I love the styling of this car Donovan. I really like the front header. Reminds me a lot of the 88/98's of the time which I have fond memories of. I really nice 98 almost followed me home a year or so ago but I got sick. I guess it was a good thing. I didn't really need it and didn't really have a place to put it. Just wanted it.

BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

D,

The spacers give the wheels a different perspective. It looks good with the wheels pushed outward a bit. Do you really trust 2" spacers though?

I know the Olds ralley wheels came in 15". My friend had them on his '77 Cutlass Salon. Apparently the 15" variety are not easy to come by, not counting the chrome 442, H/O wheels.

The aluminum wheels are still very cool looking despite being 14".

Yeah, you're right, I should send Dana a PM to break his chops. Like, "Where the heck you been, dude"?...I think you're right that he did post recently. Like a phantom, he comes out of nowhere....lol!!

OldsCool is a righteous looking ride. It does look very presentable. I certainly would not mind cruising around in it.

Thanks Jack.

I'll be the first to admit that I've never been a fan of spacers. Like you, I wasn't sure I could really trust them. I've read of several other people using them tho, so I figured I'd roll the dice and take a chance.

I now have one full season of car related shenanigans (burnouts, peel outs, aggressive cornering etc) on them, with no ill effects. Other than where they place the wheels in the wells, you'd never know they were there.

I used to have a set of 15" Olds rallies too, they came off my first car - a '76 Cutlass Salon. First thing I did when I bought my first G body (now known as The Juggernaut 😉) was try them on. No dice, the backspacing was way off - they hit the inside of the frame rails. I ended up selling them off eventually and buying the Centerlines off my dad's abandoned '71 Chevelle project instead.

Glad you like the looks of the aluminum 442 wheels, I think they suit the "stock style" old school vibe I'm shooting for on this one. I've been hard at work on restoring those aluminum wheels, and they're almost done.

Here's a couple sneak peeks at what I've been doing to them.

I'm really excited to be nearing the end of their restoration. Can't wait to finish them up and get the good tires I picked up for them last year mounted, and get 'em on the car. Should look really good I think!

Last edited:

I love the styling of this car Donovan. I really like the front header. Reminds me a lot of the 88/98's of the time which I have fond memories of. I really nice 98 almost followed me home a year or so ago but I got sick. I guess it was a good thing. I didn't really need it and didn't really have a place to put it. Just wanted it.

I get that sentiment Jared! If only we all had the time, space and money to be able to have them follow us home... we'd have a yard full of cars like Hafrod!

Lol

To be honest, I was never really a fan of the front end and grilles on the Calais'. It shares these same grilles with the wagons and sedans, so I always thought they looked a bit.... pedestrian.

That opinion is slowly fading tho, I'm becoming more and more accustomed to them, and they're slowly growing on me.

Glad to hear you guys still like the car tho, I'm actually a bit surprised to hear that, as the '78-80 models aren't near as popular as their later brothers.

They just need the right mods, and a little love to reveal their potential!

Thanks for commenting my friend!

Last edited:

Hey everyone

Once again it's been far too long since I've done an update here on this thread. My appologies for that.

This update is on the most recent thing I've done for the car, so it'll be a bit out of order as far as the timeline is concerned. I still haven't finished covering what I've already done to the car just yet, but I'm excited to have finally reached today's milestone, so I'm doing this update now anyways.

I hinted at what I've been working on these last couple months just a few posts prior. The restoration of a set of aluminum 1980 Olds 442 wheels.

I acquired the wheels from my friend Dana in a trade shortly after I got the car 2 years ago. Dana had the wheels, they came on an Olds wagon he had purchased, but he really had no use for them or idea what they were. Dana needed a double hump crossmember for his Malibu wagon project, I had an unused one for a T56 that I had changed direction on, so we arranged the trade.

Upon taking possession of the wheels 2 years ago, I immediately installed my cheapie Walmart tires (that I got for a case of beer), and a second case of beer got the tires installed and balanced on them. I bolted them on the car, and enjoyed them for the next year and a half.

Here's a quick pic from when they went on the car for the first time:

At the end of last year, I knew that I wanted to properly clean up and restore these wheels to their former glory, so I bolted the stock steel rallies on the car for storage over the winter. The 442 wheels had the tires dismounted, and I was ready to start their refurbish.

They sat mostly untouched on the bench in the garage over the winter as I worked on The Juggernaut, but I never forgot about them. As spring started to approach in roughly late February, early March, I began to evaluate and work on the wheels in hopes of having them done in time for cruising season.

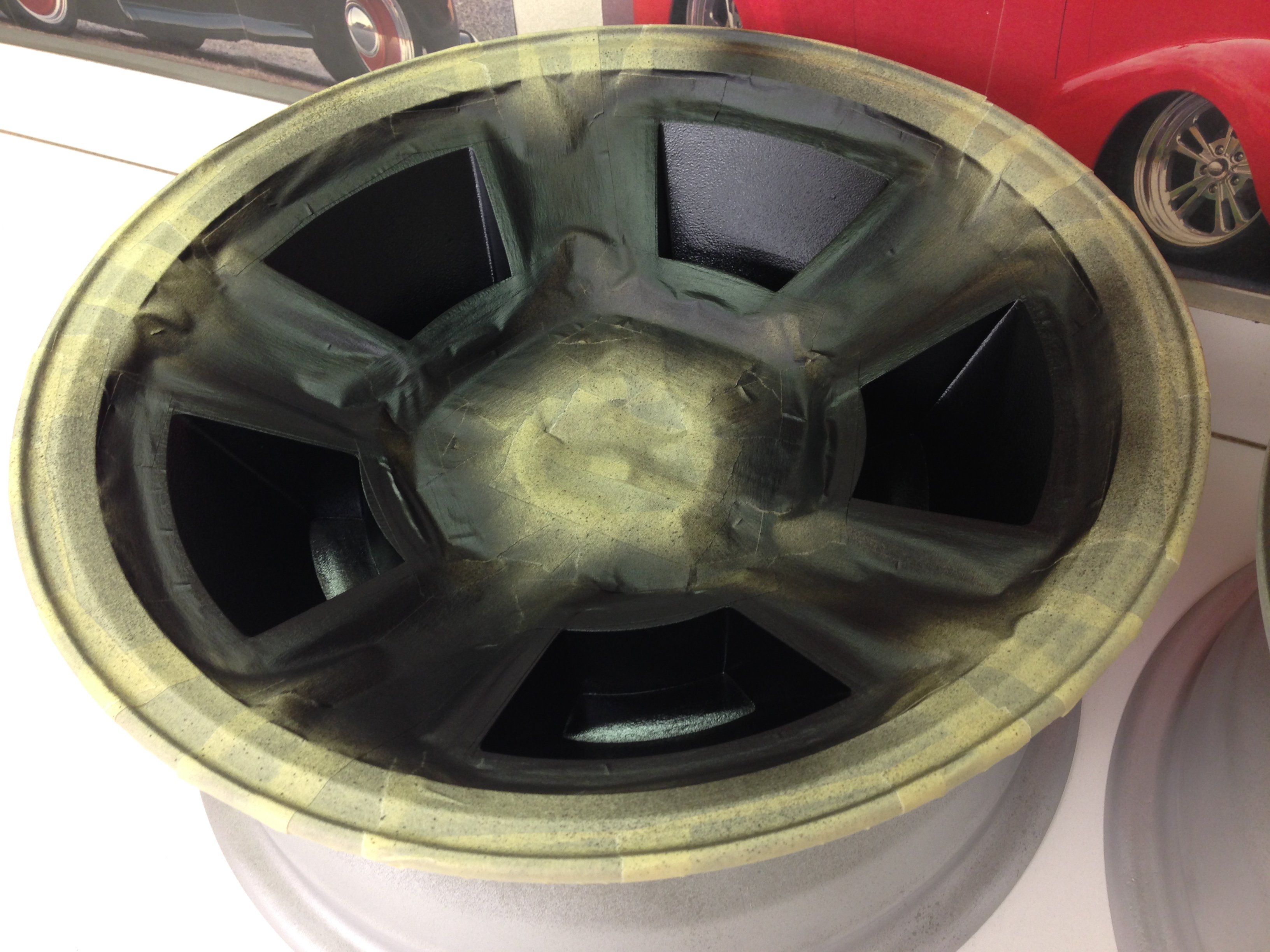

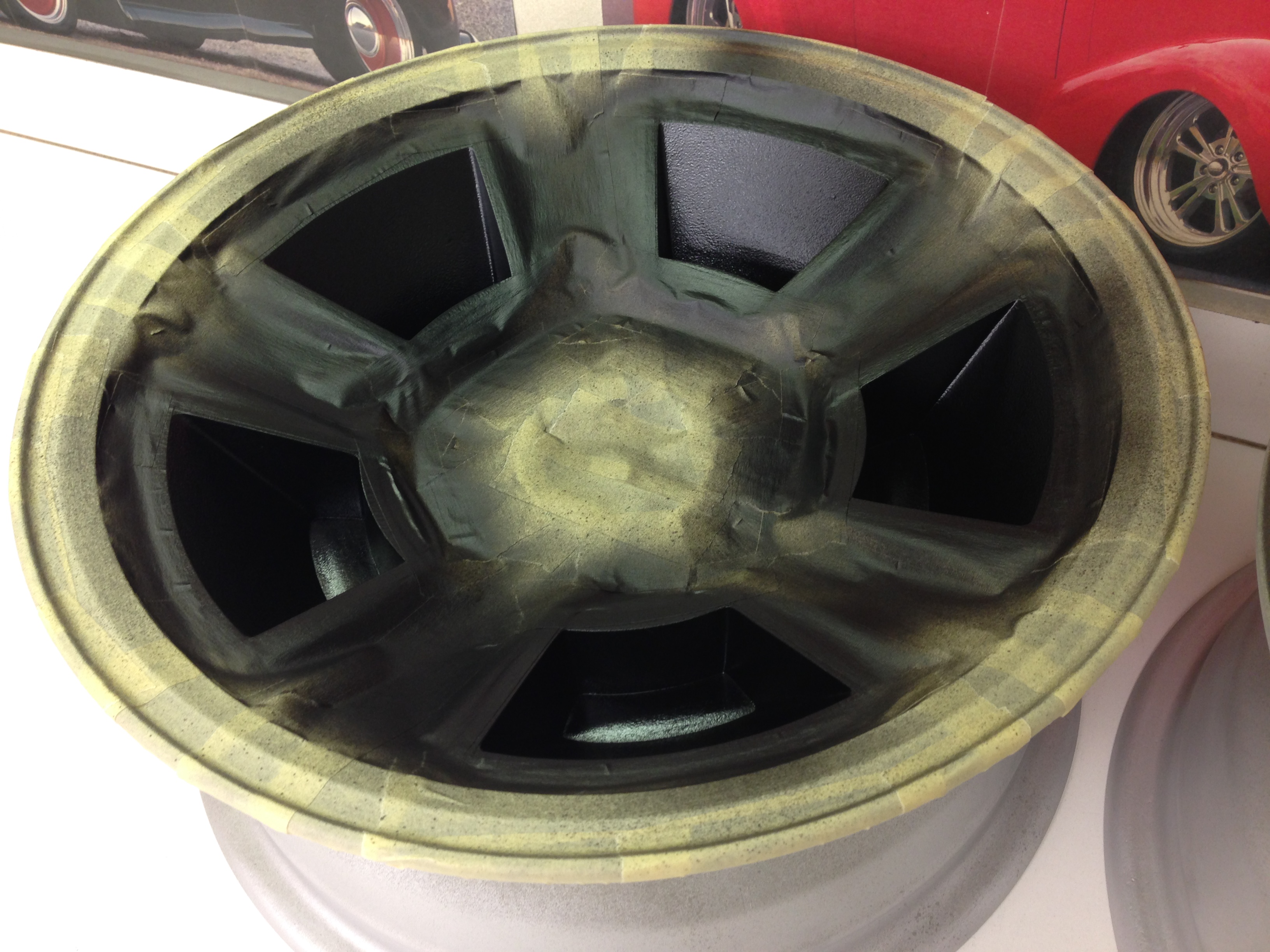

Although they looked ok from 20 feet on the car, here's what I started with once the tires had been removed:

As you can see, they were pretty crusty, and in desperate need of some TLC. The outer edges had some curb rash in places, the paint was dull and badly faded, and the insides were caked in thick brown and black brake dust.

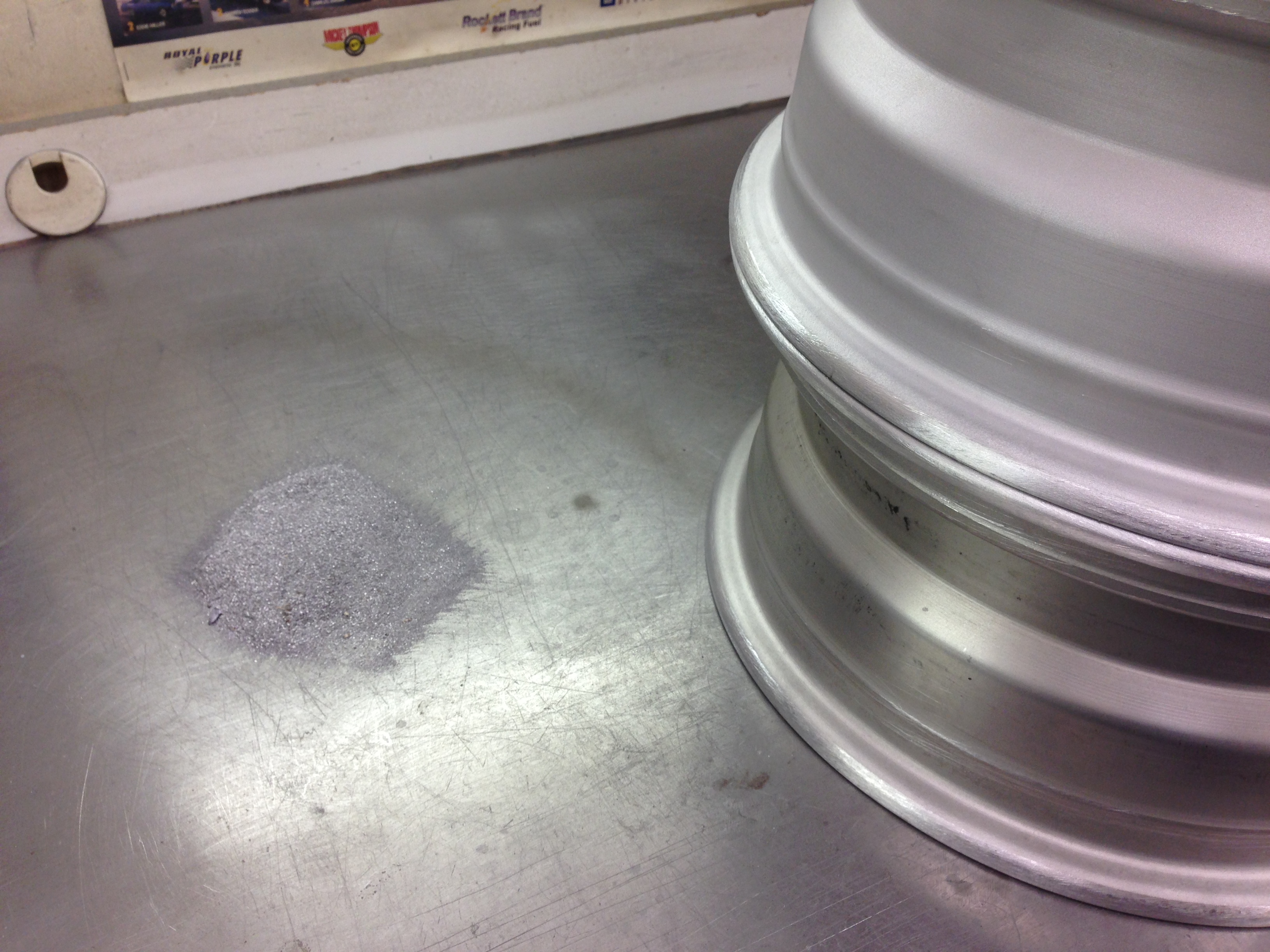

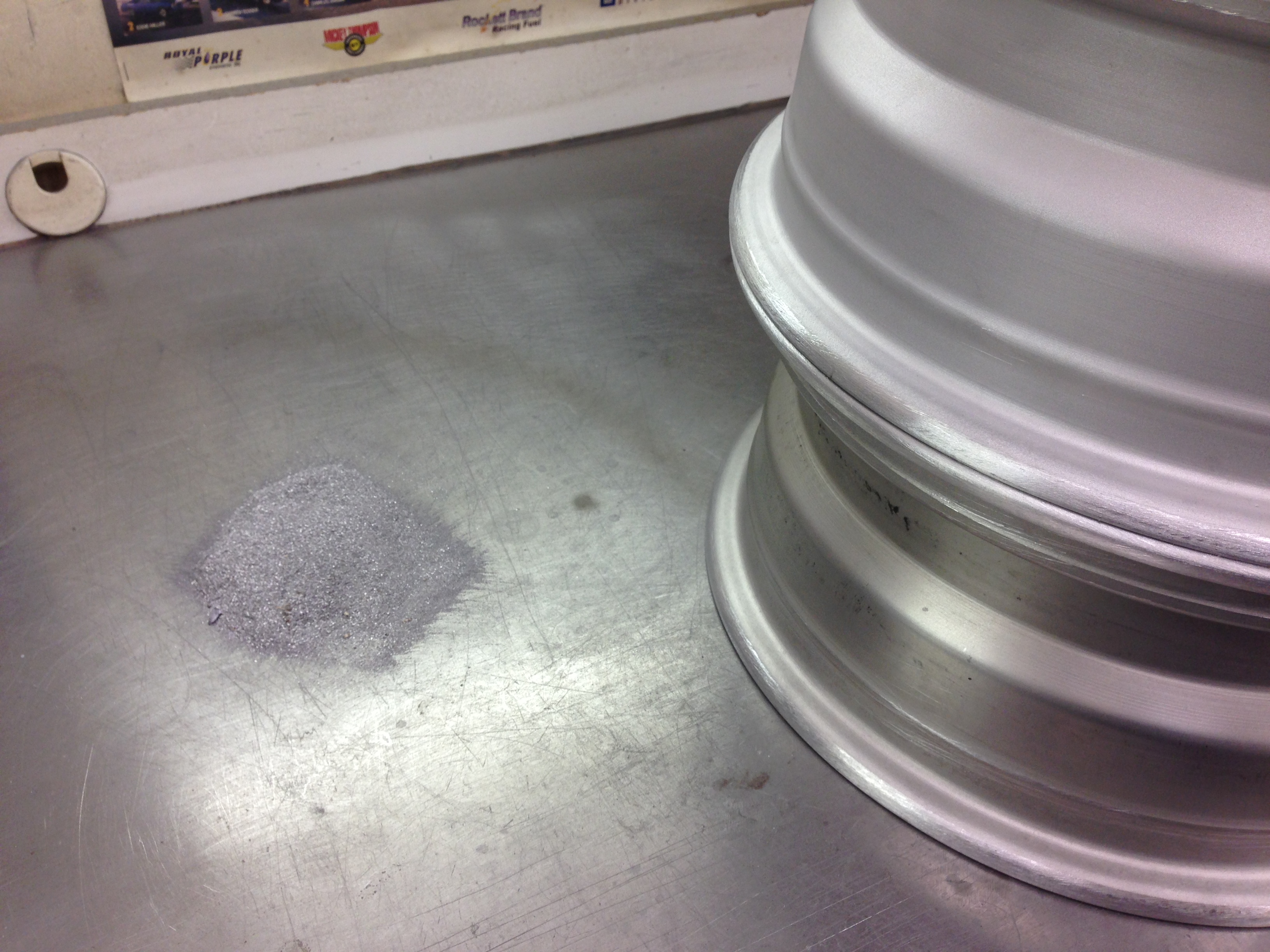

I have access to a decent cabinet blaster at work, and it just so happened that it was full of fresh glass bead when I was ready to start work on the wheels. I loaded up the rims, hauled them into work one weekend, and set out to glass bead them. Here are the exact same wheels as above, afterwards:

The difference was simply amazing. Definitely the right tool for that job!

With the decades of "scunge" and crud now removed, the real work could finally begin. Armed with a selection of my favourite hand files, I set out to clean up the areas that needed attention, and that I could easily access. These areas were primarily the tire bead sealing surfaces, and the flat machined areas inside and out.

Continued >>>

Once again it's been far too long since I've done an update here on this thread. My appologies for that.

This update is on the most recent thing I've done for the car, so it'll be a bit out of order as far as the timeline is concerned. I still haven't finished covering what I've already done to the car just yet, but I'm excited to have finally reached today's milestone, so I'm doing this update now anyways.

I hinted at what I've been working on these last couple months just a few posts prior. The restoration of a set of aluminum 1980 Olds 442 wheels.

I acquired the wheels from my friend Dana in a trade shortly after I got the car 2 years ago. Dana had the wheels, they came on an Olds wagon he had purchased, but he really had no use for them or idea what they were. Dana needed a double hump crossmember for his Malibu wagon project, I had an unused one for a T56 that I had changed direction on, so we arranged the trade.

Upon taking possession of the wheels 2 years ago, I immediately installed my cheapie Walmart tires (that I got for a case of beer), and a second case of beer got the tires installed and balanced on them. I bolted them on the car, and enjoyed them for the next year and a half.

Here's a quick pic from when they went on the car for the first time:

At the end of last year, I knew that I wanted to properly clean up and restore these wheels to their former glory, so I bolted the stock steel rallies on the car for storage over the winter. The 442 wheels had the tires dismounted, and I was ready to start their refurbish.

They sat mostly untouched on the bench in the garage over the winter as I worked on The Juggernaut, but I never forgot about them. As spring started to approach in roughly late February, early March, I began to evaluate and work on the wheels in hopes of having them done in time for cruising season.

Although they looked ok from 20 feet on the car, here's what I started with once the tires had been removed:

As you can see, they were pretty crusty, and in desperate need of some TLC. The outer edges had some curb rash in places, the paint was dull and badly faded, and the insides were caked in thick brown and black brake dust.

I have access to a decent cabinet blaster at work, and it just so happened that it was full of fresh glass bead when I was ready to start work on the wheels. I loaded up the rims, hauled them into work one weekend, and set out to glass bead them. Here are the exact same wheels as above, afterwards:

The difference was simply amazing. Definitely the right tool for that job!

With the decades of "scunge" and crud now removed, the real work could finally begin. Armed with a selection of my favourite hand files, I set out to clean up the areas that needed attention, and that I could easily access. These areas were primarily the tire bead sealing surfaces, and the flat machined areas inside and out.

Continued >>>

Starting with the inside of each wheel, I carefully worked my way around with the files, removing any lumps, bumps, high spots, displaced aluminum, and damage that I came across. The worst areas in need of attention believe it or not, were the tire bead sealing surfaces. They were very rough and uneven. I wasn't about to spend a bunch of time restoring these wheels just to find out they wouldn't hold air worth a damn because of bead leaks.

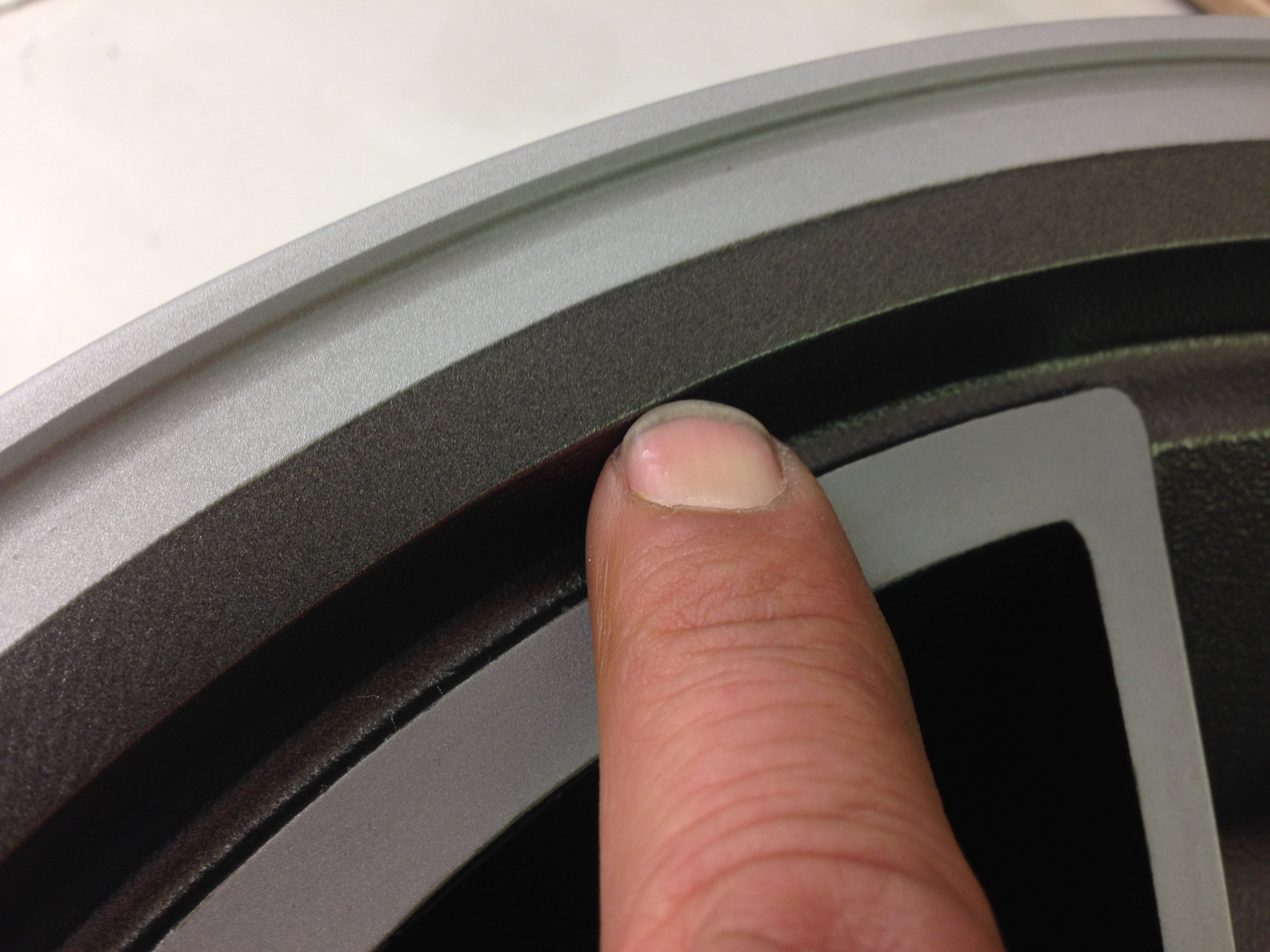

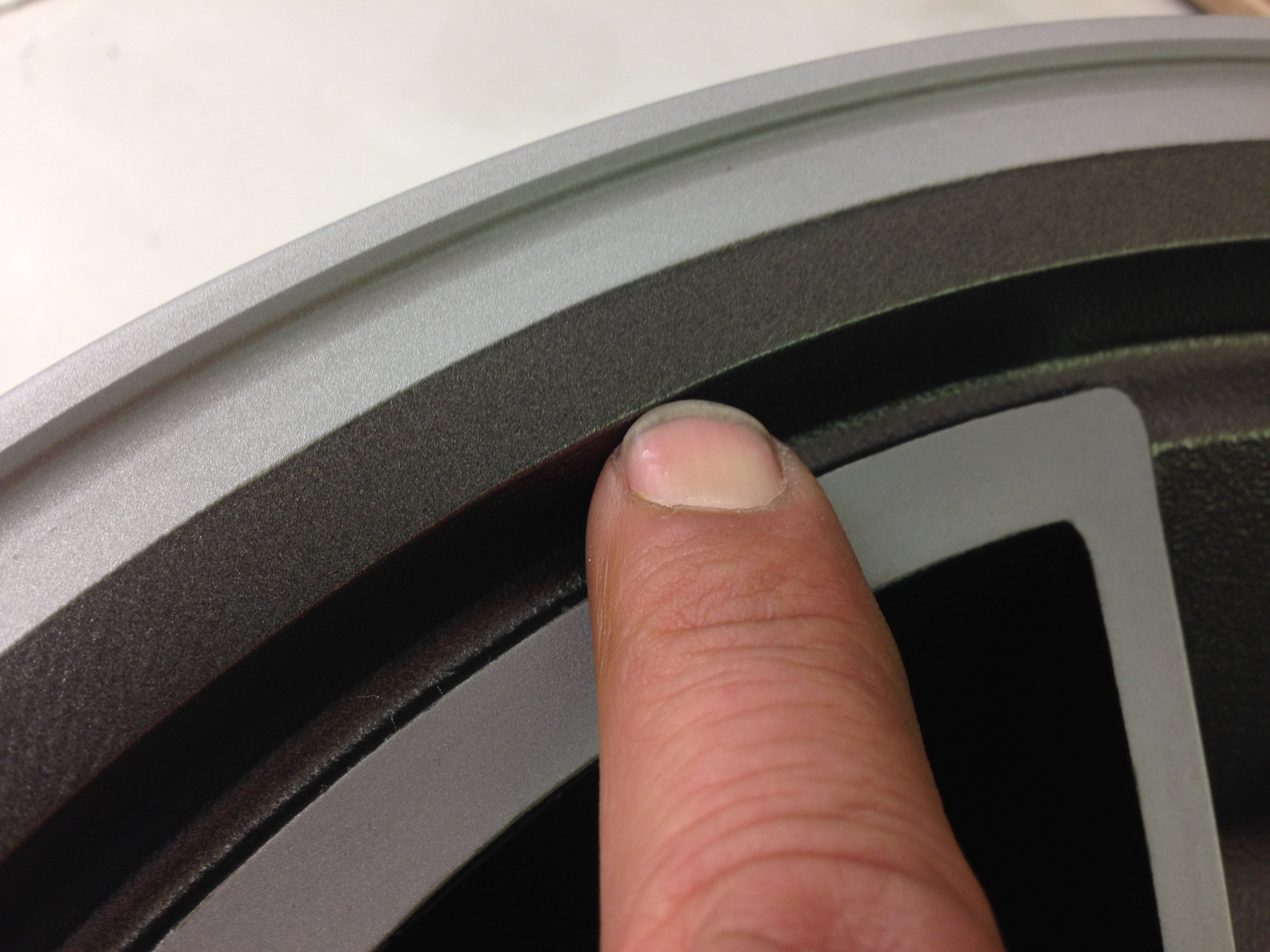

Here's a couple photos where I tried to capture the transition from lumpy bumpy bead surface, to my fine, smooth filed surface:

Once the bead surfaces were repaired, I moved onto cleaning up the machined surfaces. The heavy material removal was done with the files, then the file marks were removed and finished up with progressively finer and finer grits of sandpaper.

Two down, two to go!

When it was all said and done, and I had completed the filing and sanding processes, the pile of aluminum shavings from all 4 wheels was quite shocking!

I was able to clean up and remove all but the worst and deepest damage, these areas were from where lead wheel weights had been clamped on the edges over the years. The aluminum surfaces in these areas were simply too pitted and corroded to do much with unfortunately. All in all tho, they cleaned up exceptionally well.

Once done with the filing and sanding, it was time for a trip back to the shop for another round of glass beading. The purpose of this second blasting was to remove the last of the fine sanding scratches, and provide a fresh, clean, uniform surface for primer and paint.

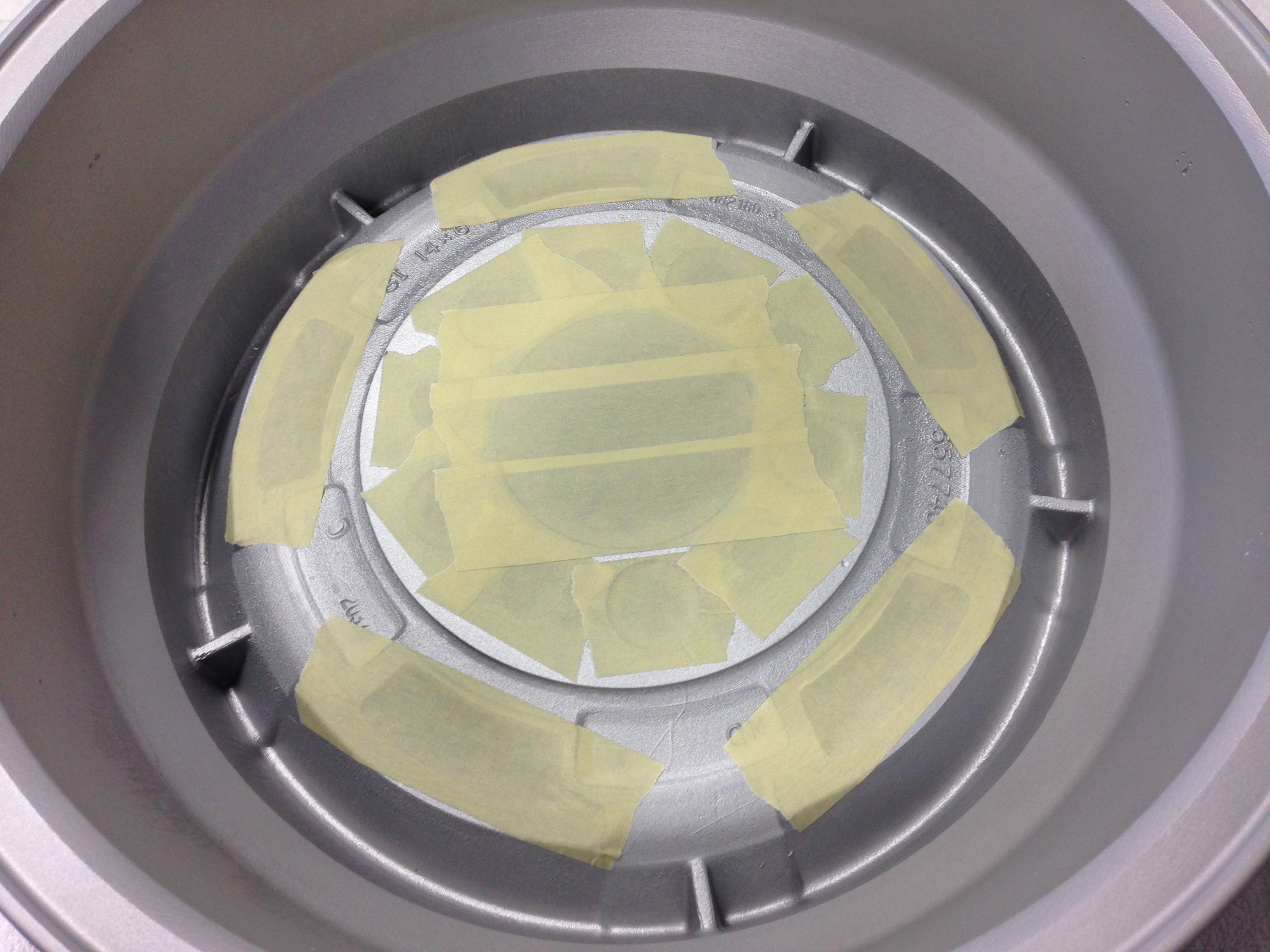

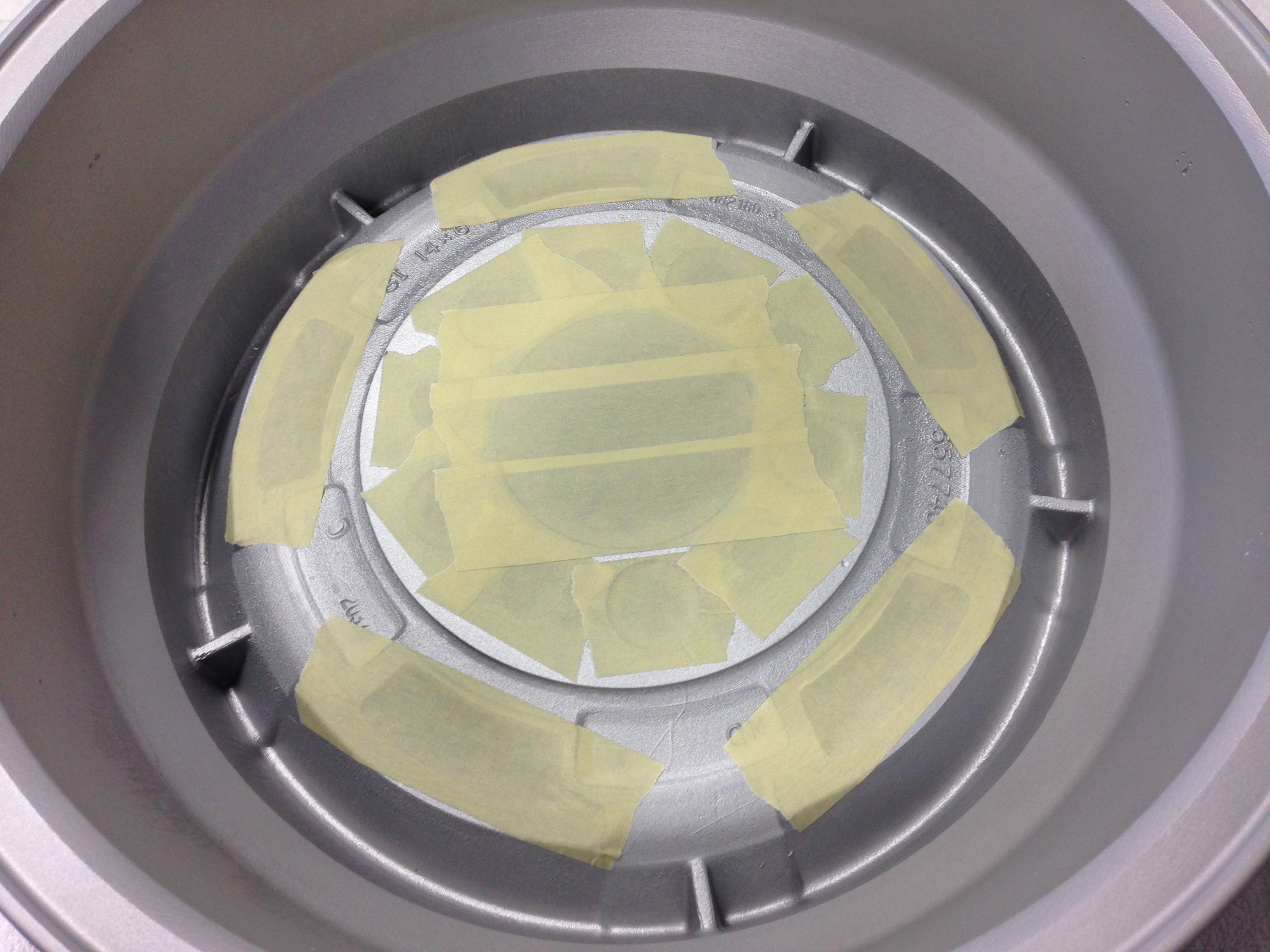

After they came out of the blast cabinet, the backsides were masked off, and the faces were hit with etch primer.

Continued >>>

Here's a couple photos where I tried to capture the transition from lumpy bumpy bead surface, to my fine, smooth filed surface:

Once the bead surfaces were repaired, I moved onto cleaning up the machined surfaces. The heavy material removal was done with the files, then the file marks were removed and finished up with progressively finer and finer grits of sandpaper.

Two down, two to go!

When it was all said and done, and I had completed the filing and sanding processes, the pile of aluminum shavings from all 4 wheels was quite shocking!

I was able to clean up and remove all but the worst and deepest damage, these areas were from where lead wheel weights had been clamped on the edges over the years. The aluminum surfaces in these areas were simply too pitted and corroded to do much with unfortunately. All in all tho, they cleaned up exceptionally well.

Once done with the filing and sanding, it was time for a trip back to the shop for another round of glass beading. The purpose of this second blasting was to remove the last of the fine sanding scratches, and provide a fresh, clean, uniform surface for primer and paint.

After they came out of the blast cabinet, the backsides were masked off, and the faces were hit with etch primer.

Continued >>>

Once the two coats of etch primer had flashed off, it was finally time for some color. Two careful coats of High Performance Graphite Grey were applied, and allowed to dry.

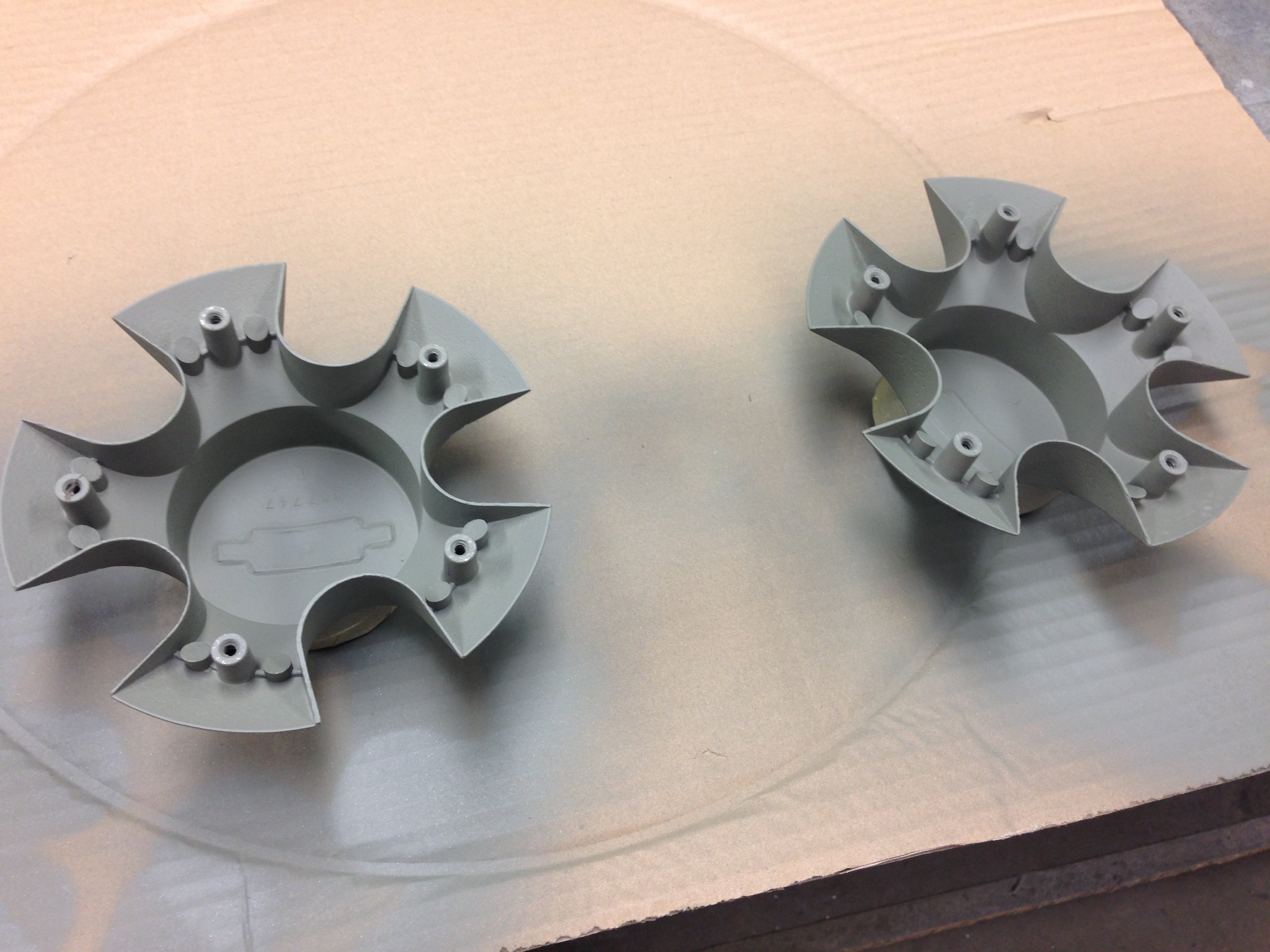

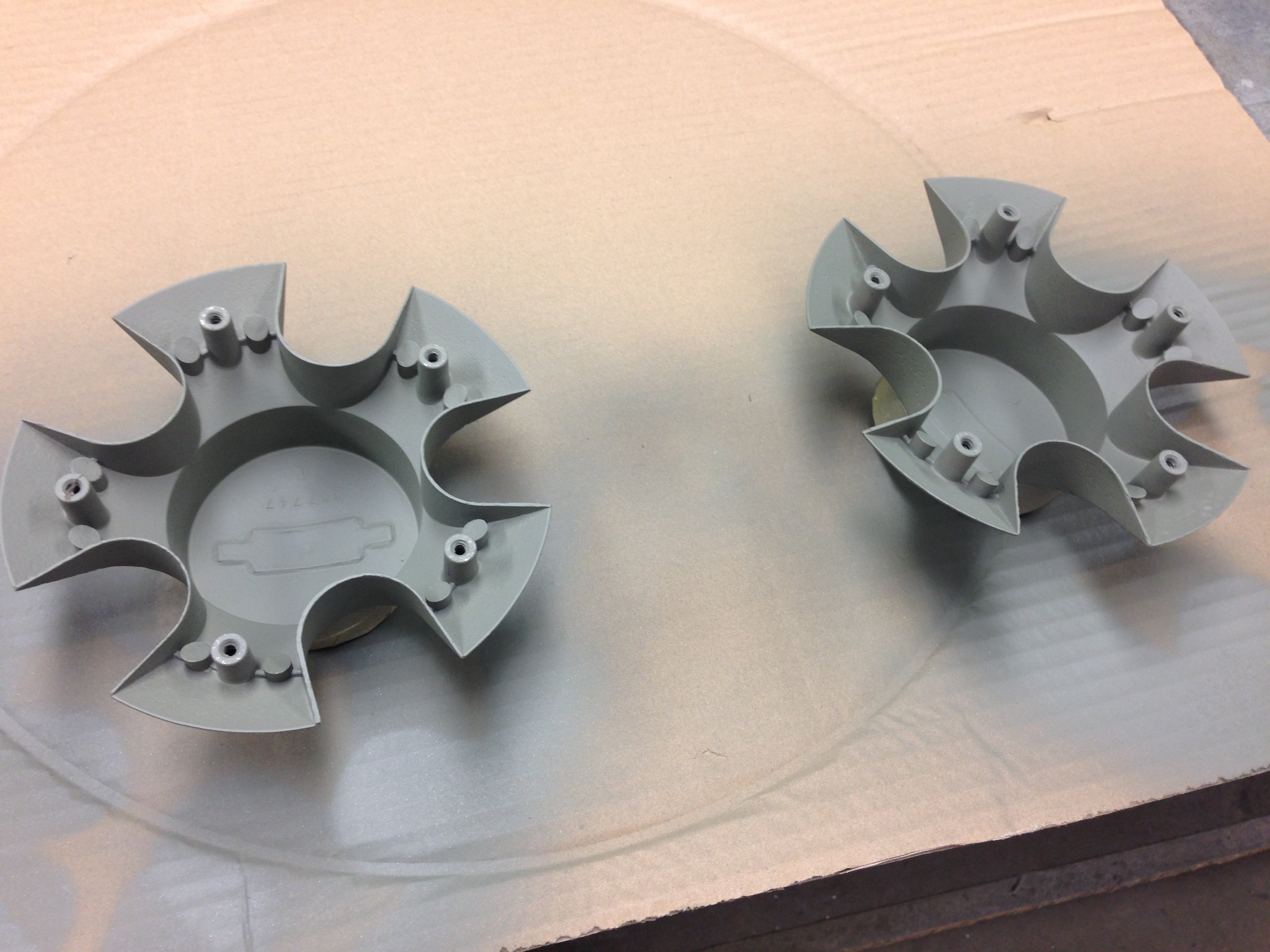

The same processes (blasting, etch priming, paint) were applied to the center caps as well.

Up till now, I've been using the term "restoring" these wheels. A more accurate term I suppose should probably be "restifying". I say this because in my opinion, as good as they looked in stock form, I felt they could have used a little help in a few small areas to help with the overall visual.

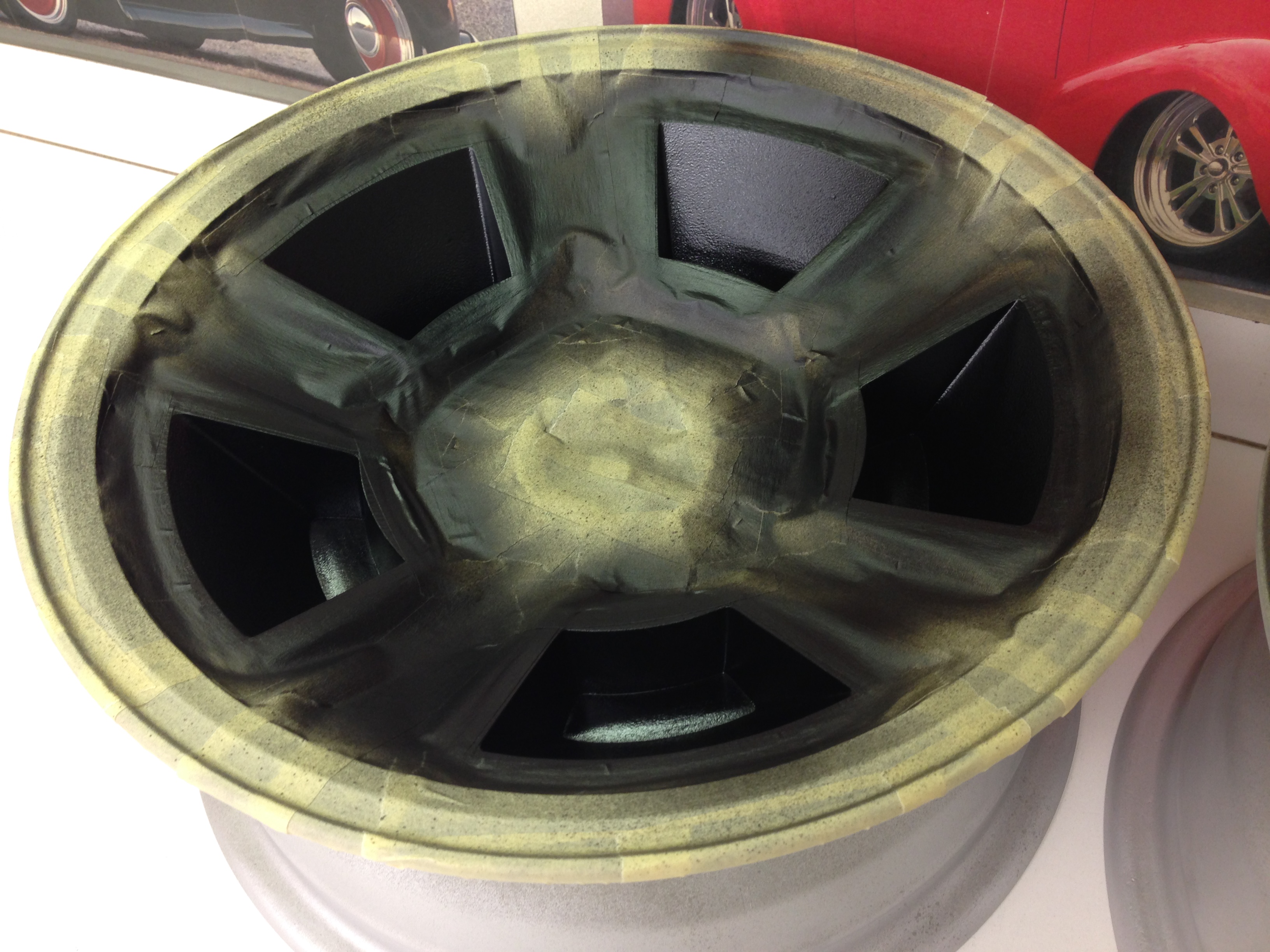

To me, the areas inside the "windows" as I call them, were a bit much being all the same color as the rest of the wheel. To me, these areas were just begging to be blacked out, in turn fooling the eye a bit and accentuating the "spoked" portion of the wheel. With that in mind, all areas of the wheels were masked off as soon as the grey was dry enough, and Satin Black was applied to the "window" openings.

Continued >>>

The same processes (blasting, etch priming, paint) were applied to the center caps as well.

Up till now, I've been using the term "restoring" these wheels. A more accurate term I suppose should probably be "restifying". I say this because in my opinion, as good as they looked in stock form, I felt they could have used a little help in a few small areas to help with the overall visual.

To me, the areas inside the "windows" as I call them, were a bit much being all the same color as the rest of the wheel. To me, these areas were just begging to be blacked out, in turn fooling the eye a bit and accentuating the "spoked" portion of the wheel. With that in mind, all areas of the wheels were masked off as soon as the grey was dry enough, and Satin Black was applied to the "window" openings.

Continued >>>

I still wasn't finished with these just yet. They were starting to look really good, but they needed the final push and the last bit of detail to truly set them off.

Once the wheels were back home and fully unmasked, I set about to remove the grey paint from the machined areas surrounding the "windows", and the outer rim edges. The other area I felt these needed help with, was this outer rim edge. In stock form, the paint color stops here at this edge:

Here's a pic of a stock wheel "borrowed" from the Internet:

To me, it seemed that these two machined surfaces side by side just seemed too wide, in turn making the wheel appear to be smaller than it actually was. With that in mind, I thought it would look much better if the inner machined surface was painted as well.

You may have noticed that I did not mask off the areas I'm talking about after they came out of the blast cabinet and before paint.

My reasoning for doing this is because aluminum oxidizes very quickly (within about 6 hours of being disturbed), and I wanted the etch primer to take hold as soon as possible after blasting. The time it would have taken me to mask off these areas on all 4 wheels prior to painting the grey would've taken me far too long, likely past my 6 hour window.

The downside of this decision however, was that I now had a huge painstaking task ahead of me in removing the paint from the unwanted areas. I didn't want to sand the paint off, as this would have left behind sanding scratches, and I definitely didn't want that.

I didn't see the point in taking any pics of this process, but all the grey was removed from the unwanted areas with Q-Tips dipped in lacquer thinner. Yup, you read that right. By hand, a tiny bit at a time.

I'm not at liberty to say exactly HOW long it took me to do this, but it's ridiculous!

Lol

If anyone's curious, it took just over 500 double ended Q-Tips to completely remove all the paint from these areas on all 4 wheels!

Here's the end result with the painted center cap installed:

Worth it? Most definitely in my opinion.

🙂

Nearing the end of the project, I sourced out two used center caps in better condition than the ones I had, from a website called Hubcaps.com. They were very friendly and helpful, and even went so far as to email me pics of what they had ahead of time for my approval.

Also in anticipation of completing the restification, I was able to locate the correct lug nuts for this style of wheel here in my city. They use an integrated washer, and are apparently commonly referred to as "Corvette" style. Up until now, I had just been using a standard shank style lug nut with double washers to prevent them from bottoming out on the studs.

This is what they're actually SUPPOSED to use:

The chrome on the center caps should tie in nicely with the chrome lug nuts.

🙂

Which finally brings me to today. One more final trip back to the shop, this time to lock everything in with a couple coats of clear. The fronts obviously received two coats of clear, but the backsides did as well to hopefully cut down on the amount of brake dust buildup. If nothing else, it'll seal off the pores of the aluminum, and hopefully make them last another 37 years!

Next weekend will be a biggie for me, I'll be taking the wheels in to have the raised white letter BFG radial T/A's I picked up last year mounted on 'em. That should really set off the old school look I'm after!

After I get the wheels and tires mounted on the car next weekend, I'll post up some pics of the final, finished end result. I think it should look great!

Who says old school, painted wheels can't look good in this age of big rims and bling?

Thanks for tuning in everyone. Check back next weekend once they're installed on the car finally!

Donovan

Once the wheels were back home and fully unmasked, I set about to remove the grey paint from the machined areas surrounding the "windows", and the outer rim edges. The other area I felt these needed help with, was this outer rim edge. In stock form, the paint color stops here at this edge:

Here's a pic of a stock wheel "borrowed" from the Internet:

To me, it seemed that these two machined surfaces side by side just seemed too wide, in turn making the wheel appear to be smaller than it actually was. With that in mind, I thought it would look much better if the inner machined surface was painted as well.

You may have noticed that I did not mask off the areas I'm talking about after they came out of the blast cabinet and before paint.

My reasoning for doing this is because aluminum oxidizes very quickly (within about 6 hours of being disturbed), and I wanted the etch primer to take hold as soon as possible after blasting. The time it would have taken me to mask off these areas on all 4 wheels prior to painting the grey would've taken me far too long, likely past my 6 hour window.

The downside of this decision however, was that I now had a huge painstaking task ahead of me in removing the paint from the unwanted areas. I didn't want to sand the paint off, as this would have left behind sanding scratches, and I definitely didn't want that.

I didn't see the point in taking any pics of this process, but all the grey was removed from the unwanted areas with Q-Tips dipped in lacquer thinner. Yup, you read that right. By hand, a tiny bit at a time.

I'm not at liberty to say exactly HOW long it took me to do this, but it's ridiculous!

Lol

If anyone's curious, it took just over 500 double ended Q-Tips to completely remove all the paint from these areas on all 4 wheels!

Here's the end result with the painted center cap installed:

Worth it? Most definitely in my opinion.

🙂

Nearing the end of the project, I sourced out two used center caps in better condition than the ones I had, from a website called Hubcaps.com. They were very friendly and helpful, and even went so far as to email me pics of what they had ahead of time for my approval.

Also in anticipation of completing the restification, I was able to locate the correct lug nuts for this style of wheel here in my city. They use an integrated washer, and are apparently commonly referred to as "Corvette" style. Up until now, I had just been using a standard shank style lug nut with double washers to prevent them from bottoming out on the studs.

This is what they're actually SUPPOSED to use:

The chrome on the center caps should tie in nicely with the chrome lug nuts.

🙂

Which finally brings me to today. One more final trip back to the shop, this time to lock everything in with a couple coats of clear. The fronts obviously received two coats of clear, but the backsides did as well to hopefully cut down on the amount of brake dust buildup. If nothing else, it'll seal off the pores of the aluminum, and hopefully make them last another 37 years!

Next weekend will be a biggie for me, I'll be taking the wheels in to have the raised white letter BFG radial T/A's I picked up last year mounted on 'em. That should really set off the old school look I'm after!

After I get the wheels and tires mounted on the car next weekend, I'll post up some pics of the final, finished end result. I think it should look great!

Who says old school, painted wheels can't look good in this age of big rims and bling?

Thanks for tuning in everyone. Check back next weekend once they're installed on the car finally!

Donovan

Damn Donovan, I don't think I've ever seen a single project that you've taken on that I haven't been impressed with the results. Those wheels are kick *ss!!!! Great work. If I can pay half as much attention to detail as you do on your cars to my Monte Carlo, I'll have a sweet ride.

Similar threads

- Replies

- 10

- Views

- 339

- Replies

- 174

- Views

- 12K

- Replies

- 13

- Views

- 535

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.