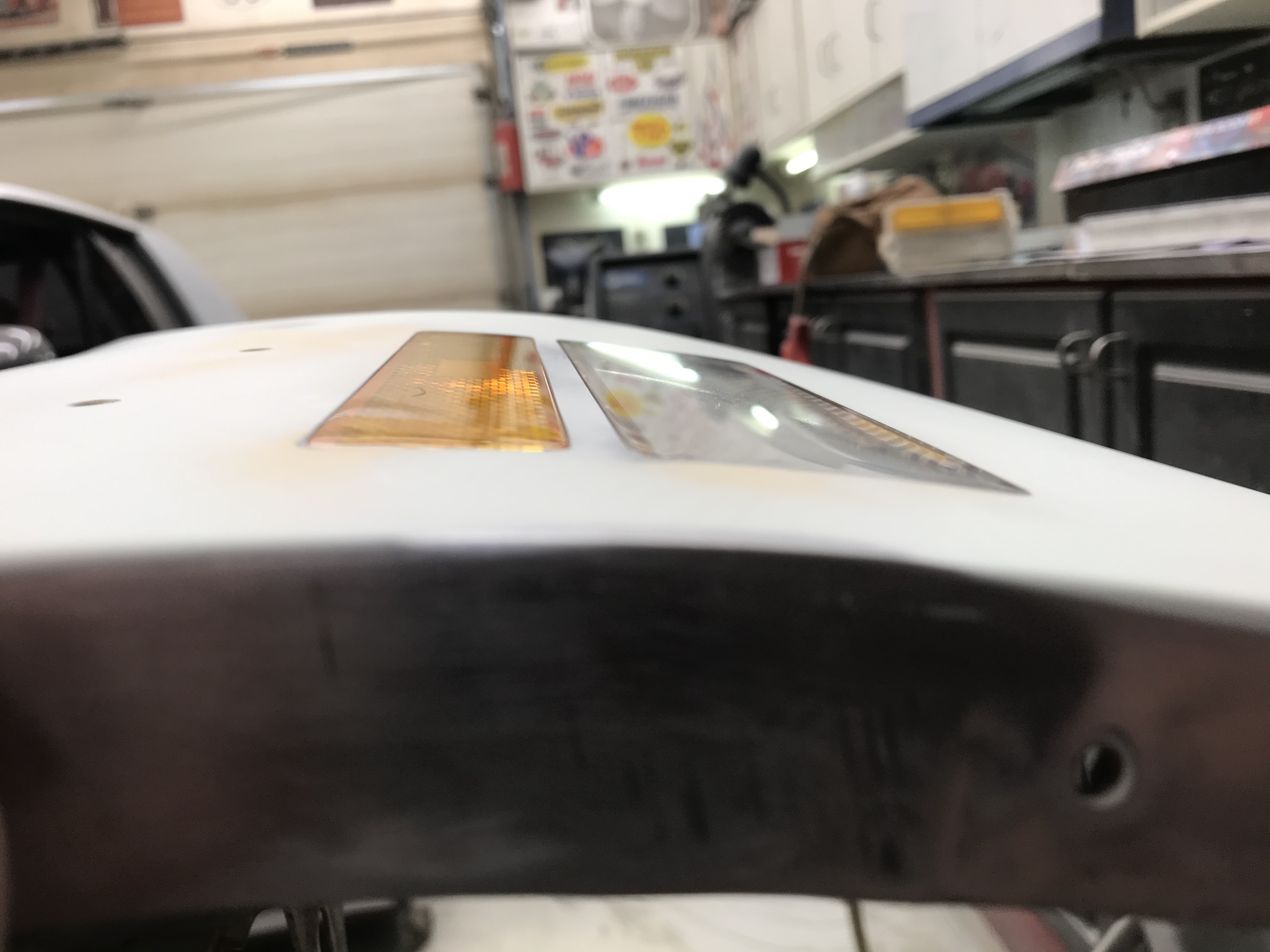

Let’s see how the restored light looks in the fender, now that it’s been skimmed with a thin layer of putty and finished out shall we?

Can’t forget that emblem, shameless pic:

😁

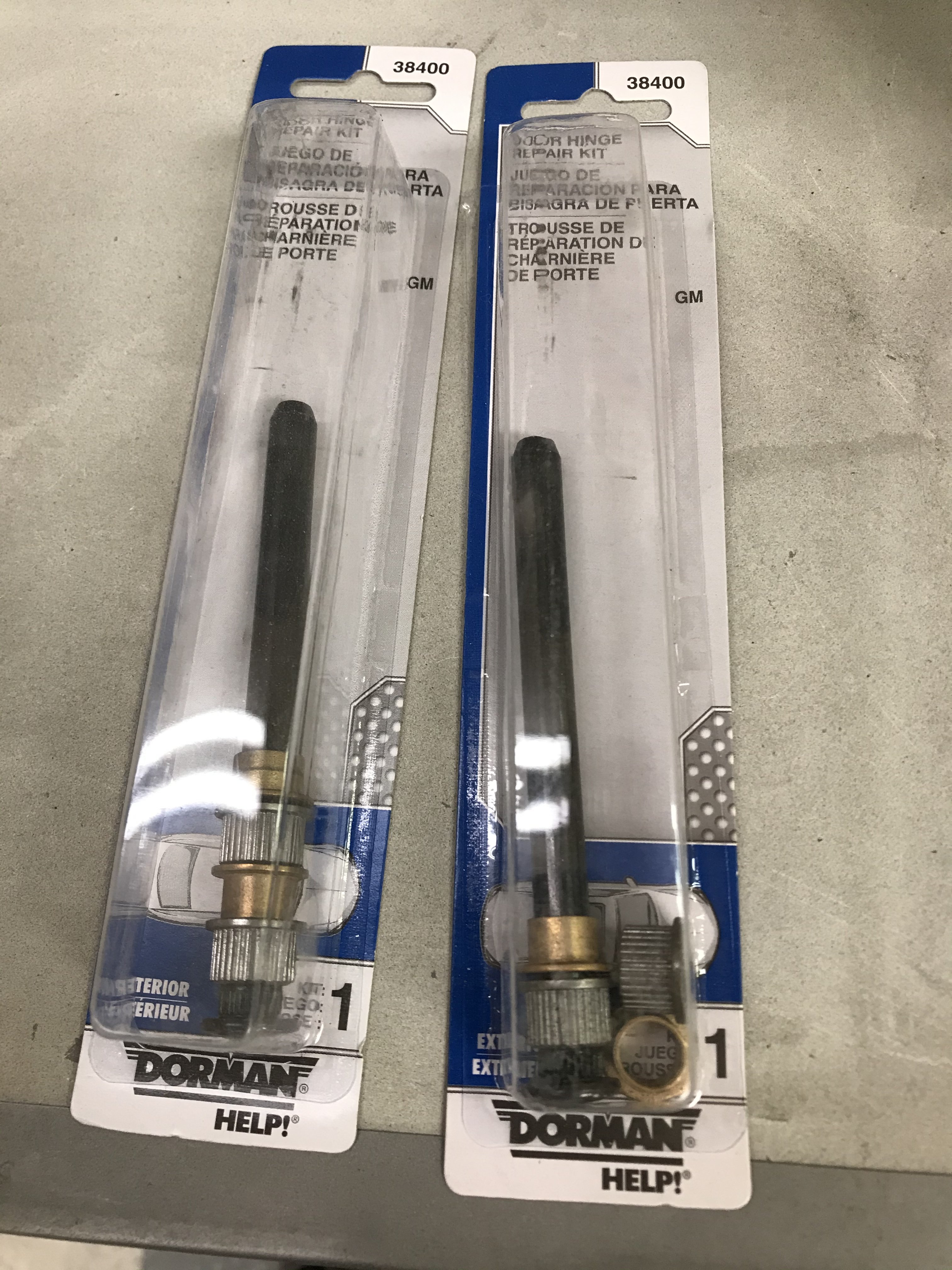

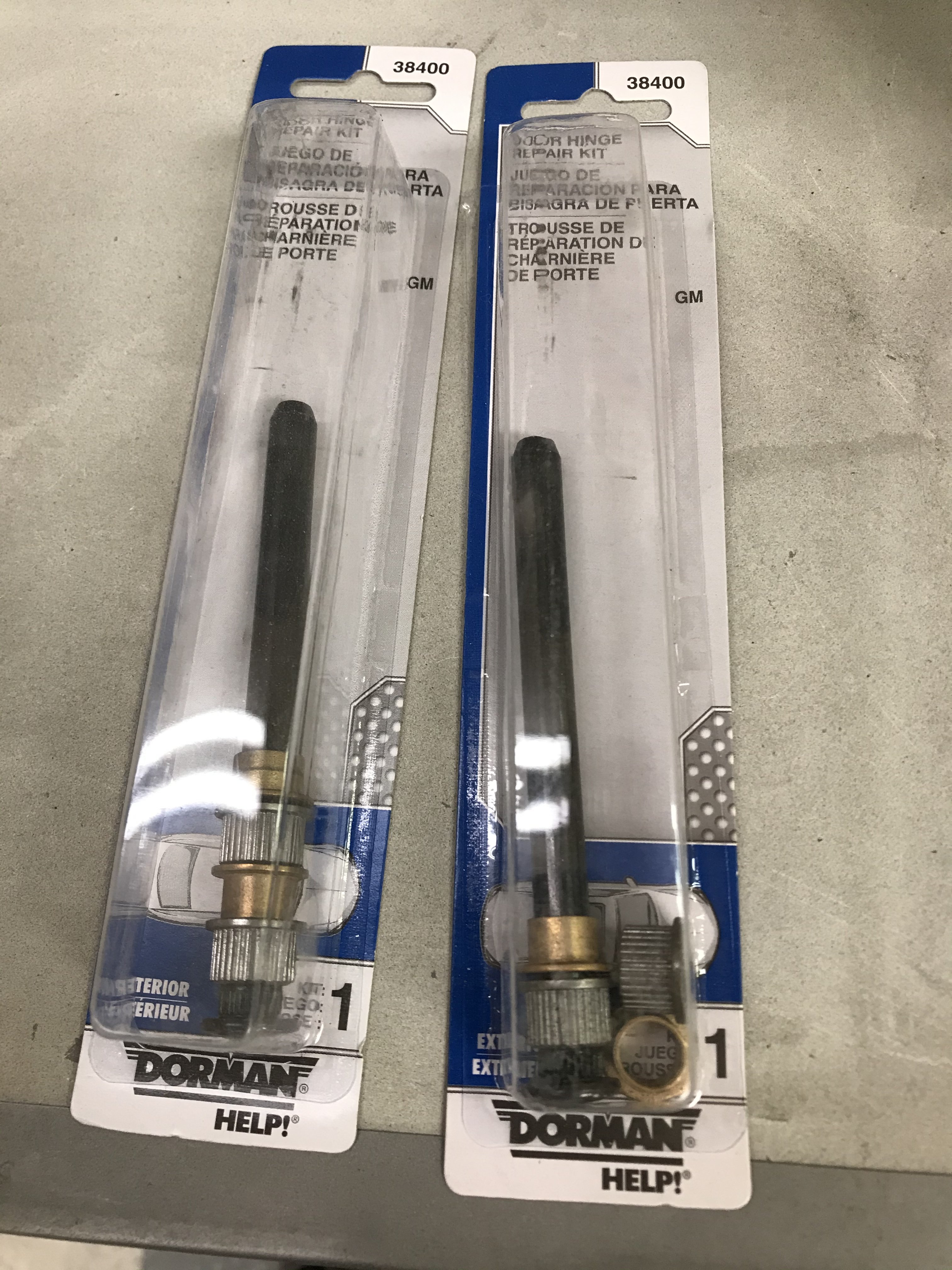

On the weekend, I checked out a new auto parts store, and, always thinking to the future, picked up some Dorman pin and bushing kits for when it comes time to rebuild the driver’s door hinges. Anyone know by chance the part number for the kit with the roller bushing in it? I still need to grab that one.

Anyways, that’s more or less it for now, I’ve got most of the other filler work done on the outside of the fender already, with only a couple of grinder marks in the wheelwells from welding left to finish up. Then the outside of the fender will be ready for epoxy and high build primers.

After that, onto the inside of the fender!

Thanks for checking back in on the project, and for your patience with this long update. Appreciate it fellas.

D.

Can’t forget that emblem, shameless pic:

😁

On the weekend, I checked out a new auto parts store, and, always thinking to the future, picked up some Dorman pin and bushing kits for when it comes time to rebuild the driver’s door hinges. Anyone know by chance the part number for the kit with the roller bushing in it? I still need to grab that one.

Anyways, that’s more or less it for now, I’ve got most of the other filler work done on the outside of the fender already, with only a couple of grinder marks in the wheelwells from welding left to finish up. Then the outside of the fender will be ready for epoxy and high build primers.

After that, onto the inside of the fender!

Thanks for checking back in on the project, and for your patience with this long update. Appreciate it fellas.

D.

Last edited:

Looks like the usual amazing work D

Cant wait for the Door Hinge update. I have the passenger side to do on mine.

Cant wait for the Door Hinge update. I have the passenger side to do on mine.

That looks really good, i cringed a little at that NOS part but in the end all of our parts were once new and nobody thinks twice about modifying them so go for it. The W-30 emblems probably are about as much sacrilege as me putting 442 stripes and emblems on a chevy diesel powered cutlass. I like the emblems better than the decals

Hope that hoof of yours heals up quickly!!! As so you can "pull the trigger" on this "missing CALais in your collection"😉 I'll give you a holler with contact given,say the weekend? If you can get some qouate for shipping...its of full weight and has original DRIVING train rocket/350.also we can discuss plans and what all you want for it to put in YOUR vision(frames,suspension,goodies,etc...)

Similar threads

- Replies

- 10

- Views

- 339

- Replies

- 172

- Views

- 11K

- Replies

- 13

- Views

- 535

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.