I'm pleased to report some progress has been made. It seemed it was going to be nearly impossible to install the motor mounts with the lower control arm in place. In addition to that the control arm bushings were dry rotted and the whole front end was pretty crusty so I decided to overhaul the front end in conjunction with the underhood project. I decided since my space is limited that I'd do the driver's side first, then move the car and do the passenger side.

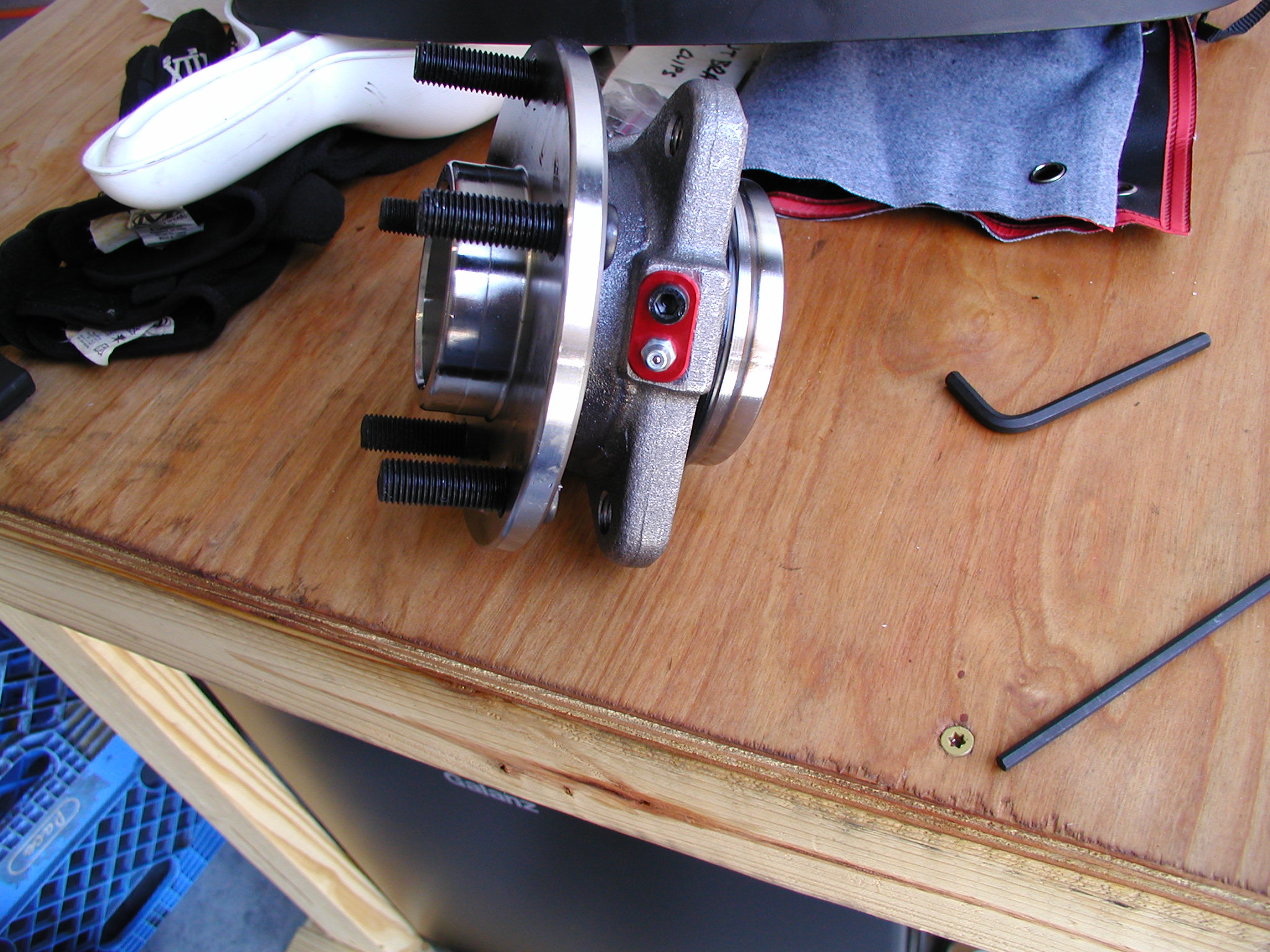

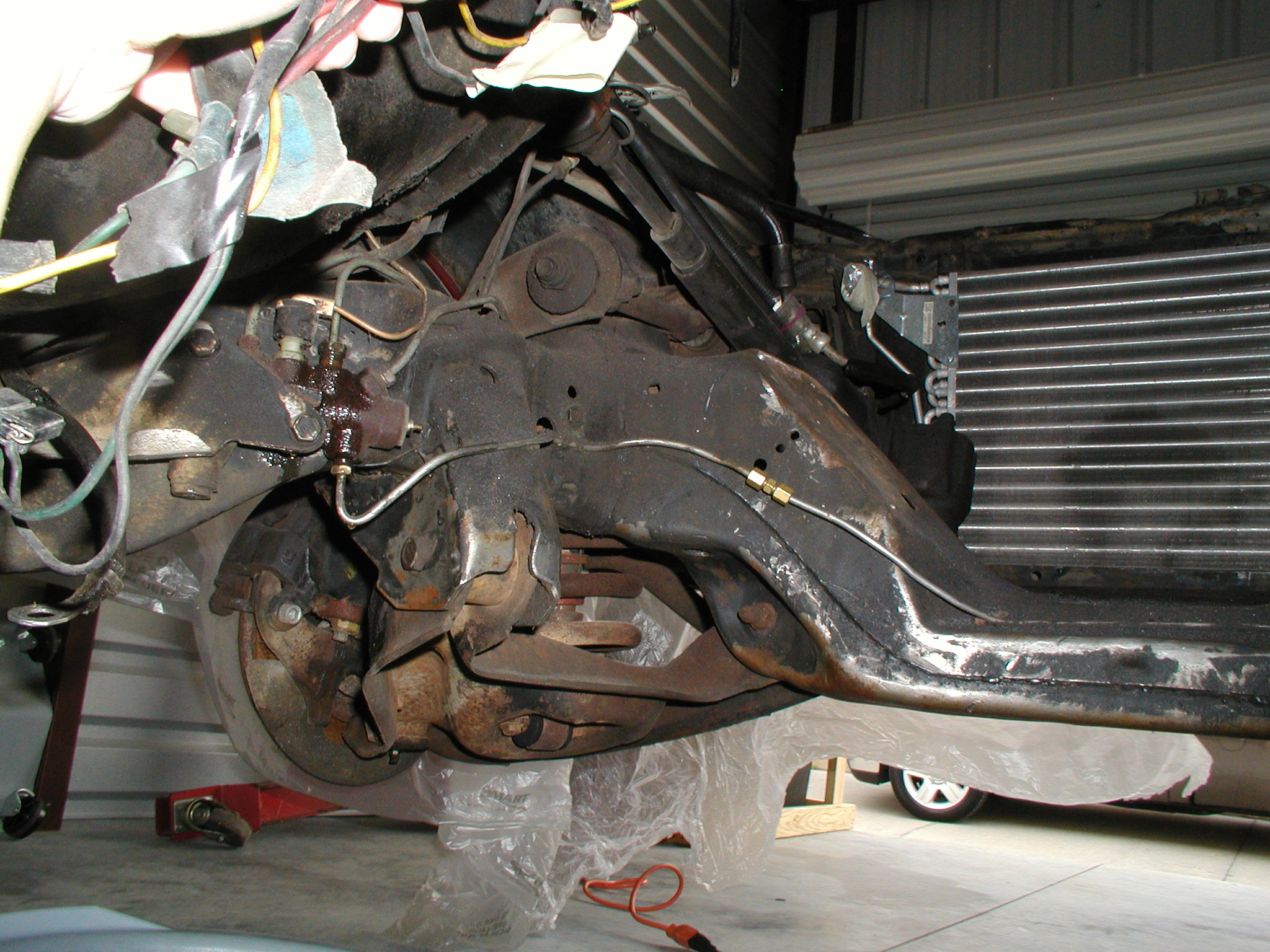

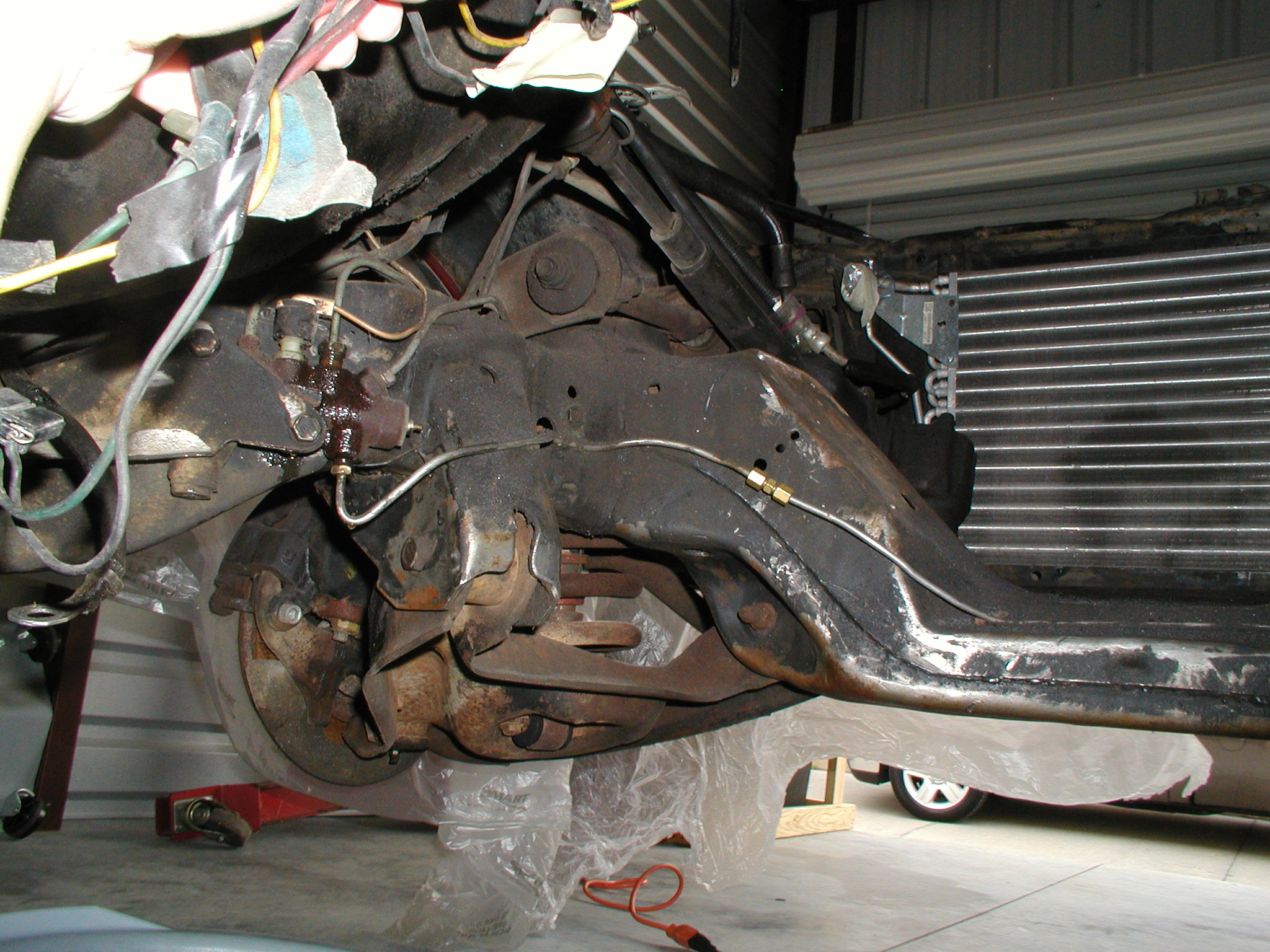

Here's what I started with...

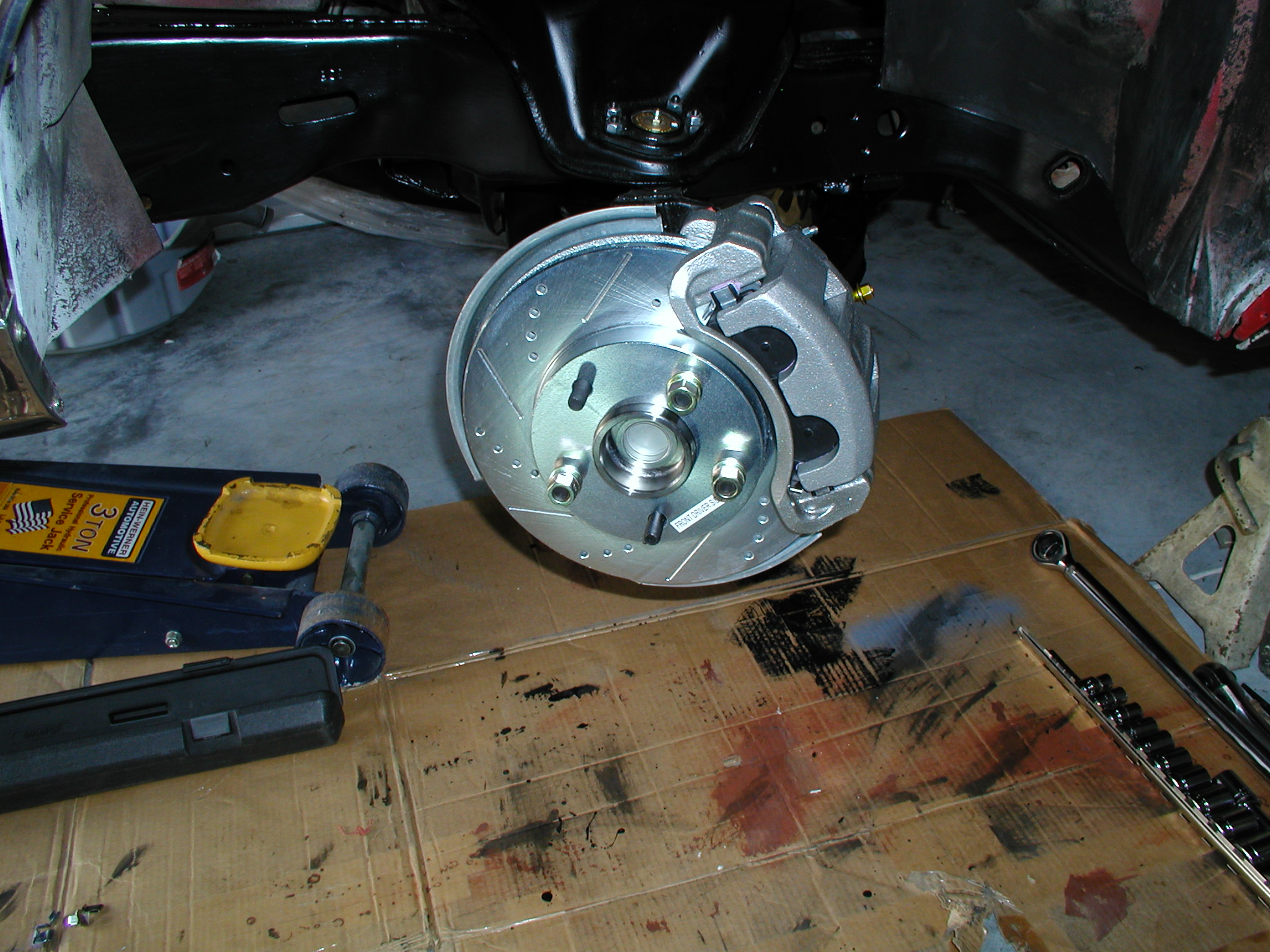

The front brake lines were patched in a couple of locations so I will be replacing them...

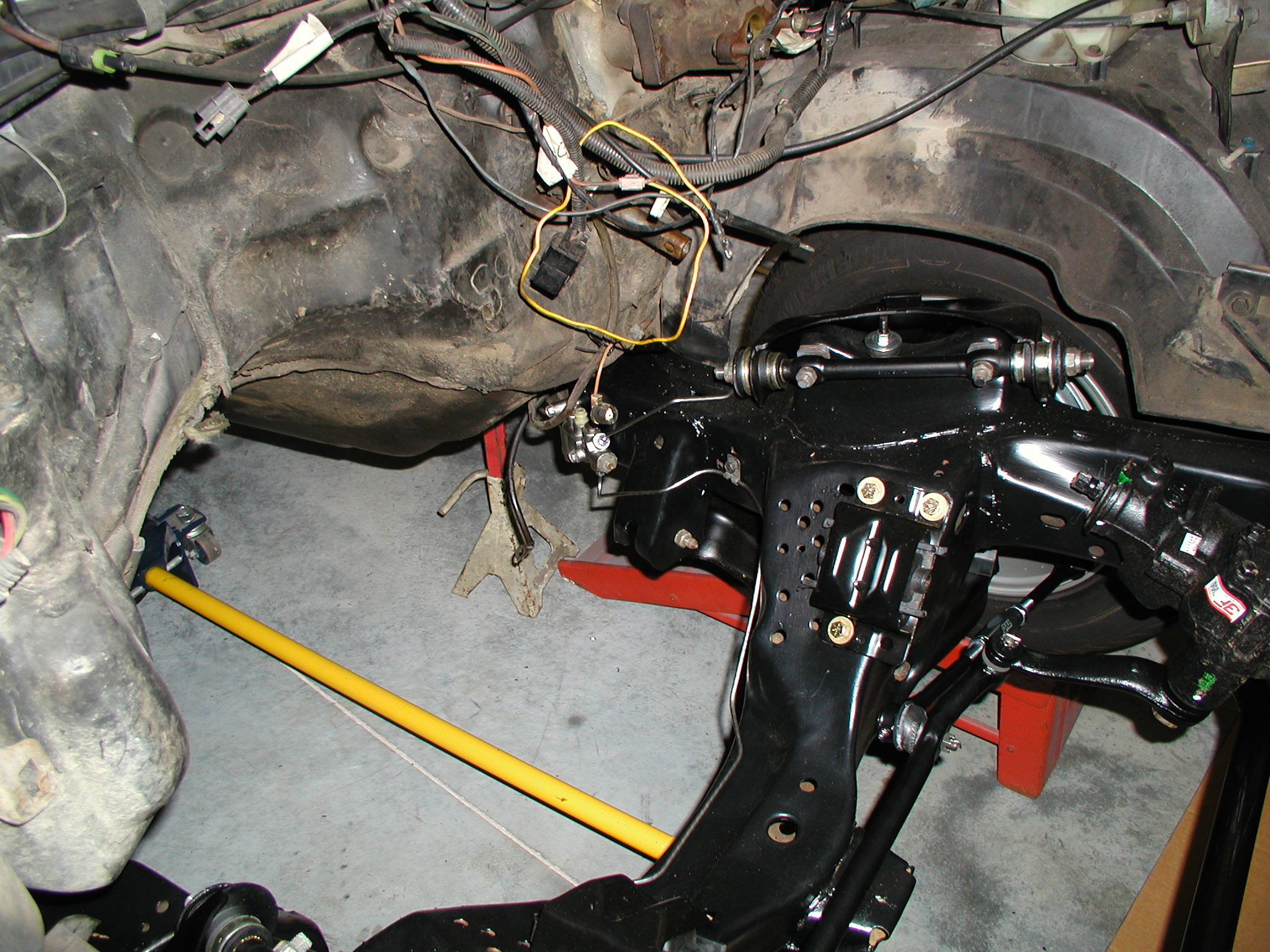

Here's a look after teardown...

Here's a shot after cleanup. I scraped it and cleaned it with mineral spirits. It's amazing what mineral spirits, rags and paper towels will do....

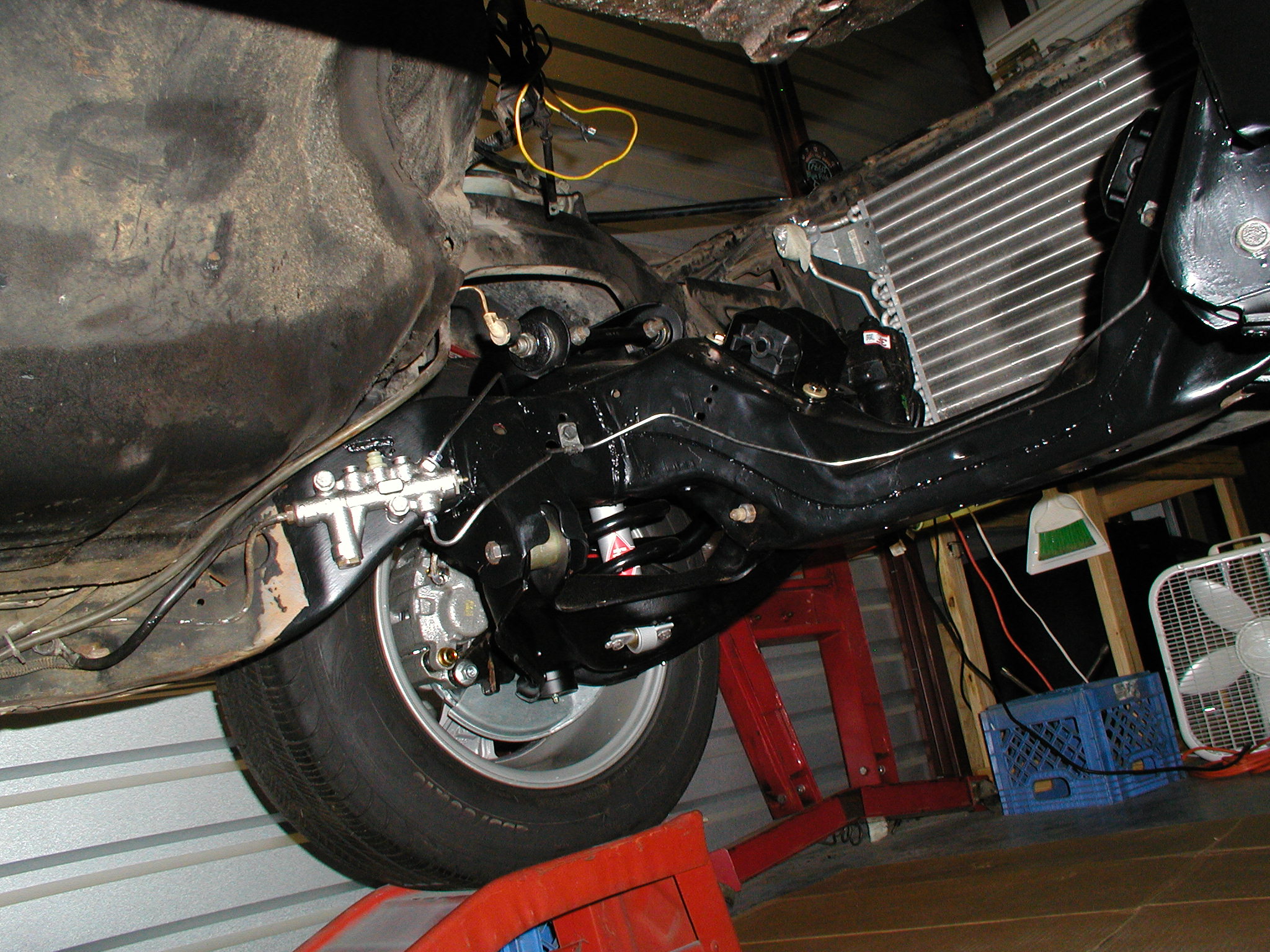

Since I'm working in a storage building and I'm not taking the body off of the frame, I decided to paint the frame with a brush. I know some will cringe at that thought but I just didn't want to deal with the overspray mess. After a lot of thought I decided to go with plain old brush on Rustoleum. I found it to go on nice and thick and found it to be very forgiving of any dirt I missed. I got the frame pretty clean but it was not perfect. After scraping it and cleaning it with mineral spirits, I gave it another pass with the mineral spirits and then went over it with lacquer thinner on an old micro-fiber cloth. First I went on with the Rustoleum "rusty metal" primer......

Followed by two coats of satin black.....

It's not perfect but it's much nicer than it was, much nicer than just leaving it and putting the engine in the way it was. It's plenty good for a cruiser and a few nice things about the Rustoleum are that its cheap, easy to touch up and seems to be fairly chip resistant.

Here's what I started with...

The front brake lines were patched in a couple of locations so I will be replacing them...

Here's a look after teardown...

Here's a shot after cleanup. I scraped it and cleaned it with mineral spirits. It's amazing what mineral spirits, rags and paper towels will do....

Since I'm working in a storage building and I'm not taking the body off of the frame, I decided to paint the frame with a brush. I know some will cringe at that thought but I just didn't want to deal with the overspray mess. After a lot of thought I decided to go with plain old brush on Rustoleum. I found it to go on nice and thick and found it to be very forgiving of any dirt I missed. I got the frame pretty clean but it was not perfect. After scraping it and cleaning it with mineral spirits, I gave it another pass with the mineral spirits and then went over it with lacquer thinner on an old micro-fiber cloth. First I went on with the Rustoleum "rusty metal" primer......

Followed by two coats of satin black.....

It's not perfect but it's much nicer than it was, much nicer than just leaving it and putting the engine in the way it was. It's plenty good for a cruiser and a few nice things about the Rustoleum are that its cheap, easy to touch up and seems to be fairly chip resistant.