What Did You Do To Your G-Body Today? [2021]

- Thread starter CopperNick

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Between inventory rotation; bringing the van in and putting the S-10 back into the front driveway, I took a 1/2 hour and used it to cut away the rear lower corner of the inner door shell for the driver's side of the Monte. While it was solid and could have been left, it was also an expedient patch job that I had jimmied into place sometime around a decade or more ago to provide a base for hanging filler or an outer skin patch later. Nebba happened.

if I am going to install the new skin properly and correctly the inner skin or shell has to be correct also or the two won't line up and look right. The next step is to go digging around in the panel leftovers and find a piece that can be shaped and trimmed to be the replacement. May end up doing it in two sections because the corner, as originally created, was a stamped shape that got formed when the inner skin was pressed into existence.

Nick

if I am going to install the new skin properly and correctly the inner skin or shell has to be correct also or the two won't line up and look right. The next step is to go digging around in the panel leftovers and find a piece that can be shaped and trimmed to be the replacement. May end up doing it in two sections because the corner, as originally created, was a stamped shape that got formed when the inner skin was pressed into existence.

Nick

Finally pulled my steering column apart in the Regal to replace both canceling springs for my turn signals, I should be able to drive now without having to remember to turn off my left signal.

Shuffled a number of items around to gain some empty floor space in anticipation of winter. Picked up a body panel stand last week and and put it together this afternoon. Removed the driver's door inner shell/skin assembly for my Monte Carlo from the two wheeler that it had been cargo strapped to for ???? years and transferred it over to the stand. This stand can be adjusted for height to get me a comfortable position for welding and dressing welds. Had to move the 5.3 over to beside the transmission trolley and pull the Miller over in front of the van to have access to it.

The next step will be to pull a couple of welding blankets out of storage and drape them over various places to protect various other toys and components. May pull a couple of the enclosure panels out from behind and set them up to create a dedicated "room" that will isolate the door skin from the outside and limit the amount of dust and flying debris that tends to drift and land on things.

No timetable for getting this ready to fly; if it stays warm I might get to do some work on Christmas Day!! Beats the alternative: I don't do Veg out all that well and X-mas week is a total shutter at work.

Nick

The next step will be to pull a couple of welding blankets out of storage and drape them over various places to protect various other toys and components. May pull a couple of the enclosure panels out from behind and set them up to create a dedicated "room" that will isolate the door skin from the outside and limit the amount of dust and flying debris that tends to drift and land on things.

No timetable for getting this ready to fly; if it stays warm I might get to do some work on Christmas Day!! Beats the alternative: I don't do Veg out all that well and X-mas week is a total shutter at work.

Nick

Just little stuff on the Regal, I bought a new black turn signal/wiper lever from Amazon for $11 and also installed the black tilt lever off my SS column.

Last edited:

Having all that fun and then some on my 81’ El Camino build. Going from auto to 5 spd. Rebuilding the steering column at moment, a new and frustrating learning experience as it’s out of a 86’ g body.So I finally managed to complete the exhaust system for my 85SS on the last day of last year. (Pictures yet to come) I am toying with an idea to add an additional set of hangers at some point along the pipes to take some of the weight and stress off the bell connections at the header reducers.

Today turned out to be back to the brakes day. Specifically back to the back brakes to remove the old cables for the hand/emergency brake and replace them with new ones so that I can re-assemble that system again. May also be looking at new shoes as the leading shoe on the driver's side seems to be showing more material consumed than the trailing shoe. As it is supposed to be the trailing shoe that hits the drum first, this is odd but not uncommon for me to discover. Elected to drop everything out as far as the bare backing plate, give it a good wire brushing, knock off most of the rusticle infestations that seem to form anywhere water and heat are present and expend some effort to apply a good coat of basic black enamel paint. That will dry over night and give me a good starting point for the re-assembly.

Part B of this exercise is to expose the passenger's side and dig into its brakes, lather, rinse, repeat.

For the amount of times that I actually use the hand/emergency brake, I probably could have left the whole business unaddressed. The only reason that it is the way it is, is that I removed the cable from the pedal to the connector clip to get room to replace the floor pan and modify the fuse block to gain swing room for the third pedal.

For those who have never been up close and personal with the firewall fuse block it essentially consists of a central core on which the fuses are located and has perimeter attachments that carry other necessary items. These perimeter sub-blocks can actually be re-clocked in terms of where they attach to the central body as all its edges carry the same tongue and groove hooks that are matched by those on the outriders. Simply and gently remove the sub-block from where it is and move it to the side on which you want it to be and snap it into place; just make sure that any wires attached to it have enough slack in them to allow the shift in location to occur and that the new configuration can be attached back onto the firewall without wrecking on anything else immediately adjacent. (No. I did not take pictures of all this. Could do it with a salvaged harness and block assembly that I have in one of the super totes but teaching and lectures do not come easily to me so...…….)

Nick

Keep up the good work!

CHANGED OUT THE 3" STUDS FOR 2" STUDS ON THE FRONT HUBS. AND BOUGHT THE PAINT FOR THE CALIPERS GOT CALIPER REBUILD SEAL KITS IN EARLIER THIS WEEK .. SO LIL PAINT AND BAKE ACTION THEN NEW SEALS . THEN NEXT IS BRAKE LINES

So these are a couple of shots of what the enclosure walls for my work station look like. The frames were created from 2 x2 x 8's and 3/8ths thick squares of plywood for corner re-enforcing brackets, all held together with deck screws. Originally these were the end panels and there was a center panel about the same length overall as these two put together. it still exists; just way too long to extract out of its resting place. All of them had heavy 6-8 mil poly-plastic sheeting stapled to them as cover material. The original intent was to have them, when assembled, form a three sided booth that could function as a spray booth for small parts and assemblies. Worked okay for that purpose but awkward to assemble due to shear physical size.

At some point my mind went into lightbulb mode and it occurred to me that these panels could also be employed to create a welding booth. The only modification that needed to occur was to add drapes that were proof against flying debris and weld spatter so, for the drapes, I scored a couple of welding blankets and used screw in "L" hooks to attach them to the upper rails. For storage the blankets can be folded in half horizontally and the lower grommets hooked onto the hooks.

The Monte Carlo's inner door skin/shell, now comfortably resting on a panel stand. For a rough and ready bench for the tools, I took a piece of particle board and slipped it partially under the shell, leaving enough width to act as a shelf. The stand itself can be adjusted for height by shortening or lengthening out the chains.

Just a progress shot of how far I have moved along in replacing the lower corner of the shell flange that faces the door latch pillar. It is sort of blurry and there are still a lot of welds to dress and smooth out. The scribe marks are there to show what has to be cut away to get the various widths of flange to match the existing exposures.

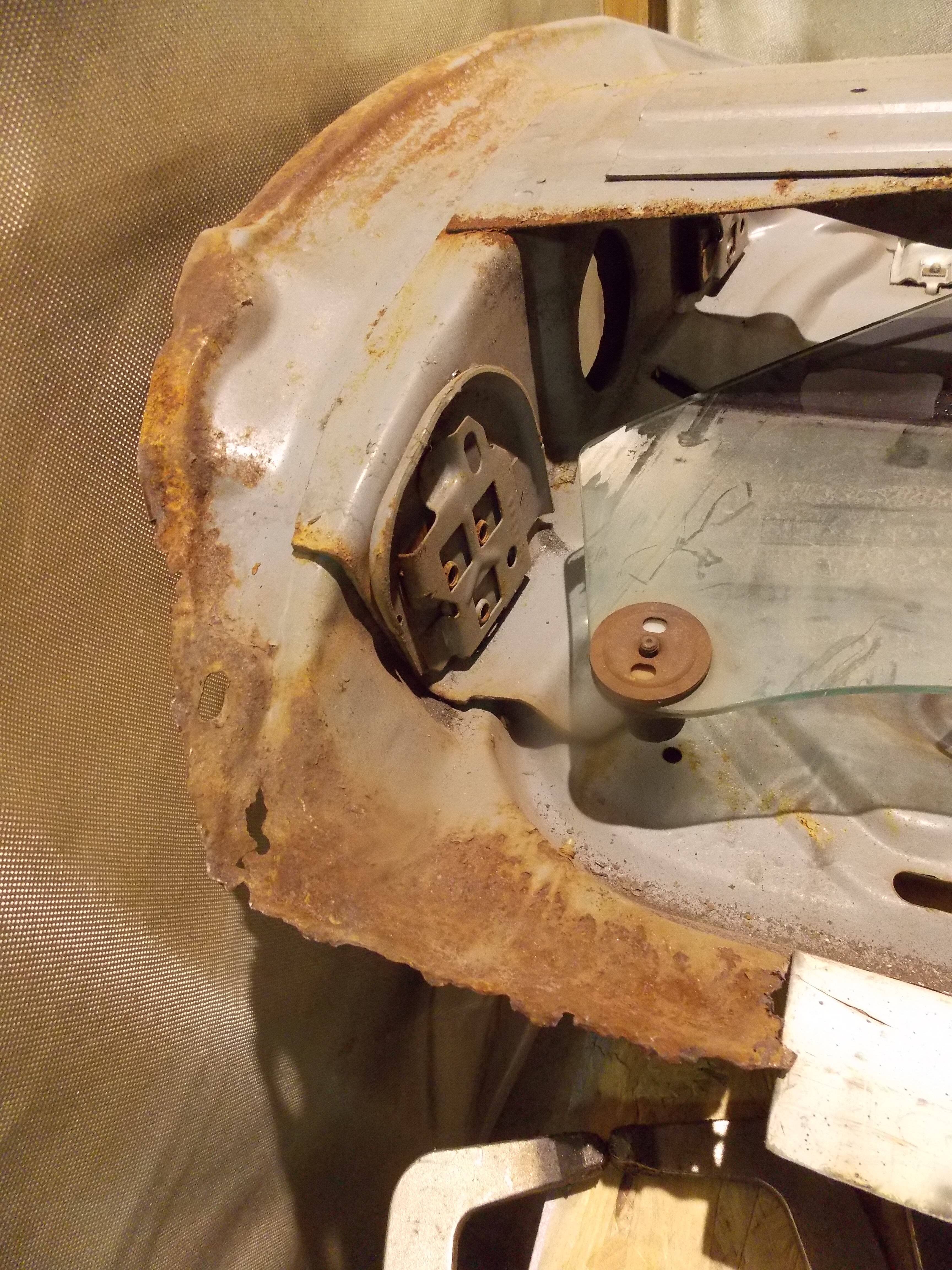

And this is the front lower corner, or what's left of it. This is why I had planned to originally hunt down a new complete door shell except the most of the ones to be had locally aren't much better. The culprit responsible for all this damage was a combination of water and salt getting into the lower seam and not draining out.. Everything back to the white section will have to be cut away and new material cut and shaped to replace it.

Just to give you some idea of the tools that I will be working with to create the basic patch panels, first tack, then dolly, then tack some more and then burn them in, and then trim them down to the final shape. As you can see in the previous picture there is a lot of surface rust that will also have to be removed to get back down to bare metal. Since this shell is 36 years old, all this will have to be done cautiously as age and wear/exposure have thinned the metal down so burn through and tearing can occur more readily than with new metal.

Nick

Im loving my 5spd, but my '78 was born a factory stick shift to begin with. As for the steering column, check your wiring diagram. 1986 might be the year that the wipers changed the way they were wired. IIRC, early wipers were wired with power starting from switch going to wiper, while later was power starting at wiper, then going to switch.Having all that fun and then some on my 81’ El Camino build. Going from auto to 5 spd. Rebuilding the steering column at moment, a new and frustrating learning experience as it’s out of a 86’ g body.

Keep up the good work!

As long as he still has the wiper switch in the dash as only the '78-'81 cars had there wouldn't be an issue with the wipers. It was about '84/'85 the wipers changed.Im loving my 5spd, but my '78 was born a factory stick shift to begin with. As for the steering column, check your wiring diagram. 1986 might be the year that the wipers changed the way they were wired. IIRC, early wipers were wired with power starting from switch going to wiper, while later was power starting at wiper, then going to switch.

- Status

- Not open for further replies.

Similar threads

- Replies

- 242

- Views

- 11K

- Replies

- 321

- Views

- 17K

- Replies

- 100

- Views

- 4K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.