Those are the ones. 👍Thanks for the kind words, I'm reading up on what the mods do. After some research it looks like The most important mod seems to be the dual feeding 3rd. From what I read and talked to jakes performance. He says skip the pressure relief switch,don't use the kits center case bolt. Use a sonnax boost valve and poly balls. Also said to drill a .060 hole in the drum. He also said leave the center seal of the drum.

Replacement Bolt 4th Clutch to Case | 4L80E Transmission Parts

www.monstertransmission.com

4L80E 4L85E TRANSMISSION BOLT FOR CENTER SUPPORT TO CASE FITS '91-'09

4L80E 4L85E TRANSMISSION BOLT FOR CENTER SUPPORT TO CASE FITS '91-'09 8661762www.transmissionpartsdistributors.com

Thanks for the vote of confidence. I ordered the hd2kit and sonnax boost valve. I'm gonna do the springs too. It doesn't seem to bad. The whole kit looks fairly simple.

NorthernRegal are those the bolts and check balls?

BUILD THREAD Rustier then I thought!!!

- Thread starter RabbitHoleSS

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Just ensure you make sure where EVERYTHING goes during re-assembly, and don't lose any of those little stupid parts that will ruin your day. And it probably goes without saying, make sure to use a torque wrench on the casing. Too many times I've heard about over-torquing stuff because the person didn't use a torque wrench and ruined threads or warped something. Stay safe in there!

Haven't had much time to mess with the car lately. I had to fix my s10 transmission, roof my uncles house,put in my garden and I took my boys to cleetus and cars a few weeks ago. Got rained on but those guys stayed out til 11pm putting on a great show. It's becoming a tradition for us. We had front row seats on the fence for the burnout contest.IRP actually built a burnout box next to the strip. If you haven't been, you should go. The rain came early so I put my phone up after the first burnout, but I thought these were pretty cool. This was my favorite of the night, it was unexpected and we were all pretty antsy.

The boys want me to build a burnout car after every show.

I think he ran 8s all night in it. There was a TT mustang and TT hemi that were the only real competition. Definitely a well built, cool car. About this time my boys were sneaking over to meet him as the tstorms were rolling in. He gave them a fistbump and we ran to the truck for intermission.

I think he ran 8s all night in it. There was a TT mustang and TT hemi that were the only real competition. Definitely a well built, cool car. About this time my boys were sneaking over to meet him as the tstorms were rolling in. He gave them a fistbump and we ran to the truck for intermission.

It's the best race/car show I've been to by far. Us nationals at night is awesome but these are more my people lol. It was pretty packed but hopefully one day it'll be like summernats in Australia.

It's the best race/car show I've been to by far. Us nationals at night is awesome but these are more my people lol. It was pretty packed but hopefully one day it'll be like summernats in Australia.

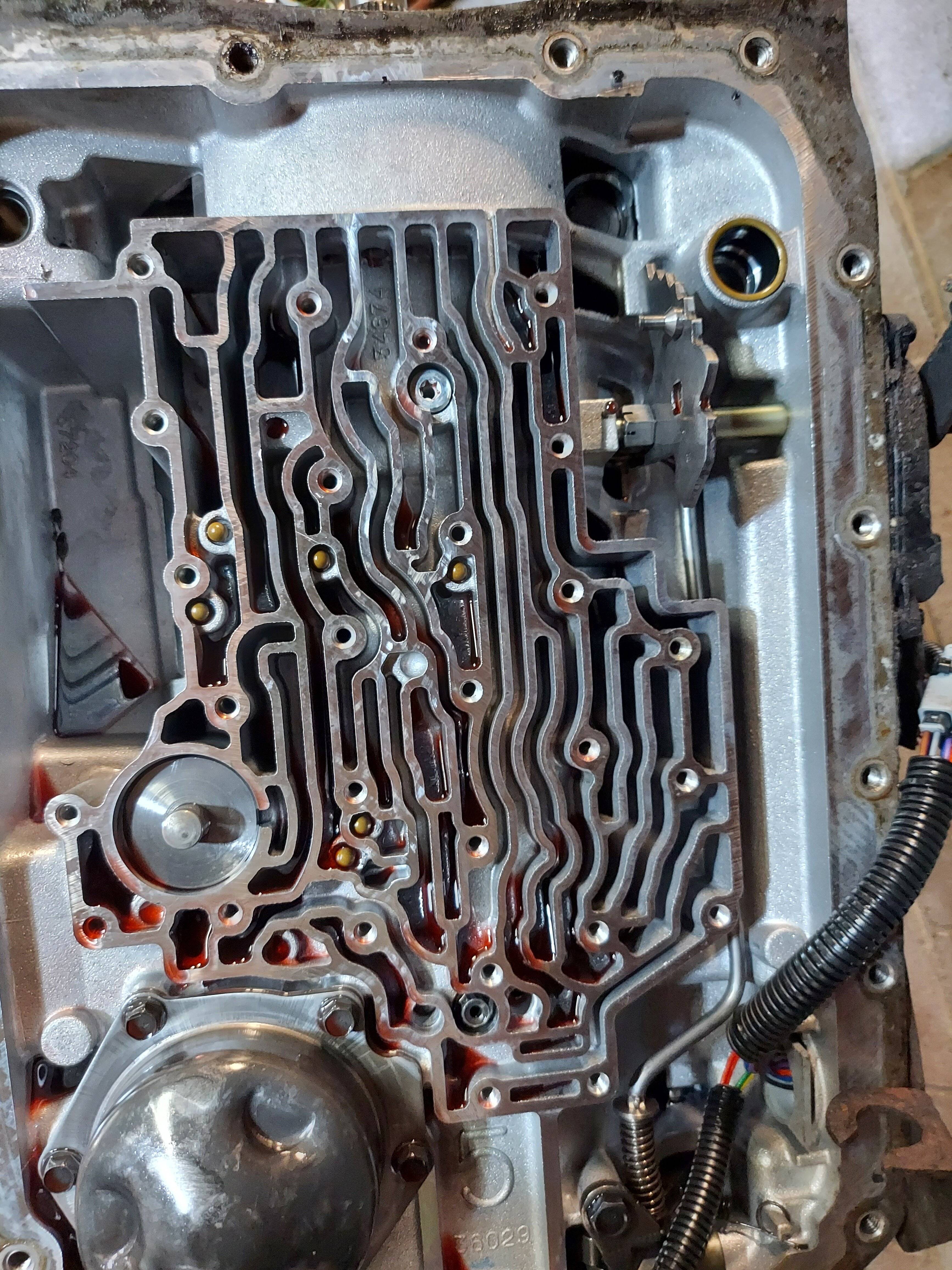

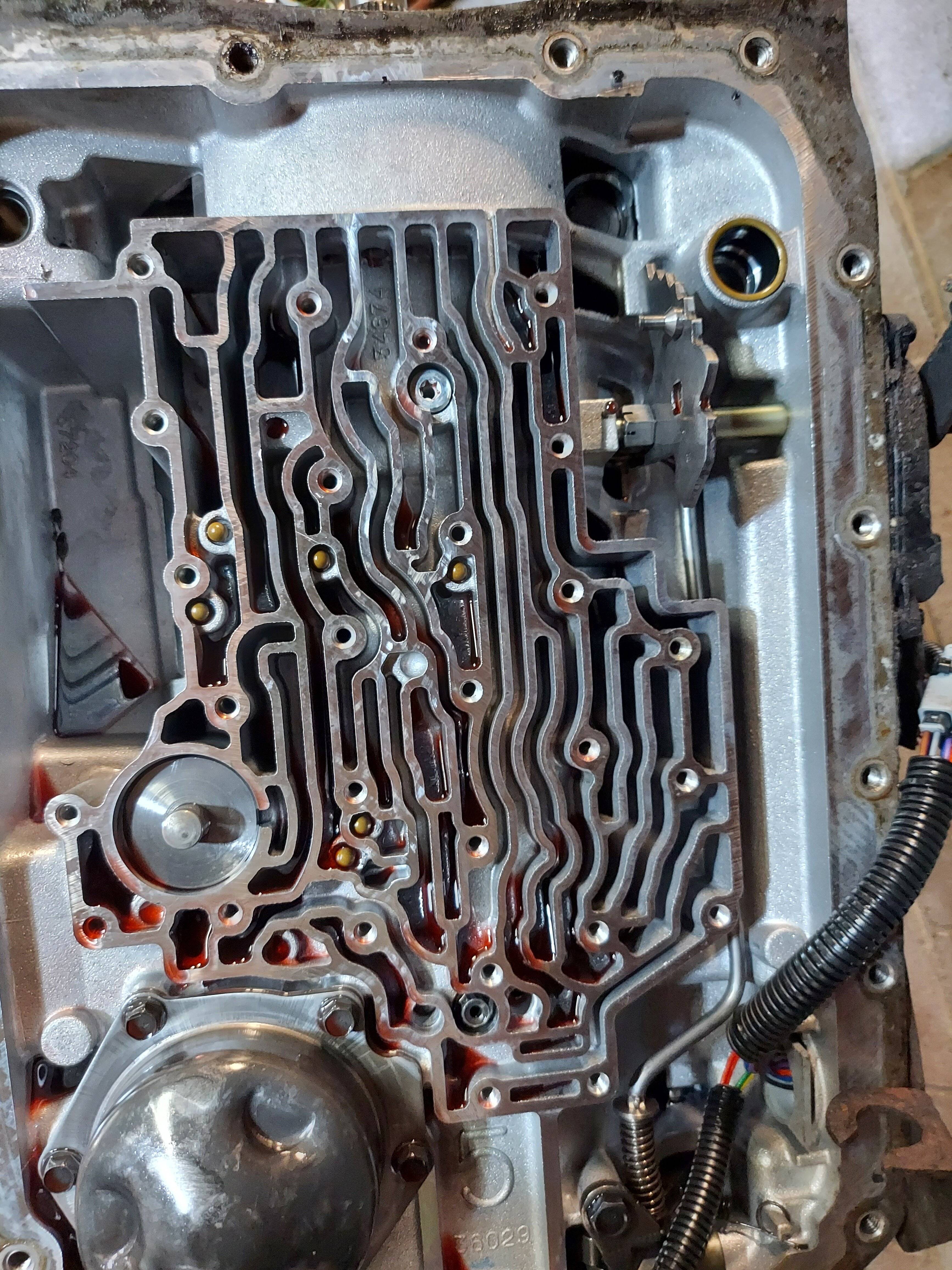

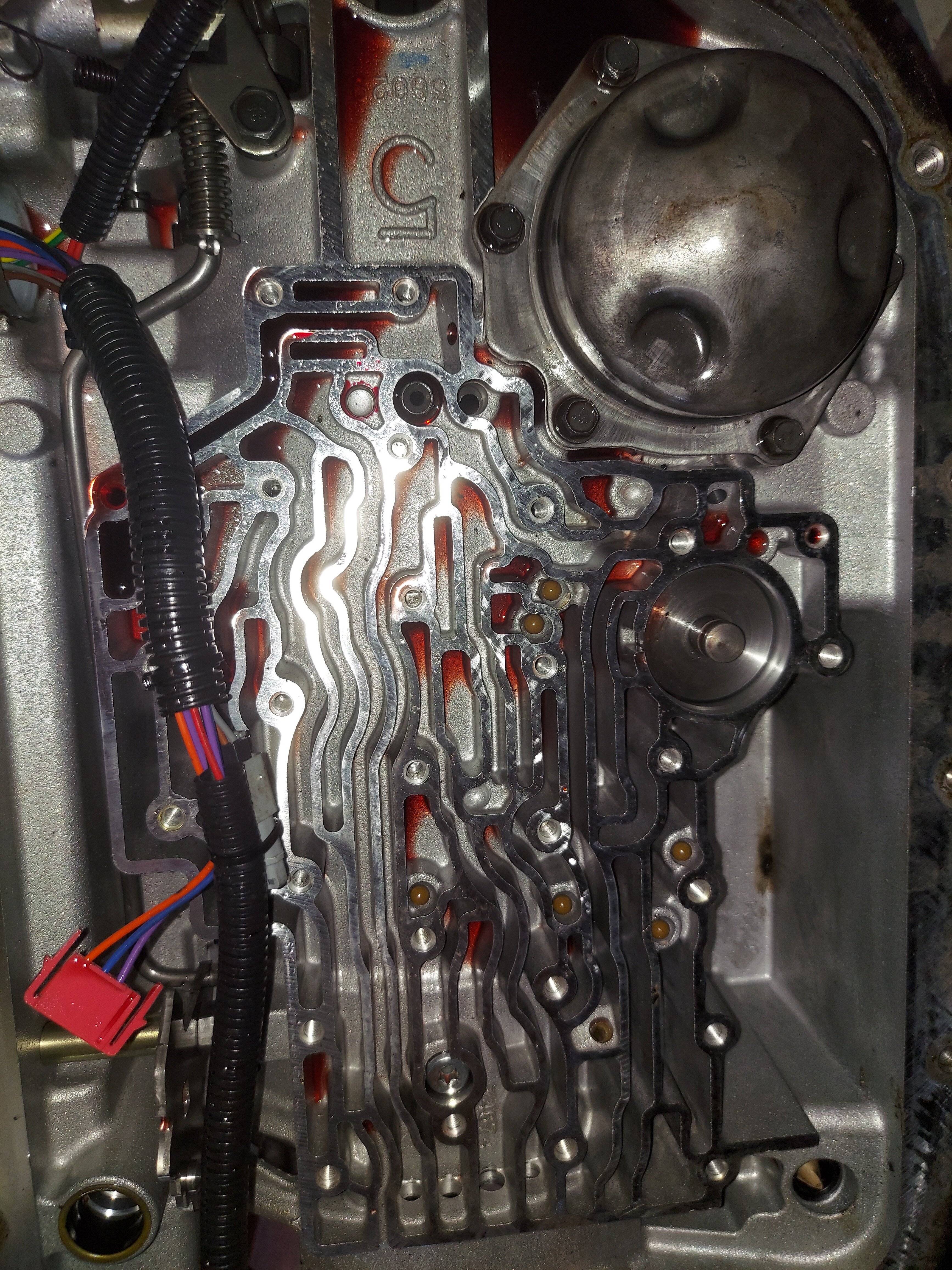

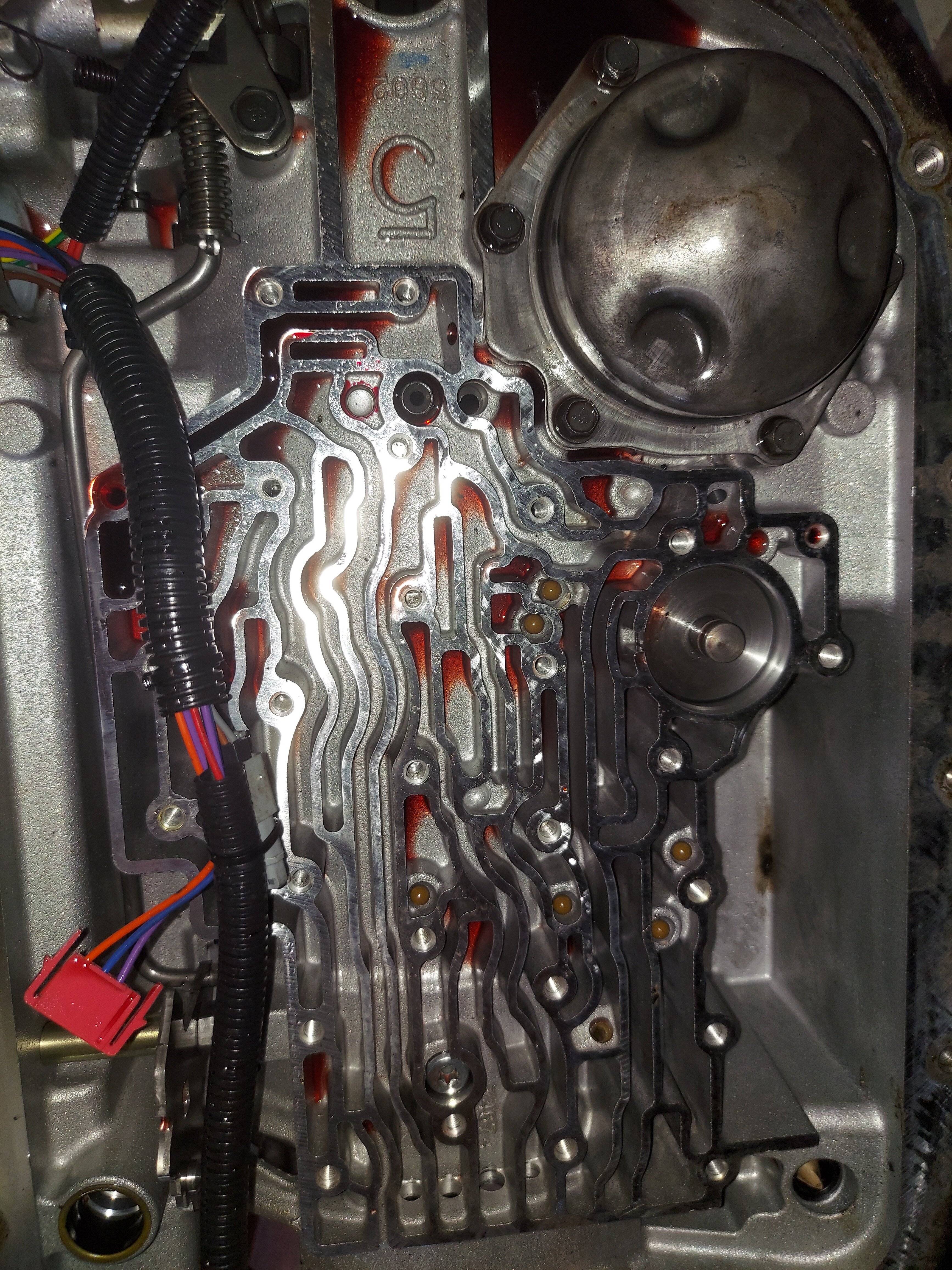

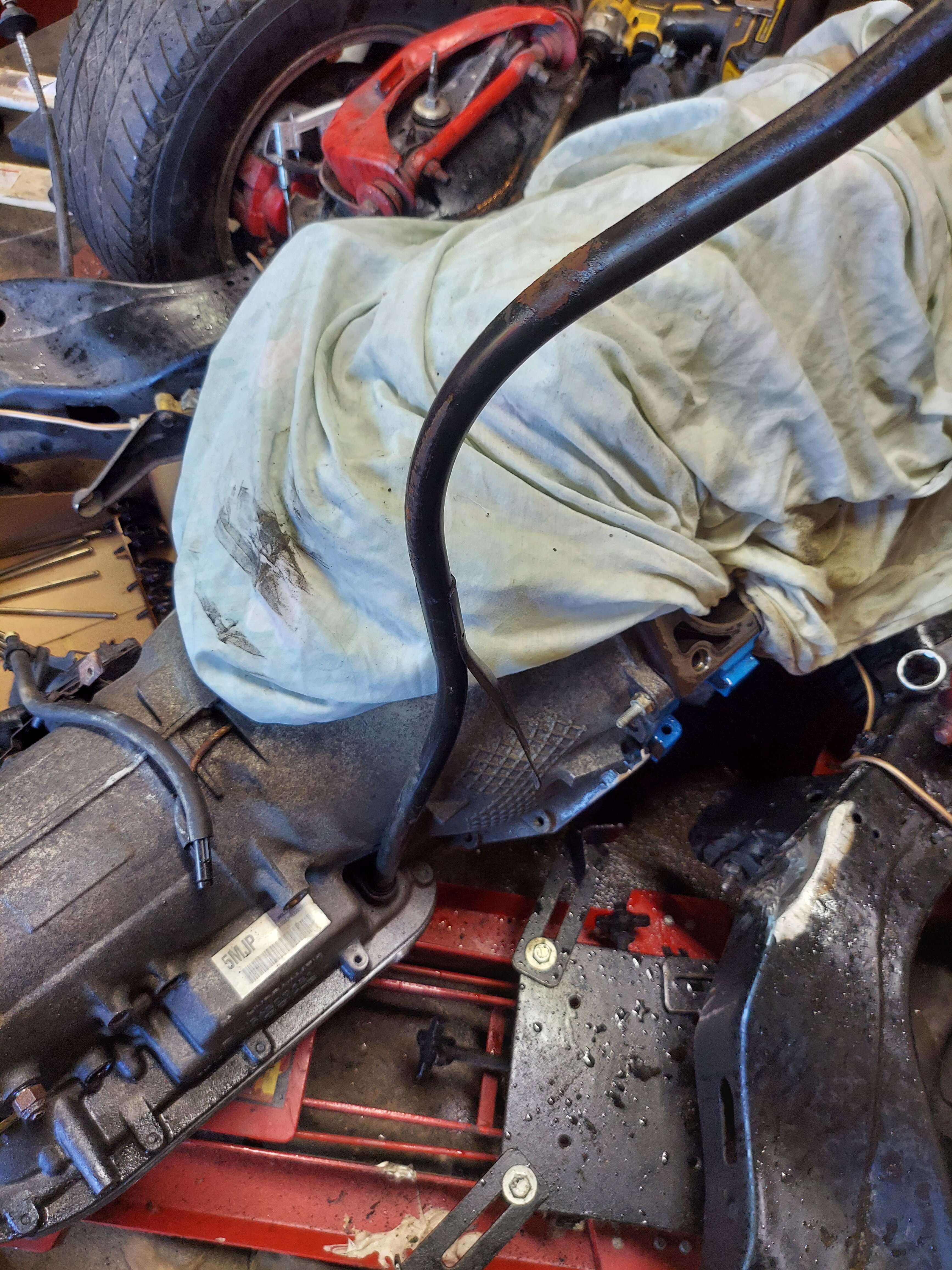

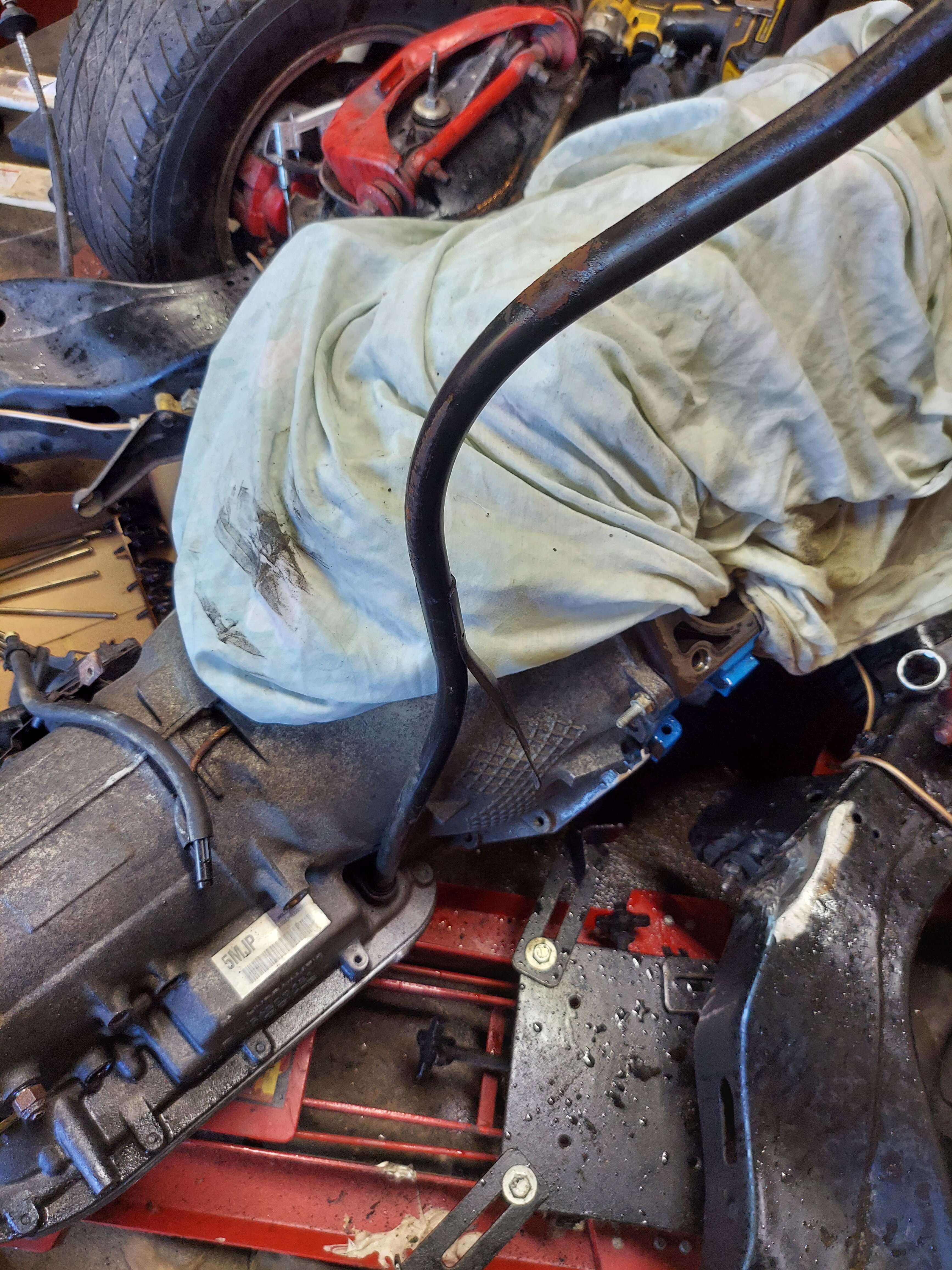

I finally got time this week to mess with putting the hd2 kit in the 4l80e. I did the vb mods except for the pressure relief valve. I drilled the sandwich plate to .108(2nd) .125(4th) and didn't drill 3rd but left the checkball out. This supposedly straightens out the 3-2 downshift. I left out 9,8,2 checkballs.

I finished up the vb and set it aside. Then I pulled the pump for the spring and snap ring mod. Don't forget to pull the oring off the shaft. I pulled the intermediate,4th frictions and steels. I guess i didnt take a pic. Im getting really bad about that. They both had orange frictions, like brand new.

I used 2 big c clamps and pc metal to take the snap ring out of the direct. They didn't look so good. Black frictions and hot spots on the steels.

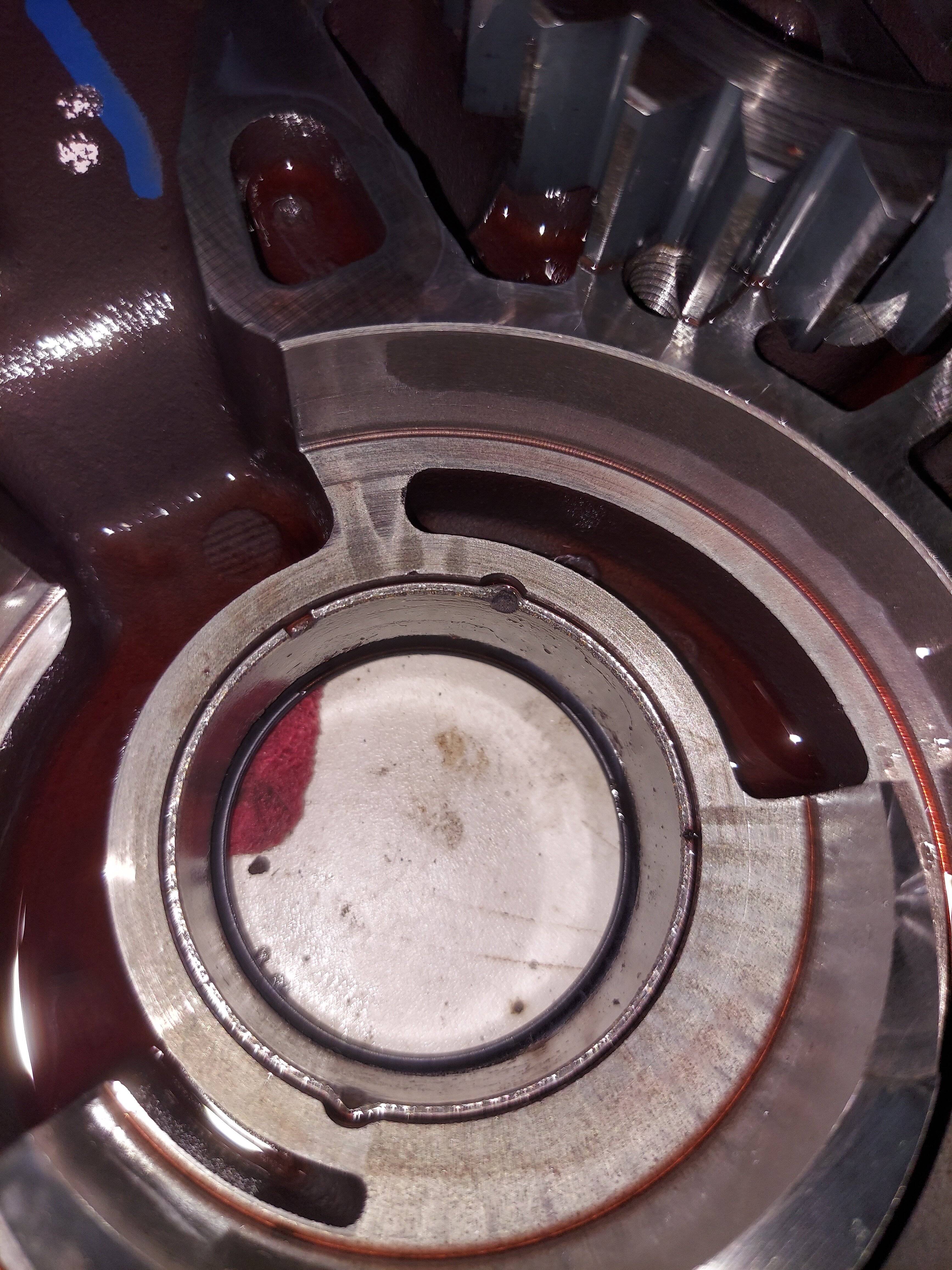

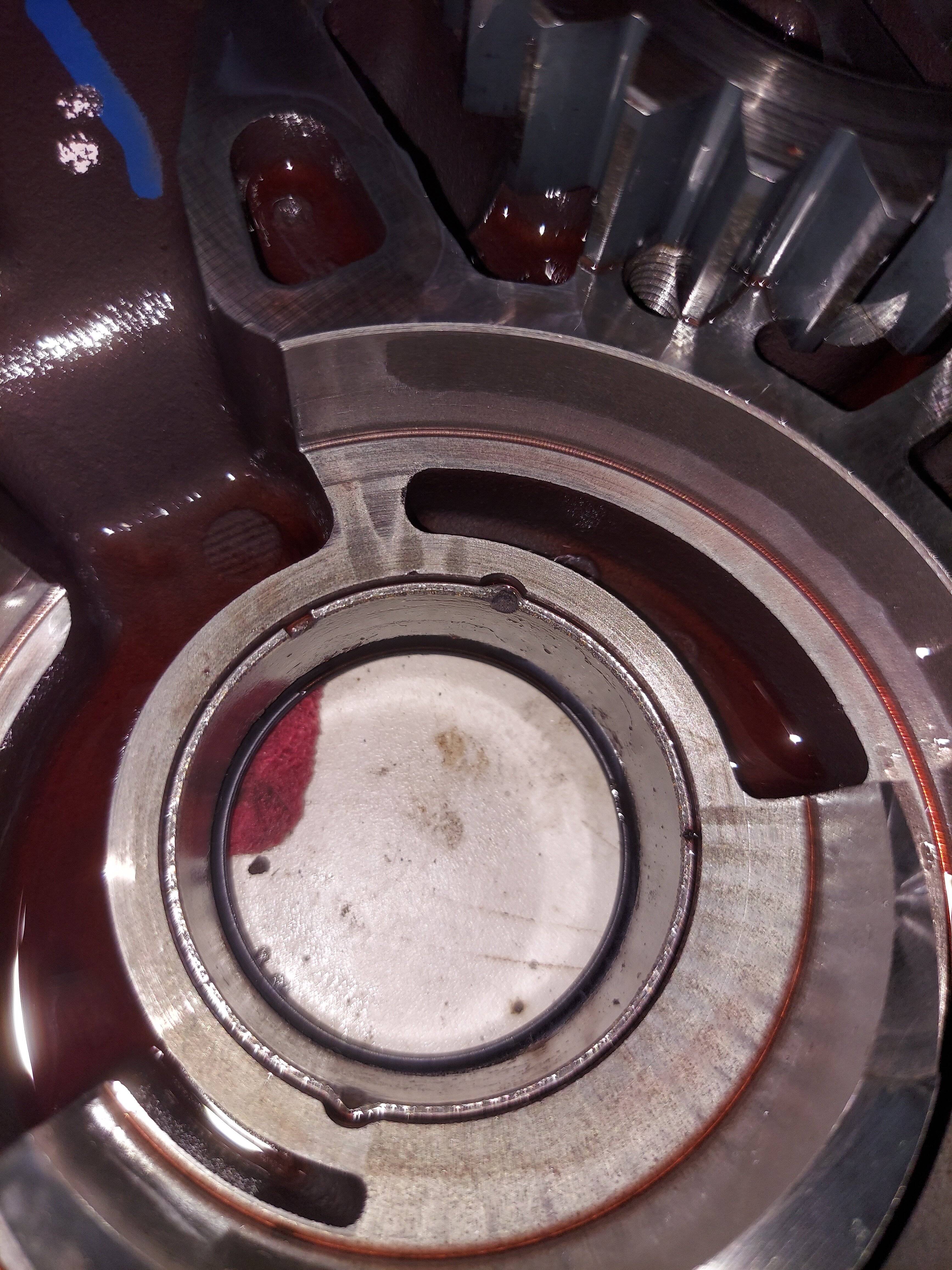

So I bought new frictions and steels. After pulling the direct and checking the intermediate, the hd2 kit seemed like a mistake. To change the springs and snap ring you have to go halfway into the transmission. Exactly as deep as is needed to internally dual feed the direct. So that's what I did. Remove the seal on the direct drum,Pop the 2nd seal from the top off the center support, which was scarf cut.

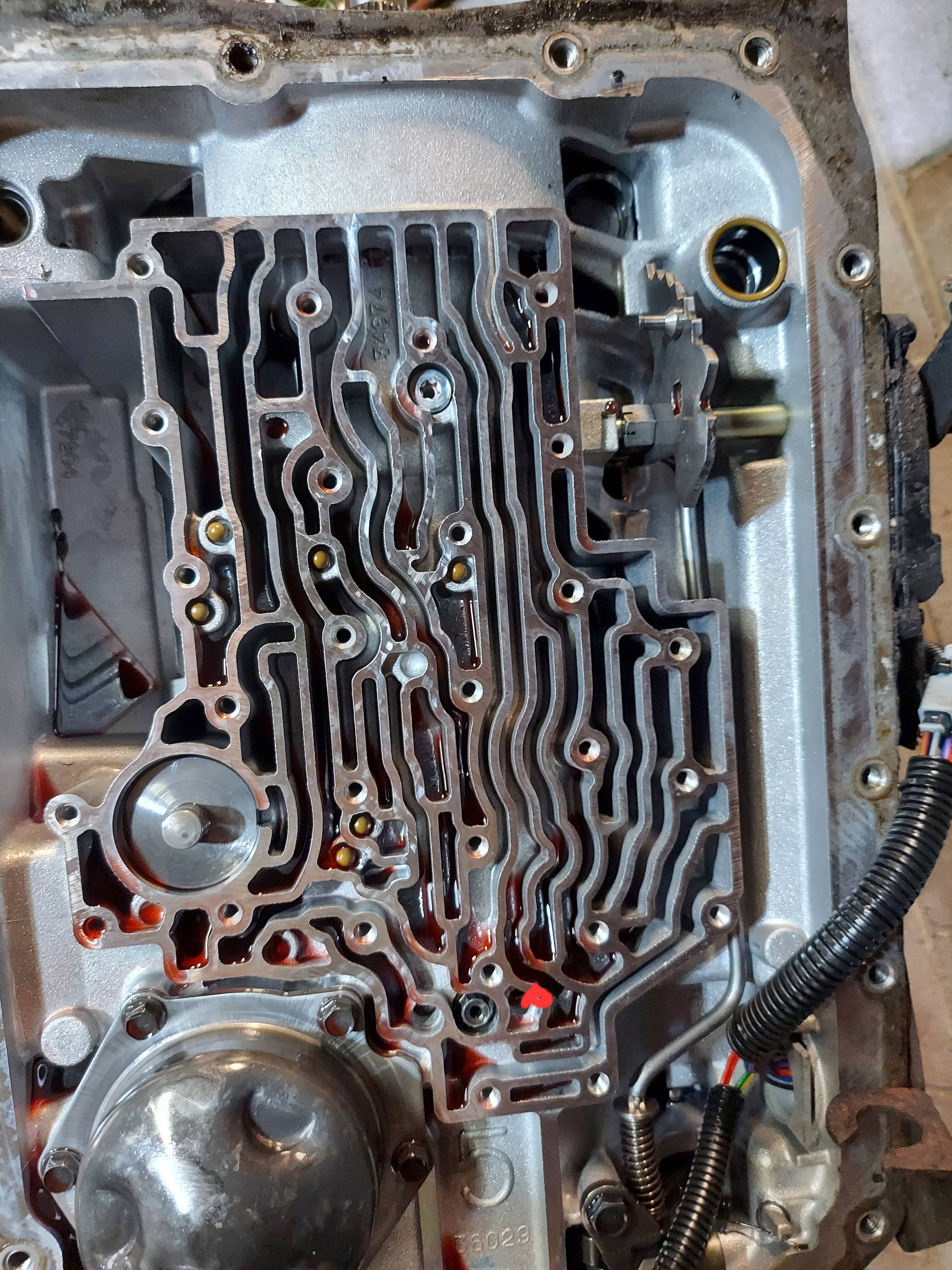

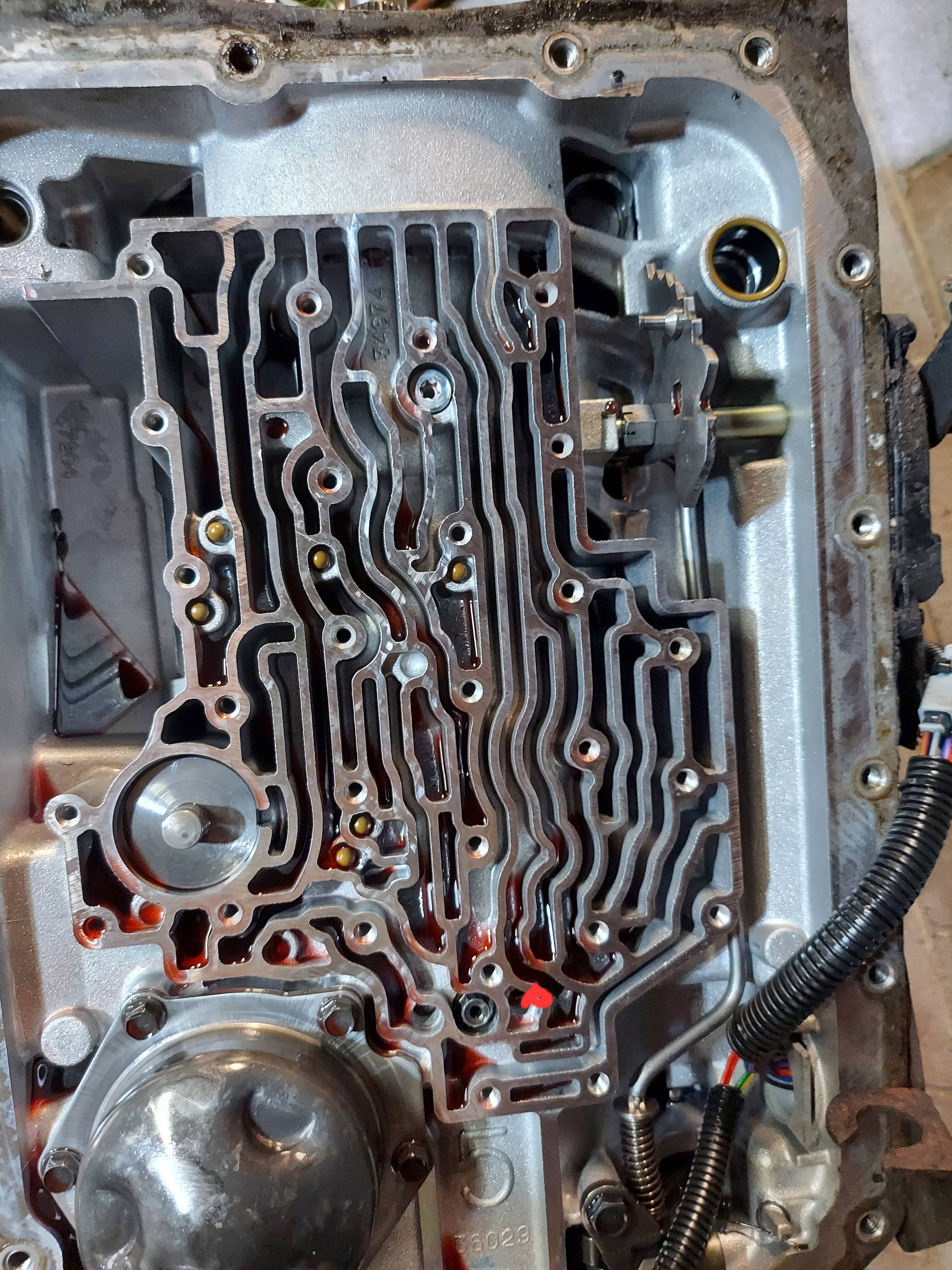

Pretty sure somebody's been in here before me. There's fluted bushings that look new too. Drill a 1/16 bleed hole in the drum (instead of replacing the springs) and jam a cup plug in the case at the reverse feed. Red dot next to the 4th clutch bolt.

Pretty sure somebody's been in here before me. There's fluted bushings that look new too. Drill a 1/16 bleed hole in the drum (instead of replacing the springs) and jam a cup plug in the case at the reverse feed. Red dot next to the 4th clutch bolt.

I put a sonnax boost valve (50$)34200-10K (EDIT: correct part number is 4l80e-Lb1)in the pump. Its supposed to keep pressure below 195 psi i think(thought wrong lol, it keeps epc pressure below 105kpa)I Ordered a gm separator plate(11$),gaskets(2$) and (30$)3/4 accumulator block off plate. I'll drill it out the same as the hd2. This would have cost a fraction of the kit that I only used the actuator parts(sonnax has better for like 50$) and snap ring(5$ 727 torqueflite snap ring). Lack of confidence led to me buying it.I'm gonna try to recoup some of the money selling the partial kit to someone who wants to dual feed with the transmission in the car. Ill have the gm plate and gaskets this week to button it back up. Converter should be done in the next few weeks, and I'm taking the hood,decklid, and doors to be blasted for 200$. I'm done stripping for good lol, and will never recommend it to anyone again. I should have paid to have it all stripped. Live and learn i guess.I thought I bought body mount bolts but I can't find them so I'll order more so I can put it back together as soon as the transmission is back in. Should be a busy June but if I work my *ss off It might be moving by the end of summer 🤞. Soon summary, if you have a 4l80e out of the vehicle do NOT buy the hd2 kit imo. The internet already told me but I didn't listen.

I finally got time this week to mess with putting the hd2 kit in the 4l80e. I did the vb mods except for the pressure relief valve. I drilled the sandwich plate to .108(2nd) .125(4th) and didn't drill 3rd but left the checkball out. This supposedly straightens out the 3-2 downshift. I left out 9,8,2 checkballs.

I finished up the vb and set it aside. Then I pulled the pump for the spring and snap ring mod. Don't forget to pull the oring off the shaft. I pulled the intermediate,4th frictions and steels. I guess i didnt take a pic. Im getting really bad about that. They both had orange frictions, like brand new.

I used 2 big c clamps and pc metal to take the snap ring out of the direct. They didn't look so good. Black frictions and hot spots on the steels.

So I bought new frictions and steels. After pulling the direct and checking the intermediate, the hd2 kit seemed like a mistake. To change the springs and snap ring you have to go halfway into the transmission. Exactly as deep as is needed to internally dual feed the direct. So that's what I did. Remove the seal on the direct drum,Pop the 2nd seal from the top off the center support, which was scarf cut.

I put a sonnax boost valve (50$)34200-10K (EDIT: correct part number is 4l80e-Lb1)in the pump. Its supposed to keep pressure below 195 psi i think(thought wrong lol, it keeps epc pressure below 105kpa)I Ordered a gm separator plate(11$),gaskets(2$) and (30$)3/4 accumulator block off plate. I'll drill it out the same as the hd2. This would have cost a fraction of the kit that I only used the actuator parts(sonnax has better for like 50$) and snap ring(5$ 727 torqueflite snap ring). Lack of confidence led to me buying it.I'm gonna try to recoup some of the money selling the partial kit to someone who wants to dual feed with the transmission in the car. Ill have the gm plate and gaskets this week to button it back up. Converter should be done in the next few weeks, and I'm taking the hood,decklid, and doors to be blasted for 200$. I'm done stripping for good lol, and will never recommend it to anyone again. I should have paid to have it all stripped. Live and learn i guess.I thought I bought body mount bolts but I can't find them so I'll order more so I can put it back together as soon as the transmission is back in. Should be a busy June but if I work my *ss off It might be moving by the end of summer 🤞. Soon summary, if you have a 4l80e out of the vehicle do NOT buy the hd2 kit imo. The internet already told me but I didn't listen.

Last edited:

I edited the above post. Idk where i got that part number but its not right. I mustve confused it with this sonnax 34200-14k, the line to lube pr valve. The correct boost valve is 4l80e lb1.

So I finished up the transmission modifications. I ended up just using the hd2 3/4 accumulator spring, 2 accumulator spring and canceled the block off plate. I can put it in, while the trans is in the car if the shifts are too long. I drilled the new gm plate as described above.2nd(.110 7/64 bit)3rd no checkball, no drilling, 4th(.125)Same checkball placement leave 9 out to speed up reverse engagement. You can see the reverse feed is plugged with a 3/8 cup plug and red loctite.

Found out that you have to drop the vb valve onto the shift lever after I ran all the bolts down by hand. 😆

Im gonna replace atleast the epc solenoid, probably all of them. The manifold pressure switch buttons all popped so I cleaned it and installed.

The pump has me a bit concerned though. After drilling the 1/16 line to lube hole in stator part of the pump i noticed marks where the gears ride.

The gears look ok. Light scratching but the pump body that they ride in is questionable.

The gears look ok. Light scratching but the pump body that they ride in is questionable.

Those dark marks on the bridge are slightly lower then everything else. I don't catch a nail on it but I can feel it with my fingertip. The marks by the crescent I cant really feel. Then I noticed the bushing was trash, very groovy. Converter has grooves too.

I pulled the new seal, and beat the bushing out of the back with an old washer and socket.

Can this pump be fixed? Ran as is? Can I buy new gears and pump body and keep my stator? Or buy a whole new pump? Any advice is appreciated, and definitely needed.

On a side note, my stepsons dad gave me this clapped out,titleless gem, 5.3 runs good,4x4, 4l60e is full of nuetrals. He just wants the cateye front end. I only want the 706 heads lol. I'll part the rest out and call my scrapper to take the shell.

I might keep the sticker though.

So I finished up the transmission modifications. I ended up just using the hd2 3/4 accumulator spring, 2 accumulator spring and canceled the block off plate. I can put it in, while the trans is in the car if the shifts are too long. I drilled the new gm plate as described above.2nd(.110 7/64 bit)3rd no checkball, no drilling, 4th(.125)Same checkball placement leave 9 out to speed up reverse engagement. You can see the reverse feed is plugged with a 3/8 cup plug and red loctite.

Found out that you have to drop the vb valve onto the shift lever after I ran all the bolts down by hand. 😆

Im gonna replace atleast the epc solenoid, probably all of them. The manifold pressure switch buttons all popped so I cleaned it and installed.

The pump has me a bit concerned though. After drilling the 1/16 line to lube hole in stator part of the pump i noticed marks where the gears ride.

Those dark marks on the bridge are slightly lower then everything else. I don't catch a nail on it but I can feel it with my fingertip. The marks by the crescent I cant really feel. Then I noticed the bushing was trash, very groovy. Converter has grooves too.

I pulled the new seal, and beat the bushing out of the back with an old washer and socket.

Can this pump be fixed? Ran as is? Can I buy new gears and pump body and keep my stator? Or buy a whole new pump? Any advice is appreciated, and definitely needed.

On a side note, my stepsons dad gave me this clapped out,titleless gem, 5.3 runs good,4x4, 4l60e is full of nuetrals. He just wants the cateye front end. I only want the 706 heads lol. I'll part the rest out and call my scrapper to take the shell.

I might keep the sticker though.

Your pump is the reason that most builders install a new pump. Those marks don't look that severe though imo. And an excellent call on the bushing. Measure the converter hub and the inside diameter of the bushing. There is an amount of clearance that is too much. If the converter hub is worn significantly, then you need a converter or a new hub put on yours. Are you running a stock converter?

If the spare 5.3 was a runner, then hold onto it until you get yours going. You never know................... A spare motor is not a bad thing to have laying around. If your concerned about it, then cut open the filter and drop the pan looking for stuff that isn't supposed to be there. Then pull the cam and look at the cam bearings (I know, you're not supposed to look at them) and put a hard look on the lifters and lobes looking for a worn out tray. If it's all good, then shim the pump and chuck it back together awaiting ...... inevitability

If the spare 5.3 was a runner, then hold onto it until you get yours going. You never know................... A spare motor is not a bad thing to have laying around. If your concerned about it, then cut open the filter and drop the pan looking for stuff that isn't supposed to be there. Then pull the cam and look at the cam bearings (I know, you're not supposed to look at them) and put a hard look on the lifters and lobes looking for a worn out tray. If it's all good, then shim the pump and chuck it back together awaiting ...... inevitability

New bushing and send it....

looks like the parts are mated to me.

looks like the parts are mated to me.

Thanks, Idk if it's ideal to run the pump as is, but they're not necessarily cheap. Fwiw, i never had an issue with the transmission, except it refused to lock up half the time. It never got much above 160 if I remember correctly. So I think I'll bang a sonnax bushing in the body and put it together. The stock converter is definitely grooved out. I noticed it when I pulled it. I should have known the bushing was wiped out. Would have saved me 5 bucks on the new seal I had to destroy.Your pump is the reason that most builders install a new pump. Those marks don't look that severe though imo. And an excellent call on the bushing. Measure the converter hub and the inside diameter of the bushing. There is an amount of clearance that is too much. If the converter hub is worn significantly, then you need a converter or a new hub put on yours. Are you running a stock converter?

If the spare 5.3 was a runner, then hold onto it until you get yours going. You never know................... A spare motor is not a bad thing to have laying around. If your concerned about it, then cut open the filter and drop the pan looking for stuff that isn't supposed to be there. Then pull the cam and look at the cam bearings (I know, you're not supposed to look at them) and put a hard look on the lifters and lobes looking for a worn out tray. If it's all good, then shim the pump and chuck it back together awaiting ...... inevitability

I have a converter on the way.Its In the 6th week of 4-6. The 5.3 runs good, has goldish oil.

I was gonna put the heads on my 6.0. But maybe I'll keep it as a spare and hit the yard for a set of heads, instead of tearing down a runner. I didn't look at the 6.0 cam bearings tbh, it didn't come out with the cam so I figured they're ok. I haven't looked at the lifters/trays either, but I drove it for 2 years. Only time it ticked was early on cold mornings and I think it was piston slap. Kind of a hollow aluminum sound for 2 secs tops. I have a transtar 5 min away so I'll go get the front seal,pump oring, pan gasket/filter and bushing. That should be all I need to put it together.

Yea, I think that's what I'll do. I also think they are machined for each other. Although you can buy either half separately.New bushing and send it....

looks like the parts are mated to me.

Yea, I think that's what I'll do. I also think they are machined for each other. Although you can buy either half separately.

A rebuilt pump is pretty easy to get, just be sure to get the right one. Ask me how I know.

Run it, keep an eye on the trans pressure, if you're under 150psi in reverse or 180psi WOT its probably worn and you can address later. Pump change is minor surgery.

I've been plugging away at the car, just too lazy to update the thread. I put the new bushing in durabond #34001cstg. I used an old body mount washer and socket to beat the bushing out and back in. New front seal,pump oring and epc solenoid also. Make sure the overrun clutch and roller assembly is together all the way. I fought the pump for an hour on install before I figured it out. Then had to pull it back out cuz I forgot the gasket. The converter showed up last week. It was well packaged and had a little fluid in it from testing. Used a straight edge to confirm it was 1" back of the bellhousing flange. Then I spun it after i got it in place. I used red loctite on the converter bolts.

So It's all back together, with the ears cut off. I just have to build a dipstick and verify fluid level.

I don't remember how that dipstick mounted or what it mounted too. But it's not the bellhousing bolt.

I don't remember how that dipstick mounted or what it mounted too. But it's not the bellhousing bolt.

I've been messing with some 706 heads I got from the yard on half price day. Assembled 50$. The only issue with them is extreme valve shrouding. They are so close to the chamber wall. I had an old timer show me on a set of 186 double humps with big valves. I just did the same thing we did to those.

I marked the 4" bore gasket onto the heads. I used 2 sacrificial valves to protect the seats. I removed material straight down the wall instead of at an angle. I didn't worry about the exhaust as much. They already outflow the intake in comparison. I used carbide bits for steel, rubbing grease on the teeth and wire brushing them off often so not to gum up the bit with aluminum.

I marked the 4" bore gasket onto the heads. I used 2 sacrificial valves to protect the seats. I removed material straight down the wall instead of at an angle. I didn't worry about the exhaust as much. They already outflow the intake in comparison. I used carbide bits for steel, rubbing grease on the teeth and wire brushing them off often so not to gum up the bit with aluminum.

Both heads are done, cleaned and ready for the valve springs and install. I got felpro gaskets 26192pt. Btr valve seals.Plus some copper spray gasket.

The internet says these heads crack all the time but I couldn't find many pics of these cracked heads that are so commonly cracked. But it had me investigating 😒. I was gonna take them to get checked, 2" intake installed,valve job,bowl cut/blend for 450$ plus 75$ in valves. But after I looked them over multiple times and haven't seen anything I decided I'm just gonna install them. I'll bolt these back on and then I'm back to body work I hope to have the shell in epoxy/high build by next week. Then back on the frame. I only have 3 somewhat expensive parts left. Headers, fuel module, hp tuner mpvi2/credits and wideband. Oh and paint, always needing more paint supplies it seems, spi SS black Black is what im gonna use(500$)I haven't figured out a way to get a y of those things cheaper unfortunately.

I hope to have the shell in epoxy/high build by next week. Then back on the frame. I only have 3 somewhat expensive parts left. Headers, fuel module, hp tuner mpvi2/credits and wideband. Oh and paint, always needing more paint supplies it seems, spi SS black Black is what im gonna use(500$)I haven't figured out a way to get a y of those things cheaper unfortunately.

I sent my boy to clearwater for the month so I have no excuses, just gotta get it done. I really desperately want to be done and doing donuts. I did a burnout(kinda) in my 2.2L s10 cuz my boy said I didn't know how and the old lady definitely thinks I should just JRP the build. They have little faith, but I do enjoy proving my girl wrong.

So It's all back together, with the ears cut off. I just have to build a dipstick and verify fluid level.

I've been messing with some 706 heads I got from the yard on half price day. Assembled 50$. The only issue with them is extreme valve shrouding. They are so close to the chamber wall. I had an old timer show me on a set of 186 double humps with big valves. I just did the same thing we did to those.

Both heads are done, cleaned and ready for the valve springs and install. I got felpro gaskets 26192pt. Btr valve seals.Plus some copper spray gasket.

The internet says these heads crack all the time but I couldn't find many pics of these cracked heads that are so commonly cracked. But it had me investigating 😒. I was gonna take them to get checked, 2" intake installed,valve job,bowl cut/blend for 450$ plus 75$ in valves. But after I looked them over multiple times and haven't seen anything I decided I'm just gonna install them. I'll bolt these back on and then I'm back to body work

I hope to have the shell in epoxy/high build by next week. Then back on the frame. I only have 3 somewhat expensive parts left. Headers, fuel module, hp tuner mpvi2/credits and wideband. Oh and paint, always needing more paint supplies it seems, spi SS black Black is what im gonna use(500$)I haven't figured out a way to get a y of those things cheaper unfortunately.

I hope to have the shell in epoxy/high build by next week. Then back on the frame. I only have 3 somewhat expensive parts left. Headers, fuel module, hp tuner mpvi2/credits and wideband. Oh and paint, always needing more paint supplies it seems, spi SS black Black is what im gonna use(500$)I haven't figured out a way to get a y of those things cheaper unfortunately.I sent my boy to clearwater for the month so I have no excuses, just gotta get it done. I really desperately want to be done and doing donuts. I did a burnout(kinda) in my 2.2L s10 cuz my boy said I didn't know how and the old lady definitely thinks I should just JRP the build. They have little faith, but I do enjoy proving my girl wrong.

Well I've started updating the thread a few times. Get sidetracked and lose all my progress by the time I came back to it. So I'll try again. Before installing the heads we lapped the valves by hand and cleaned them and the block.

Poured gas in the chamber to see if it leaked, no gas or light made it through. I chased/cleaned out the holes then reused the bolts, I set my wrench to 75 ft lb and followed the torque angle procedure. All but 2 bolts clicked right before the final turn. Installed the rockers and misplaced the valve cover gaskets. I have to make a junkyard run anyway.

I got the transmission dipstick made. Just need to verify fluid level. I also got the rear suspension back together. The UCA needed to come down 1 hole, but the frame was in the way. This is the trick chassis 8.8 instant center kit.

I put some cheap kyb kg5548 shocks on it. I wanted bilsteins but figured I might as well run these so I can feel the difference when I switch. I was gonna buy spohn shock relocation brackets, but they wanted like 15$ to ship in 1-2 weeks. So I made them out of scrap.

I got the brake kit and wheel adapters installed . I need som hubcentric rings for them but i think theyre gonna fit the stock rims in the wheel well. The lugnut sticks past the adapter but the n90s have a machined spot in them so they sit flush. My zq8s wont go on with these lugnuts. I cant find a lower profile with the proper bulge. Theyll work for now. But im gonna have to build a proper 8.8 at some point. I have a buddy that can make the pucks for the 9" end jig, but trying to keep project creep at bay as it is. Id probably use an exploder setup anyways.

I got the brake kit and wheel adapters installed . I need som hubcentric rings for them but i think theyre gonna fit the stock rims in the wheel well. The lugnut sticks past the adapter but the n90s have a machined spot in them so they sit flush. My zq8s wont go on with these lugnuts. I cant find a lower profile with the proper bulge. Theyll work for now. But im gonna have to build a proper 8.8 at some point. I have a buddy that can make the pucks for the 9" end jig, but trying to keep project creep at bay as it is. Id probably use an exploder setup anyways.

The real time eater has been this damn qtr panel I jacked up originally, then thought I fixed it but actually didnt... The body lines were caved in, pushed out, wavy. They couldn't be finished. I'd have had 2" of bondo making up the wheel arch. So I tried again, this time I cut it out.

I was able to get the black patch in straight without issue but the wheel arch was a pita. I made it from 2 pcs of scrap off the inner wheelhouse panels i have. Then just slowly stacked welds and grinded smooth until i got the right shape.

I was able to get the black patch in straight without issue but the wheel arch was a pita. I made it from 2 pcs of scrap off the inner wheelhouse panels i have. Then just slowly stacked welds and grinded smooth until i got the right shape.

This is how it sits now. I have the rest of the body and fenders in 80 grit da. Scratches. But im gonna add a little more filler in a few spots and block it out. The rest of the car looks and feels straight so Im hoping i wont have to add filler to this extent anywhere else.

This is how it sits now. I have the rest of the body and fenders in 80 grit da. Scratches. But im gonna add a little more filler in a few spots and block it out. The rest of the car looks and feels straight so Im hoping i wont have to add filler to this extent anywhere else.

It's getting doused in epoxy this week for sure. Hopefully tonight. If not, Tommorow morning for sure.

Poured gas in the chamber to see if it leaked, no gas or light made it through. I chased/cleaned out the holes then reused the bolts, I set my wrench to 75 ft lb and followed the torque angle procedure. All but 2 bolts clicked right before the final turn. Installed the rockers and misplaced the valve cover gaskets. I have to make a junkyard run anyway.

I got the transmission dipstick made. Just need to verify fluid level. I also got the rear suspension back together. The UCA needed to come down 1 hole, but the frame was in the way. This is the trick chassis 8.8 instant center kit.

I put some cheap kyb kg5548 shocks on it. I wanted bilsteins but figured I might as well run these so I can feel the difference when I switch. I was gonna buy spohn shock relocation brackets, but they wanted like 15$ to ship in 1-2 weeks. So I made them out of scrap.

The real time eater has been this damn qtr panel I jacked up originally, then thought I fixed it but actually didnt... The body lines were caved in, pushed out, wavy. They couldn't be finished. I'd have had 2" of bondo making up the wheel arch. So I tried again, this time I cut it out.

It's getting doused in epoxy this week for sure. Hopefully tonight. If not, Tommorow morning for sure.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 202

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.