I am loving this thread!! So motivating! Awesome work as always Donovan!

BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gentlemen, my sincere apologies for the very late reply to your comments.

I've been really pushing and trying to stay focused on the car of late rather than surfing the forum and writing updates. I greatly value everyone's comments tho, and don't want y'all to stop, so please don't let my lack of replying affect anything.

Thank you Darin.

I'll settle for "almost" inspiring you, but I totally get it. We all need a break from them every once in a while, especially when they fight us.

If there's anything I can do in the way of offering advice to help with your large patch, don't hesitate to ask on here or a PM.

Good luck with it, and keep at it. You'll get it!

Thanks Eric.

I have to remind myself of that every once in a while, that small progress is still progress. It just never seems to happen as quickly as we'd like.

Thanks for continuing to follow along!

Jared,

As our mischievous friend Scott so humorously contributed, the new (and correct) windshield is indeed now in stock and awaiting me at my glass supplier.

They've contacted me a couple of times to try and set up appointments to come out and install it for me, but I keep having to put them off as I'm still not quite ready for them yet. This is adding to my stress level considerably, as I really want to accommodate them, but I'm also not willing to sacrifice my quality for the same. Hence my pushing so hard to try and get these window channels done.

Thanks very much for the encouragement and support. Guys like you are the foundation of this fine site.

Thanks so much Jack.

I figure if I have to go to the effort of repairing these areas anyways, I might as well attempt to make them better than The General ever did. Yeah it takes longer, and is more finicky, but I really do feel it's worth it in the end.

As hard as I am on the fit and finish on our cars, we have to keep in mind the manufacturing processes weren't as good or precise as they are nowadays. It was as good as they could do at the time with what they had, and within a budget that still made the cars affordable to the average working stiff.

That doesn't stop me from trying to improve on it tho!

😛

Thank you!

I really appreciate all the feedback and comments everyone. This week's update to follow...

D.

I've been really pushing and trying to stay focused on the car of late rather than surfing the forum and writing updates. I greatly value everyone's comments tho, and don't want y'all to stop, so please don't let my lack of replying affect anything.

nice work, as usual, Mr. Riddler! almost has me inspiried to get back out and try to get the last patch on the Chief re-worked.... got the little patches done, but am having troubles with the large one behind the t-tops, so am stepping away for another week to clear my head, and work on the honey-do list...

Thank you Darin.

I'll settle for "almost" inspiring you, but I totally get it. We all need a break from them every once in a while, especially when they fight us.

If there's anything I can do in the way of offering advice to help with your large patch, don't hesitate to ask on here or a PM.

Good luck with it, and keep at it. You'll get it!

Looks great but remember any progress is good progress on these cars there still disappearing by the day and so few of us are saving them

Thanks Eric.

I have to remind myself of that every once in a while, that small progress is still progress. It just never seems to happen as quickly as we'd like.

Thanks for continuing to follow along!

Thanks for the awesome updates Donovan. The repairs look fantastic. When are you expecting the new windshield to come in?

As Donovan's unofficial PR rep I will fill in the blank Jared lol! The glass shop has the new windshield, but Mr. Ridler is holding them off until he has the window channels painted and done.

Disclaimer: any further questions must be directed to me via PM to avoid Donovan from being distracted in getting Olds Cool back on the road 😀!!!!

Signed.....Scott being a jackass on a Monday lol!!!! Cheers guys!!!!

Jared,

As our mischievous friend Scott so humorously contributed, the new (and correct) windshield is indeed now in stock and awaiting me at my glass supplier.

They've contacted me a couple of times to try and set up appointments to come out and install it for me, but I keep having to put them off as I'm still not quite ready for them yet. This is adding to my stress level considerably, as I really want to accommodate them, but I'm also not willing to sacrifice my quality for the same. Hence my pushing so hard to try and get these window channels done.

Thanks very much for the encouragement and support. Guys like you are the foundation of this fine site.

Great work as always, Mr. D.

If the General had done work on their cars to this degree they'd probably go bankrupt.

The mouldings have never fit this well from the factory. You can't compare the exemplary care you've been giving it. Keep up the good work as always.

Keep us thirsty for updates my friend.

Thanks so much Jack.

I figure if I have to go to the effort of repairing these areas anyways, I might as well attempt to make them better than The General ever did. Yeah it takes longer, and is more finicky, but I really do feel it's worth it in the end.

As hard as I am on the fit and finish on our cars, we have to keep in mind the manufacturing processes weren't as good or precise as they are nowadays. It was as good as they could do at the time with what they had, and within a budget that still made the cars affordable to the average working stiff.

That doesn't stop me from trying to improve on it tho!

😛

I am loving this thread!! So motivating! Awesome work as always Donovan!

Thank you!

I really appreciate all the feedback and comments everyone. This week's update to follow...

D.

Well in the past week, I've managed to make a little more headway on the old girl. Still nothing earth shattering mind you, but a bit more progress anyways.

I got the last of the old paint and primer finally stripped from the roof, along the front edge of the windshield:

While the windshield is out, my VIN tag was looking the worse for wear, it had no paint whatsoever left on it and was just a coating of rust.

Using a Roloc rubber bristled pad on my air angle grinder, I carefully buffed the surface back to clean shiny metal. This was the perfect tool to use here, it got rid of all the rust without affecting any of the raised letters or numbers.

Once clean, I masked off the area in preparation for some etch primer and paint:

It's clean and shiny here, ready for the next steps. I intentionally took the photo off center, because, well, it's the Internet. I don't need my entire VIN broadcast out there for all to see, thanks.

😎

After a couple light coats of etch and satin black VHT:

I'm still not totally done with it here just yet, I will highlight the letters and numbers with silver before the new windshield goes back in.

While I was messing around in this area, I found a couple of spots where the old paint had flaked off leaving some surface rust just below where I had planned to repaint.

This is the area I'm referring to, just below the surface that the windshield sits on:

After cleaning up those areas, I found some more serious rusted areas hiding underneath the seam sealer where the cowl area transitions to the firewall.

In trying to take a decent picture of the area, the light reflecting off the shiny metal next to it was playing havoc with the camera. I had to lay my hand over the area to cut down on the glare, but now at least you can see the rust.

After spending a little time addressing the area, I had all the rust removed, and ready to recoat. I'm going to be spraying epoxy and color here anyways, so to move my planned cutoff area down a couple inches was no big deal, especially considering that I could eliminate the corrosion.

After the rust removal:

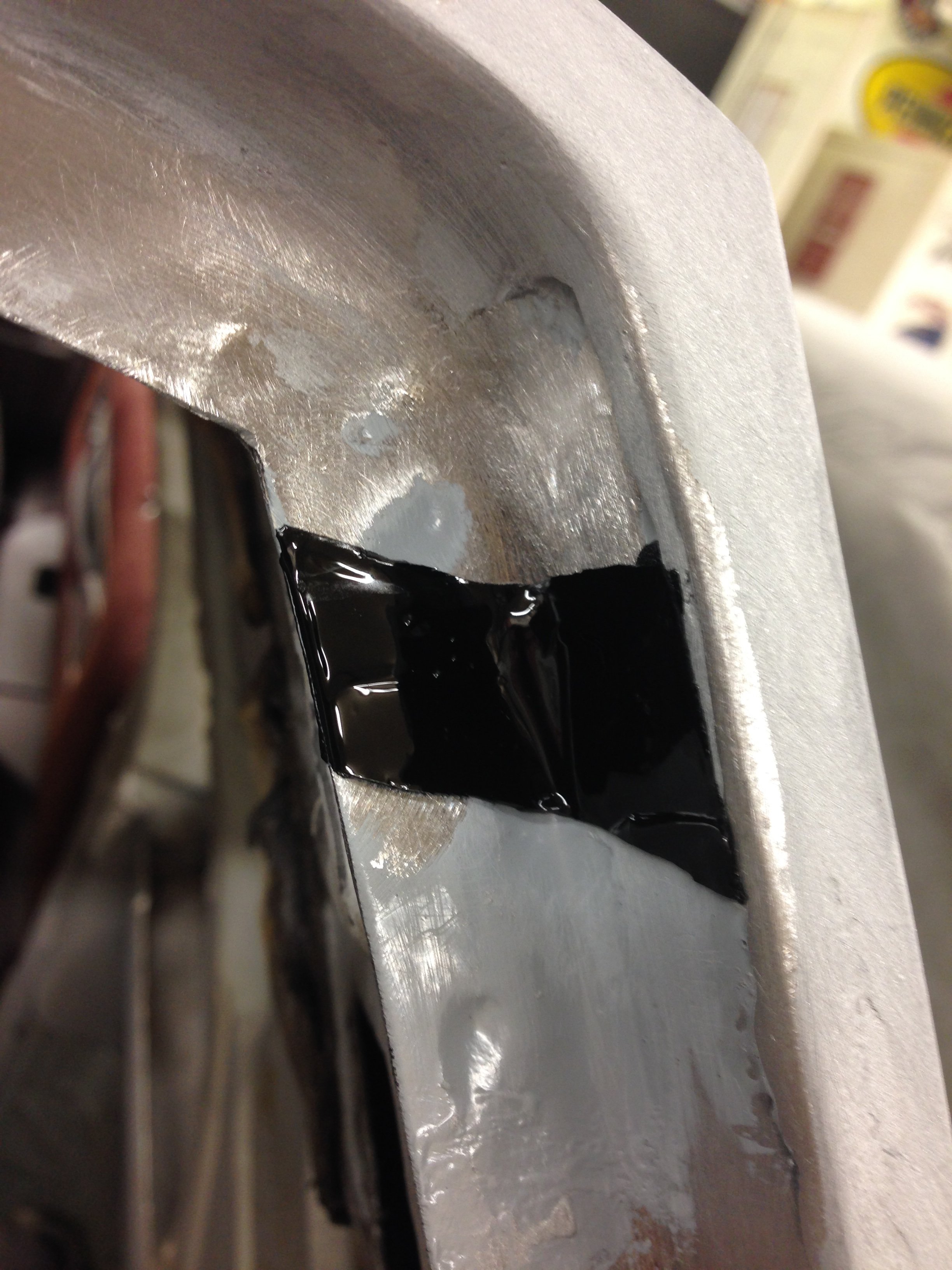

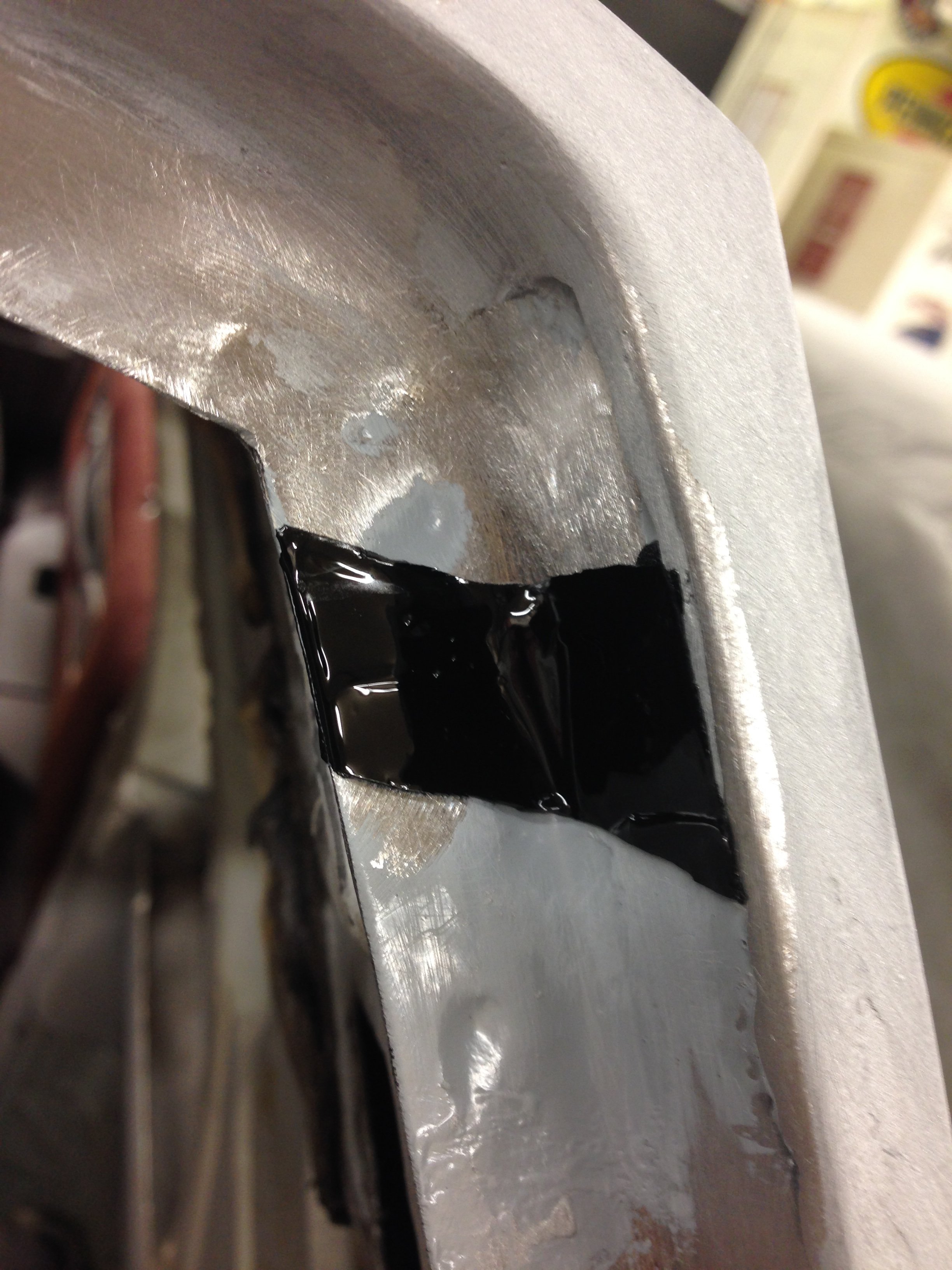

Satisfied that the front channel was finally finished (again), and ready for paint and primer, I moved back to the back window opening.

When I brushed in the epoxy on the front before seam sealer, I had applied a bit to the areas in the back window channel that would need seam sealer as well.

I prepped them with red ScotchBrite, then masked them off to keep the excess to a minimum. No "GM style" seam sealer application here, where it ended up everywhere, and on everything!

Continued >>>

I got the last of the old paint and primer finally stripped from the roof, along the front edge of the windshield:

While the windshield is out, my VIN tag was looking the worse for wear, it had no paint whatsoever left on it and was just a coating of rust.

Using a Roloc rubber bristled pad on my air angle grinder, I carefully buffed the surface back to clean shiny metal. This was the perfect tool to use here, it got rid of all the rust without affecting any of the raised letters or numbers.

Once clean, I masked off the area in preparation for some etch primer and paint:

It's clean and shiny here, ready for the next steps. I intentionally took the photo off center, because, well, it's the Internet. I don't need my entire VIN broadcast out there for all to see, thanks.

😎

After a couple light coats of etch and satin black VHT:

I'm still not totally done with it here just yet, I will highlight the letters and numbers with silver before the new windshield goes back in.

While I was messing around in this area, I found a couple of spots where the old paint had flaked off leaving some surface rust just below where I had planned to repaint.

This is the area I'm referring to, just below the surface that the windshield sits on:

After cleaning up those areas, I found some more serious rusted areas hiding underneath the seam sealer where the cowl area transitions to the firewall.

In trying to take a decent picture of the area, the light reflecting off the shiny metal next to it was playing havoc with the camera. I had to lay my hand over the area to cut down on the glare, but now at least you can see the rust.

After spending a little time addressing the area, I had all the rust removed, and ready to recoat. I'm going to be spraying epoxy and color here anyways, so to move my planned cutoff area down a couple inches was no big deal, especially considering that I could eliminate the corrosion.

After the rust removal:

Satisfied that the front channel was finally finished (again), and ready for paint and primer, I moved back to the back window opening.

When I brushed in the epoxy on the front before seam sealer, I had applied a bit to the areas in the back window channel that would need seam sealer as well.

I prepped them with red ScotchBrite, then masked them off to keep the excess to a minimum. No "GM style" seam sealer application here, where it ended up everywhere, and on everything!

Continued >>>

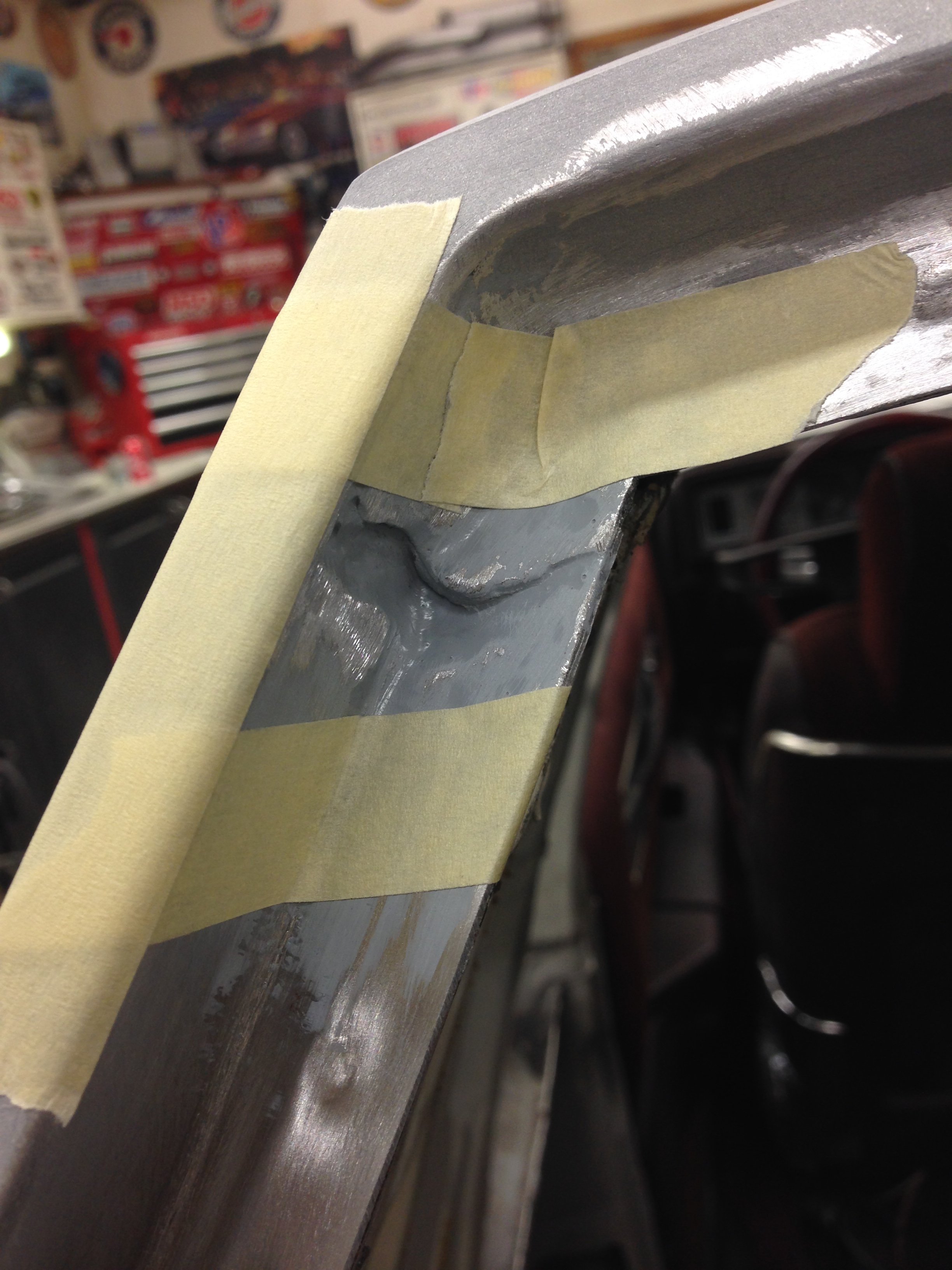

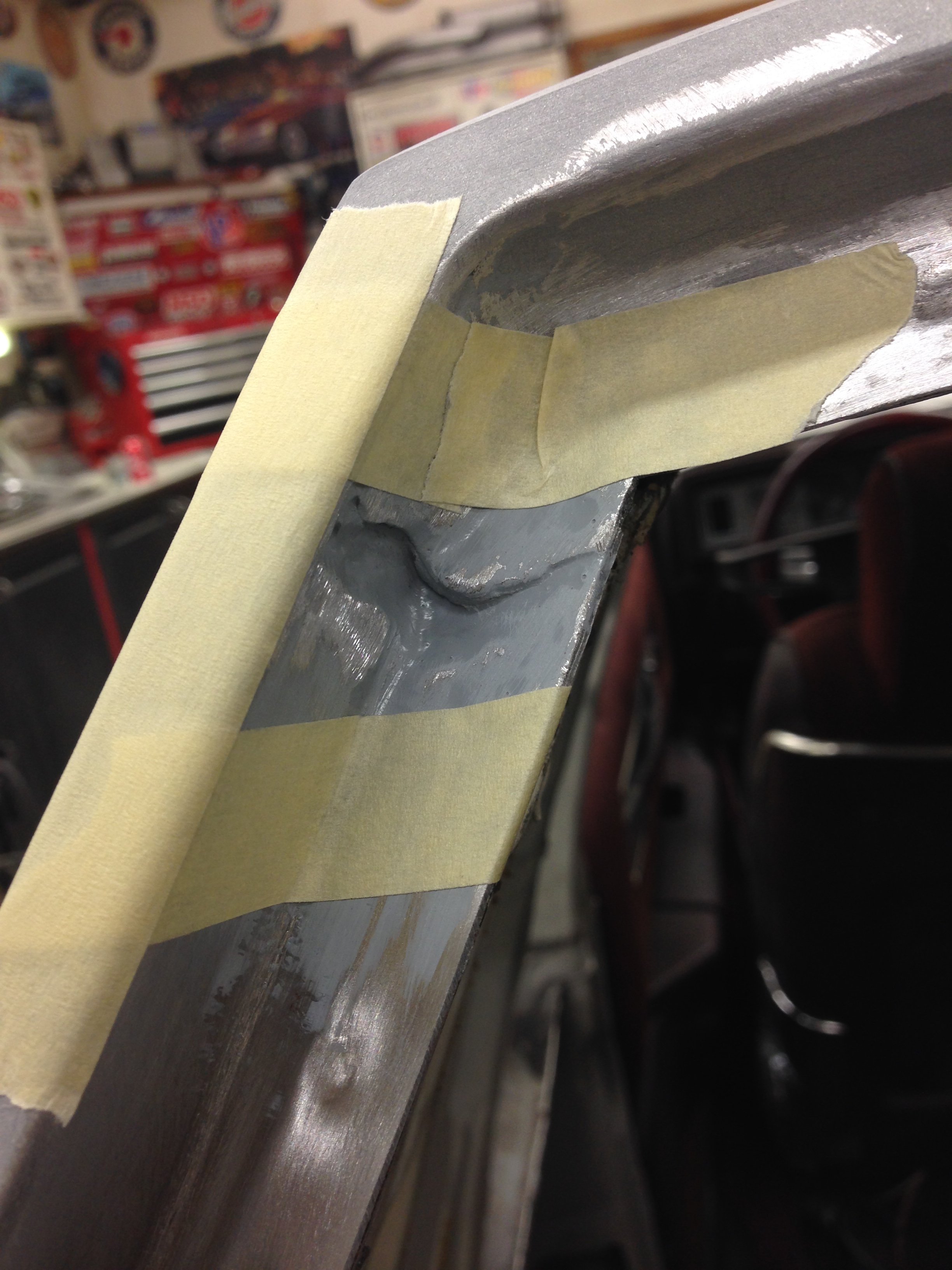

Here are the seams in the upper back corners after applying the seam sealer:

Remember the low area I had after goofing up welding in the one patch?

Well after evaluating the area and weighing my options, I elected to just fill it. It really wasn't that bad, and my fear was that I could actually make things worse by attempting to cut it open and try to reweld it.

Here it is after a bit of filler work. You can see how just a little bit of warping can affect a much larger area.

Of course, while doing the filler work, I skimmed and blocked the entire surrounding area as well. The blue tape is to keep the excess from the areas I don't want it.

These are "work in progress" pics, I'm still working on these areas. They were also taken prior to applying the seam sealer in the corners.

While this next pic is mostly an "overall" shot, if you look closely under all the dust, you can see that I've sanded and feathered out the old paint where it transitions under the trunk filler panel:

Continued >>>

Remember the low area I had after goofing up welding in the one patch?

Well after evaluating the area and weighing my options, I elected to just fill it. It really wasn't that bad, and my fear was that I could actually make things worse by attempting to cut it open and try to reweld it.

Here it is after a bit of filler work. You can see how just a little bit of warping can affect a much larger area.

Of course, while doing the filler work, I skimmed and blocked the entire surrounding area as well. The blue tape is to keep the excess from the areas I don't want it.

These are "work in progress" pics, I'm still working on these areas. They were also taken prior to applying the seam sealer in the corners.

While this next pic is mostly an "overall" shot, if you look closely under all the dust, you can see that I've sanded and feathered out the old paint where it transitions under the trunk filler panel:

Continued >>>

Tonight I decided to take a mini break from bodywork and all the dust and sanding and tackle some mechanical and cosmetic changes.

But first, a brief bit of history.

Back in May of this year when the car was still on the road, I had the MagnaFlow mufflers I had on the car cut off and replaced. I really disliked the sound of the MF's, they always sounded like they had a broken baffle in them, right from day 1. I ended up going back to some old school DynoMax super turbos, they provide a decent exhaust note without being excessively loud or obnoxious. (In my opinion anyways)

While the mufflers were being replaced, I had the exhaust shop fab up and install a set of tail pipes to further cut down on the drone. I had them make them "side exit", just behind the rear tires.

While I was much happier with the sound level and exhaust note, the visible portion of the pipes under the quarters looked unfinished.

Fast forward to today. Stopping in at my local speed shop on a whim today, I found some really nice stainless steel slash cut tips with a rolled edge. To seal the deal, they were extremely reasonable at $45 each.

Here is the exhaust as finished by the muffler shop, nothing fancy, just two pipes sticking out the sides:

The new tips are slip fit over the existing pipes, but they'd only go on about 2". To get them to where I wanted them, I'd have to cut some off. This required getting the rear up on stands:

After some careful measuring and cutting, I had 6" removed from the tail pipes:

Here's the payoff, I still have to final weld them in place, but I like the look much better. Apologies for the so-so pics, it was dark outside, and the car was still up on stands. I'll try and get some better ones tomorrow, maybe outside in the daylight.

Continued >>>

But first, a brief bit of history.

Back in May of this year when the car was still on the road, I had the MagnaFlow mufflers I had on the car cut off and replaced. I really disliked the sound of the MF's, they always sounded like they had a broken baffle in them, right from day 1. I ended up going back to some old school DynoMax super turbos, they provide a decent exhaust note without being excessively loud or obnoxious. (In my opinion anyways)

While the mufflers were being replaced, I had the exhaust shop fab up and install a set of tail pipes to further cut down on the drone. I had them make them "side exit", just behind the rear tires.

While I was much happier with the sound level and exhaust note, the visible portion of the pipes under the quarters looked unfinished.

Fast forward to today. Stopping in at my local speed shop on a whim today, I found some really nice stainless steel slash cut tips with a rolled edge. To seal the deal, they were extremely reasonable at $45 each.

Here is the exhaust as finished by the muffler shop, nothing fancy, just two pipes sticking out the sides:

The new tips are slip fit over the existing pipes, but they'd only go on about 2". To get them to where I wanted them, I'd have to cut some off. This required getting the rear up on stands:

After some careful measuring and cutting, I had 6" removed from the tail pipes:

Here's the payoff, I still have to final weld them in place, but I like the look much better. Apologies for the so-so pics, it was dark outside, and the car was still up on stands. I'll try and get some better ones tomorrow, maybe outside in the daylight.

Continued >>>

While I was under the car, I fell into the "while I'm here, I might as well..." syndrome.

I've been experimenting with different spring combinations in the back lately, trying to find that "just right" stance. I've got 2" BelTech drop spindles in the front, and while I'm happy with where the front sits, I'm still playing with the rear. I have a set of rear drop springs (compliments of MrEvil, thanks Rick!), but in my opinion they made the *ss end look a bit droopy. I found and installed a set of cargo springs from a Malibu in the wreckers, but it was too much the other way. It gave it a bit of a stink bug stance.

Some enterprising individual decided he needed my original springs more than I did, so during one of my last trips to the auto wreckers, I snagged the springs from the '80 442.

Time to install them while I had the car up in the air.

I don't know if it's as apparent in the pic, but the original 442 spring is about an inch taller than the drop spring:

Installation was easy peasy, I just popped them out and in.

While I was addressing the rear suspension, I also wanted to install what I found buried in my cabinets the other day. Funny story here...

I hate the stories you hear of these guys that "just happened to have" whatever lying around.

"I installed these aluminum race Dart heads for a big block Chevy on my engine the other day that I just happened to have lying around..."

Yeah right.

You know what I mean.

Well, it turns out I'm one of these a**holes!

I had completely forgotten that I had a brand new set of unused RideTech single adjustable rear shocks left over from The Juggernaut when I modified the air bag installed height. I needed a shorter shock, so these got tucked away, and apparently forgotten about.

Damn. I hate when I unintentionally become a hypocrite!!

After cleaning off the dust, and preliminarily setting the adjustment, they went on the car. They sure look purdy under there!

And in case anyone was wondering, yes I do indeed have one of the über desirable 8.5" 10 bolts under the car. Courtesy an '85 442, complete with 3:73 gears. I kept the untouched "patina" to fly under everyone's radar...

😀

So that's it for now guys. Little bits of progress, and lots of pics in my usual fashion.

Thanks for checking in on the build!

D.

I've been experimenting with different spring combinations in the back lately, trying to find that "just right" stance. I've got 2" BelTech drop spindles in the front, and while I'm happy with where the front sits, I'm still playing with the rear. I have a set of rear drop springs (compliments of MrEvil, thanks Rick!), but in my opinion they made the *ss end look a bit droopy. I found and installed a set of cargo springs from a Malibu in the wreckers, but it was too much the other way. It gave it a bit of a stink bug stance.

Some enterprising individual decided he needed my original springs more than I did, so during one of my last trips to the auto wreckers, I snagged the springs from the '80 442.

Time to install them while I had the car up in the air.

I don't know if it's as apparent in the pic, but the original 442 spring is about an inch taller than the drop spring:

Installation was easy peasy, I just popped them out and in.

While I was addressing the rear suspension, I also wanted to install what I found buried in my cabinets the other day. Funny story here...

I hate the stories you hear of these guys that "just happened to have" whatever lying around.

"I installed these aluminum race Dart heads for a big block Chevy on my engine the other day that I just happened to have lying around..."

Yeah right.

You know what I mean.

Well, it turns out I'm one of these a**holes!

I had completely forgotten that I had a brand new set of unused RideTech single adjustable rear shocks left over from The Juggernaut when I modified the air bag installed height. I needed a shorter shock, so these got tucked away, and apparently forgotten about.

Damn. I hate when I unintentionally become a hypocrite!!

After cleaning off the dust, and preliminarily setting the adjustment, they went on the car. They sure look purdy under there!

And in case anyone was wondering, yes I do indeed have one of the über desirable 8.5" 10 bolts under the car. Courtesy an '85 442, complete with 3:73 gears. I kept the untouched "patina" to fly under everyone's radar...

😀

So that's it for now guys. Little bits of progress, and lots of pics in my usual fashion.

Thanks for checking in on the build!

D.

liquidh8

Comic Book Super Hero

Two things:

You are getting those amazing factory 4x10 speakers ah dirty! Good news is you can just vacuum and air hose them out and they won't sound any worse . . . 😛

I predict you will pretty up that 10 bolt rear before you are done. I noticed it right away when I started sticking all these shiny new parts on mine and, always garaged with only 28K miles, it wasn't that bad. Then I popped the cover to put on a Trickflow and all of this wonderful metal came out with the fluid. I mean a BUNCH! Don't remember what your plans were/are for under the hood when you are done but you might want to take a peek inside yours as well. Granted, mine could be a fluke but, I only have about 4000 miles on my rear with the big block but I haven't been that hard on it and only 24,000 before that with the 307 so I suspect by the 80s that perhaps the quality of the internals had gone down? Anyway, better safe than sorry . . .

Looking good dude!

You are getting those amazing factory 4x10 speakers ah dirty! Good news is you can just vacuum and air hose them out and they won't sound any worse . . . 😛

I predict you will pretty up that 10 bolt rear before you are done. I noticed it right away when I started sticking all these shiny new parts on mine and, always garaged with only 28K miles, it wasn't that bad. Then I popped the cover to put on a Trickflow and all of this wonderful metal came out with the fluid. I mean a BUNCH! Don't remember what your plans were/are for under the hood when you are done but you might want to take a peek inside yours as well. Granted, mine could be a fluke but, I only have about 4000 miles on my rear with the big block but I haven't been that hard on it and only 24,000 before that with the 307 so I suspect by the 80s that perhaps the quality of the internals had gone down? Anyway, better safe than sorry . . .

Looking good dude!

Donovan,

No words . Absolutely amazing work. I have definitely been an unintentional hypocrite myself. You're not alone my friend!

No words . Absolutely amazing work. I have definitely been an unintentional hypocrite myself. You're not alone my friend!

Similar threads

- Replies

- 25

- Views

- 856

- Replies

- 14

- Views

- 780

- Replies

- 10

- Views

- 467

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.