Someone asked me if there was info about this so I figure this would help some people out.

Putting a T56 6spd into a Gbody is pretty simple and straighforward, not much to it, just like installing any other Transmission pretty much.

It's good to start with getting all the parts:

T56 6spd Transmission (LT1/LS1 Fbody or GTO Type)

Clutch, Flywheel, Pressure Plate, Pilot Bushing/Bearing

Clutch Pedal & Hydraulics

Shifter & Crossmember (several companies make one now for Gbodies)

Depending on what you have in the car you may need a driveshaft or work done to the current one you have if you do not want to buy a new one. It uses the standard GM 27 Spline Slipyoke

I bought and built up a low mileage (like 20k miles on it) Tremec T56 6spd Transmission. Along with it, I bought the GM LS7 Clutch Kit with ARP Flywheel Bolts., I have a 6.0l LS Engine in my car, you guys with the Gen 1 & 2 SBC just get the appropriate parts & LT1 Fbody style T56 Transmission.

Since most of these cars were factory automatic there is no factory Clutch Pedal that will work with this. You can buy one from the few people that build them, or you can build your own.

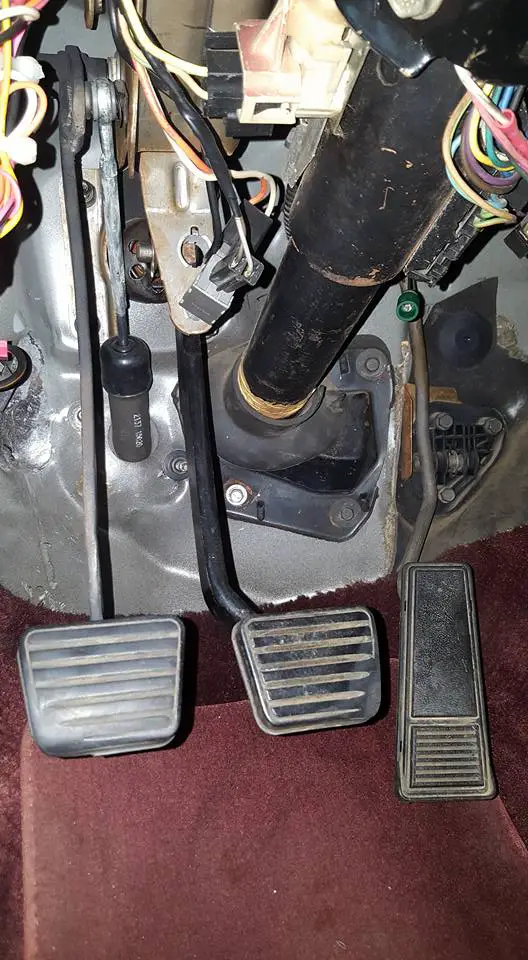

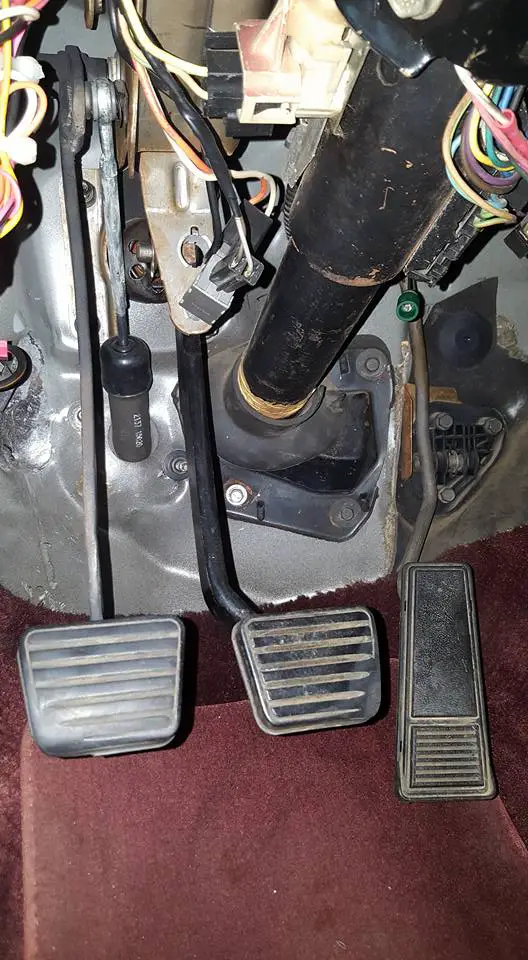

I installed the Master Cylinder on the fire wall like it would have come in a LS Fbody. Once I did this I built a Clutch Pedal using parts from an early 90's S10 Pedal. This seemed to work perfectly for the geometry and full movement of the Master Cylinder. The geometry and movement are critical in this case, it has to have full movement as straight as possible so the rod will not bind and bend.

$7 at the junkyard and a few hours of time I had a Clutch Pedal built

I hammered on the fire wall until I got it flat to get the proper angle for the Master Cylinder

The Fluid Reservoir was mounted on a bracket I made then bolted to the Brake Booster

I used a longer grade 8 bolt and mounted it next to the factory Brake Pedal. I cut the Brake Pedal down so it would clear the Clutch Pedal and use the proper size Pedal Pad

I bought the T56 and got to the shop with it, then tore it down for inspection. Everything looked pretty much new but I always upgrade them

Parts showed up a couple days after to build it with the LS7 Clutch Kit. If going LS buy a Speed Bleeder, they are worth it

I re-built the T56 with the upgrades and it was ready for install

Pilot Bushing installed and LS7 Flywheel was bolted to the back of the 6.0l

LS7 Clutch Disc and Pressure Plate installed

Recently I over-hauled my setup and installed a Monster Stage 3 Clutch, it's holding much better. Putting the pic here for reference.

Slave Cylinder with Speed Bleeder mounted on the Transmission ready for install into the car

Once I figured out where the Transmission ended up I cut the hole for the Shifter

After the shifter hole was cut then the Crossmember was installed into the car and driveshaft bolted up

The Shifter was then installed and the Center Console put back together. I made the custom Shifter Plate for my SS

I painted an extra gear indicator plate that I had to put on the speedo to cover up the original automatic gear indication

Then bleed the Clutch out and take it for a drive. Nothing much to it really and it's pretty fun to row gears with..

Putting a T56 6spd into a Gbody is pretty simple and straighforward, not much to it, just like installing any other Transmission pretty much.

It's good to start with getting all the parts:

T56 6spd Transmission (LT1/LS1 Fbody or GTO Type)

Clutch, Flywheel, Pressure Plate, Pilot Bushing/Bearing

Clutch Pedal & Hydraulics

Shifter & Crossmember (several companies make one now for Gbodies)

Depending on what you have in the car you may need a driveshaft or work done to the current one you have if you do not want to buy a new one. It uses the standard GM 27 Spline Slipyoke

I bought and built up a low mileage (like 20k miles on it) Tremec T56 6spd Transmission. Along with it, I bought the GM LS7 Clutch Kit with ARP Flywheel Bolts., I have a 6.0l LS Engine in my car, you guys with the Gen 1 & 2 SBC just get the appropriate parts & LT1 Fbody style T56 Transmission.

Since most of these cars were factory automatic there is no factory Clutch Pedal that will work with this. You can buy one from the few people that build them, or you can build your own.

I installed the Master Cylinder on the fire wall like it would have come in a LS Fbody. Once I did this I built a Clutch Pedal using parts from an early 90's S10 Pedal. This seemed to work perfectly for the geometry and full movement of the Master Cylinder. The geometry and movement are critical in this case, it has to have full movement as straight as possible so the rod will not bind and bend.

$7 at the junkyard and a few hours of time I had a Clutch Pedal built

I hammered on the fire wall until I got it flat to get the proper angle for the Master Cylinder

The Fluid Reservoir was mounted on a bracket I made then bolted to the Brake Booster

I used a longer grade 8 bolt and mounted it next to the factory Brake Pedal. I cut the Brake Pedal down so it would clear the Clutch Pedal and use the proper size Pedal Pad

I bought the T56 and got to the shop with it, then tore it down for inspection. Everything looked pretty much new but I always upgrade them

Parts showed up a couple days after to build it with the LS7 Clutch Kit. If going LS buy a Speed Bleeder, they are worth it

I re-built the T56 with the upgrades and it was ready for install

Pilot Bushing installed and LS7 Flywheel was bolted to the back of the 6.0l

LS7 Clutch Disc and Pressure Plate installed

Recently I over-hauled my setup and installed a Monster Stage 3 Clutch, it's holding much better. Putting the pic here for reference.

Slave Cylinder with Speed Bleeder mounted on the Transmission ready for install into the car

Once I figured out where the Transmission ended up I cut the hole for the Shifter

After the shifter hole was cut then the Crossmember was installed into the car and driveshaft bolted up

The Shifter was then installed and the Center Console put back together. I made the custom Shifter Plate for my SS

I painted an extra gear indicator plate that I had to put on the speedo to cover up the original automatic gear indication

Then bleed the Clutch out and take it for a drive. Nothing much to it really and it's pretty fun to row gears with..

Last edited: