Okie dokie guys, update time and it's gonna be a big one again tonight.

So get comfy with your favourite beverage, and let's get down to it!

I failed to mention in my most recent update that I'm now on my last week of holidays, so it's been GO time around here lately.

I'll try and keep the text to a minimum tonight, and let the pics do most of the talking.

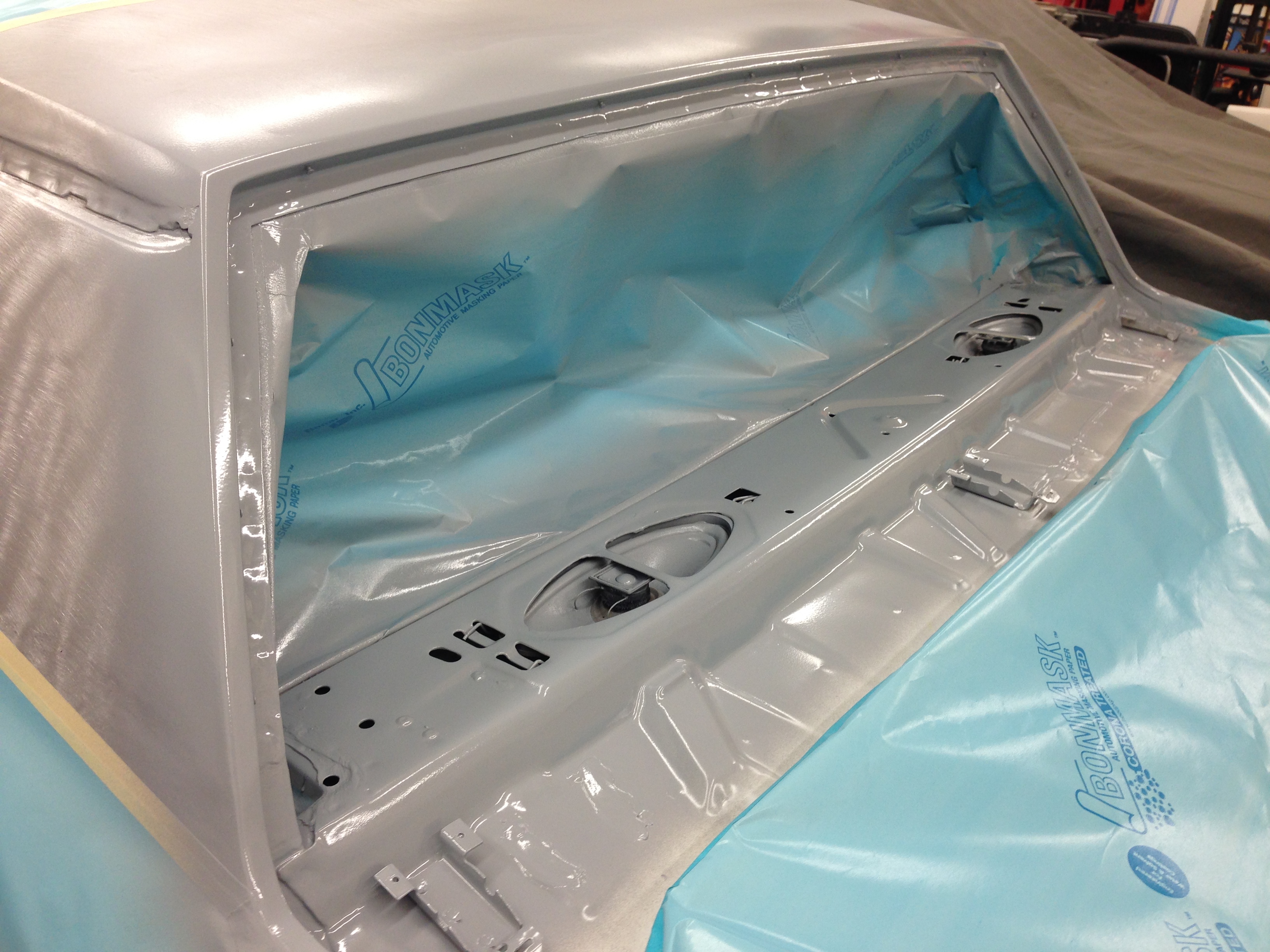

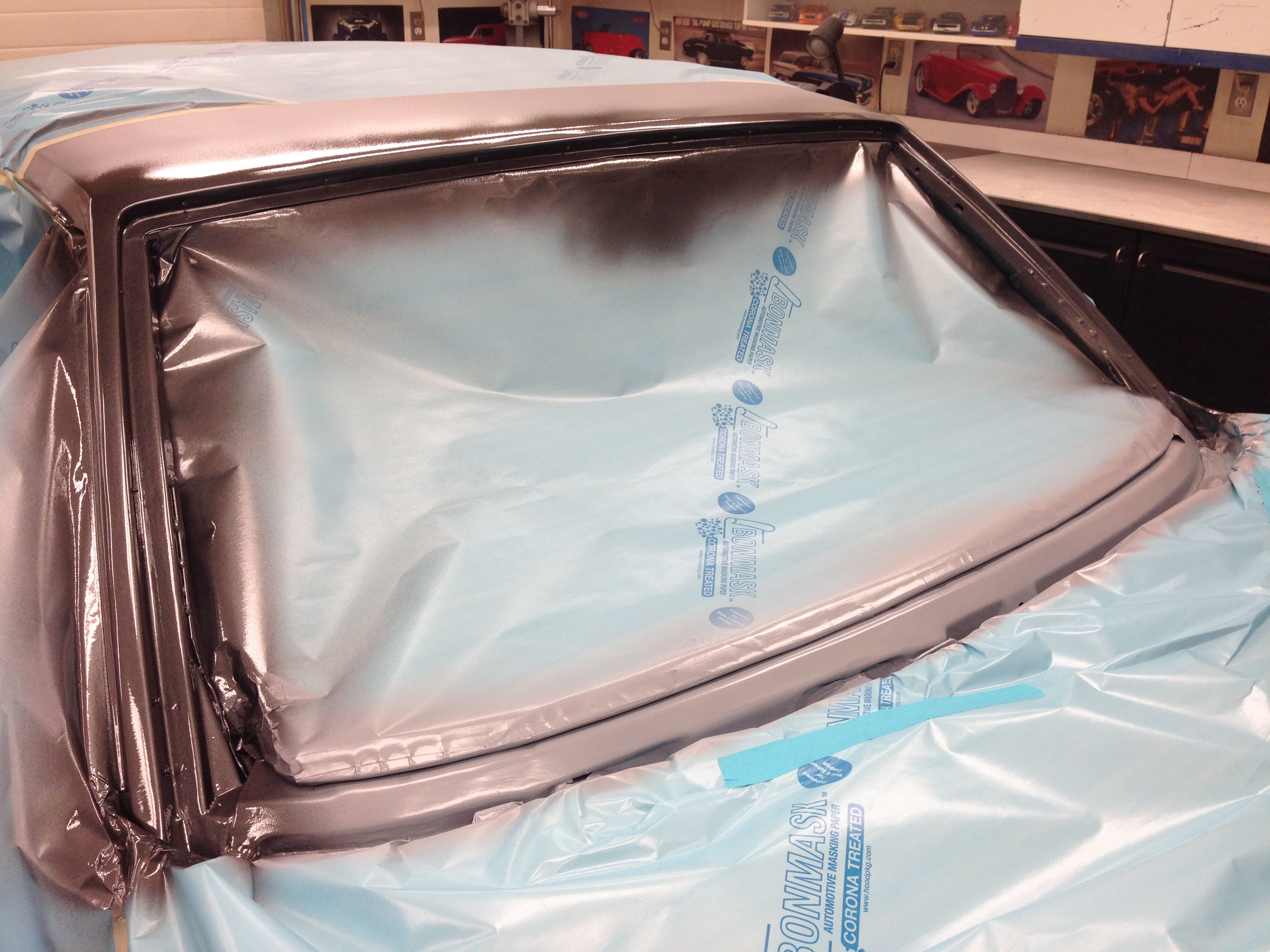

After another day and a bit of more filling, blocking and sanding (sometimes insanely little areas), I finally got the filler work around the back window done.

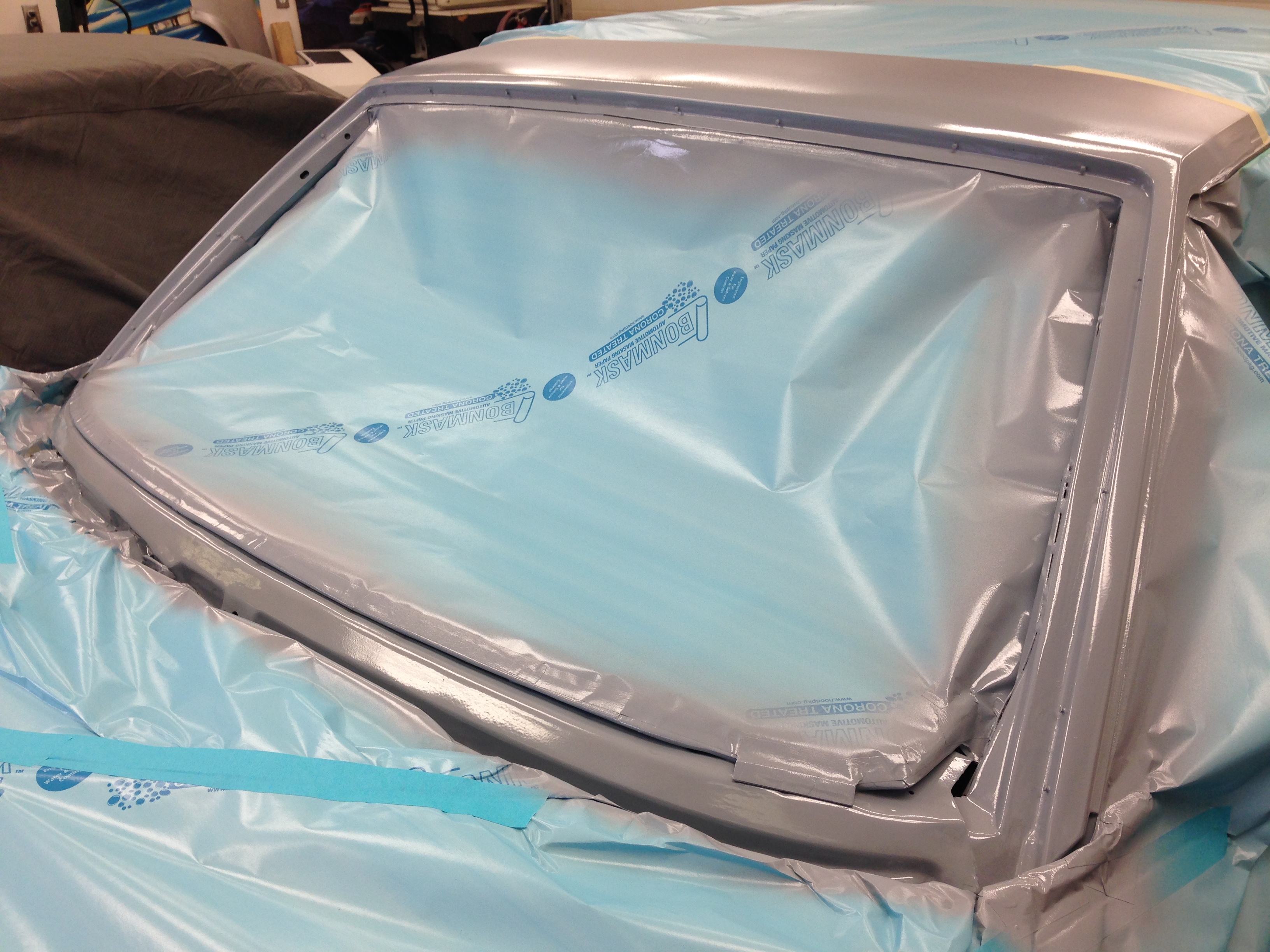

After finishing that up mid afternoon yesterday, I consulted the reconnaissance photos I took of the 442 in the wreckers a couple weeks ago for placement of the trim studs.

I laid out 1/4" masking tape at the spots that needed a stud, as near as I could determine from my pictures.

Once I had one side laid out, I measured their placement and duplicated it on the other.

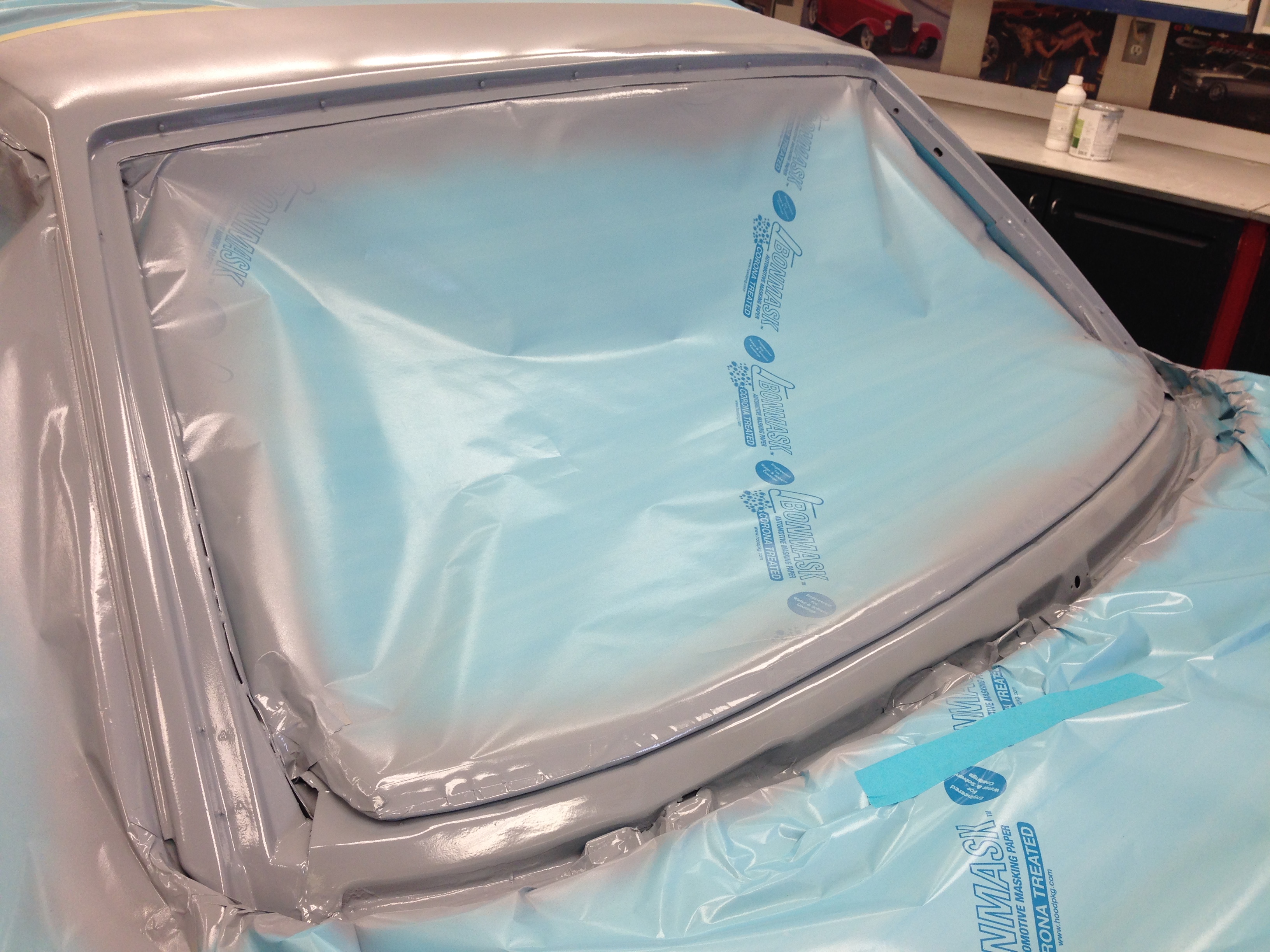

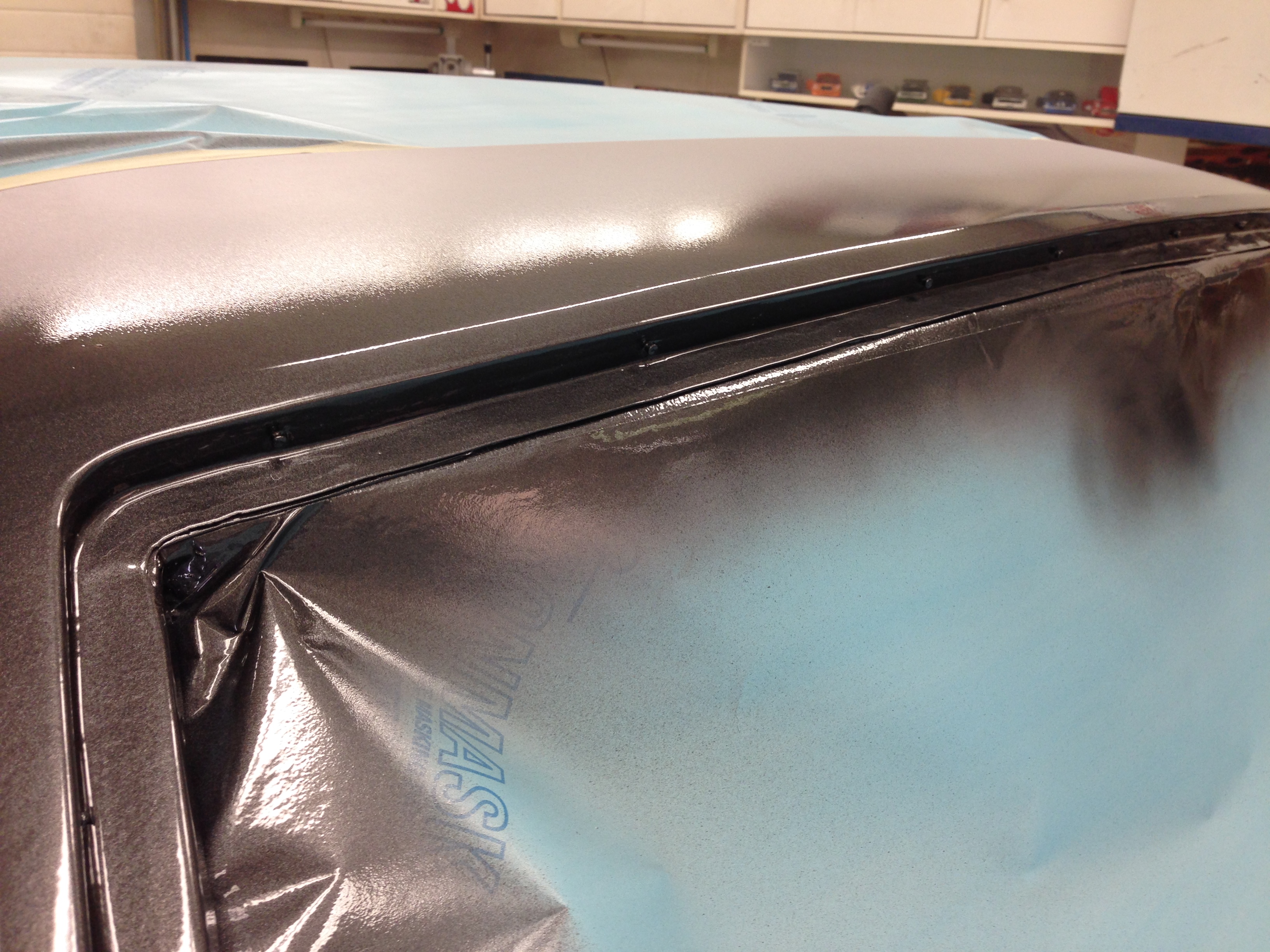

Once I had that done, I removed any filler that may have been underneath, and began welding the studs in with the UniSpotter. I had to redo roughly a half dozen or so, just to get the optimum positioning of the mouldings once they were installed. In most instances, I didn't need to move them much, only about a 1/16" or so. This made a huge difference in how far the mouldings sat down flush tho.

Then install the clips, to make sure they went on all the way:

Outta room for pics, so...

Continued >>>

So get comfy with your favourite beverage, and let's get down to it!

I failed to mention in my most recent update that I'm now on my last week of holidays, so it's been GO time around here lately.

I'll try and keep the text to a minimum tonight, and let the pics do most of the talking.

After another day and a bit of more filling, blocking and sanding (sometimes insanely little areas), I finally got the filler work around the back window done.

After finishing that up mid afternoon yesterday, I consulted the reconnaissance photos I took of the 442 in the wreckers a couple weeks ago for placement of the trim studs.

I laid out 1/4" masking tape at the spots that needed a stud, as near as I could determine from my pictures.

Once I had one side laid out, I measured their placement and duplicated it on the other.

Once I had that done, I removed any filler that may have been underneath, and began welding the studs in with the UniSpotter. I had to redo roughly a half dozen or so, just to get the optimum positioning of the mouldings once they were installed. In most instances, I didn't need to move them much, only about a 1/16" or so. This made a huge difference in how far the mouldings sat down flush tho.

Then install the clips, to make sure they went on all the way:

Outta room for pics, so...

Continued >>>