Swapped alternator. From pull, to driving to the store, coming home and installing, less than an hour... I enjoy working on old junk. Lol. Sure beats new junk.

What Did You Do To Your G-Body Today? [2021]

- Thread starter CopperNick

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Swapped in a brand new battery, put the other into my non-G Pinto project.

Started to dig into the RKE conversion.

Built a new-to-me Quadrajet for the coupe. Fingers crossed that this will make this car actually drivable without sweating bullets over where/how it's going to leave me walking.

I also may have figured out what is actiually wrong with the previous one by accident. I'll have to crack it open to check.

I also may have figured out what is actiually wrong with the previous one by accident. I'll have to crack it open to check.

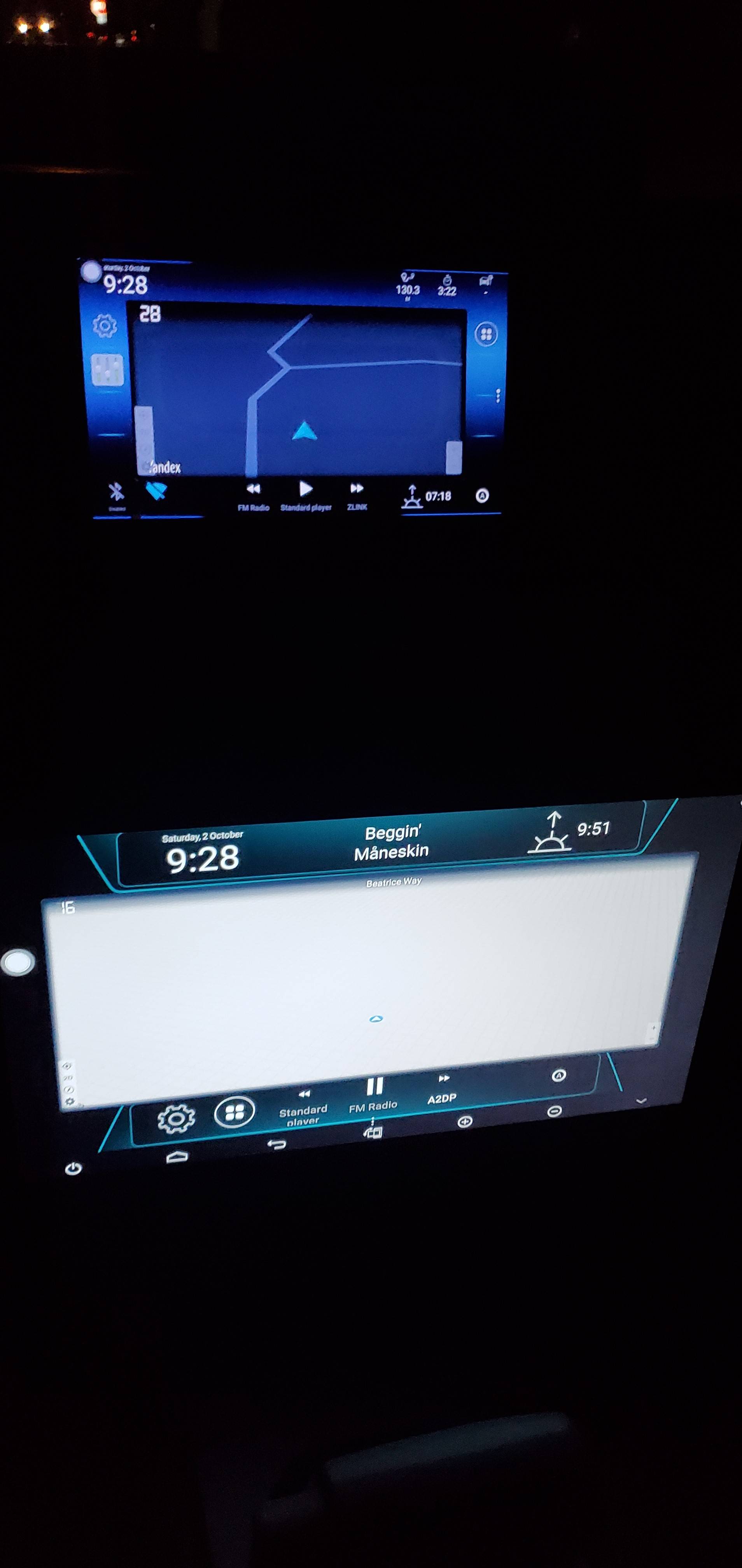

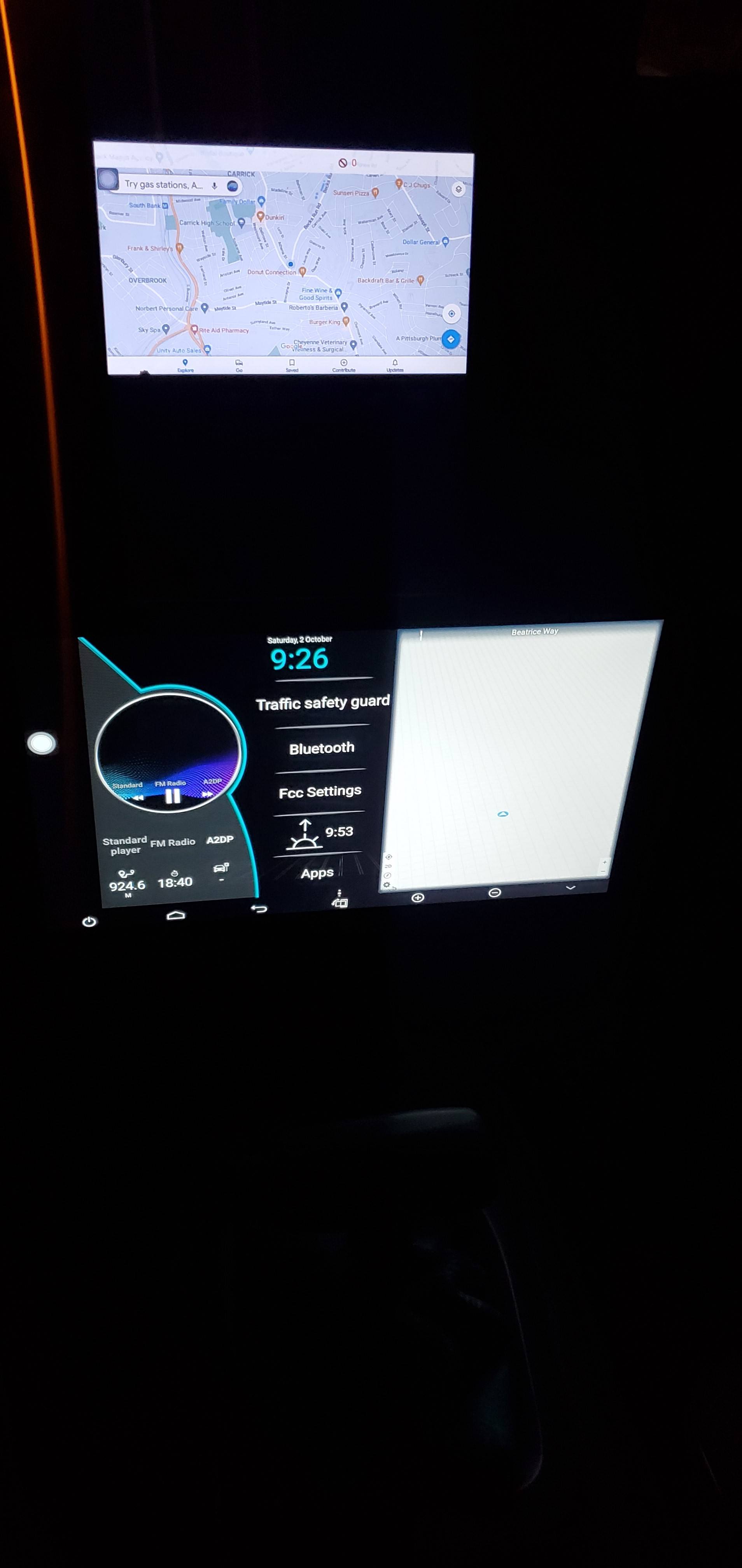

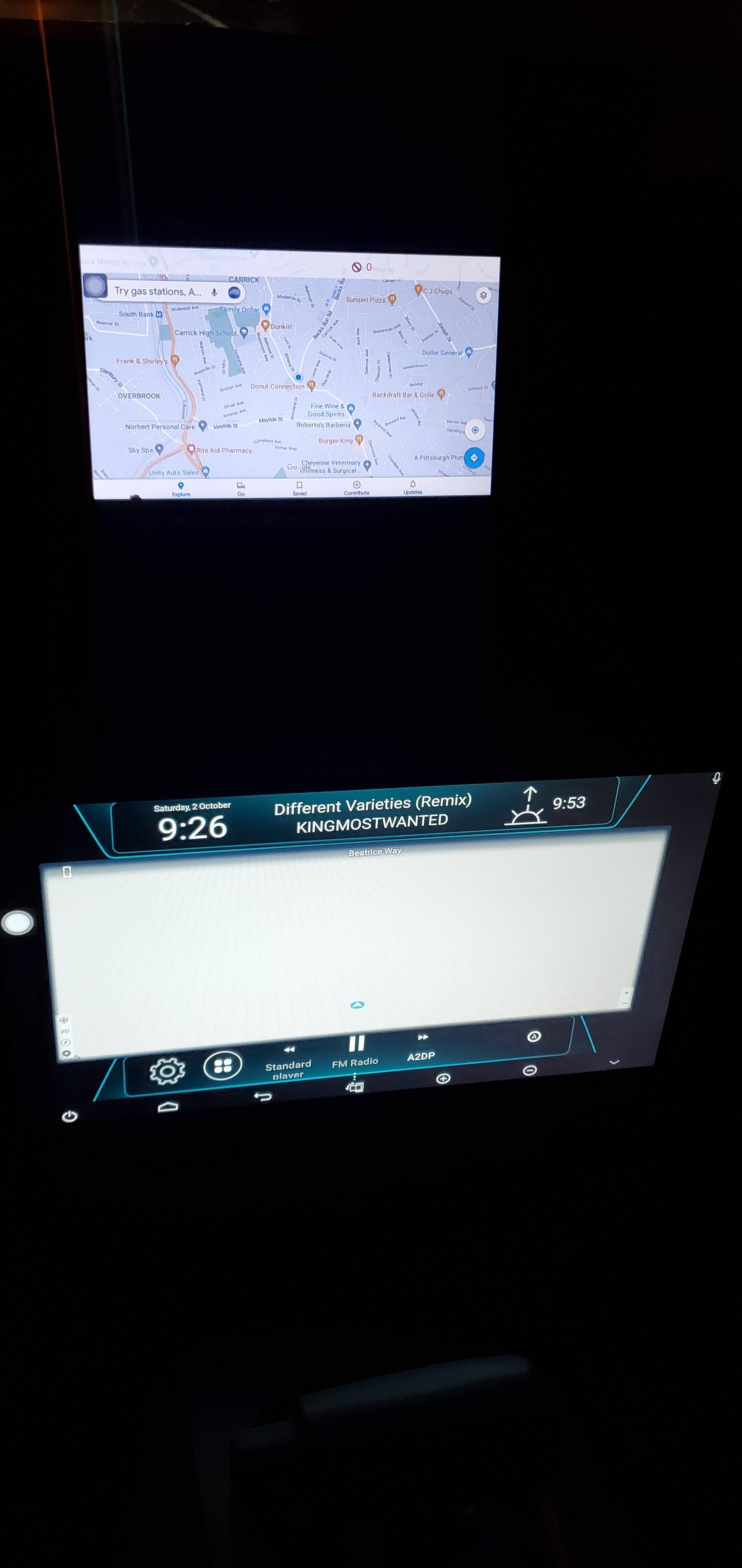

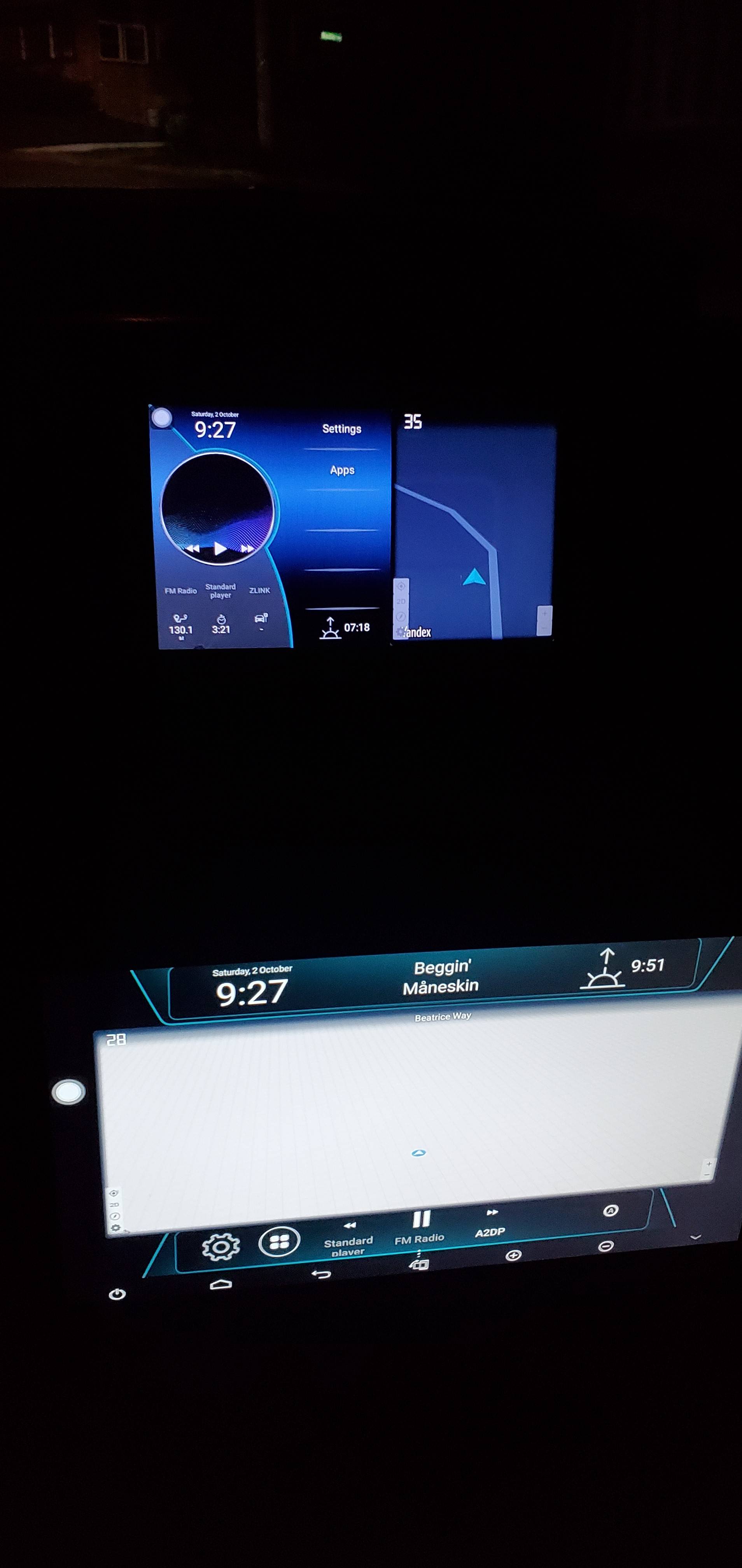

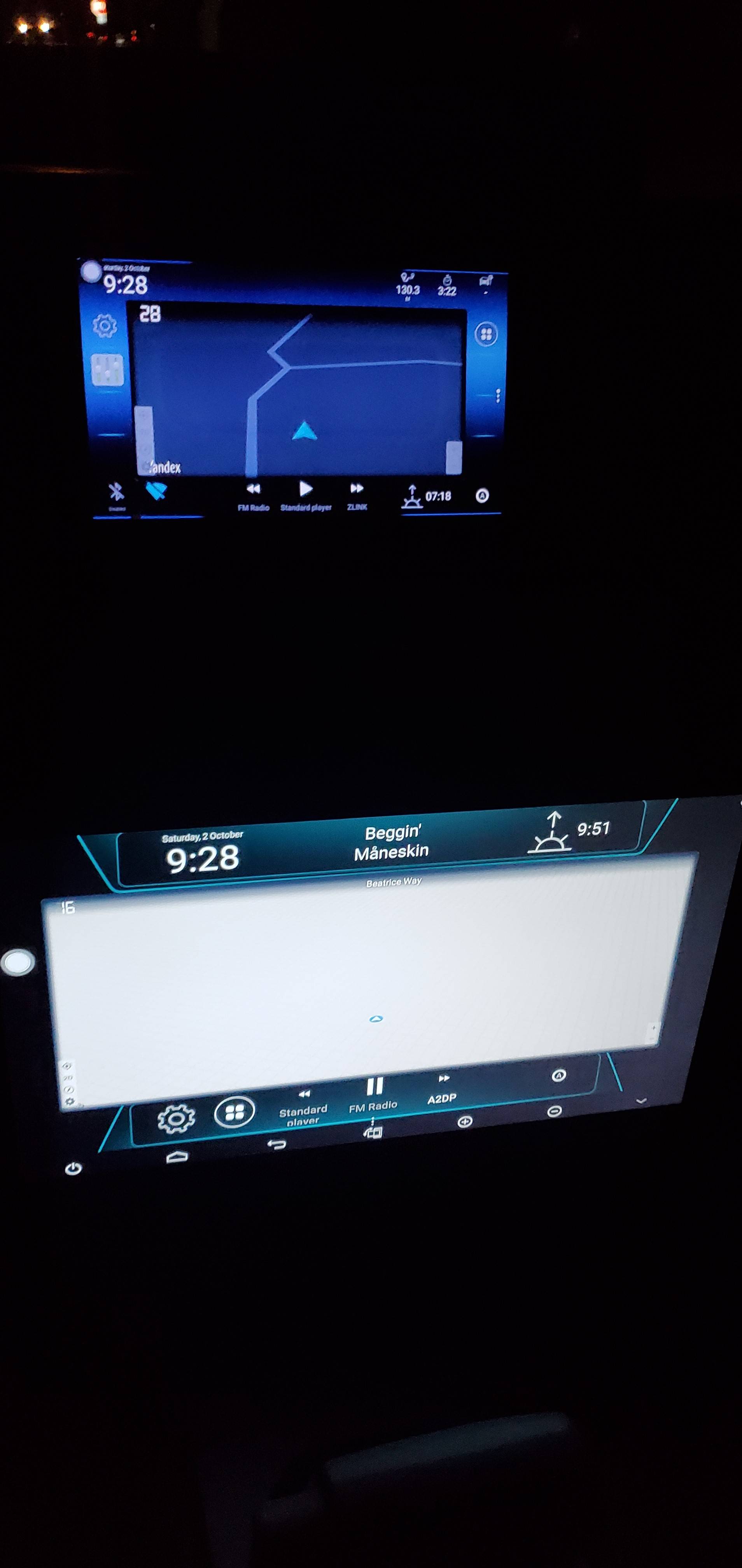

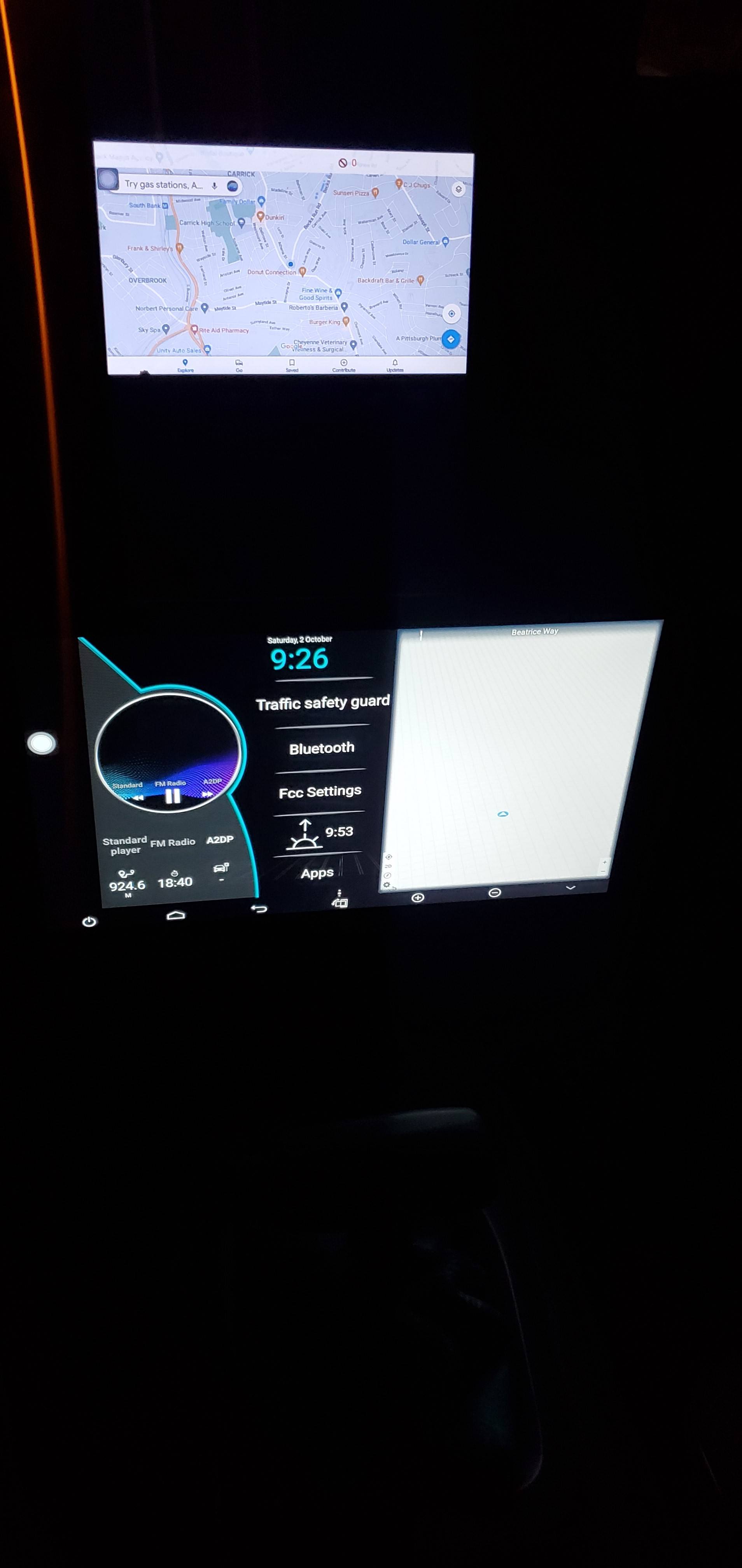

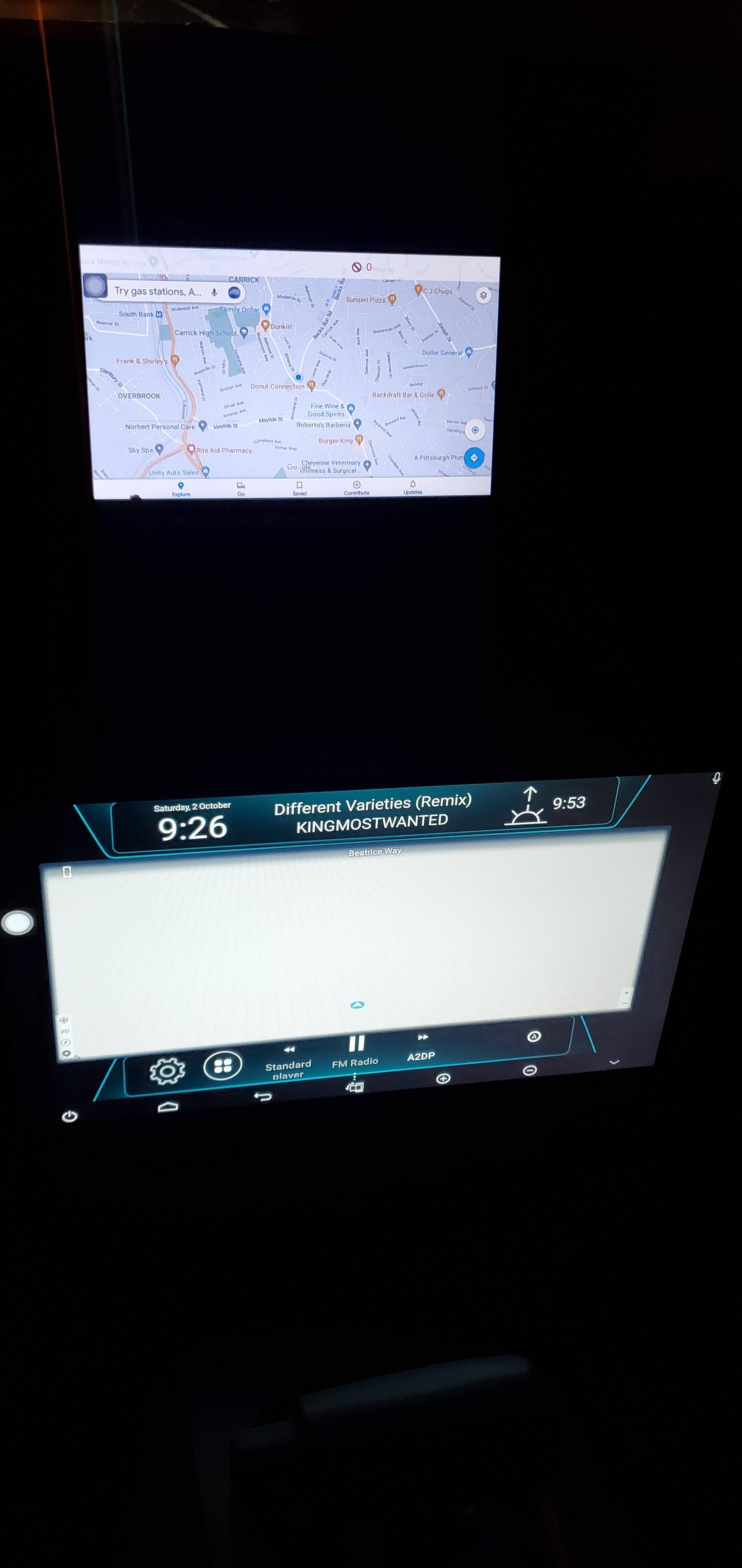

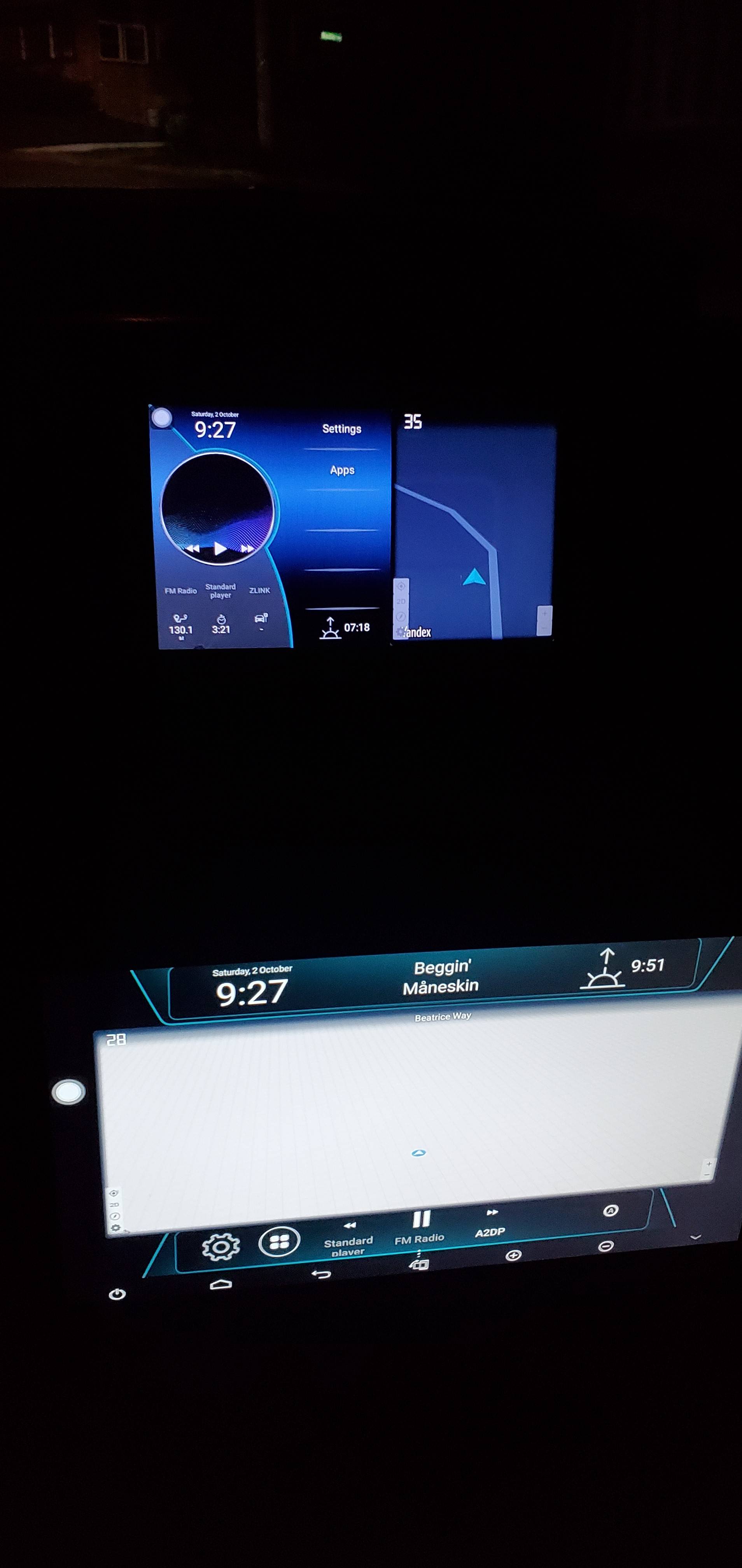

Continued to messed with the head units and still no luck......

Installed carb. Seems good, but this isn't my first rodeo. Probably take it to lunch the rest of the week before the big trip home. I hate walking, and I hate waiting for a ride just as much....especially if said car is in a remote area.

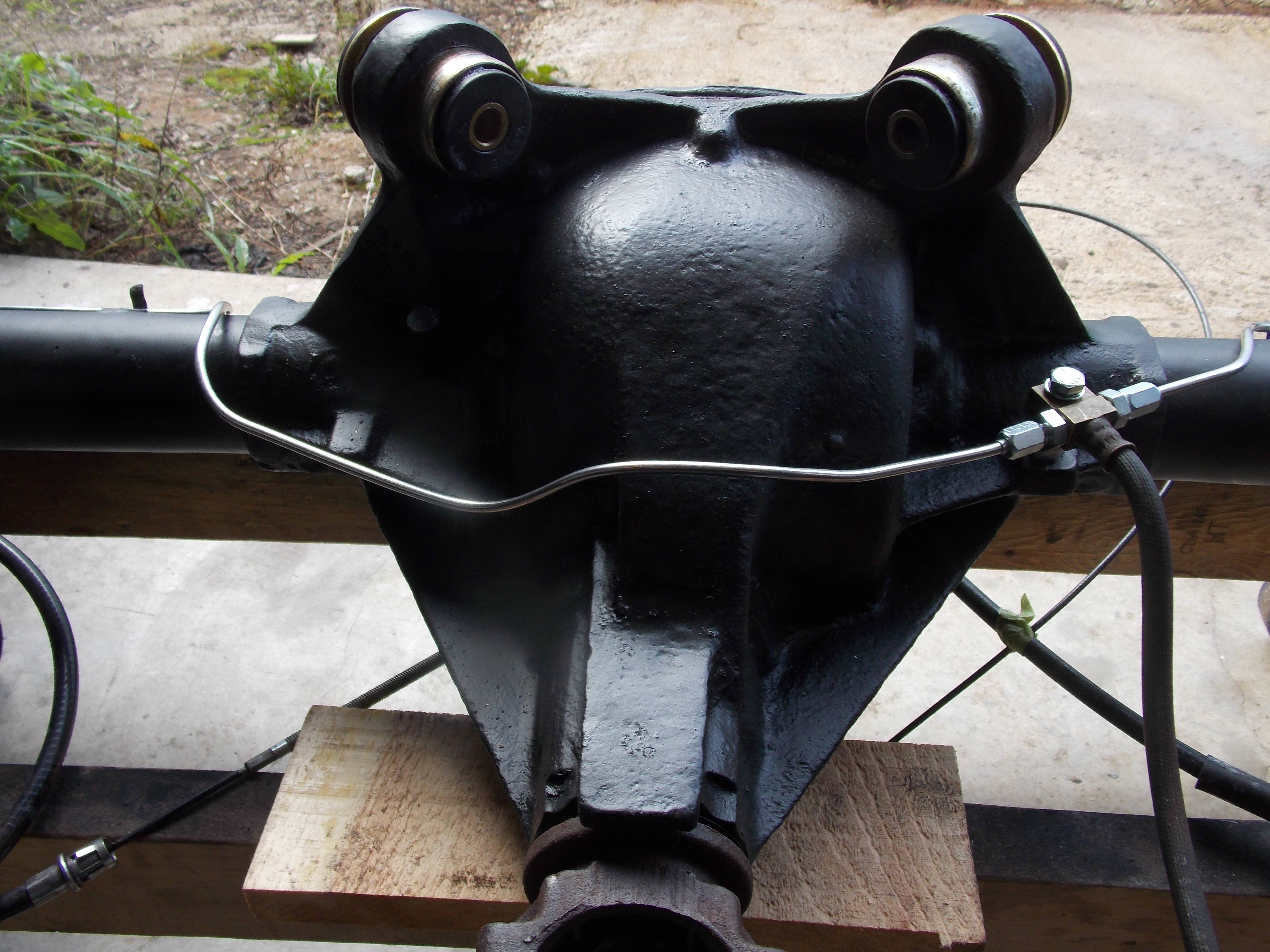

So yesterday became brake line day and here are some shots of what I created along that line. The first thing here is that these are not made of standard mild steel brake line tube, they are 3/16th inch Stainless Steel and were scratch built using bulk tube and matching fittings. Stainless has the virtue of being slightly easier to bend; but it will not take a tight curve or bend, can tend to kink instead. Stainless also cannot be double flared the way mild steel can and the flare itself is not a 45 degree, it is a 37 degree, aka an A-N style flare. All this means that special flaring tools are needed as a standard flaring block and screw won't produce the correct flare angle, unless you have enough experience to known how far to turn the screw and when to stop short. Can be done but the practice needed is expensive. Stainless tube, even in bulk, is not cheap, Eastwood makes a nice flaring tool that can be clamped into a bench vise and which has an accessory kit for doing A-N flares. Catch? $$$$$$.

For those on the site and in the various forums and boards who have gone with stainless before, you already know the process and the use of the supporting ferrule and gland nut to make the connection with the A-N x invert flare adapter that gets fitted into the wheel cylinders and the splitter/distribution block. There is a slightly more detailed description of it all posted over on the construction pages under "Project Regress".

Essentially, what I attempted to create were replicas of the old mild steel lines in that the new ones follow the paths that the old ones used. The sharp eyed will notice deviations, particularly in the shape of the new lines as they bend to both conform wiith the diff casting and approach the splitter. There are pictures posted earlier of what I did to adapt the location of the splitter to make it easier to bring the lines to it and attach them.

For anyone thinking this was all a waste of energy and time, maybe,, but the paremeters for what I had planned to create never included beauty, it was all about the durability and longevity. In terms of end result, the complete brake line system in my Monte is entirely made of Stainless Steel, 3/1ths and 1/4 inch dia as and where needed, all the way from the master cylinder to the rear wheel cylinders. None of it was store made and it possesses its own matching stainless fittings, ferrules and gland nuts and invert adapters. Sure i could have gone to Inline Tube or one of its competitors and paid their price for their product but, by doing it myself, I am the author of any problems or false starts and returns of parts and components becomes as simple as throwing them at the scrap bin or onto a shelf to gather dust; no repackaging or authorization numbers or customs duty or shipping fees necessary. There is also the personal aspect involved when someone peeks and sees what you have done and asks who made it and you get to say, "I did". Which is an awful lot of this this site and its boards and forums are all about.

Oh, yeah, on another aspect of this project that has been both ongoing and stalled for some time now.....I GOT MY DOOR SKIN, I GOT MY DOOR SKIN, I GOT MY DOOR SKIN, I GOT MY DOOR SKIN!!!!

Was at the yard to settle up on some other parts that I had scored and in the door it came, all brand new and pretty and packed in its heavy cardboard carton and not a blemish or nick on it ('Cause Junior opened the box right in front of me to take a peek!)

So now I get to be a bodyman......HEE, HEE, HEE, HEE, HEE, HEE ,HEE, HEE, HEE.....................................

Nick

It appears that you don't have a map set installed for the location you are in. It is normally installed on the units SD card, but it can vary widely from model to model.Continued to messed with the head units and still no luck......

View attachment 184977View attachment 184978View attachment 184979View attachment 184980

I'm so torn between adding some kind of double din style screen or just a bluetouch radio-less amp.Continued to messed with the head units and still no luck......

I like the fact that I can have apple carplay and gps and such but also the simplicity of not having anything to have the clean looks.

I've also been looking into the rear view mirrors that have a built in dash cam and rear view cam with a built in screen, they add to the clean look.

Although I love the nice screens like your setup.

- Status

- Not open for further replies.

Similar threads

- Replies

- 244

- Views

- 11K

- Replies

- 347

- Views

- 18K

- Replies

- 101

- Views

- 4K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.