Work continues on the LT1 "refresh". The scope has grown to the point I am no longer calling it a tune-up. Last Saturday I spent most of the day cleaning the front of the engine. What a mess! I also pulled the balancer hub, the optispark and the throttle body. I know, I'm slow. Hopefully the results look thorough though.

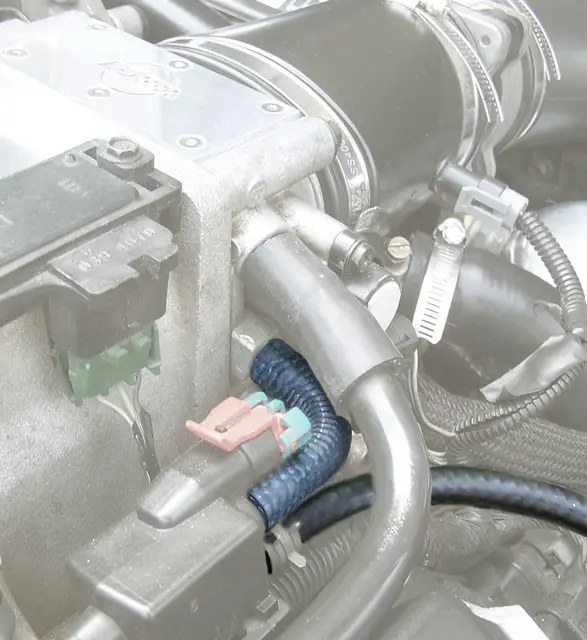

When I pulled the throttle body I discovered some decrepit emissions hoses and vacuum lines, which I should have expected. I spent some time Saturday looking for and purchasing replacements for all of those and that ate up some of my time. I still haven't found one of them. Its a rubber 90° boot. It is a strange duck. It reduces from 3/8" to 1/4". It appears to be unobtanium. I don't have that figured out yet. Enough words. Here are some pics....

This is a pic of the PCV hose going into the front of the intake. It crumbled when I tried to remove it. I'm pretty sure it was the source of most of the crud on the upper front of the engine. I meant to take a picture before I scraped/vacuumed the area but forgot. I'll bet there was 3/8" to 1/2" thick of accumulation around it on the front of the intake. Still this picture represents a decent starting point for my Saturday. I did struggle to get the throttle body off some. It was stuck good and I was being pretty soft with it....

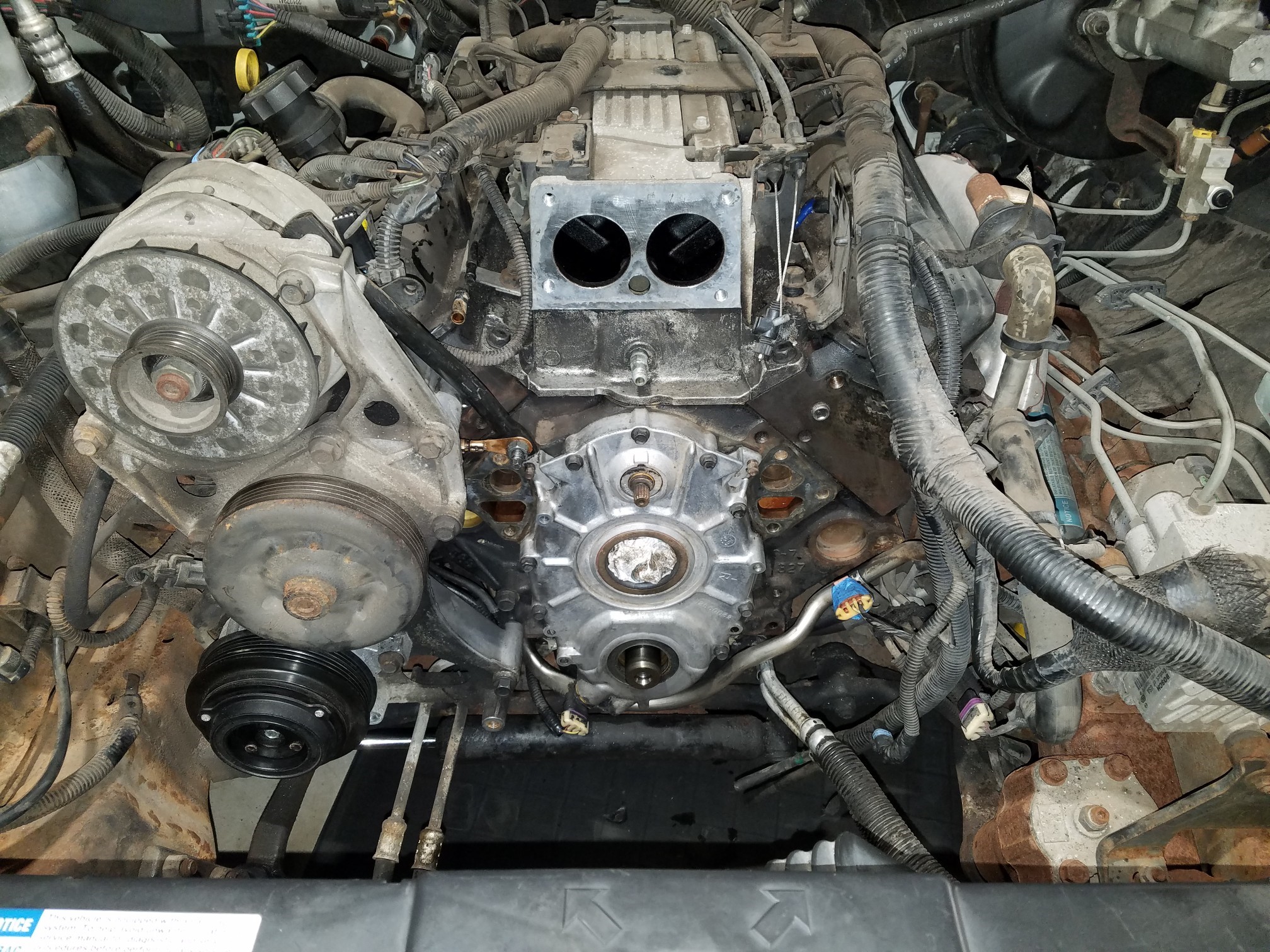

Finished product after a lot of cleaning and pulling the optispark and the balancer hub...

Certainly not perfect but much, much better. I'm satisfied with it for a driver. I can put the new plug wires on for the passenger bank without getting them filthy dirty now. Here's a look at what I used to pull the balancer hub. The bolt holes are 7/16 coarse but my balancer puller won't take bolts that big. I through bolted with Grade 8 3/8" bolts. I used about a 4" 1/4"-drive extension for the puller to push against since the hole in the balancer hub is the same size as the bolt hole in the crank. I didn't want to thread a longer bolt in there and push against the threads in the crank. Not my idea, just something I came across online....

I didn't get much done Sunday. I had chores to do (laundry, etc.) that morning. I wasted a lot of time running around to the four local auto parts store chains trying to find a solution on the rubber evap 90 and didn't come up with anything satisfactory. Also, I had ordered a new balancer hub earlier that week as I was concerned my hub would have a groove in it from the front seal. I thought it would be nicer to have a new hub rather than to put a seal saver on mine. The new hub came in Saturday while I was at the storage. Sunday, I figured out it wasn't going to work. The hub for my car is

B-body specific and is 96 year model (OBD II) specific. A new one appears to be unobtanium. Realizing this lead me to start the restoration of my hub late Sunday afternoon/early evening. First I cleaned up the nub that goes in the engine with carb spray and a brass wire brush. Then I wire brushed the rest of the hub with a regular steel brush to get any loose paint or rust. That got me to here.......

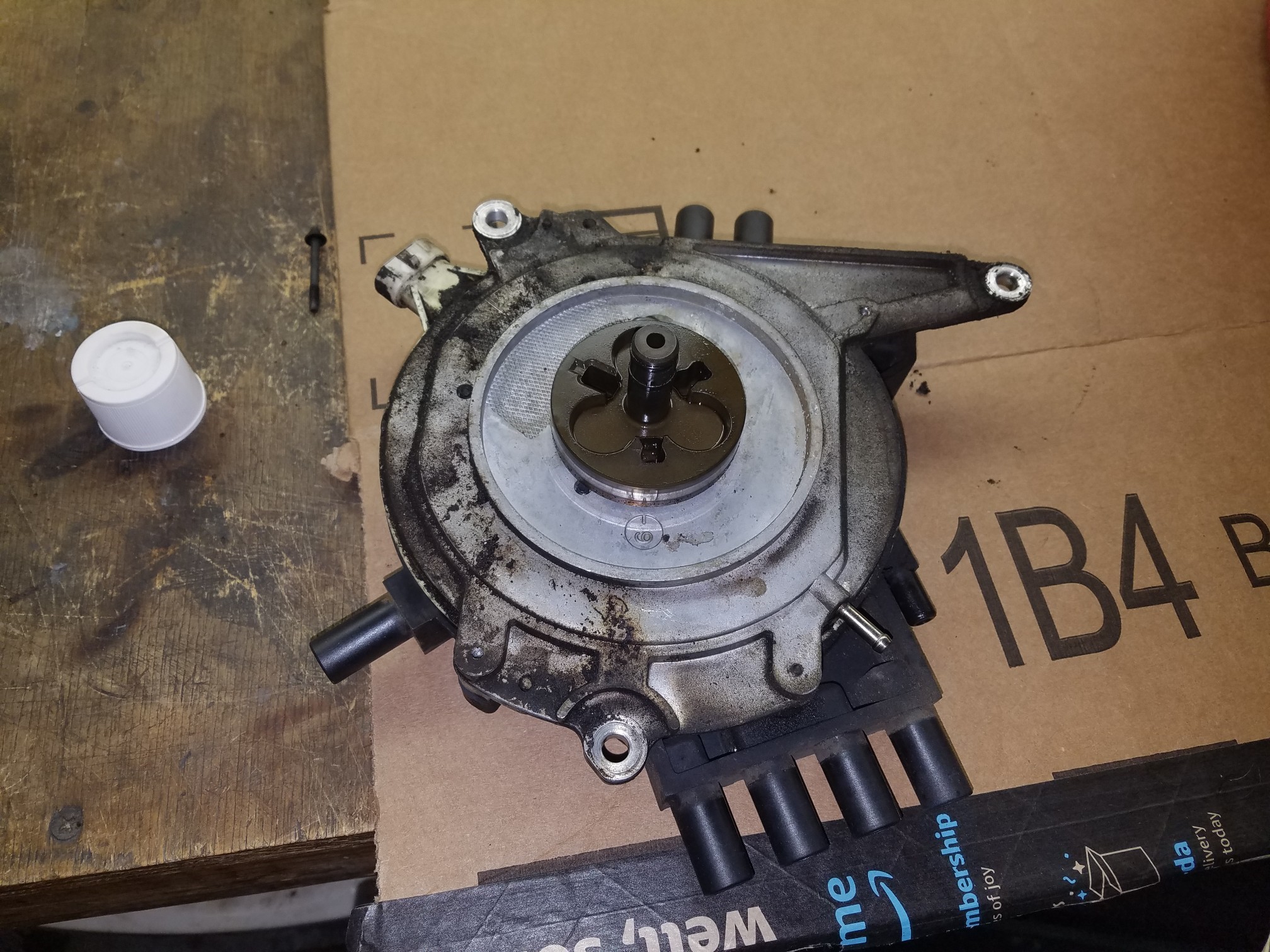

I couldn't feel the line that you see on the sealing surface with my fingernail but I was still concerned about it. Next, I went and bought a gallon of Evaporust. When I got back, I put the hub in a tupperware container full of it and called it a day. When I got home Monday after work, I decided to let the hub soak some more and to work on the optispark refresh. I started by putting the cap back on it and giving it a good cleanup. It was pretty dirty...

I cleaned it up with carb spray, a small nylon bristle brush (a little bigger than a toothbrush) and a microfiber cloth. Then I pulled the cap, the rotor and the "shield". Here is a look inside an Optispark for those who haven't seen one before.....

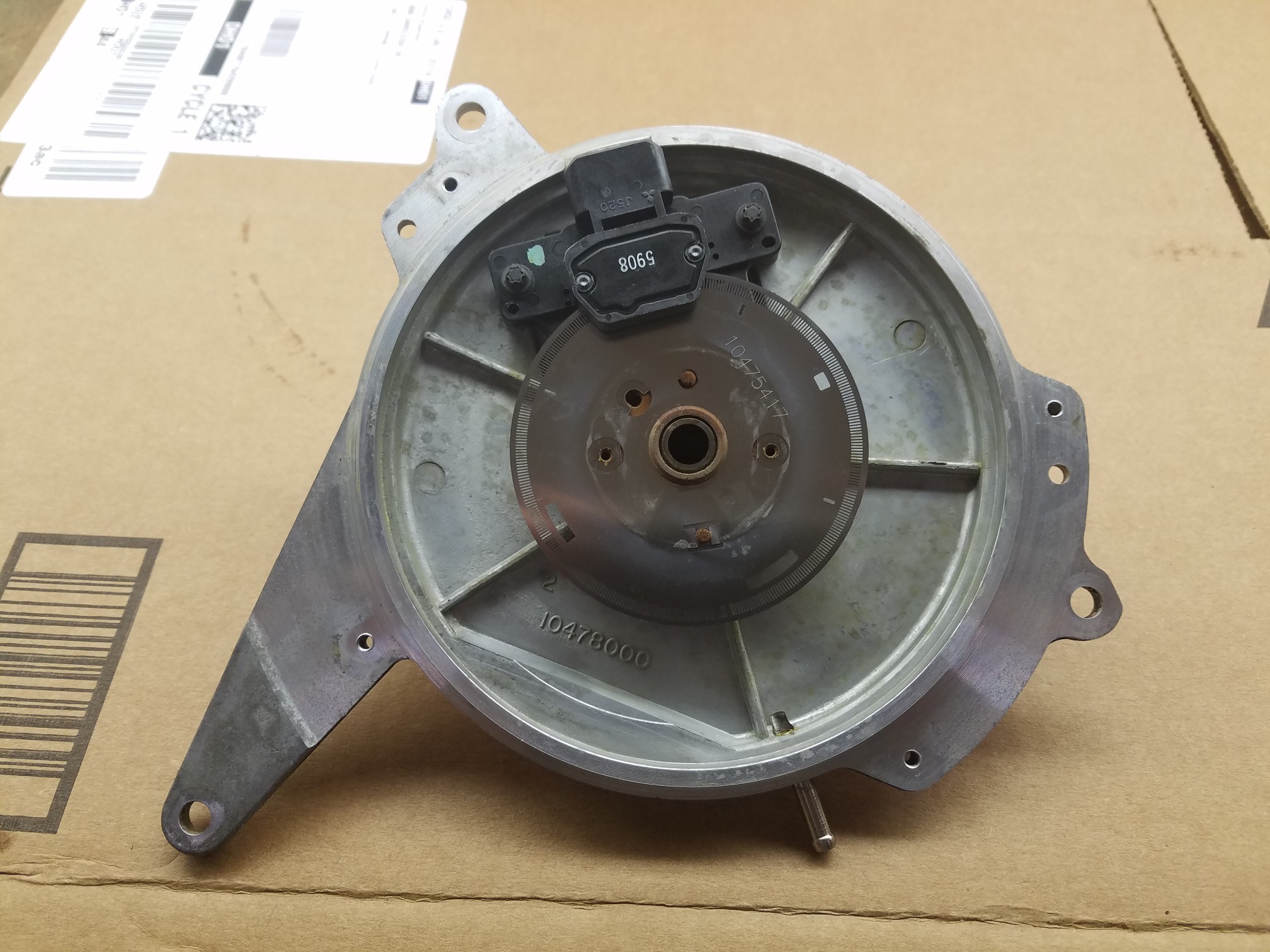

Here's the back....

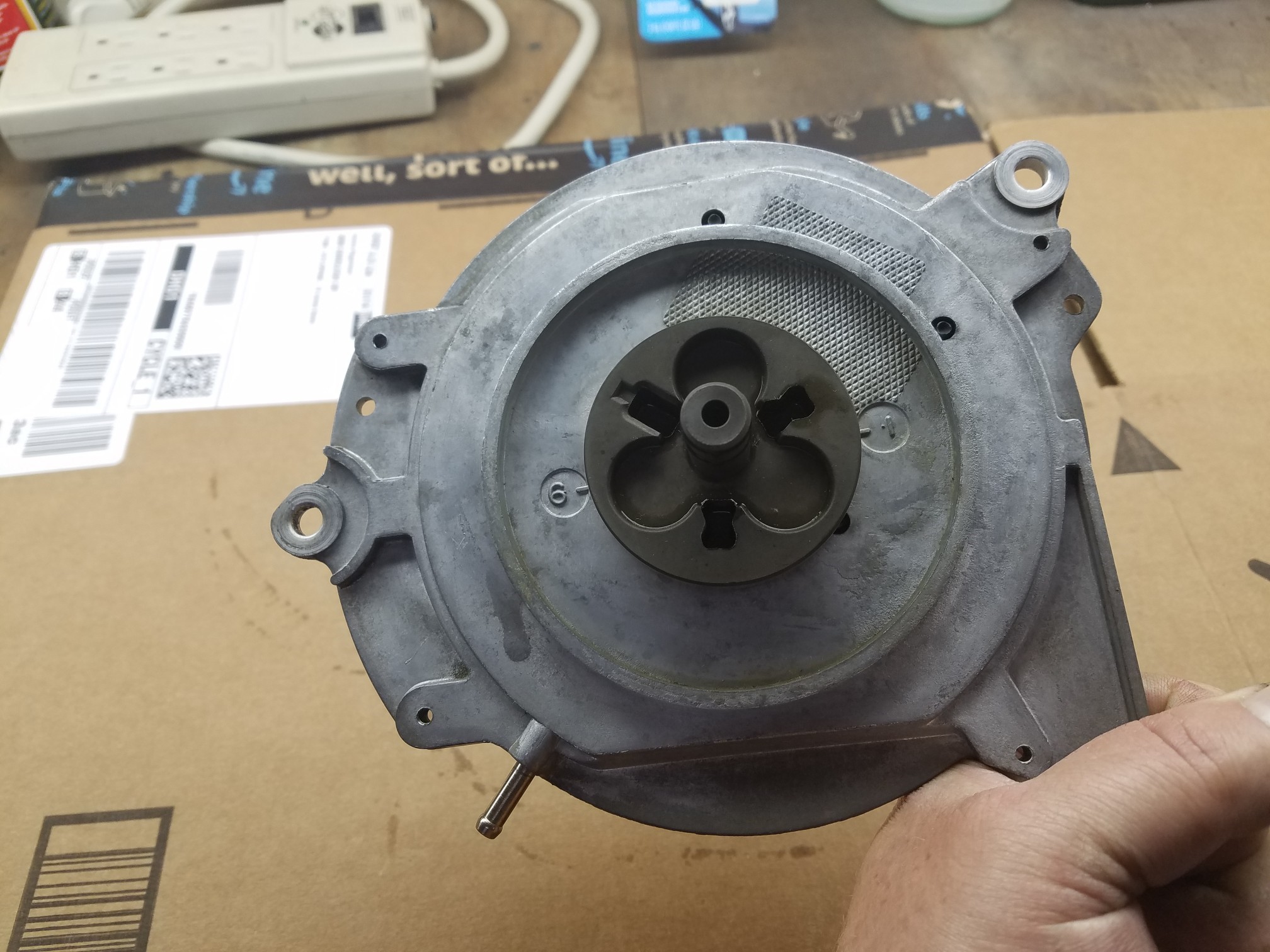

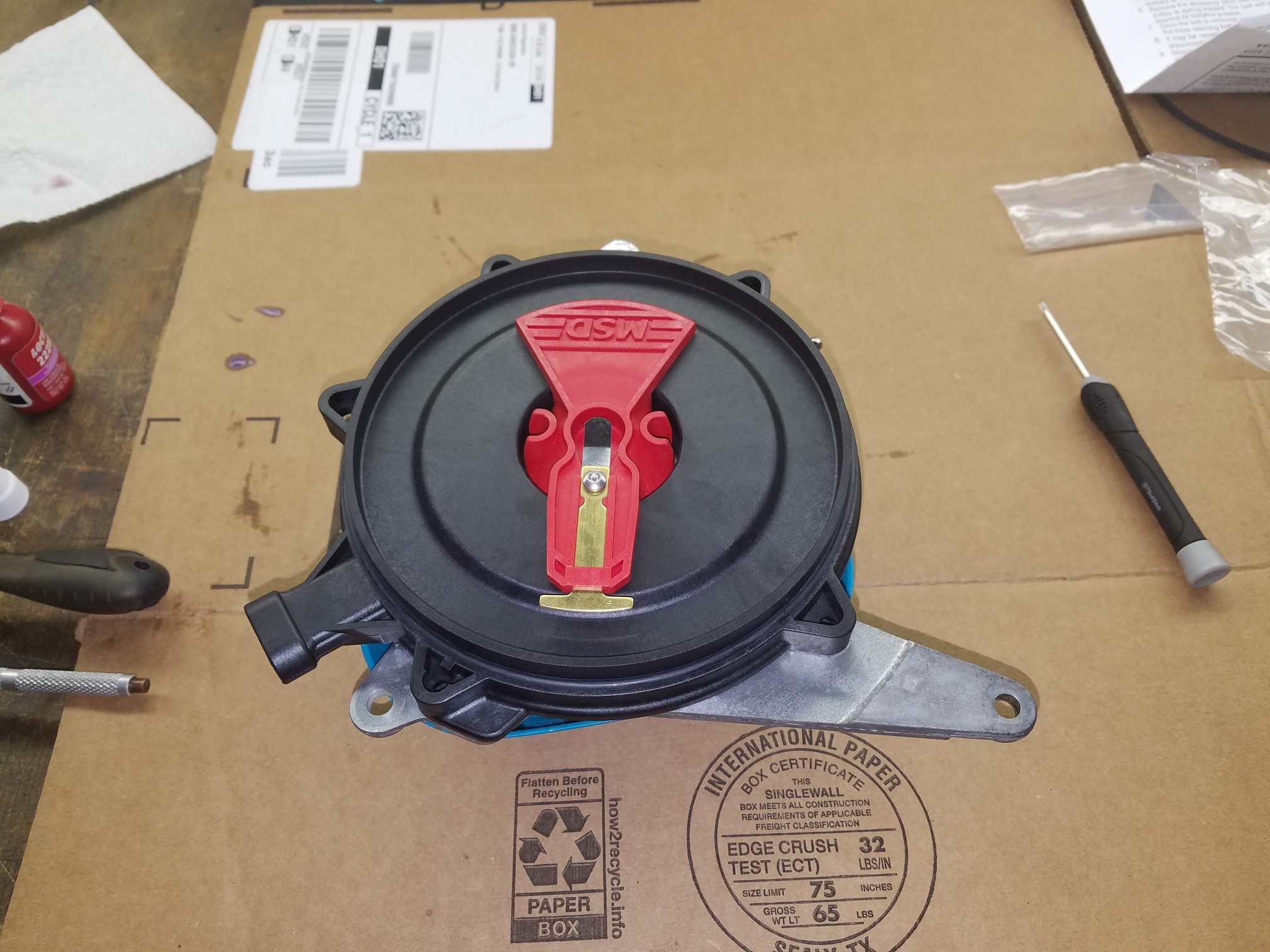

Then I went back together with the new shield, rotor, cap and seals I got from MSD...

I used the purple (low strength) Locktite on all the screws. MSD provides Phillips head screws for the rotor and the cap but I elected to use the original hardware, especially now that I have the tools for it. The one Phillips screw you see in the picture above is an additional screw that MSD added to their cap. they provide an aluminum block that the screw threads into and this provides additional clamping of the cap in that area. The stock cap doesn't have a fastener there at all. Here's a look at that aluminum block from the back....

When I initially tested the optispark to see if it would hold vacuum, it failed miserably. I was pretty disappointed since I was pretty proud of what I had done. Then I realized that the lead that plugs into the optical sensor seals that opening in the cap (weatherpak connector). Once I put my thumb over that opening, it held vacuum fine.

Tuesday, I had a Dr.'s appointment at 11:15 so I hung around the house. That morning I pulled the balancer hub out of the Evaporust and gave it a rinse in the sink. I was pretty happy with the results. I was still fretting about that line on the machined surface...…

I decided to try a red Scotchbrite pad on it and it polished it right off with ease! Enthused, I decided to tape the hub up and give it a coat of paint. I used VHT Engine Enamel. I was able to follow the instructions and do the two light coats and then one medium wet coat with both the primer and the paint. Then I went to my Dr. appointment and then on to work. When I got home, I un-taped it. The paint job turned out pretty good. A little shinier than I wanted but it will be fine.....

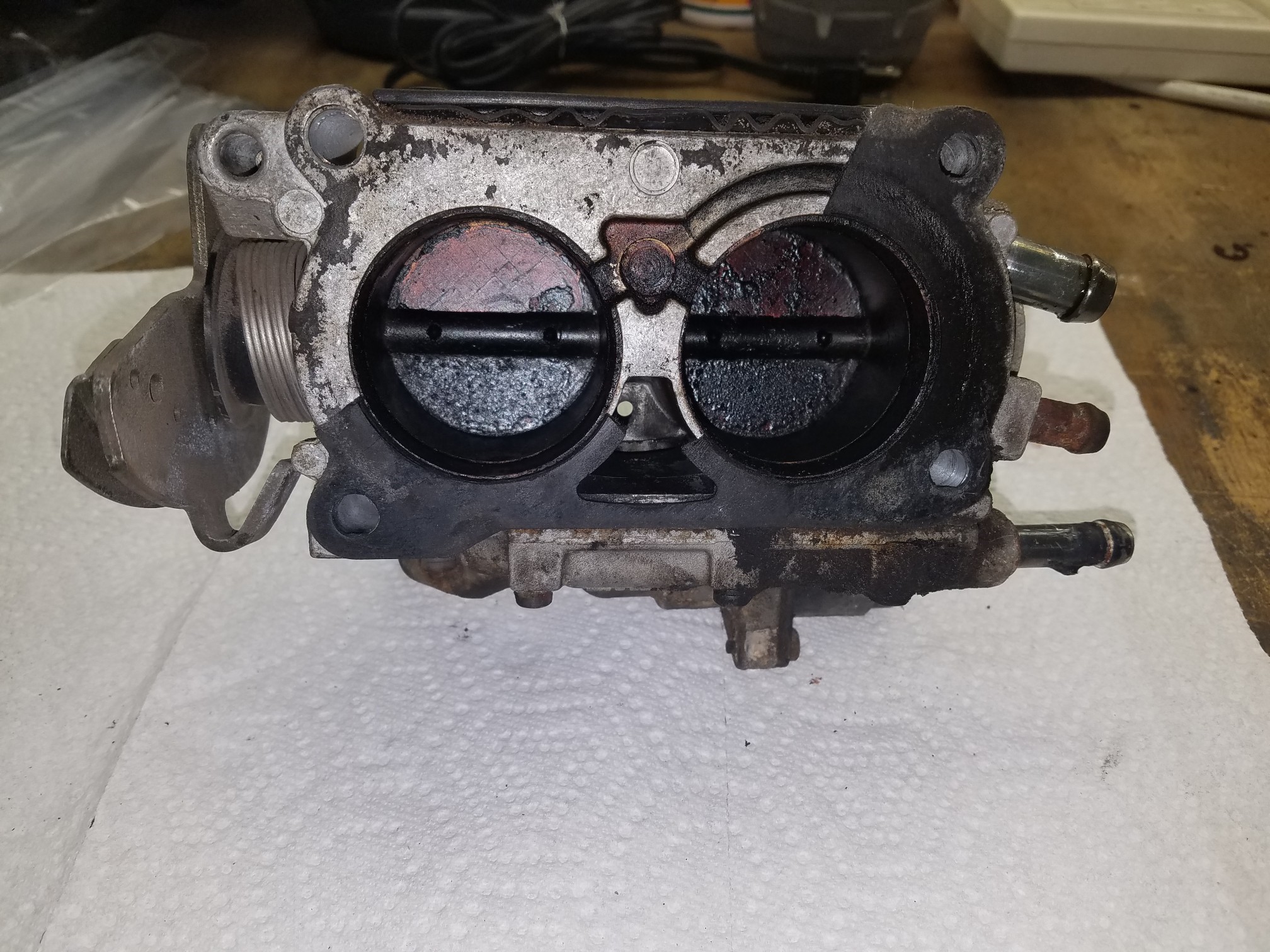

With the optispark and the hub done, I moved on to disassembling and cleaning up the throttle body. I don't think it's ever been cleaned...

Notice the wavy gravy gasket under the top cover in the picture above. More before pics...

Believe it or not, I spent 4-5 hours and two cans of carb spray cleaning that thing up. Don't worry, I pulled the TPS and the IAC first. I don't have pictures of the clean parts. By the time I finished up last night and cleaned up after myself (I've been doing these small projects at home) I was tired. At this point I'm waiting on new gaskets to put it back together.

That's it for now friends. I may have another update this week if I get the gaskets and get the throttle body back together. Saturday I plan to replace the three seals in the timing cover. Then, I'm going to replace the valve cover gaskets. The next project after that I think will be the plugs and wires. Then I'll start putting the front of the engine back together. Until then, thanks for following along and take care!

Best,

Jared