So, because I hadn't beat myself up sufficiently enough while stripping the first part of the S-10 frame, I decided to add insult to injury by taking a run at the old door skin on driver's door of my Monte.

This door has been dismounted and strapped to a wheeler for so long I can't remember how long. Being mobile, though, let me roll it outside to take advantage of today's lull in the wet and woolly that we have been getting this weekend.

The front edge of the skin where it had been folded over to trap the inner skin/shell broke away fairly easily. As suggested by Ribbed Roof, I went mechanical but elected to fly a 120 gr in my 4.5 to make the material removal as least invasive as possible. Lots of very gentle passes made until just the shadow of the seam started to show and then stop. I also chose to lay the wheel in at an angle that took more from the outer skin and left the inner as unmolested as possible.. Seemed to result in what I was looking for.

On the way from A to B, I found that GM had out done itself in how it had attached the leading edge of the skin to the shell. Not only did they use tack welds but there were actually either 3, or possibly 4, ( one gone mia due to rust in the lower corner) of them!!! Looked to be the kind that get made by one of those two fingered long reach fusion welders. Also found that the edge of the inner shell fell short of actually fitting tightly into the fold-over of the skin at the edge; about a 1/4 inch of just outer skin with the barest amount of it actually trapping the inner skin/shell. That I will have to measure and transfer to the new skin because it may have a bearing on how the new skin is to be placed and located when the time comes.

The lower seam was entirely another matter. This door had come with the car and when I subsequently surveyed it was found to suffered a major delamination of the outer skin and the inner skin along the bottom seam. Succinctly total rust out. At the time what I had had to do was fabricate two sections of angles from body metal and set them in place to replicate the lost sill almost from end to end. Back then my engine of choice was my Lincoln 180 but it had been set up for Flux core due to most of my work being done outside in the environment (No garage or even the thought of one back then) and, even at its lowest settings, 18/19 body metal was marginal for thickness that could tolerate the heat and the metals being joined had to be eat off it clean, which most of that door was anything but.

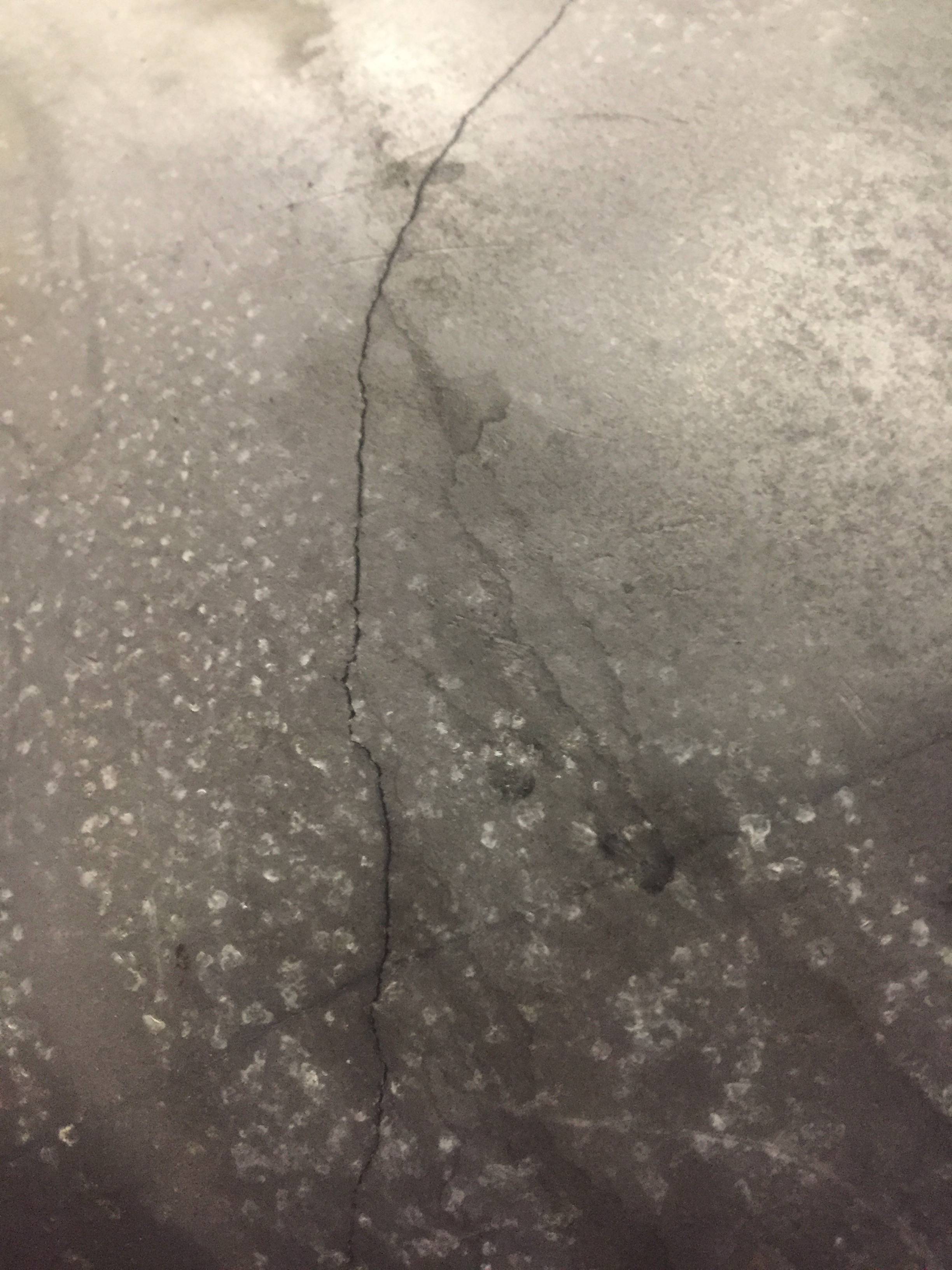

I did get as far as getting it all closed up but the bottom seam ended up having to have a series of multiple light tacks and short shots run along its edge to build it all up to get back to a close match to the cabin sill. About that time I had decided to go ahead and strip the outer skin to bare metal so i could start prepping it for any filler or hammer and dollly work needed and get it into primer. That was when I discovered all the damage to the lower "sponson" or whatever it is actually called, and that discovery put an end to rehabbing that door as it was.

Today, in order to peel that skin, I had to revisit all that weld I had laid to build up that edge. I did not want to just grind it all away as I knew that if I were to do that, in all likelihood I would end up having to put some of it back so what ended up having to happen was that I carefully ground away the skin itself and avoided touching the "seam", then used a wide bladed scraper and a body hammer to "persuade" the two panels to part company. Grind a little, tap on the side edge of the blade a little, lather, rinse, repeat.

All this leaves me with just the back edge to split along with about 3-4 inches of the remaining lower seam where it meets up with the back bottom corner. That too is a rotten area so will require metal to be shaped and set in place.

And more frame stripping is still on the agenda.

Nick