Congratulations on the find Donovan. Shame that car ended up in the yard. How was it underneath? Was it rusty? Awesome work on Olds Cool as always. I'm glad you were able to harvest that sail panel. I'm looking forward to seeing how it simplifies the repair on the passenger side.

BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Great find at the junkyard! Wish I could find them like that around here. Or any g body at the pic and pull for that matter. The sail panel looks like it will be a real time saver for you. Great story on the nice guy you met. There are a few good people left in this crazy old world. Keep up the great work your doing.

Thank you, I will certainly try to!

Finding that car in my auto wreckers is thanks directly to here. If the original post wasn't made, I would've had no clue the car was even there! (It's been some time since I last wandered the boneyards in search of parts).

G bodies like that here are few and far between nowadays, and certainly not the norm. Especially one that old. Usually there's none to be found for months at a time. The timing on finding this one was extremely lucky indeed!

Thanks for all the "likes" and for tuning back for each update. I really appreciate it.

Congratulations on the find Donovan. Shame that car ended up in the yard. How was it underneath? Was it rusty? Awesome work on Olds Cool as always. I'm glad you were able to harvest that sail panel. I'm looking forward to seeing how it simplifies the repair on the passenger side.

Definitely a shame Jared. I was pissed when they wouldn't let me buy the car, knowing it's headed for the crusher. Another rare piece of history to be lost forever.

Even knowing that it was ultimately headed for recycling, it was hard to bring myself to take the saw to it. It just felt wrong. I'm pretty sure it's sacrilege to cut up a 442 in that manner!

Underneath it was a bit rusty, but certainly not a basket case. It would've been quite restorable in the right hands. If anything, it appears to have suffered the indignity of just being neglected. It may have sat unwanted and ignored for a long period of time before it finally ended up where it is.

All the valuable 442 specific stuff was already missing, the steering wheel, aluminum wheels like the ones I have on Olds Cool, even the interior and exterior 442 badges were gone. Really, now unfortunately it's pretty much just a gold and black '80 Cutlass.

Stay tuned, I'll be jumping back on the passenger's side rust repair right after fixing up the front and rear window channels.

D.

Last edited:

Tonight was a bit frustrating.

I was in the mood to continue to make some headway, but wasn't really overly interested in working on the back window channel yet again.

So I did what I really shouldn't when I'm in that mindset, and that's push on through it anyways.

It always bites me in the *ss.

I just wanted to finish it off tonight, so I rushed through it a bit. I shouldn't have, I know better. Things never really go that well when my head is just not in it.

But I was so close...

I started by continuing on with the larger of the two patches I had made last night. I pulled it back off the car, prepped the backside and hit it with some weld-thru primer.

Ditto for the opening:

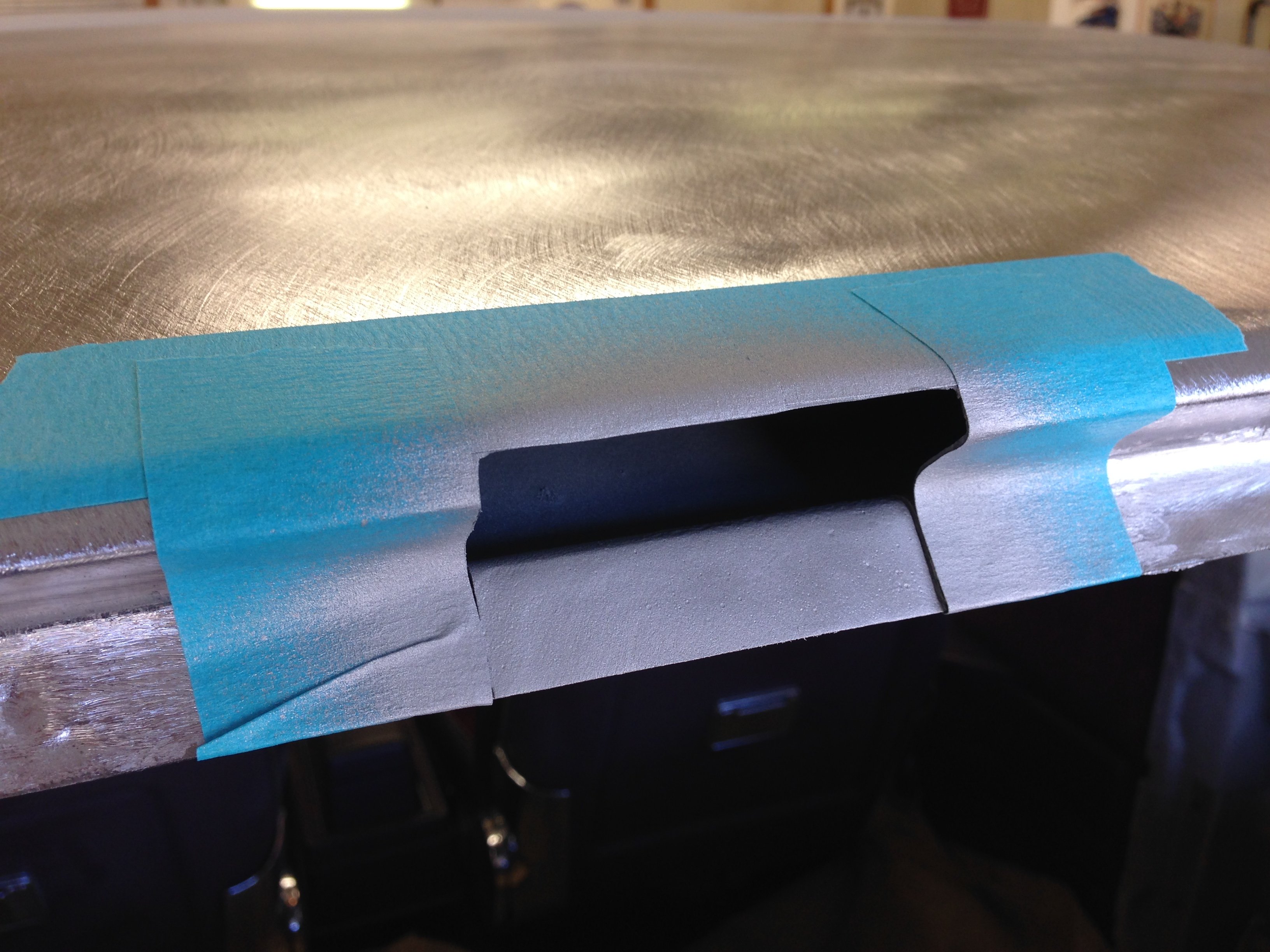

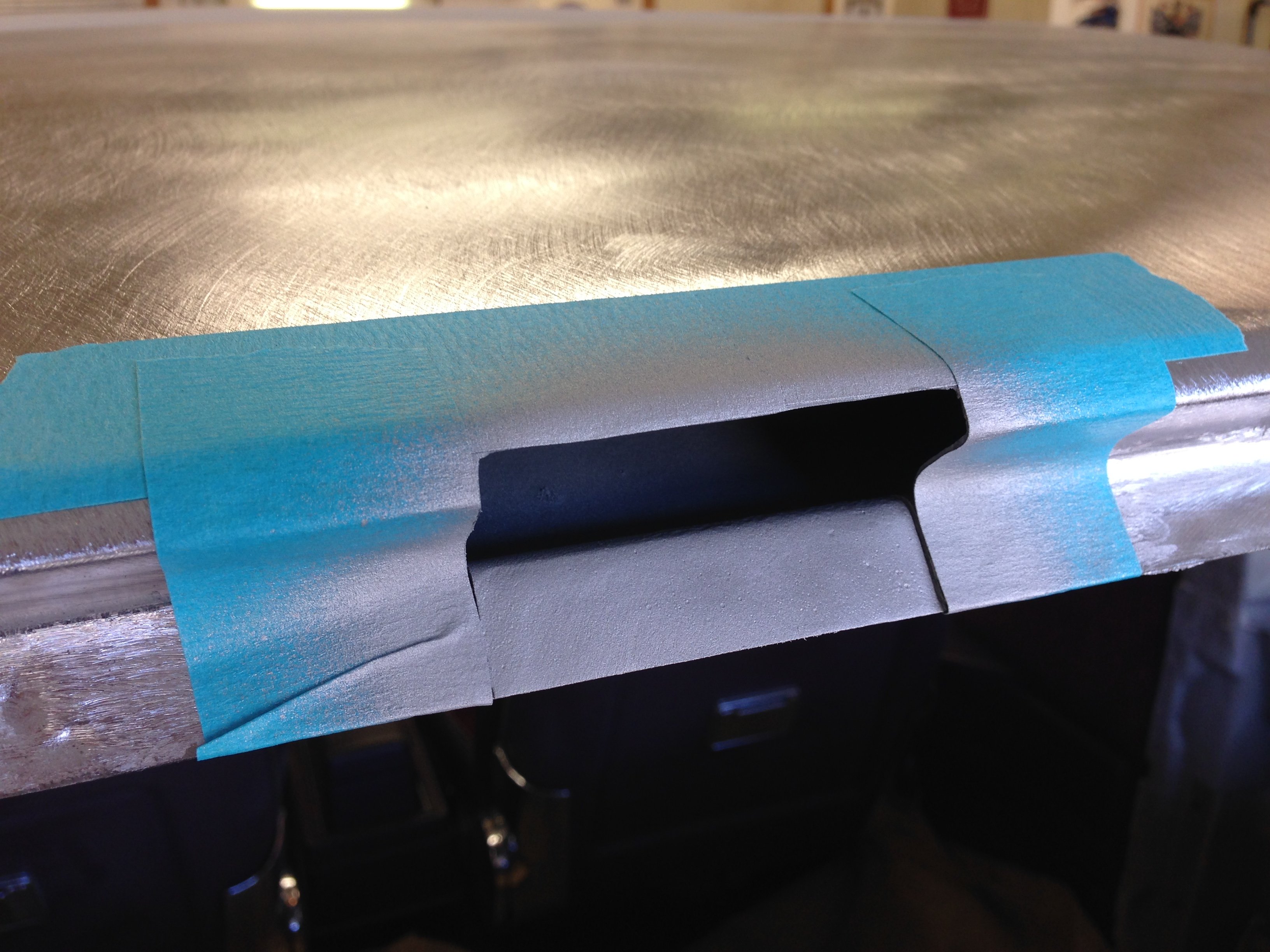

Once the primer had dried, I put some holes in the flange area for some plug welds, and clamped it back into place:

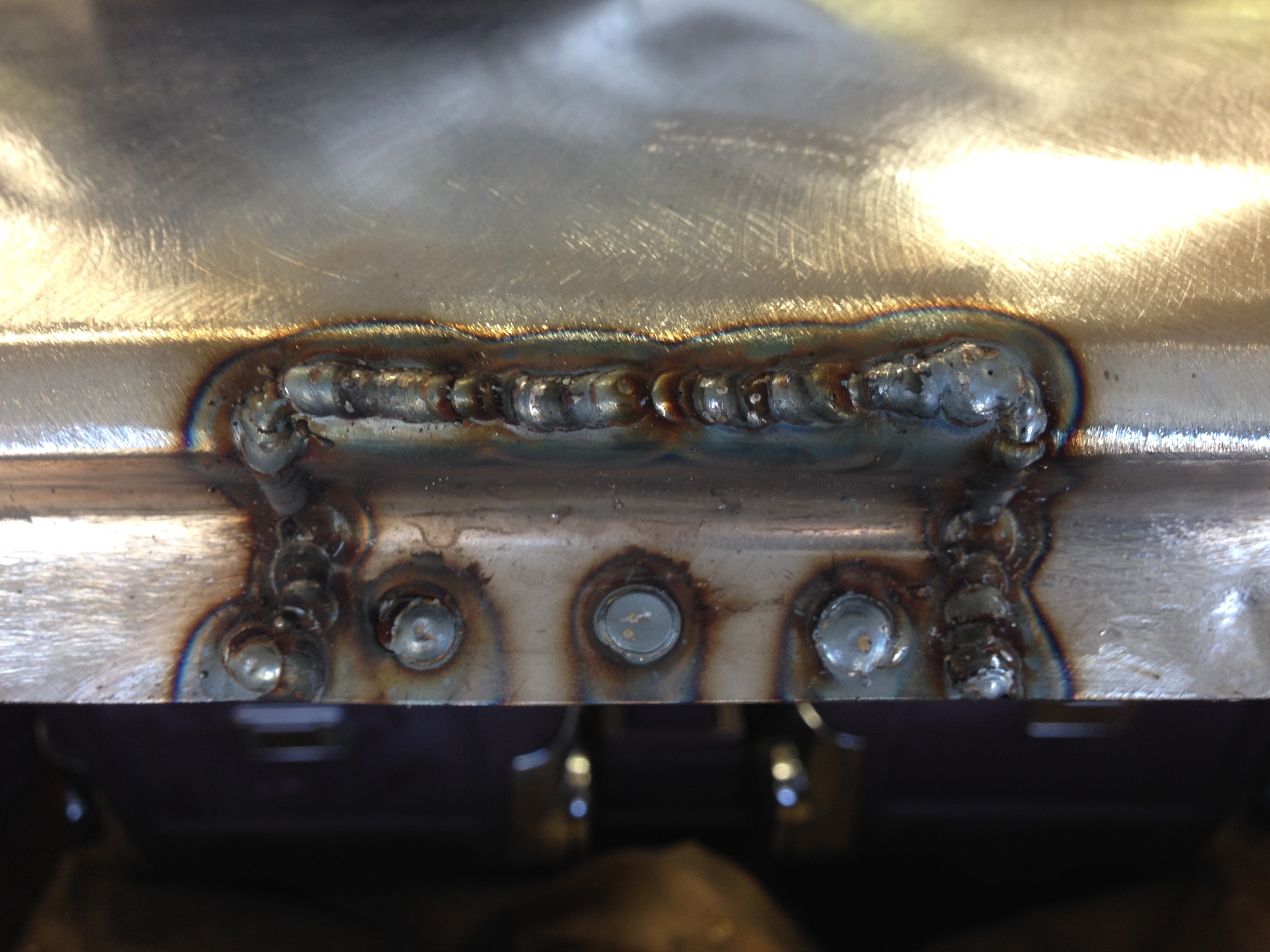

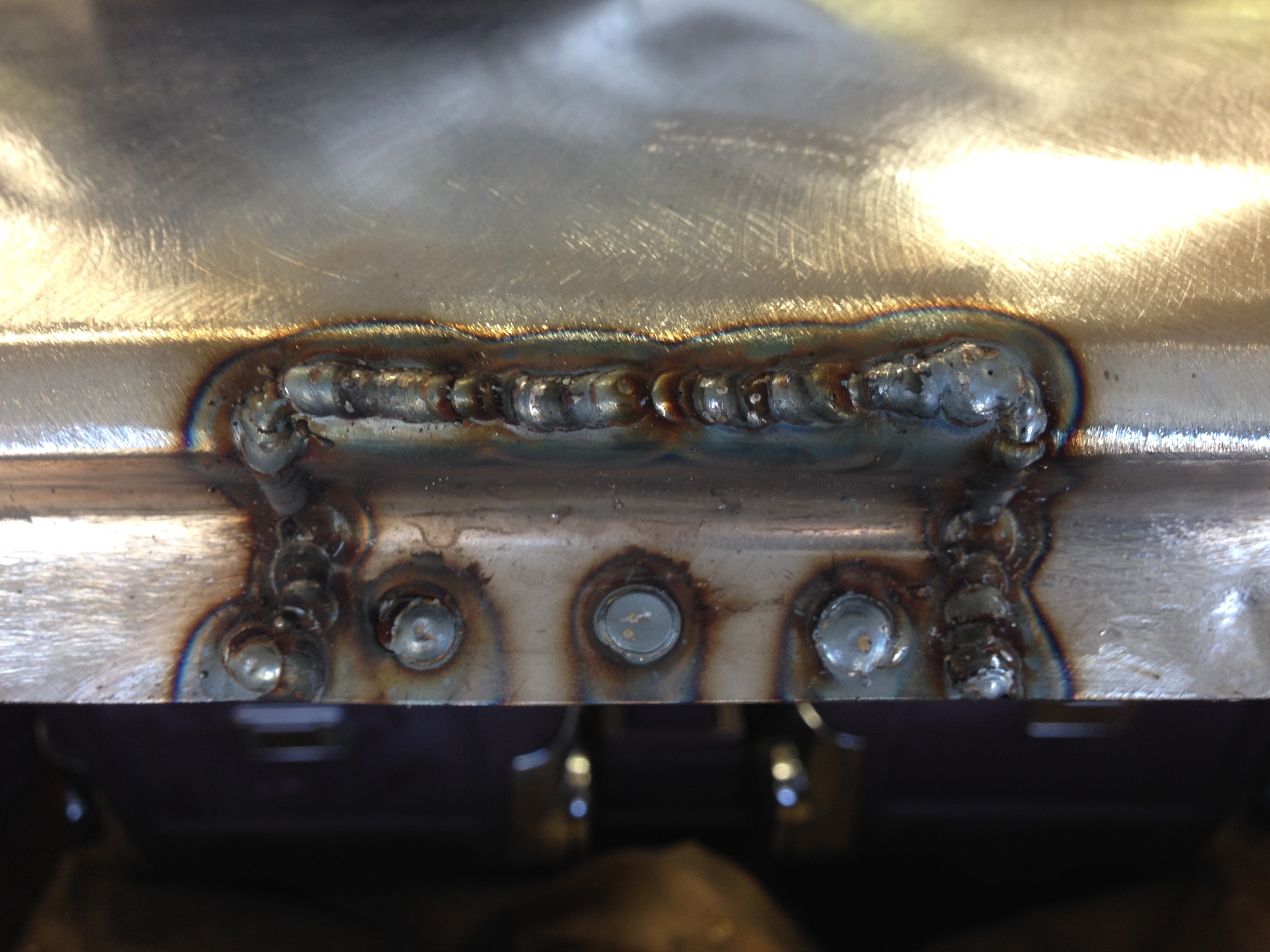

After burning it all in:

This is where my regret is. In my haste before starting to fully weld it in, I forgot to place one tack weld at the center top of the patch to keep everything in alignment. Instead, I welded the top of the patch from one end to the other, a big no-no.

This had the effect of pulling the center and the roof skin down a bit with the heat.

It's not terrible, but now I'll likely have to go back and pull this area back up with some studs and the UniSpotter. (The area is inaccessible from the underside, there's a large roof support there)

If you look close, you can see the low spot:

Similarly, the smaller patch gave me a bit of trouble too. Although the patch was a perfect fit before I started welding it in, after a couple of tacks it seemed to move around on me and not fit properly anymore. I had to cut several of the tack welds and reposition it a couple times.

I didn't take any pics of that patch, not even one of it welded before grinding. All I have for a pic of the smaller patch is this one; after all the work had already been done:

That left only one more small area that had a couple pin holes after grinding out the rust pits. Thankfully these didn't give me too much grief, and they welded up ok:

And finally, here we are. The back window channel is now fully 100% rust free despite my struggles with it tonight.

Check another area off the rust repair list!

🙂

I'll come back to the rear channel in a bit for some further work before the window goes back in, but for right now the next thing to tackle is cleaning out the front windshield channel. All the old urethane, paint and surface rust has gotta go just like I did on the back one. This should go pretty quickly, I may even be able to knock it all out tomorrow night.

Here's hoping.

That's all for now gents, thanks for tuning in.

We're getting there, slowly but surely!

Donovan

I was in the mood to continue to make some headway, but wasn't really overly interested in working on the back window channel yet again.

So I did what I really shouldn't when I'm in that mindset, and that's push on through it anyways.

It always bites me in the *ss.

I just wanted to finish it off tonight, so I rushed through it a bit. I shouldn't have, I know better. Things never really go that well when my head is just not in it.

But I was so close...

I started by continuing on with the larger of the two patches I had made last night. I pulled it back off the car, prepped the backside and hit it with some weld-thru primer.

Ditto for the opening:

Once the primer had dried, I put some holes in the flange area for some plug welds, and clamped it back into place:

After burning it all in:

This is where my regret is. In my haste before starting to fully weld it in, I forgot to place one tack weld at the center top of the patch to keep everything in alignment. Instead, I welded the top of the patch from one end to the other, a big no-no.

This had the effect of pulling the center and the roof skin down a bit with the heat.

It's not terrible, but now I'll likely have to go back and pull this area back up with some studs and the UniSpotter. (The area is inaccessible from the underside, there's a large roof support there)

If you look close, you can see the low spot:

Similarly, the smaller patch gave me a bit of trouble too. Although the patch was a perfect fit before I started welding it in, after a couple of tacks it seemed to move around on me and not fit properly anymore. I had to cut several of the tack welds and reposition it a couple times.

I didn't take any pics of that patch, not even one of it welded before grinding. All I have for a pic of the smaller patch is this one; after all the work had already been done:

That left only one more small area that had a couple pin holes after grinding out the rust pits. Thankfully these didn't give me too much grief, and they welded up ok:

And finally, here we are. The back window channel is now fully 100% rust free despite my struggles with it tonight.

Check another area off the rust repair list!

🙂

I'll come back to the rear channel in a bit for some further work before the window goes back in, but for right now the next thing to tackle is cleaning out the front windshield channel. All the old urethane, paint and surface rust has gotta go just like I did on the back one. This should go pretty quickly, I may even be able to knock it all out tomorrow night.

Here's hoping.

That's all for now gents, thanks for tuning in.

We're getting there, slowly but surely!

Donovan

Keep at it Donovan. You're making good progress. Hopefully that low spot doesn't give you much trouble to straighten out. You had some good luck finding that sail panel. That should speed things up when you get back on the passenger's side rust repair.

Great work as always Donovan. Can't wait to see the next update.

Great work as always Donovan. Can't wait to see the next update.

D,

Nice score on the junkyard 442 parts. I could understand your reluctance to put the sawblade to the 442's sail panel. As sacrilegious as it may be in our eyes, it's better that you got what you needed before it became a cube destined to be sent to China.

Again, it's a shame that they wouldn't sell you the whole car...but once the vultures get to it, it's pretty much a done deal.

I'm glad you were able to correct the rear window channel/ roof area.

As always, keep up the good work.

Nice score on the junkyard 442 parts. I could understand your reluctance to put the sawblade to the 442's sail panel. As sacrilegious as it may be in our eyes, it's better that you got what you needed before it became a cube destined to be sent to China.

Again, it's a shame that they wouldn't sell you the whole car...but once the vultures get to it, it's pretty much a done deal.

I'm glad you were able to correct the rear window channel/ roof area.

As always, keep up the good work.

Looking forward to the next installment of Cutting a Cutlass!

Shame to see that 442 like that, but glad you got some parts to help another Gbody live on. Nice work on the rear window channel despite the low spot...but you'll have that looking top notch in no time.

So that's at least two 80 442's in Canada gone to the crusher...one popped up here a couple of years ago...

It looked like it also had been neglected....I did harvest some usable parts from it to help others.

So that's at least two 80 442's in Canada gone to the crusher...one popped up here a couple of years ago...

It looked like it also had been neglected....I did harvest some usable parts from it to help others.

Well everyone, I'm back for an overdue update.

To be perfectly honest, nearly nothing has been done since the last one. Not because I lost interest, or didn't feel like working on it, but more because I needed some time to lick my wounds and contemplate my next move.

Let me explain...

With the last of the rust repair over the back window completed, I cleaned up the shop and repositioned the car for better access to the front windshield channel area. With the old windshield cut out and gone, the procedure here was SUPPOSED to be to simply strip and clean out all the old paint, seam sealer, urethane and surface rust.

At least it APPEARED to be surface rust...

After spending 20 minutes or so with the Clean and Strip wheel, I was quickly faced with the reality that things weren't going to be that simple. I shouldn't have been surprised, I've been snakebit by this car a couple of times now, but it caught me off guard anyways.

While the "A" pillars are quite good...

...the top channel above the windshield wasn't so sh*t-hot.

With the old crud mostly stripped out of the this area, this is what I was left with:

Not good. Deep rust pits throughout, on both the horizontal and vertical edges. It wouldn't be so bad if it was only in a couple isolated areas, but this is pretty much prevalent from one edge to the other. Any way you look at it, it's going to be a monumental task to fix.

It was at this point in the week that I walked away and left it for a few days to consider my options.

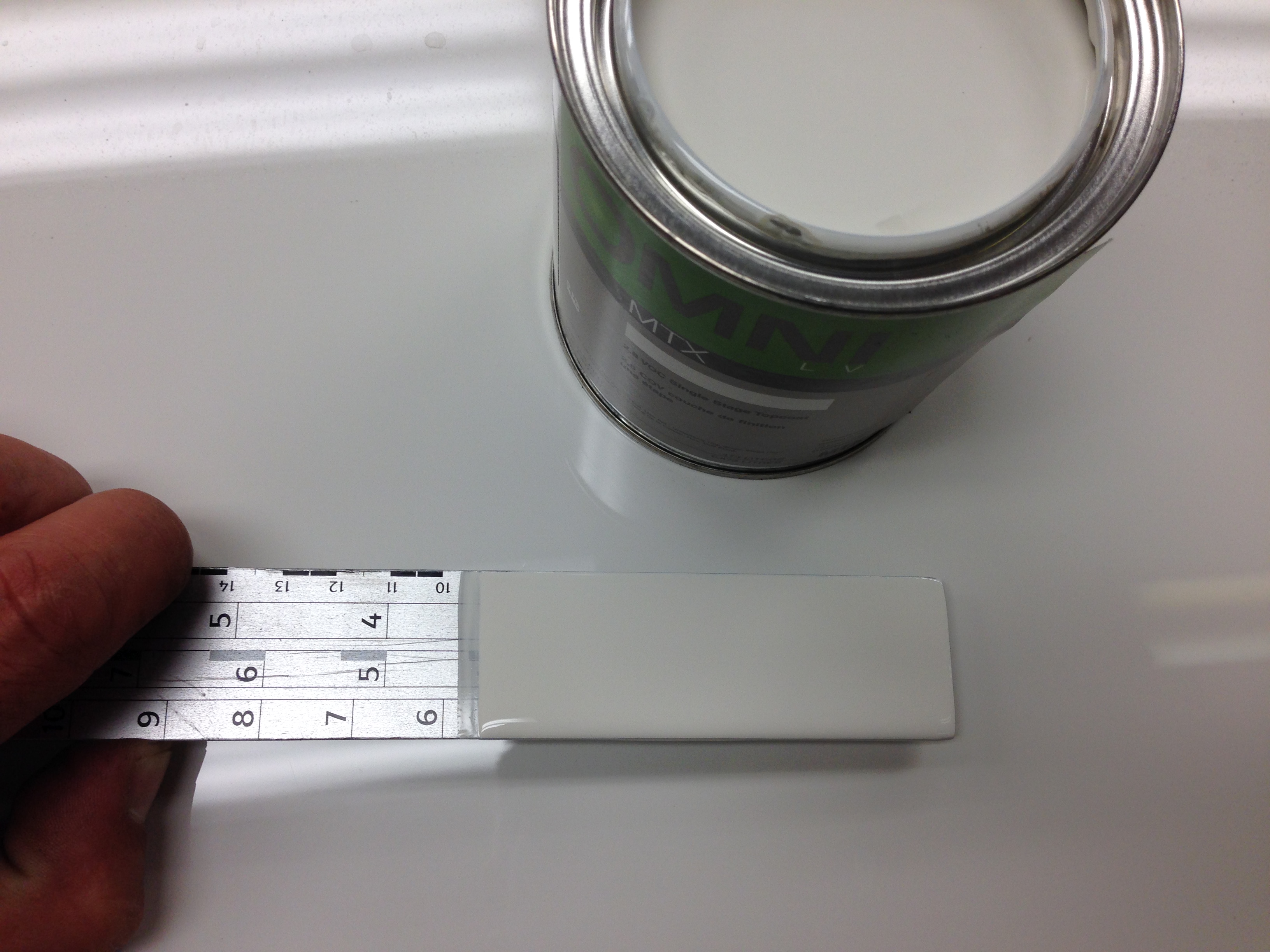

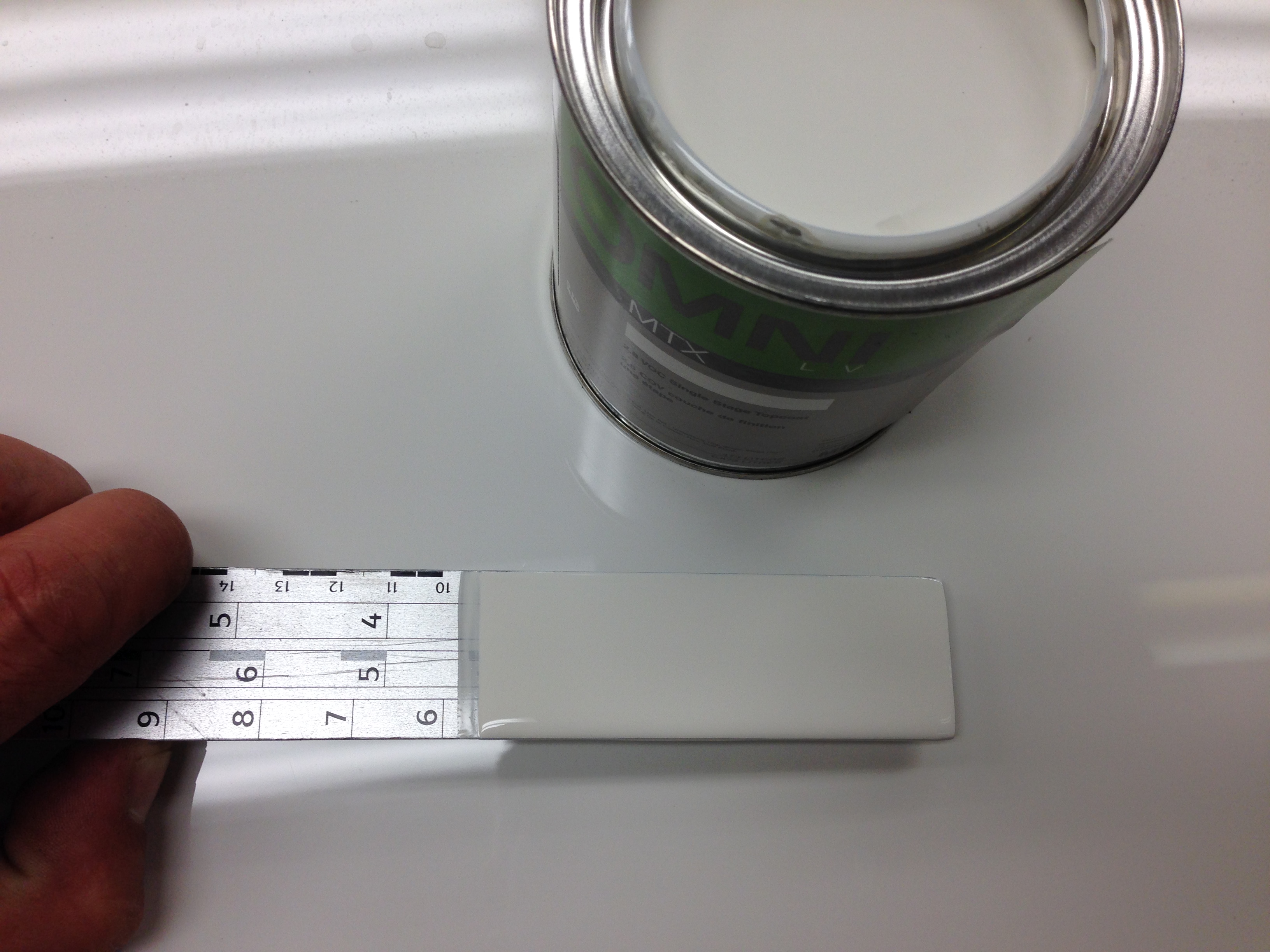

In the meantime, I swung by my local bodyshop supplier and picked up some goodies for the upcoming stages:

More Clean and Strip wheels for cleaning up/out the windshield channel, and some single stage paint for the same before the front and rear glass goes back in.

Yup, you read that right, single stage. I'll be going wet on wet over DP50 epoxy primer just in the window channel areas. Just so it has some protection and some color in there. The rest of the outside will go base/clear, don't worry!

Here's the color, it appears to be a good match, and is correct for the car:

I'm eventually going to have to cut in the jams and trunk drain channel areas too, so it makes more sense to use single stage in these spots than base/clear for better coverage and protection.

As for addressing the rust problem area above the windshield, I pretty much came to the conclusion that my only real recourse was to revisit the 442 from the wrecking yard last week and see if that area was any better on it. This is no area to try and make homemade patch panels.

This left me with a slight dilemma: I would need a way to cut more off the car again. I'm a firm believer that, if you need to borrow or use a tool more than twice, you'd better buy one of your own!

Already having some DeWalt 20 volt cordless stuff, I picked up this "tool only" piece at the local Home Despot:

Continued >>>

To be perfectly honest, nearly nothing has been done since the last one. Not because I lost interest, or didn't feel like working on it, but more because I needed some time to lick my wounds and contemplate my next move.

Let me explain...

With the last of the rust repair over the back window completed, I cleaned up the shop and repositioned the car for better access to the front windshield channel area. With the old windshield cut out and gone, the procedure here was SUPPOSED to be to simply strip and clean out all the old paint, seam sealer, urethane and surface rust.

At least it APPEARED to be surface rust...

After spending 20 minutes or so with the Clean and Strip wheel, I was quickly faced with the reality that things weren't going to be that simple. I shouldn't have been surprised, I've been snakebit by this car a couple of times now, but it caught me off guard anyways.

While the "A" pillars are quite good...

...the top channel above the windshield wasn't so sh*t-hot.

With the old crud mostly stripped out of the this area, this is what I was left with:

Not good. Deep rust pits throughout, on both the horizontal and vertical edges. It wouldn't be so bad if it was only in a couple isolated areas, but this is pretty much prevalent from one edge to the other. Any way you look at it, it's going to be a monumental task to fix.

It was at this point in the week that I walked away and left it for a few days to consider my options.

In the meantime, I swung by my local bodyshop supplier and picked up some goodies for the upcoming stages:

More Clean and Strip wheels for cleaning up/out the windshield channel, and some single stage paint for the same before the front and rear glass goes back in.

Yup, you read that right, single stage. I'll be going wet on wet over DP50 epoxy primer just in the window channel areas. Just so it has some protection and some color in there. The rest of the outside will go base/clear, don't worry!

Here's the color, it appears to be a good match, and is correct for the car:

I'm eventually going to have to cut in the jams and trunk drain channel areas too, so it makes more sense to use single stage in these spots than base/clear for better coverage and protection.

As for addressing the rust problem area above the windshield, I pretty much came to the conclusion that my only real recourse was to revisit the 442 from the wrecking yard last week and see if that area was any better on it. This is no area to try and make homemade patch panels.

This left me with a slight dilemma: I would need a way to cut more off the car again. I'm a firm believer that, if you need to borrow or use a tool more than twice, you'd better buy one of your own!

Already having some DeWalt 20 volt cordless stuff, I picked up this "tool only" piece at the local Home Despot:

Continued >>>

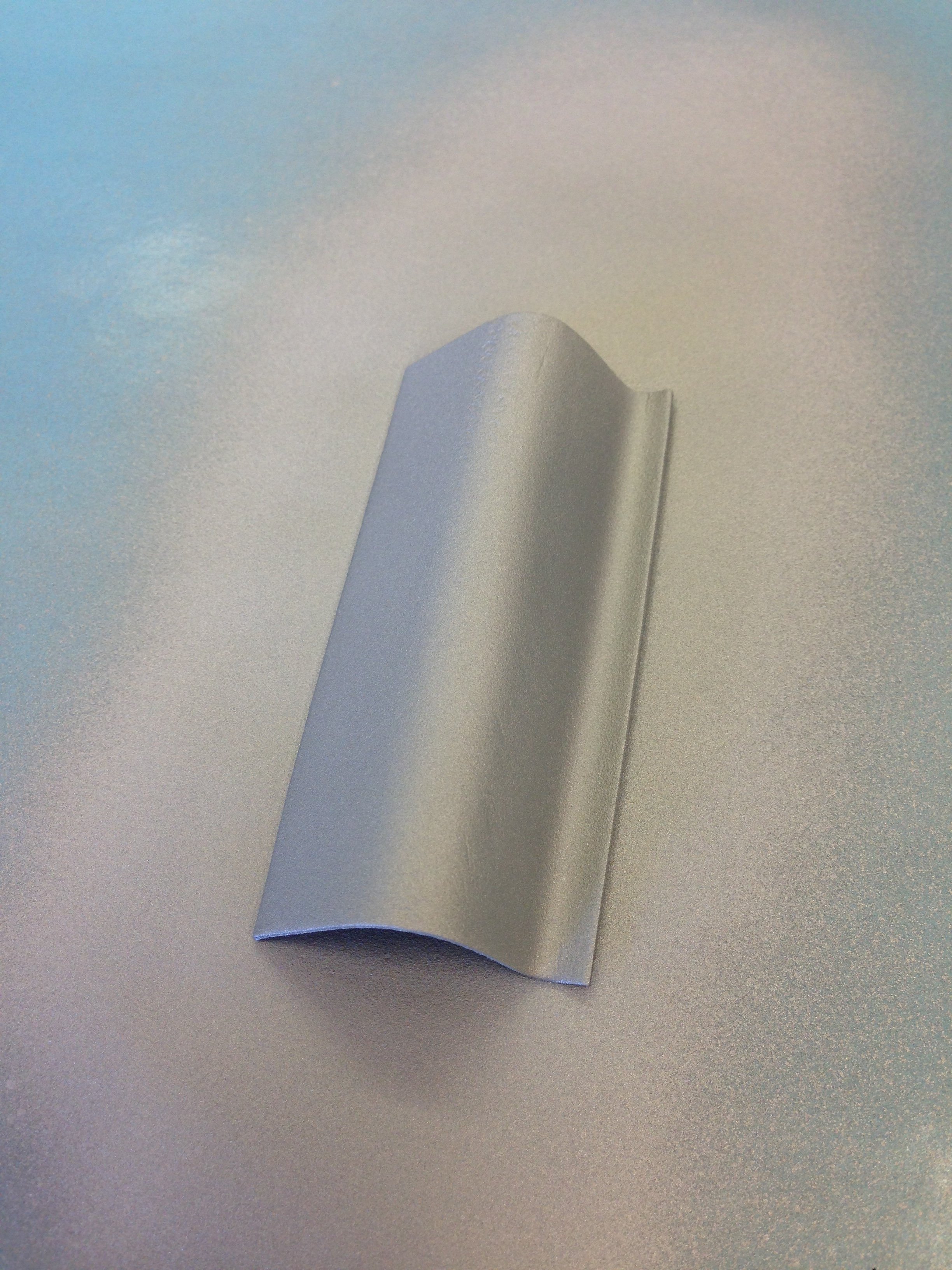

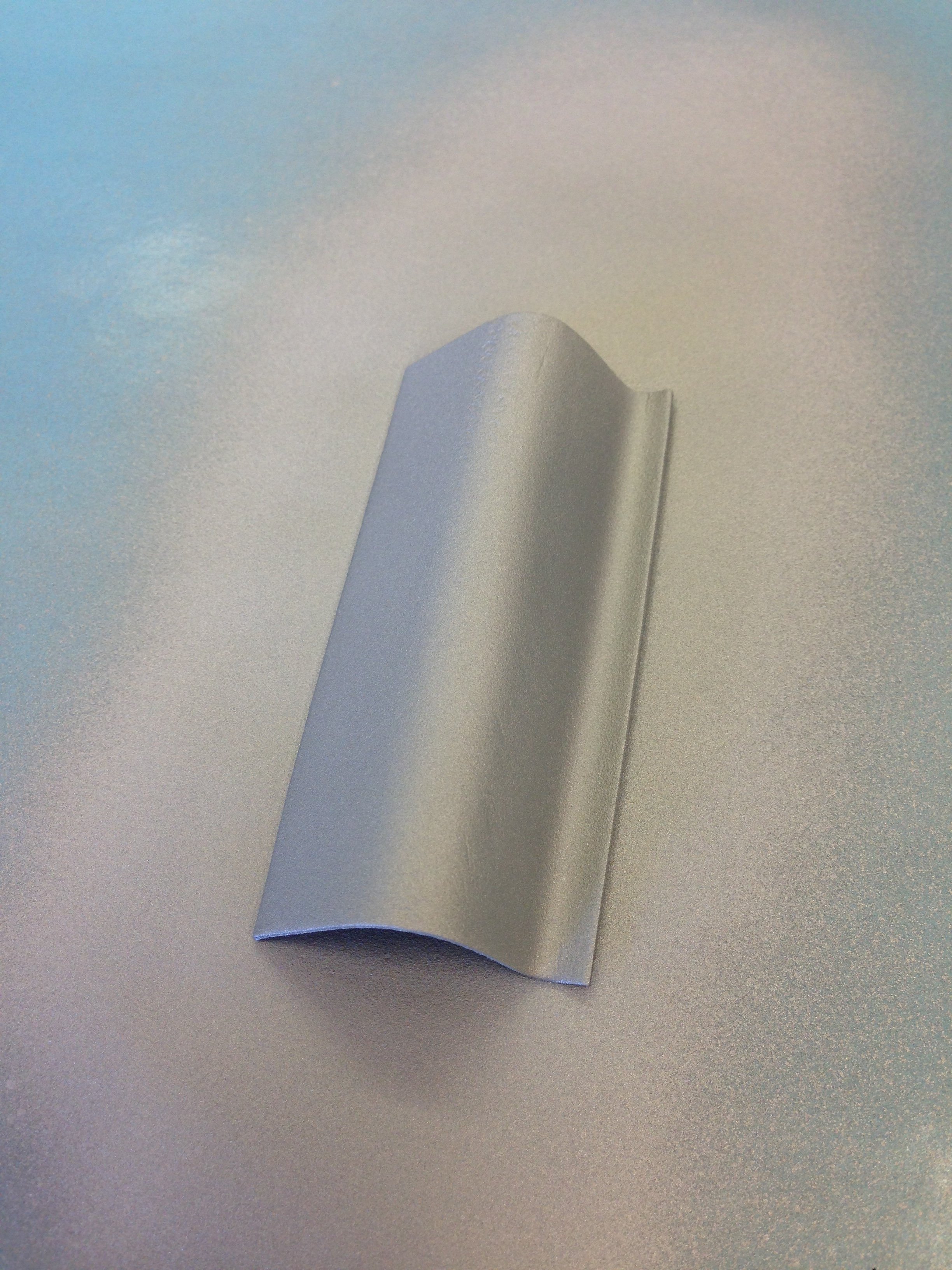

Fast forward to yesterday morning: after dragging the girlfriend out of bed and heading down to the yard bright and early, we returned home with this:

My initial assessment of it in the wrecking yard was a bit dubious, I could see surface rust in areas that looked remarkably similar to how Olds Cool looked before I started stripping the channel.

However I didn't buy a brand new saw, a bunch of blades and pay admission just to not take a chance on it.

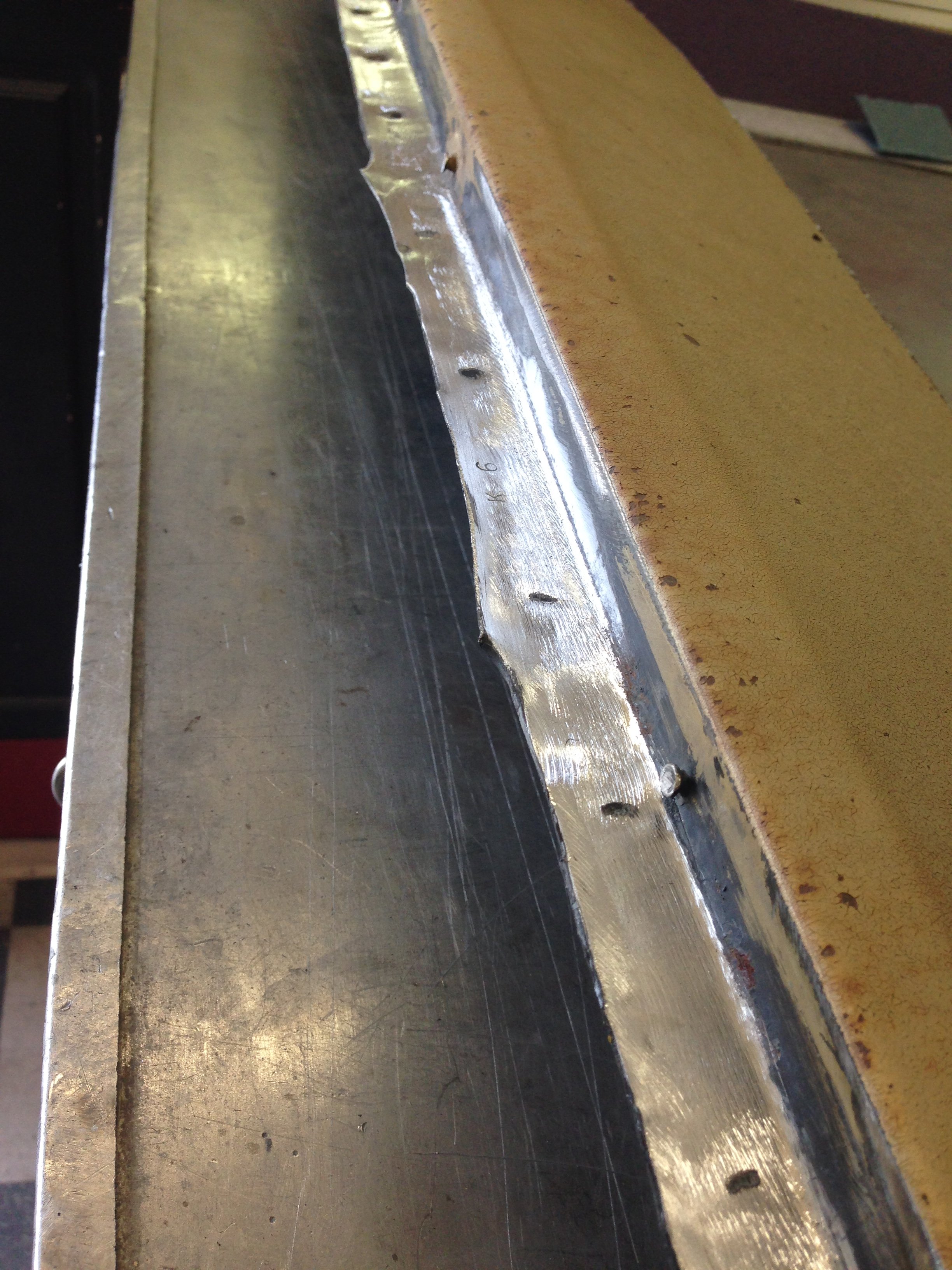

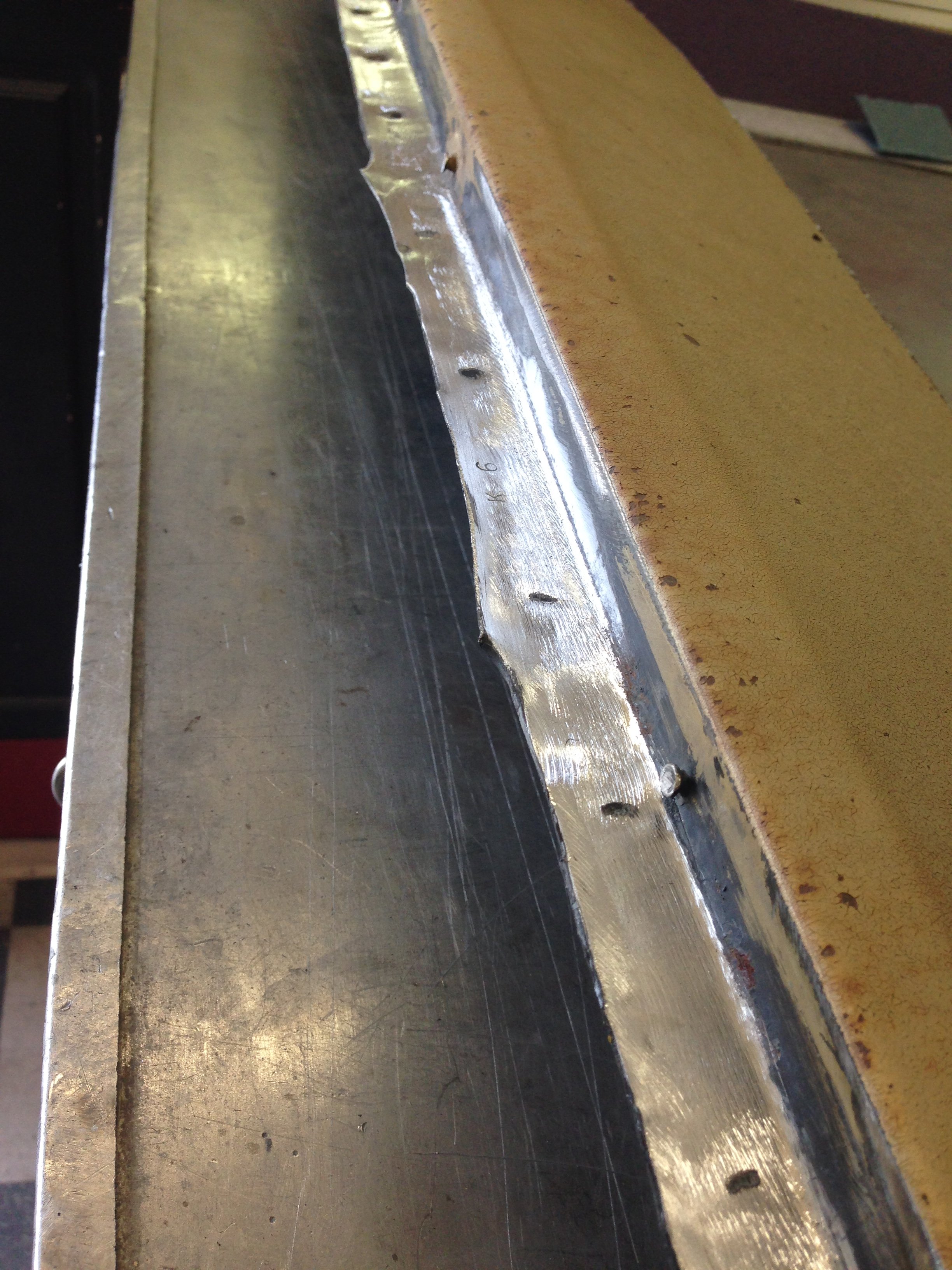

As soon as I got it home and on the bench, I hit the worst looking areas to see if it would be useable:

Imagine my delight at seeing that! Perfect, exactly what I needed and had hoped for! Now at least I had something I could work with.

Later on in the evening I returned to it and continued cleaning up the new piece:

After a bit of cleanup...

...and a bit more cleanup...

...it's looking great. This piece is not rusty in the least beyond that little bit of surface stuff. That's what the channel on Olds Cool was SUPPOSED to look like underneath!

Now that I've got the channel on the new piece cleaned up and ready to go, today I'll start to drill out the spot welds and separate it into just the part I'll need. It's still going to require a whole TON of welding (and yes, I'm more than a bit nervous about warping the roof), but at least now I have something I can work with.

I'm open to advice and suggestions as to how to incorporate this into its future home with minimal issues and potential warping. I've already considered flanging the new piece at the roof skin and panel bonding it in, but I don't really think that's the best or strongest approach.

Thanks all, for once again checking back. I'm looking forward to hearing your thoughts, comments, and general rantings!

Donovan

My initial assessment of it in the wrecking yard was a bit dubious, I could see surface rust in areas that looked remarkably similar to how Olds Cool looked before I started stripping the channel.

However I didn't buy a brand new saw, a bunch of blades and pay admission just to not take a chance on it.

As soon as I got it home and on the bench, I hit the worst looking areas to see if it would be useable:

Imagine my delight at seeing that! Perfect, exactly what I needed and had hoped for! Now at least I had something I could work with.

Later on in the evening I returned to it and continued cleaning up the new piece:

After a bit of cleanup...

...and a bit more cleanup...

...it's looking great. This piece is not rusty in the least beyond that little bit of surface stuff. That's what the channel on Olds Cool was SUPPOSED to look like underneath!

Now that I've got the channel on the new piece cleaned up and ready to go, today I'll start to drill out the spot welds and separate it into just the part I'll need. It's still going to require a whole TON of welding (and yes, I'm more than a bit nervous about warping the roof), but at least now I have something I can work with.

I'm open to advice and suggestions as to how to incorporate this into its future home with minimal issues and potential warping. I've already considered flanging the new piece at the roof skin and panel bonding it in, but I don't really think that's the best or strongest approach.

Thanks all, for once again checking back. I'm looking forward to hearing your thoughts, comments, and general rantings!

Donovan

Ughhh...that looks eerily familiar to my roof rot malibu. But not nearly as bad. Good that you found the piece you needed and in great shape. Especially locally. I think you already have a good plan of attack. Removing the spot welds along the channel. Then of course the brass that's melted to the area where skin meets A pillar. On mine, the first replacement skin I had which was easier to work with not on car, I ground along the top of drip rail channel to remove those tiny spot welds and used a cutoff wheel in between the welds to seperate and peel away. In hindsight I wish I would have used my dremel to seperate instead of grinder. It took away a little more than I wanted in a couple places. Those spot welds in the drip rail area are tiny and numerous.

The new replacement whole skin I have I will do the same, a little more carefully, from the underside as if I was sitting in car with it still attached to car. So as not to damage the outer skin. The old skin still on car, well 3/4 of it, will be done from the top to leave the bottom structure intact.

I believe you already have a great plan in your head mr Donovan. You do great work. With great attention to detail. You already did one section across roof that came out great, maybe try that same or similar approach with this section. That was just my .02 cents and ramblings. I am very interested to see what you finally decide to do.

The new replacement whole skin I have I will do the same, a little more carefully, from the underside as if I was sitting in car with it still attached to car. So as not to damage the outer skin. The old skin still on car, well 3/4 of it, will be done from the top to leave the bottom structure intact.

I believe you already have a great plan in your head mr Donovan. You do great work. With great attention to detail. You already did one section across roof that came out great, maybe try that same or similar approach with this section. That was just my .02 cents and ramblings. I am very interested to see what you finally decide to do.

Similar threads

- Replies

- 25

- Views

- 864

- Replies

- 14

- Views

- 793

- Replies

- 10

- Views

- 480

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.