Well our long weekend has now come to a close, just in time for my Southern friends to start their celebrations. Happy Fourth of July everyone!

My weekend was productive, not as much so on the car, but just overall.

After spotting a thread titled "Cutlass in Calgary" Saturday night, my curiosity was peaked as the car being referred to appeared to be a 1980 442!

After a near sleepless night I was in the wrecking yard parking lot the next morning at ten minutes to opening, and was the first one in the door.

Sure enough the car actually was a real gen-u-wine 1980 442, not a clone!

I immediately inquired about purchasing the entire car outright, and was answered with flatout denial. The only way I could purchase the car was if I bought the whole thing in parts only.

Ridiculous.

Cursing and swearing under my breath, I headed back to the car and began to pull what I needed. A few minutes in, another guy appeared and notified me that he was going to continue pulling the exhaust he had started yesterday. No problem, I had no interest in the exhaust.

A casual conversation was started up, and in doing so, I found he had four G bodies, including an '84

Hurst Olds! We carried on about our work, and after I had unbolted everything I could, I began sizing up the passenger's side sail panel. It was rust free, and would provide the ideal patch to repair the rust damage on Olds Cool.

This gentleman noticed me doing so, and mentioned that he had a cordless sawzall that I could borrow. I have a sawzall too, but mine is NOT cordless. Agreeing to his offer, I come to find out it's not in his truck, but actually at his house.

Believe it or not, he went home, grabbed the saw, stopped at Home Depot and bought metal cutting blades, and came all the way back. Just for me!!! I couldn't believe it.

People and random acts of kindness like that restore my faith in humanity!

After cutting out what I needed, we exchanged numbers, and I tried to convince him to join the forum. I paid for his admission, bought him a bottle of water (it was hotter than blazes), but he wouldn't accept anything further. After agreeing to contact each other and possibly hook him up with some parts from me in trade for using his saw, we went our individual ways.

Patrick, if you're reading this, THANK YOU again. You're a saviour.

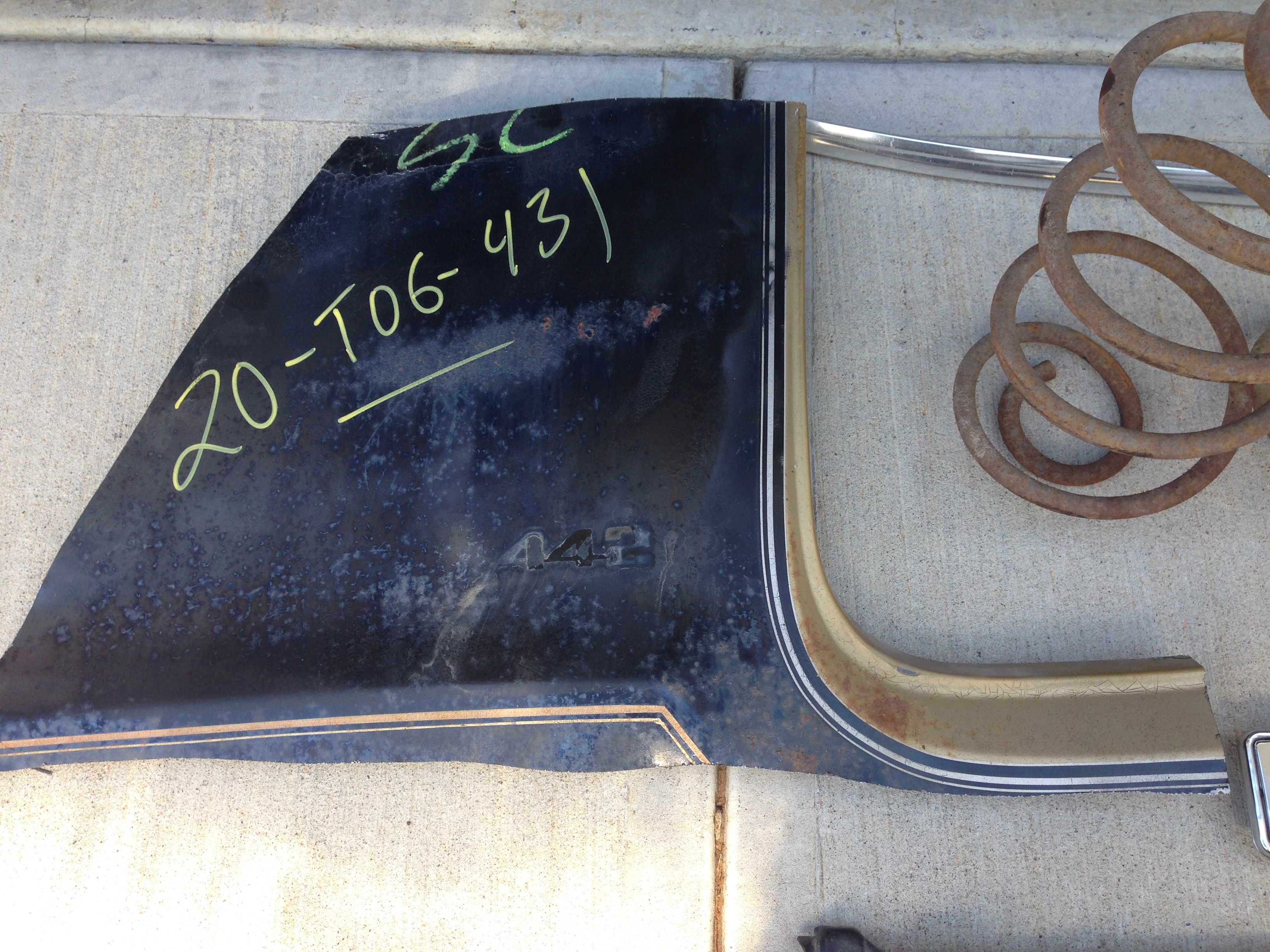

This is the haul from the junkyard:

Cutlass radiator top plate:

The crown jewel.

The sail panel that will save me so much work replacing the rust on the passenger's side:

I also grabbed the carb off it. Should flow good CFM being already sized for a 350, and it's pre-CCC like I need. The center fuel inlet isn't an issue, I'll bend up a new line from my fuel pump if need be.

Today I did a much needed cleanup and organization of my shop. I contacted my friend that tinted the windows, he swung by and grabbed all three back windows to clean up and retint. This needs to be done before the glass guys return to install the new windshield and the back window in a couple weeks.

After the shop was tidied a bit, I dove into the back window channel again. It took a long time and was very meticulous work, but I got the last of the seam sealer, paint, urethane etc stripped from all the nooks and crannies.

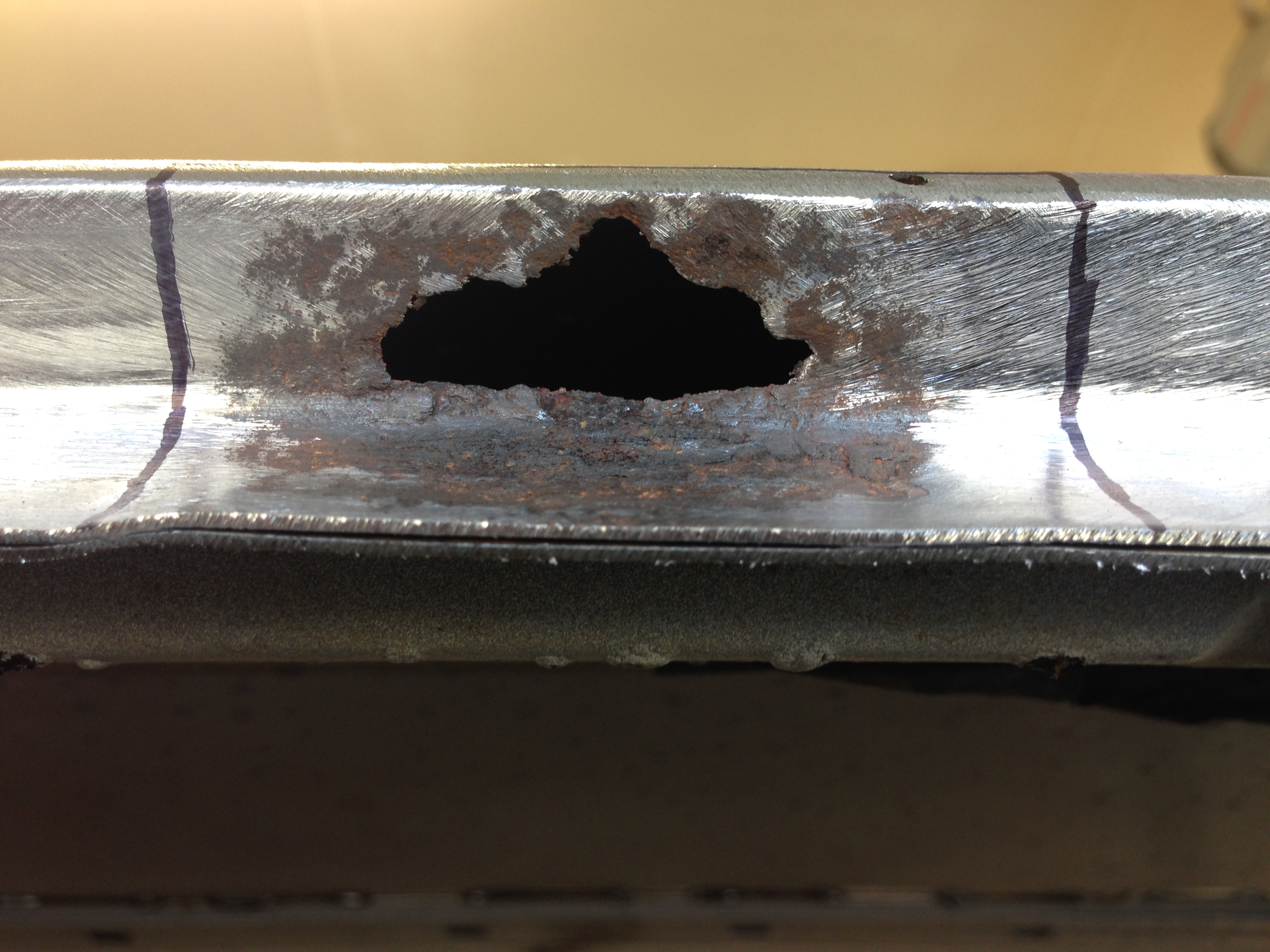

Once that was done, I turned my attention to the rusty spots. Wherever I could I ground out the rust pits down to clean bare metal, hammer and dollied the pinch weld straight, and flushed up the edges.

Even with the rust holes still present, it looks way better:

Continued >>>