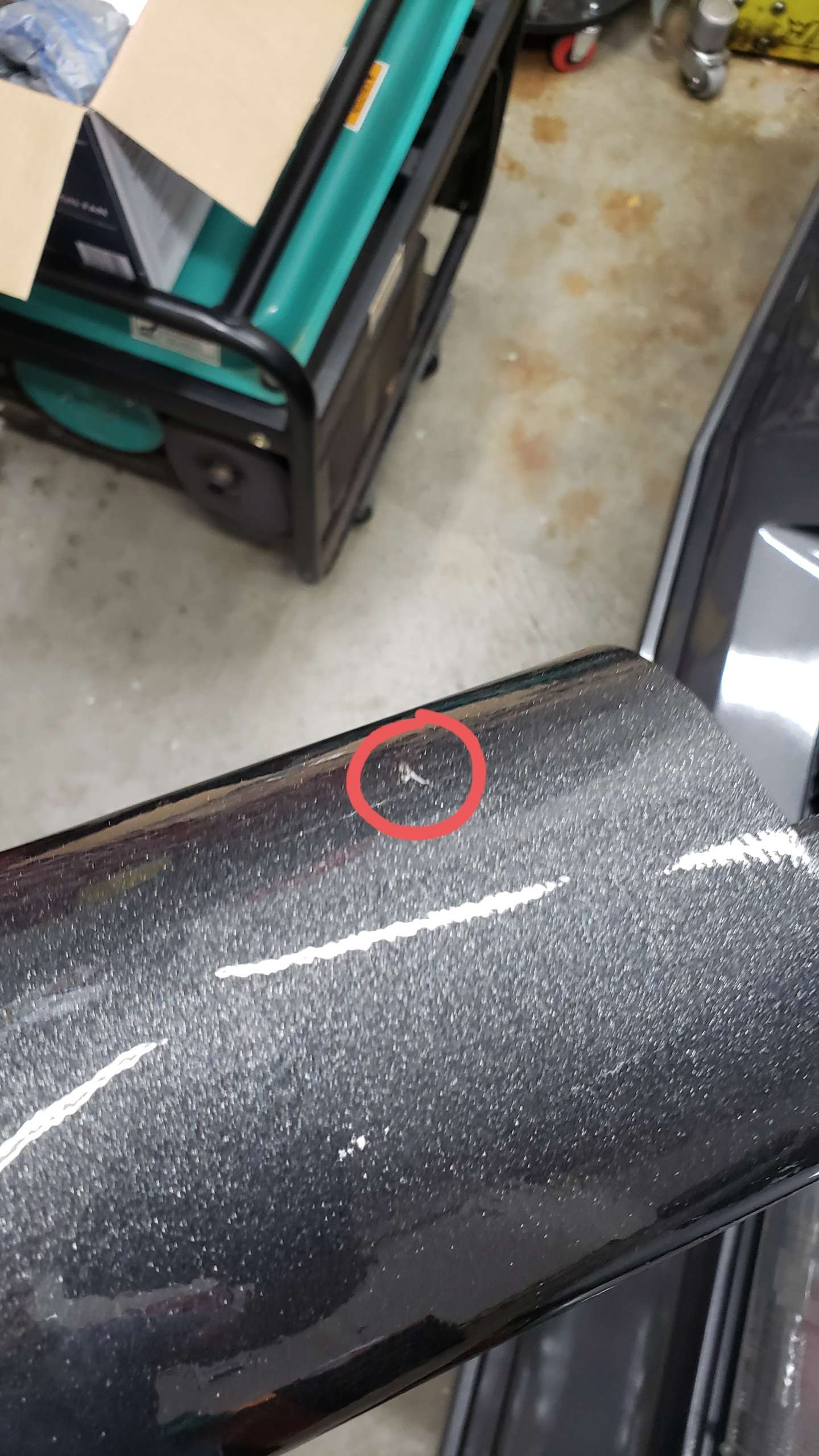

Went another round with the old inner shell. Got some of the patch work cut apart so I could hammer it into a better degree of alighment with the existing edges. Looking at the door shell from the top leading edge you can easily see how badly deformed the lower flange is. Essentially it is one long concave bowl for about 75 percent of the entire length of the flange. What is going to have to happen is that, once I finish dealing with the front lower corner and cutting apart all the lap joints so I can recreate them as butt joints is that the lower shelf above the flange will have to be split, probably right along the bend, and then the drop can be lifted and tacked back into alignment. After that the entire flange itself will get ground away and a whole new one tacked on. Due to other projects demanding time, about as far as I will get with this is the tacks, or maybe the complete seams, then the whole shell will get stashed away for later. it is getting on towards rotation time again and I need to get the S-10 back in for its oil/filter change, as well as swapping out the summer tires for my winter treads. Snigger or chortle if you must but the weather up here has gone from weird to weirder and the long range the next few months is nothing but nasty, getting nastier and nastier as the days go by. My winter (gasp) shop time will be limited; heat costs and my lungs can't take too much cold any more.

The shell did express its displeasure at being assaulted by a grinder and cut off wheel by trying to amputate my right index finger using a thin strip of shrapnel as the razor. 3/4 inch 3M green masking tape makes a great pressure bandage!! The other tip is to have a styptic pencil handy. Normally used for shaver cuts, the stuff works just as well on messy bleeders. The active ingredient is aluminum sulfate which reacts with the blood to coagulate it. it is water soluble so you pour a little water on the stick and then "paint" it on the gash. When it starts to sting, you know it is working. Give it a couple of applications and let stand.

For how I got bit, what I did was to put a turn or two of the masking tape around the finger right over the slash to put direct pressure on the wound. Then I went back to exacting my revenge on the offending edge/panel.

After supper, I gently snipped the tape away and slathered a soggy layer of the styptic juice on the open edges of the gash where it was most likely to ooze or weep. Right now I am typing this, very gingerly, and using that finger to do so. For tomorrow, I will probably wind a turn or two of masking tape over the damage to keep it clean and keep the edges from catching a pulling apart. it will take about a week for it to get fully into healing mode; this isn't the first one of these that I have had to deal with. Body metal can be right vindictive for some reason........................

Oh yeah, before I was so heinously assaulted, I did manage to modify the window actuator mounting plate by tack welding some 1/4NC heavy hex nuts over the holes through which the rivets used to fit. The factory uses Cherry Q rivets and you pretty much need an air riveting gun to set them. Having the nuts permanently tacked into place means that I can use 1/4 NC bolts and that makes putting the actuator assembly back into the shell, particularly if I end up having to do it with the shell already hung and aligned, substantially simpler.

Nick

The shell did express its displeasure at being assaulted by a grinder and cut off wheel by trying to amputate my right index finger using a thin strip of shrapnel as the razor. 3/4 inch 3M green masking tape makes a great pressure bandage!! The other tip is to have a styptic pencil handy. Normally used for shaver cuts, the stuff works just as well on messy bleeders. The active ingredient is aluminum sulfate which reacts with the blood to coagulate it. it is water soluble so you pour a little water on the stick and then "paint" it on the gash. When it starts to sting, you know it is working. Give it a couple of applications and let stand.

For how I got bit, what I did was to put a turn or two of the masking tape around the finger right over the slash to put direct pressure on the wound. Then I went back to exacting my revenge on the offending edge/panel.

After supper, I gently snipped the tape away and slathered a soggy layer of the styptic juice on the open edges of the gash where it was most likely to ooze or weep. Right now I am typing this, very gingerly, and using that finger to do so. For tomorrow, I will probably wind a turn or two of masking tape over the damage to keep it clean and keep the edges from catching a pulling apart. it will take about a week for it to get fully into healing mode; this isn't the first one of these that I have had to deal with. Body metal can be right vindictive for some reason........................

Oh yeah, before I was so heinously assaulted, I did manage to modify the window actuator mounting plate by tack welding some 1/4NC heavy hex nuts over the holes through which the rivets used to fit. The factory uses Cherry Q rivets and you pretty much need an air riveting gun to set them. Having the nuts permanently tacked into place means that I can use 1/4 NC bolts and that makes putting the actuator assembly back into the shell, particularly if I end up having to do it with the shell already hung and aligned, substantially simpler.

Nick

Last edited: