That is some killer block work Donovan. If one thing i despise in all of bodywork it would be bodyworking a roof, they can be so fickle to get flat and true, especially if its done small patches at a time and not as one large panel.Trainees trying out for Navy Seals have to endure something they call "Hell Week".

I am in no way comparing myself to those tough SOB's, however I've been going through my own "Hell Week" here myself.

So, in the week since my last update I've started in on the filler work.

In a big way.

I'll get to the pics and descriptions here in a sec, but I just wanted to say this first:

Having the AstroRoof stamped in the middle of the roof has sure had some weird effects on the straightness of the roof. This roof is wavy as hell, and very little of it is or was related to my repairs. In fact, this roof has more waves in it than a Hawaiian surf competition!

😕

There are strange high spots in weird places, and the edges around the AstroRoof opening are much flatter than the surrounding areas. This all adds up to a very challenging surface to try and get perfectly flat and straight.

I attribute it to the poor stamping practices of the time, I can think of nothing else that would create these weird characteristics. I can certainly see why they painted this one white and slapped a vinyl roof on it. Far cheaper to cover up all the sins than to try and fix them/make them acceptable.

As for my "Hell Week", it's been just that. In the last week I've created and eaten/breathed in more dust than I care to admit. It's hard work blocking out such a large flat surface, I've been drinking nearly an entire 2L bottle of water every time and sweating most of it back out again.

In the mornings I ache. Everywhere.

The back from leaning over at weird angles, my arms from the long blocking strokes, even my legs from keeping my balance on step stools and the floor inside the car.

Anyways, you get the point, so I'll stop my complaining. It's hard work.

It took me 4 full days alone to get just the large flat area of the roof from the back window to the AstroRoof opening blocked out and straight, and finished in 120 grit.

I started off all the filler work by filling the roof seams with short strand fibreglass filler and blocking them out, but I didn't see the point of taking any pics. It's just the foundation before body filler anyways. You can see them done in some of the following pics.

This was the first full application of filler on the roof:

View attachment 72560

View attachment 72561

And yes, I know what you're thinking.

"Damn D, that's a LOT of filler!!"

And you'd be right. But before y'all start flaming me for having a "bondo bucket", or other such terms, this is the correct way to do a large flat panel.

A common mistake that many novices make is trying to fill many small areas and sand each one individually. This doesn't work, this just creates waves in the final product. You have to skim the ENTIRE area, then block it all out as one. The filler will stay in the low areas, and will get removed from the high ones.

As bad as it looks to have that much filler spread across the roof, keep in mind 90% of it gets sanded off and ends up on the floor. In fact I've become very proficient at turning large quantities of expensive product into worthless dust!

Lol

Anyways, back to some pics. Most of these are just "in progress" pics, usually taken at the end of a fairly substantial step.

These were after the above application was finish sanded in 40 grit:

View attachment 72563

View attachment 72564

View attachment 72565

As you can see, it creates quite the mess!

View attachment 72562

After that step, the area was blocked out in 80 grit to remove the 40 grit scratches, but this left the area slightly low.

Time for an application of glazing putty. The putty serves several purposes, it fills any pinholes in the underlying filler, adds a thin skim coat, and provides a finer, smoother easier sanding surface prior to primer.

Again, ya gotta skim the whole area:

View attachment 72566

The masking paper covering the back window is to keep any drips or spillage from getting into the window channel areas and off the window itself. The putty is quite a bit more runny than the filler, so I didn't want to take any chances.

View attachment 72567

This is the back part of the roof now completely blocked out and flat, finished in 120 grit.

View attachment 72569

It still looks thick, but as you can tell by the bare metal areas, it's actually pretty thin. I can't sand any more off, or I'll get into low areas and will create waves. It took 4 days just to get to this point.

Continued >>>

BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

That is some killer block work Donovan. If one thing i despise in all of bodywork it would be bodyworking a roof, they can be so fickle to get flat and true, especially if its done small patches at a time and not as one large panel.

Thanks for the comment Kevin!

It's nice to know some of you guys understand how difficult it can be to get things straight and flat on a large panel such as the roof.

Btw, nice to hear from you again!

C'mon man, we need our weekly fix! 😀

Lol

Sorry man. I didn't think too many of you would be interested in seeing filler work and pictures of dust!

With that being said, I guess I do have a few things I can update y'all with.

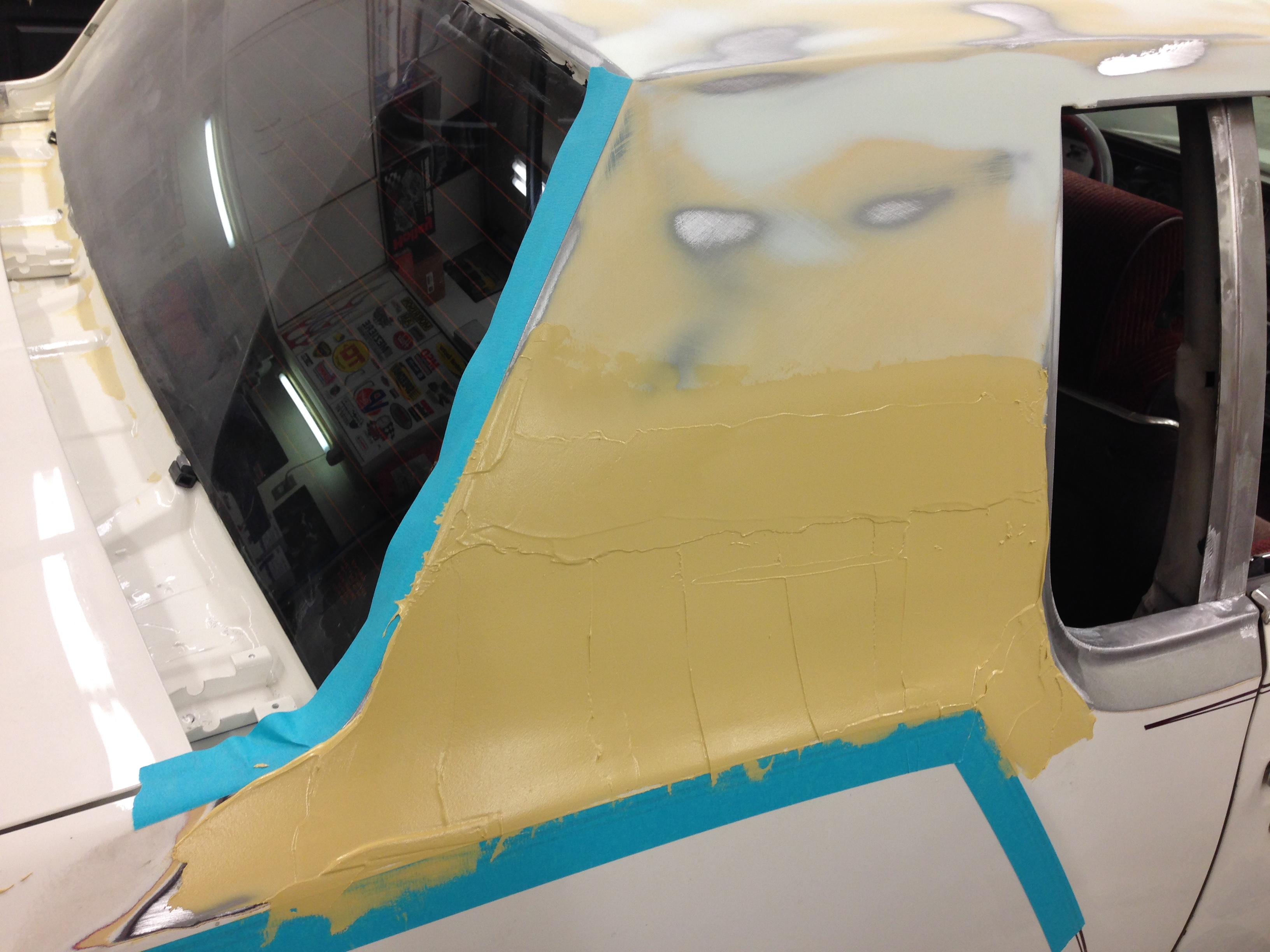

So in the past 2 weeks since the last update, I've just been continuing to pick away at the filler work. With the roof blocked out and ready for primer, I turned my attention to starting on the side of the roof and the sail panel on the passenger's side.

I won't go into too much detail on it, but suffice to say the transition from the roof side into the sail panel was a real bi*%ch. The roof side skimmed out and blocked out fairly nicely, with the exception of one high spot I missed in knocking flat when I welded the patch in.

The transition area however fought me tooth and nail. The shape and contour of the roof side is actually different than where the sail panel meets the roof. So a gentle, careful blend must be made where the two change so as to be unnoticeable. It took me no less than 6 or 7 attempts to get it right. I remember having this issue with The Juggernaut when I converted it to a hardtop too, but not to this extent.

Here's a couple of pics as I was working on it:

Once I had the transition area close, I started working on the area approximately halfway down the sail panel to the body line on the quarter panel:

It went much easier, and after blocking it flat and a couple skim coats of putty I had it done. I found some waves in the quarter below the body line despite my attempts to minimize the warping, so those got a light skim of putty and blocked out as well once the old paint was sanded off.

Tonight I finished up the sail panel and "B" pillar bodywork, again just light skims of putty where I had welded up holes and had some deeper grinding marks.

This is how the car looks currently:

It ain't pretty by any stretch, but unfortunately it's a necessary evil. I am however happy to report that everything I have block sanded is nice and flat and true. It all feels really good to the hand at this point. The plan is to have the entire roof, "B" pillars, and both quarter panels bodyworked and done before I mask and prime. It should be a bit easier to manage by doing sections at a time that way.

The driver's side filler work is next, starting tomorrow night.

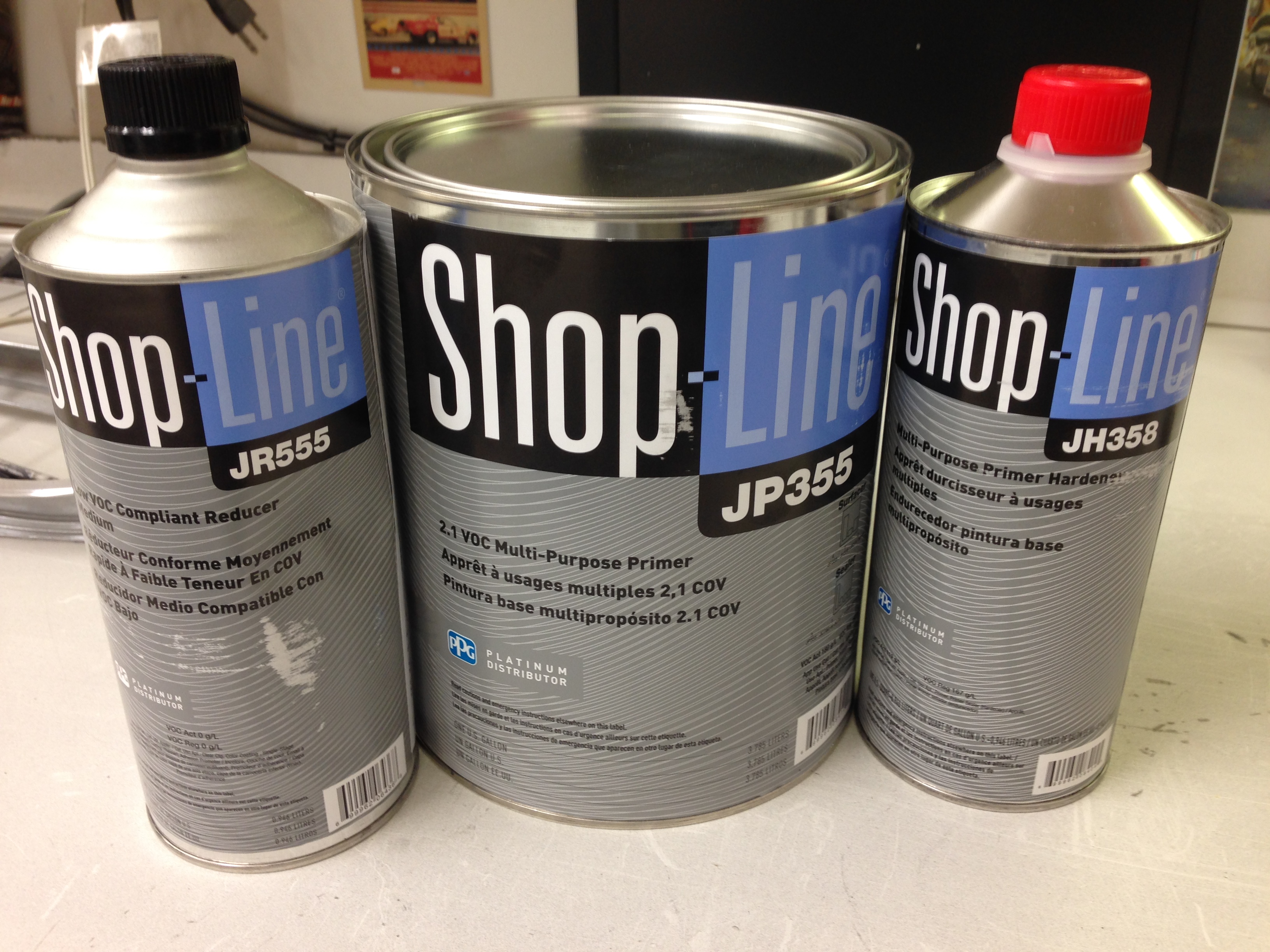

In other news, based on the experiences and recommendations of a few members here, I changed the high build primer I will be using. I was originally going to try the Omni stuff, but decided against it when I went in to buy it earlier last week. Instead, I went with PPG's ShopLine stuff:

It should be a decent economical product to use for what I need. We shall see.

The plan as far as priming the panels (and maybe the current bodyshop professional members here can comment on the wisdom of doing this) is to prime everything with epoxy first, then follow up with 3 coats of the high build, wet on wet. I'd like to go this route if possible, rather than screw around with etch primer on the bare metal areas. The epoxy as a base should provide excellent corrosion resistance, and fill in some of the low spots in the filler work before the high build goes on. Essentially a fourth coat of primer. Plus the epoxy can still go on the bare metal spots.

Continued >>>

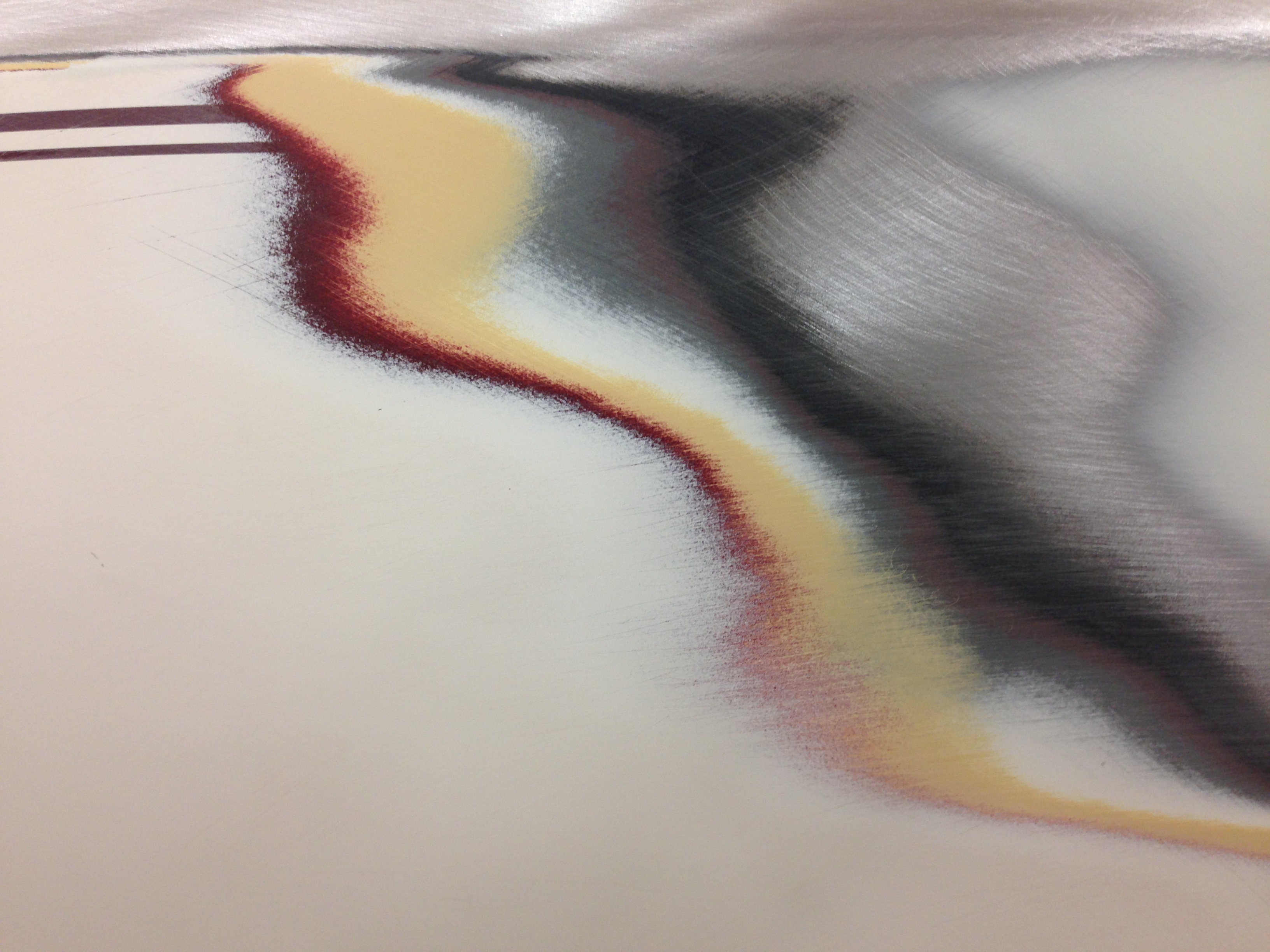

Just as a quick aside, here are the many layers of paint and primer that are already on the car:

Obviously the car has been repainted once already, and not very well at that. The burgundy layer was actually for the pinstripe. It's weird that they'd do such a crappy job of painting the car, yet go to all the effort of painting the pinstripes on.

Unfortunately I do not trust the primer work that was already done on the car, in the course of stripping some areas I've found little faux pas like unfeathered rock chips, and rust specs that were forming. EVERY panel will have to be stripped down to bare metal, and started again from scratch.

Sucks to be me.

Over the weekend, I found a guy local to me that was renting out his fender roller for $25 a day on Kijiji. (Thanks for the tip Steve!)

I contacted him about renting it for a day, and went and picked it up Saturday. Since the quarter panels are going to be next in my sights, it seemed the perfect time to do it.

After experimenting with the best technique on the driver's side, I got comfortable with what and how to do it.

The passenger's side went much quicker and easier:

I tried taking some pics of the inner flanges after rolling them, but they didn't turn out very well. You'll just have to trust me when I say they rolled very well, especially considering they're double thick and spot welded. Something that Eastwood doesn't suggest attempting.

After these pics were taken, I stripped off the remaining old paint, rust and crud from the flanges. They look really good now.

That's all I've got for y'all tonight, tomorrow will be more of the same, more filler and blocking work.

Thanks for checking out the progress guys.

Till next time,

Drive angry my friends!

D.

Obviously the car has been repainted once already, and not very well at that. The burgundy layer was actually for the pinstripe. It's weird that they'd do such a crappy job of painting the car, yet go to all the effort of painting the pinstripes on.

Unfortunately I do not trust the primer work that was already done on the car, in the course of stripping some areas I've found little faux pas like unfeathered rock chips, and rust specs that were forming. EVERY panel will have to be stripped down to bare metal, and started again from scratch.

Sucks to be me.

Over the weekend, I found a guy local to me that was renting out his fender roller for $25 a day on Kijiji. (Thanks for the tip Steve!)

I contacted him about renting it for a day, and went and picked it up Saturday. Since the quarter panels are going to be next in my sights, it seemed the perfect time to do it.

After experimenting with the best technique on the driver's side, I got comfortable with what and how to do it.

The passenger's side went much quicker and easier:

I tried taking some pics of the inner flanges after rolling them, but they didn't turn out very well. You'll just have to trust me when I say they rolled very well, especially considering they're double thick and spot welded. Something that Eastwood doesn't suggest attempting.

After these pics were taken, I stripped off the remaining old paint, rust and crud from the flanges. They look really good now.

That's all I've got for y'all tonight, tomorrow will be more of the same, more filler and blocking work.

Thanks for checking out the progress guys.

Till next time,

Drive angry my friends!

D.

Last edited:

Looking good Donovan!

Thank you Kevin!

The progress is glacial, but it's progress nonetheless I suppose!

😕

Man I really would like to use one of those. Looks way easier than any of the primitive methods we've grown to love.

Ive always wondered about those fender rollers and came close to buying one myself. I was always terrified id mess it up though

Man I really would like to use one of those. Looks way easier than any of the primitive methods we've grown to love.

Check your local Craigslist and other classifieds around you. I was surprised to find this guy renting it out in my area. Chances are pretty good that someone near you will be too.

I've gone the medieval route in the past too, a BFH, brute strength and ignorance. This is a much more refined method of achieving the same results.

Looks like it works better than my bace ball bat technique I'd like to try it

Similar threads

- Replies

- 25

- Views

- 861

- Replies

- 14

- Views

- 789

- Replies

- 10

- Views

- 468

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.