Just a quick peek in the box that holds my brand spanking new Monte Carlo driver's door skin. These panels just by themselves are almost every bit of 6 feet long.

Tried for a detail shot here with mixed results but the intent was to show that the perimeter flanging for both sides and the bottom edge has already been measured and initially creased. No guess work as to how to locate the skin against the inner frame/skin/shell/aka ??. Apparently the secret here is to use a leather faced or dead blow hammer so as to not mar or dent the skin as the edge is being hammered over.

The carton says it all. A genuine Goodmark product, which was what I had hoped to get,

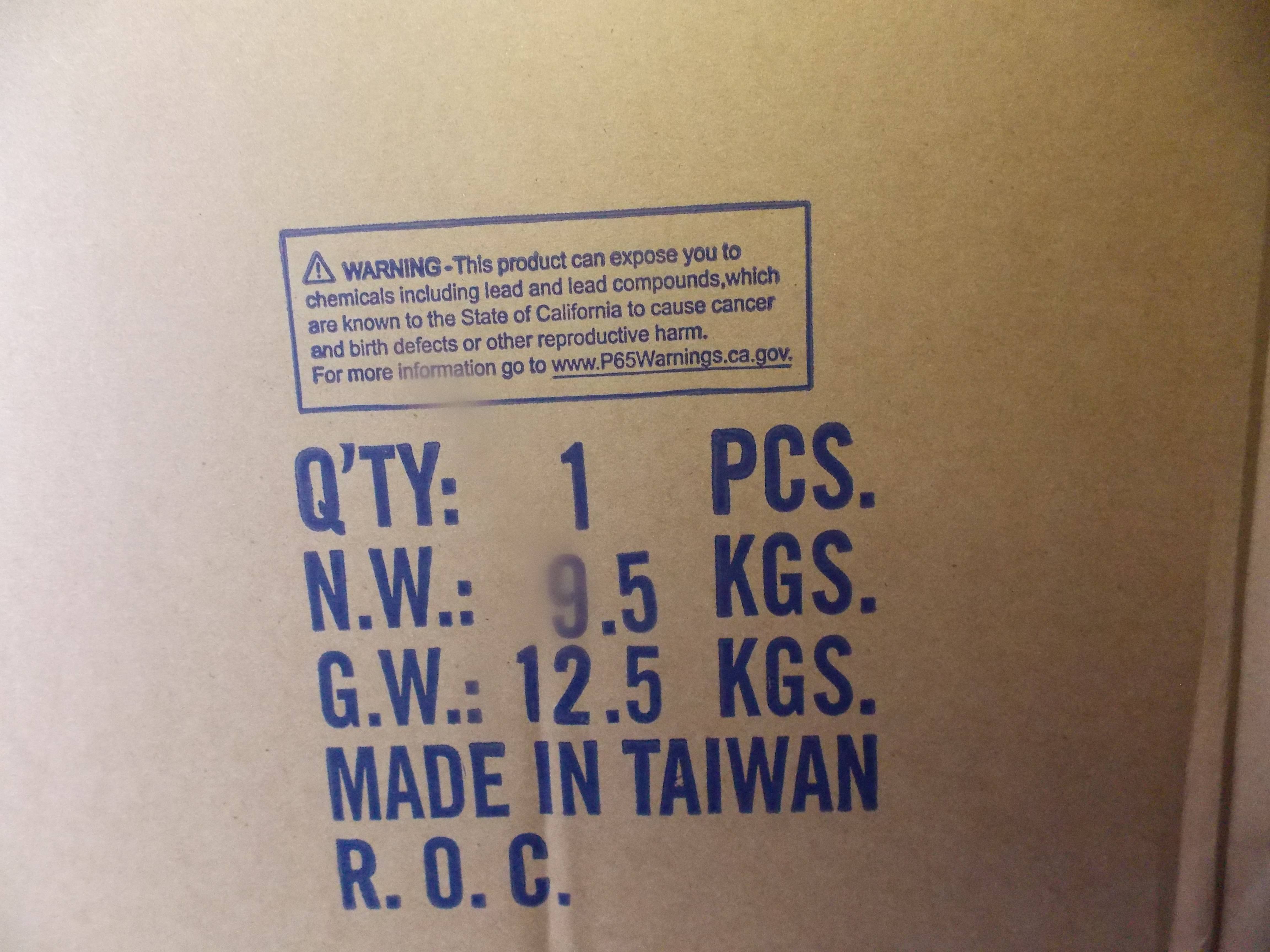

This is a shot of the packing details. Things like the net and gross weight of the box are bits of information that the couriers need but the big ticket item is the location of production.

"Made in Taiwan, REPUBLIC of CHINA". Not across the Formosa Strait in Pee-Roc land, but from a nation that the UN disowned over 50 years ago, and which is now one of the leading producers and manufacturers of VHT (very high tech) components found in service all over the world. This is by no means a plug but if I can't get a product made in Canada, or the USA, having it come from Taiwan disturbs me not in the least.

Actually the source kind of explains why the prolonged lead time to delivery, not that the pandemic helped any.

(Side Bar Here; Taiwan, currently, is suffering from a prolonged drought. Nothing new in many places but they are also the leading manufacturer of the chips that go into the present generation ECU's found in a substantial number of vehicles all over the world. For the chip making process, a large steady supply of clean water is needed; part of the various stages of manufacture to keep the product clean and sterile. No recycled water allowed.)

So, for this panel to get to me, it had to be made, packaged, loaded into a container, the container put on a ship, the ship had to avoid the "mainland pirates" and successfully reach the Port of Vancouver, where the container would have been offloaded, sent through customs, the contents sorted at the receiving terminal and rerouted to wherever in the country. BUT TWO YEARS?!?!

So for anyone out there waiting on a large ticket item, (like a door skin?) do be prepared for the long wait. There actually was a news item aired today about the ports at Long Beach and Los Angeles and the problems they are having with their receiving schedules. The port press rep commented that they had something like between 100-160 container ships waiting out in the approach for permission to enter the ports for unloading. About a week delay or more. The problem? No truck drivers to move the short haul donkeys that receive the containers being offloaded from the holds by the cranes. The scheduled turn around for a container ship from full to empty and back again is about a day or less. Right now, just for the unloading, it is days, plural.

All of which means that if you want a christmas tree and things to put under it you had better order yesterday because finding stock on the shelves for your christmas shopping is anything but guaranteed this year.

Me, I think I just got my Christmas present a little early this year; so I put it back in its box and taped it closed. I can wait, and it is the perfect excuse to take my shop tree out of its carton and put it up this year. (Didn't happen last year.)

Doesn't stop me from skinning out the old door and making any repairs to the inner skin that have to occur.

Nick