It had definetly seen better days.it was a Caballero caught in a flash flood and completely non-restorable. roof got hammered, dirt, mud, silt, gravel got put in to every crevice, nook, and cranny (behind the dash, in the frame rails, above the headliner, in the engine block, etc). everything behind the cab actually survived unscathed, so perfect for my plans.

What Did You Do To Your G-Body Today? [2023]

- Thread starter 83MonteCarloSS

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

it had been used as a practical vehicle all its life to haul stuff by the first owner and the second owner, so it wasn't even a nice daily driver, just an older car that could be driven and where people would look and say "still running 👍 ". that's why I said it was perfect for my projectIt had definetly seen better days.

Smugglers box will make a nice spare holder and toolbox safe.it had been used as a practical vehicle all its life to haul stuff by the first owner and the second owner, so it wasn't even a nice daily driver, just an older car that could be driven and where people would look and say "still running 👍 ". that's why I said it was perfect for my project

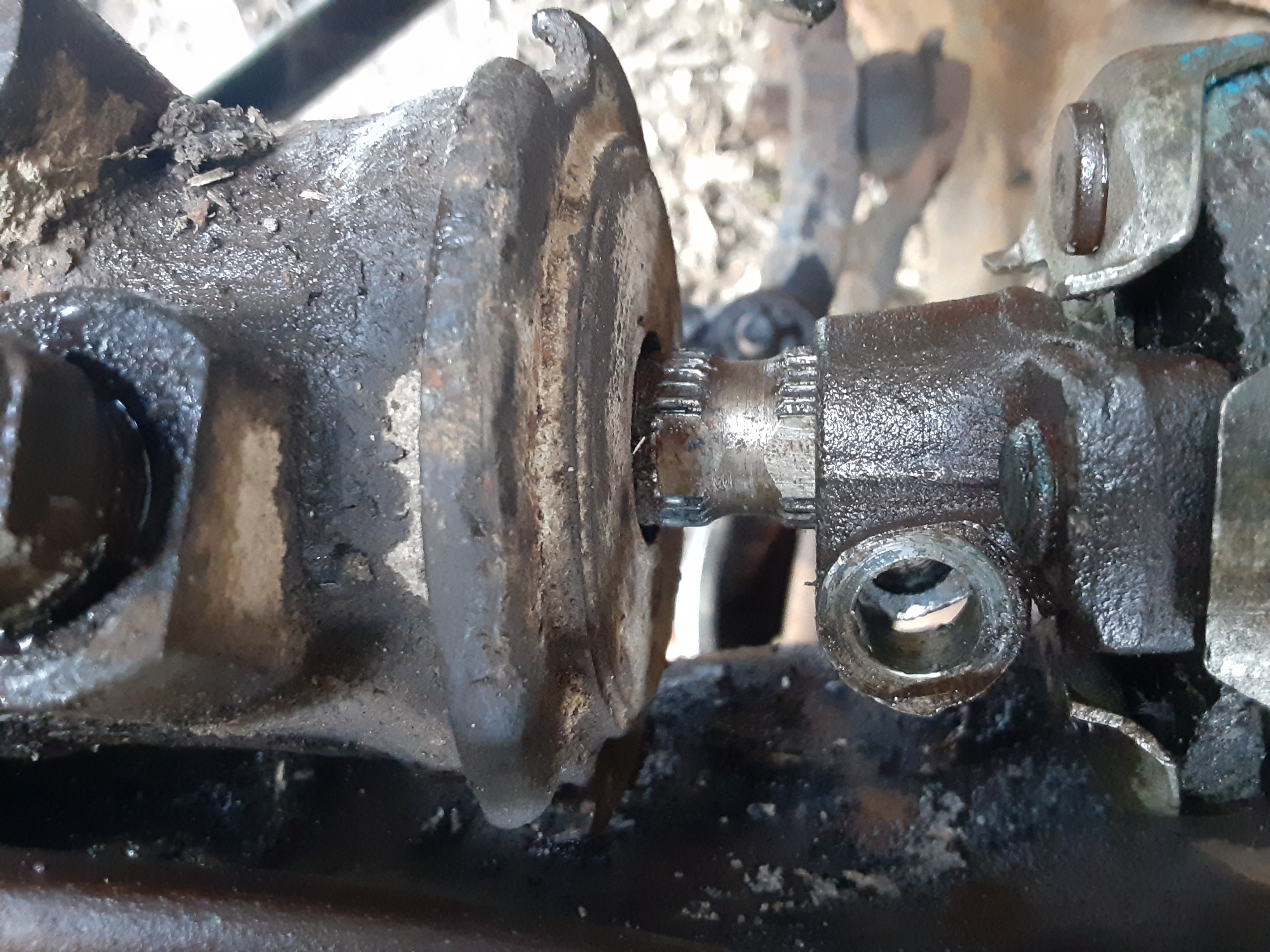

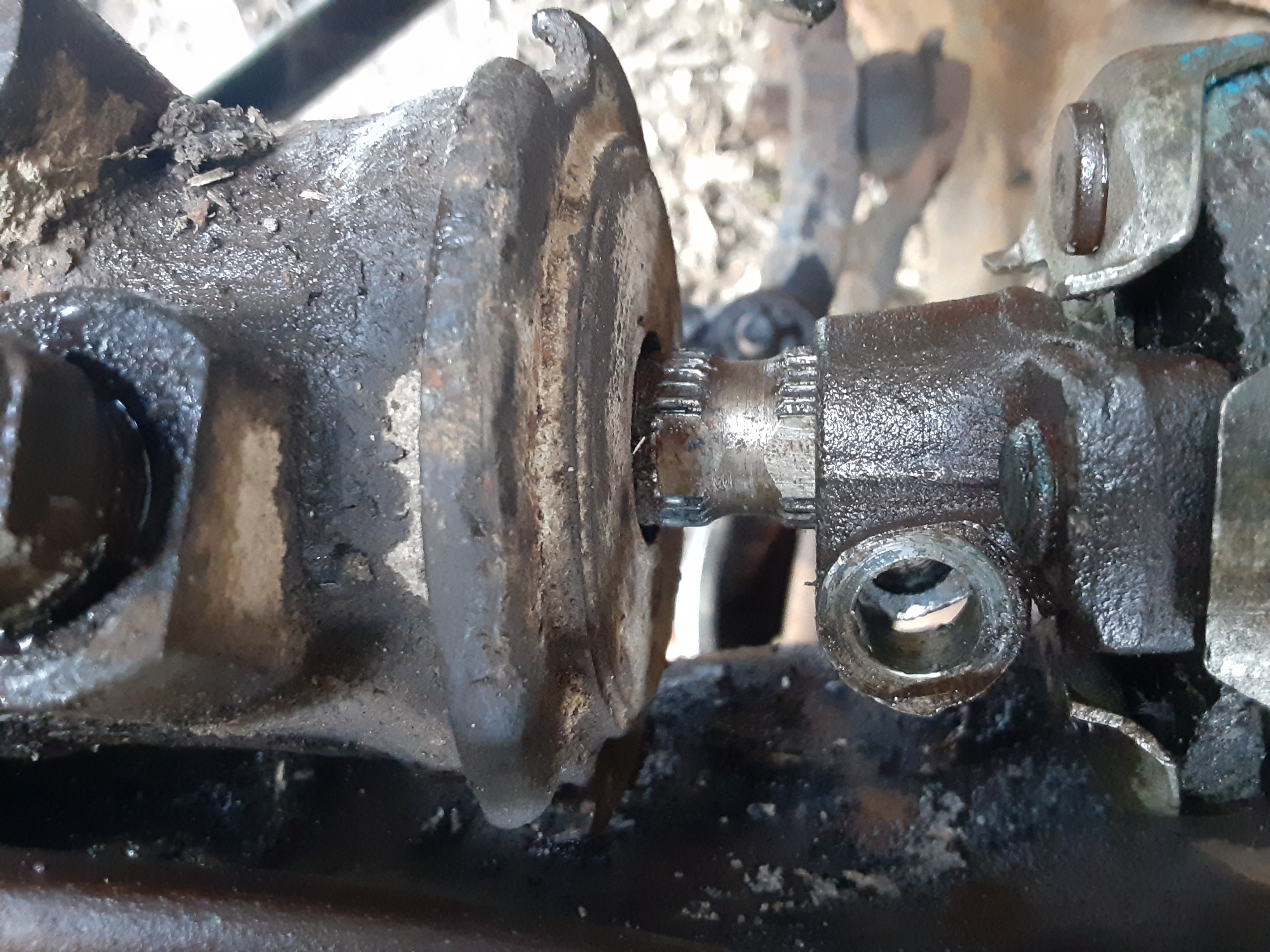

What I did was change / mod the steering box .Like several people here befor me I happened to get a different steering box,off a 97 jeep grand cherokee rumoured to

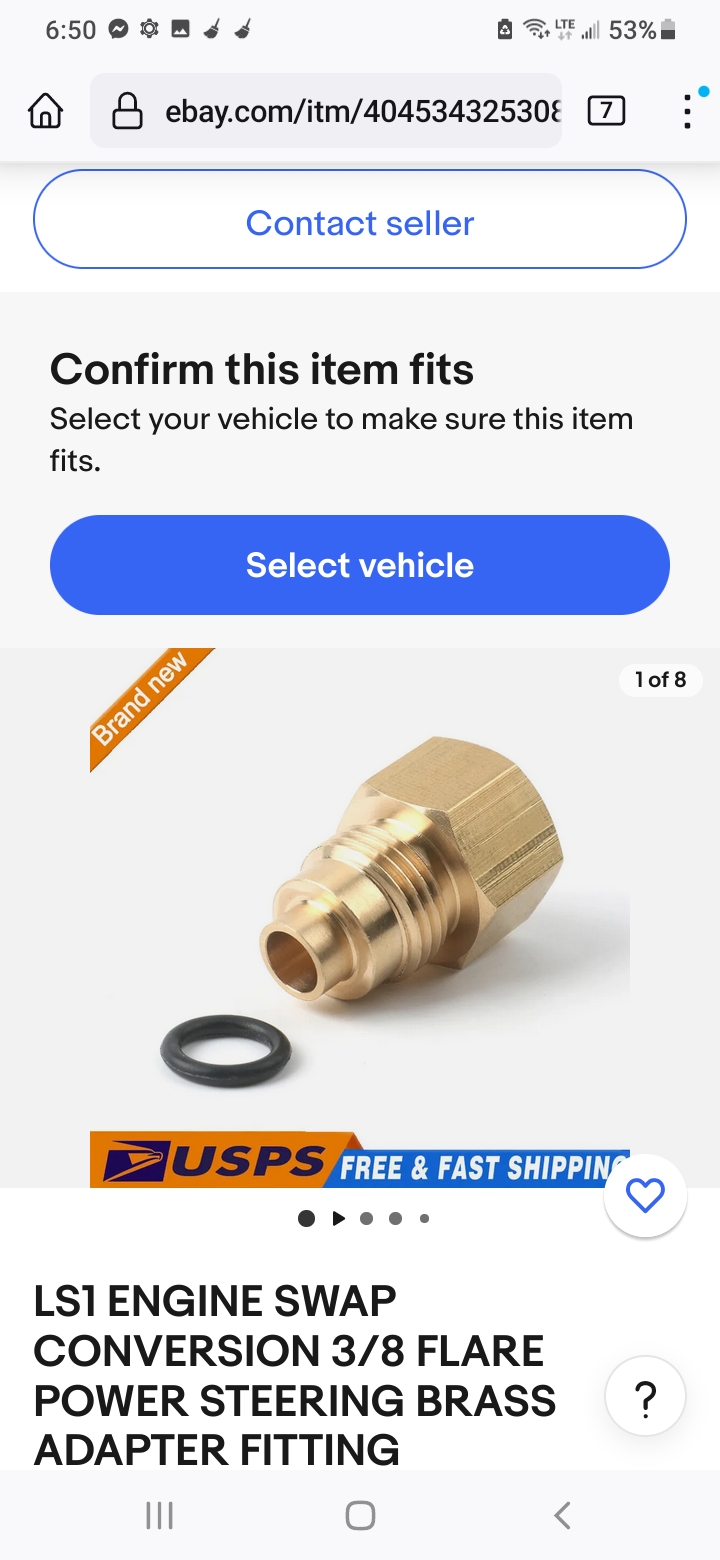

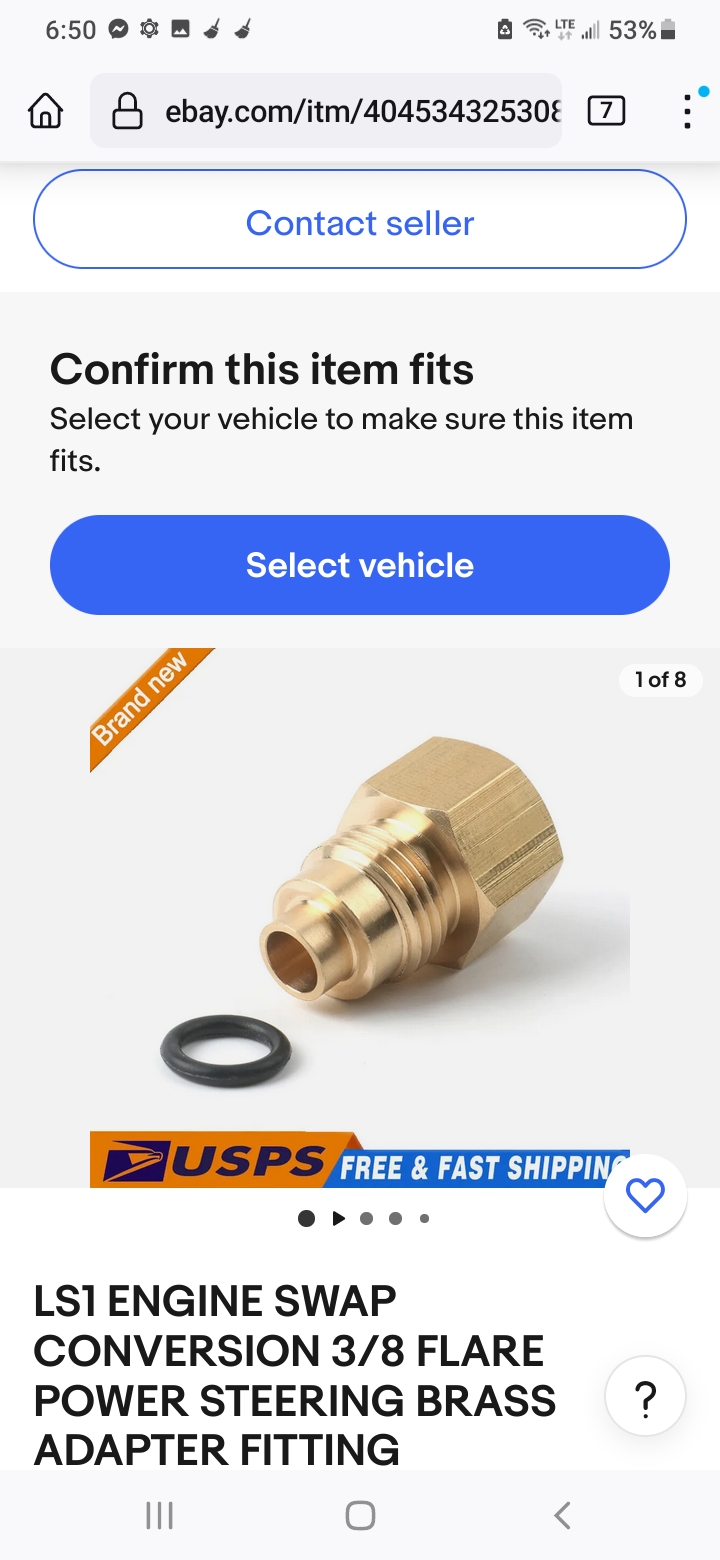

have a faster ratio ( less turns more motion) .Now as to references from you tube videos ,or of what I have read here on gbody forum..uhh" I have noted' a few pointers I will try and convey with words. In short order possibly get the pressure hose for the unite your buying when you buy it also fitting on back of power steering pump ( o ring type)#2 you can use you're old steering column shaft and coupler (rag joint). You 'will hear about changing to a universal that might make you think you have to..well you don't nessesarily have to as the oem stuff fits fine.(when aligned right)#3 you can rent a pitnum arm puller from auto zoan: youl need it the switch the gbody pitnum arm onto the jeep ps unit...( more shortly)#4 my 78 used flared pressure hose the jeep unit is going to have a O ring on the box end I'm having mine switched at a hydraulic hose place but I think napa can do the clamping if you can saw the old crimps off with a cut off wheel,or hack saw..#5 some one is saying some things about the t*ts (pilot) on the end of the spline coupler your shaft clamps too", the tit that's (pilot) in question is not on the jeep splined input, in fact there's no provision on the factory spline coupler to where it even centers to the shaft its hollow but the tit (pilot) .Some tips use some oil to lube shaft telescoping area the coupling bolts on the coupling steering shafts upper and lower (clamps bolts).... oil the pitum large 34mm(1&5/16") nut under the pitnum arm and, oil the ends of the saganaw box to frame bolts to make easy removal . I personally used a long cast iron 1 inch by 26" pipe to hit the top of the old pitnum arm after I had tighten the pitnum arm removal tool as tight as I though it would sustain pressure without springing it( to much) I might of had 65 to 70 ft lbs I don't know?.. the thought being that while it was attached and having a lot of pull weight that some hammering would assist in vibrating the pressed fit (pitnum arm) for removal...after pounding the pipe I held to the top several times with a hammer (don't bust plastic shaft sheild)I returned underneath to add some final turns to the pitnum puller tool this worked, for me ( hopefully for others) .... OK I did leave the pitnum arm in the car still attached to the steering drag link as it seemed practicle...as far as reinstaling and hooking the shaft couplers I found one important fact you dont' align it by the splines ( teeth) you align the couples ( on rag joint) by the flats set the couple by the flats there us a flat spot on the input shaft ( nubb) and it has to match the flat spot on the coupler so don't expect the steering wheel to be sitting the same it will be( sitting different) from the old way it looked youl have to pull the wheel later ( really) or live with it!..you can mark the top of the shaft with nail polish if your forgetful..( top side) turn the key on so you can locate the rag joint to where both flat places are exactly corresponding..I suggest you pry the clamp apart some like 1/16"inch for the rag end 1/32 for the upper steering colum end ( if you even bother this) if you take the whole shaft out to look at it be advised the upper end near the firewall has finer teeth and aligns by the little flat spot ( place with no teeth on bottom of view you have to make a mark were the little blank spot is) if the flat spot isn't lined clockwise you aint getting it on" so you probly don't need to take that end off unless you got anouther shaft with extra universal joints .( more steps) the attachment bolts on my old 78 saganaw unit where 5/8" the pressure fitting is 18mm wrench . I moved the brace from out of the way to take pitnum nut off and pushed it sideways it had a 15mm bolt the clamp lock bolt on yhe rag end was 7/16"( Probly different sizes) you might want to get a machine shop to removed you jeep pitnum arm certainly be careful of any hammering or possibly cut diagonally through the side of the pitnum arm just enough to weak in the grip.ok befor installing the newer saganaw unit turn the input back and fourth several times count what turns I think mine was just 3 .25 turns that meant center was 1 and a half turn plus 1/8 a turn to split ( devide)the .25 ( you have to find center) I practiced it a couple times and noticed the 4 flat places on splined sector shaft were at the same spots ( yes) I was now ready to put it in reverse order the input end shaft flat spot will be off by say 1/10 a turn as it has less turns in the ratio ( yes) therefore the different steering wheels position ( or better explanation)...out side of this I recomend Dexron mercon the red stuff although you may decide to check the chrysler dealer for info ( jeep?) I did decide to get a flared adaptor fitting for the pressure hose to deal with the flared to O ring fitting...(the picture is wrong size it will be 7/16 siize nut maybe 24 tpi or 1/2" 21tpi nut ?) I takes 1 quart to refill ps sys..and it will foam a lot so fill in increments of say 1/3 a cup and let it mix then set for 5 minets or you will get foaming overflow past the cap that you car dry it off .Get 2 new o rings for ps line (specific).. I There was no difference in the pressure ( pumps) that I noticed,even with chevy pump and valve ...After thought is I wouldn't have swopped it if I knew how dead the steering becomes if you stall engine ( flood ect) impossible to turn (without rolling) in certain stances "!!!! .Thanks for listening hope it's not to confusing

have a faster ratio ( less turns more motion) .Now as to references from you tube videos ,or of what I have read here on gbody forum..uhh" I have noted' a few pointers I will try and convey with words. In short order possibly get the pressure hose for the unite your buying when you buy it also fitting on back of power steering pump ( o ring type)#2 you can use you're old steering column shaft and coupler (rag joint). You 'will hear about changing to a universal that might make you think you have to..well you don't nessesarily have to as the oem stuff fits fine.(when aligned right)#3 you can rent a pitnum arm puller from auto zoan: youl need it the switch the gbody pitnum arm onto the jeep ps unit...( more shortly)#4 my 78 used flared pressure hose the jeep unit is going to have a O ring on the box end I'm having mine switched at a hydraulic hose place but I think napa can do the clamping if you can saw the old crimps off with a cut off wheel,or hack saw..#5 some one is saying some things about the t*ts (pilot) on the end of the spline coupler your shaft clamps too", the tit that's (pilot) in question is not on the jeep splined input, in fact there's no provision on the factory spline coupler to where it even centers to the shaft its hollow but the tit (pilot) .Some tips use some oil to lube shaft telescoping area the coupling bolts on the coupling steering shafts upper and lower (clamps bolts).... oil the pitum large 34mm(1&5/16") nut under the pitnum arm and, oil the ends of the saganaw box to frame bolts to make easy removal . I personally used a long cast iron 1 inch by 26" pipe to hit the top of the old pitnum arm after I had tighten the pitnum arm removal tool as tight as I though it would sustain pressure without springing it( to much) I might of had 65 to 70 ft lbs I don't know?.. the thought being that while it was attached and having a lot of pull weight that some hammering would assist in vibrating the pressed fit (pitnum arm) for removal...after pounding the pipe I held to the top several times with a hammer (don't bust plastic shaft sheild)I returned underneath to add some final turns to the pitnum puller tool this worked, for me ( hopefully for others) .... OK I did leave the pitnum arm in the car still attached to the steering drag link as it seemed practicle...as far as reinstaling and hooking the shaft couplers I found one important fact you dont' align it by the splines ( teeth) you align the couples ( on rag joint) by the flats set the couple by the flats there us a flat spot on the input shaft ( nubb) and it has to match the flat spot on the coupler so don't expect the steering wheel to be sitting the same it will be( sitting different) from the old way it looked youl have to pull the wheel later ( really) or live with it!..you can mark the top of the shaft with nail polish if your forgetful..( top side) turn the key on so you can locate the rag joint to where both flat places are exactly corresponding..I suggest you pry the clamp apart some like 1/16"inch for the rag end 1/32 for the upper steering colum end ( if you even bother this) if you take the whole shaft out to look at it be advised the upper end near the firewall has finer teeth and aligns by the little flat spot ( place with no teeth on bottom of view you have to make a mark were the little blank spot is) if the flat spot isn't lined clockwise you aint getting it on" so you probly don't need to take that end off unless you got anouther shaft with extra universal joints .( more steps) the attachment bolts on my old 78 saganaw unit where 5/8" the pressure fitting is 18mm wrench . I moved the brace from out of the way to take pitnum nut off and pushed it sideways it had a 15mm bolt the clamp lock bolt on yhe rag end was 7/16"( Probly different sizes) you might want to get a machine shop to removed you jeep pitnum arm certainly be careful of any hammering or possibly cut diagonally through the side of the pitnum arm just enough to weak in the grip.ok befor installing the newer saganaw unit turn the input back and fourth several times count what turns I think mine was just 3 .25 turns that meant center was 1 and a half turn plus 1/8 a turn to split ( devide)the .25 ( you have to find center) I practiced it a couple times and noticed the 4 flat places on splined sector shaft were at the same spots ( yes) I was now ready to put it in reverse order the input end shaft flat spot will be off by say 1/10 a turn as it has less turns in the ratio ( yes) therefore the different steering wheels position ( or better explanation)...out side of this I recomend Dexron mercon the red stuff although you may decide to check the chrysler dealer for info ( jeep?) I did decide to get a flared adaptor fitting for the pressure hose to deal with the flared to O ring fitting...(the picture is wrong size it will be 7/16 siize nut maybe 24 tpi or 1/2" 21tpi nut ?) I takes 1 quart to refill ps sys..and it will foam a lot so fill in increments of say 1/3 a cup and let it mix then set for 5 minets or you will get foaming overflow past the cap that you car dry it off .Get 2 new o rings for ps line (specific).. I There was no difference in the pressure ( pumps) that I noticed,even with chevy pump and valve ...After thought is I wouldn't have swopped it if I knew how dead the steering becomes if you stall engine ( flood ect) impossible to turn (without rolling) in certain stances "!!!! .Thanks for listening hope it's not to confusing

Last edited:

Wow that's a lot, and thank you for all of it. I'd like to offer up a small tip though: if you want you can just use the Jeep pump. Really. Short of that I highly recommend taking the fitting from the back of the Jeep pump (that the hose fitting threads into), as it will thread directly into your Saginaw pump- those threads are the same. The orifice size is important to the Jeep gear box line pressure being absolutely correct. Then you can also utilize the Jeep pressure hose without modification.What I did was change / mod the steering box .Like several people here befor me I happened to get a different steering box,off a 97 jeep grand cherokee rumoured to View attachment 235512View attachment 235513View attachment 235514have a faster ratio ( less turns more motion) .Now as to references from you tube videos of what I have read here on gbody forum..uhh" I have noted' a few pointers I will try and convey with words. In short order possibly get the pressure hose for the unite your buying when you buy it...#2 you can use you're old steering column shft and coupler (rag joint).YOU will hear about changing to a universal that might make you think you have to..well you don't nessesarily have to as the oem stuff fits fine.(when aligned right)#3 you an rent a pitnum arm puller from auto zoan: youl need it the switch the gbody pitnum arm onto the jeep ps unit...( more shortly)#4 my 78 used flared pressure hose the jeep unit is going to have a O ring on the box end I'm having mine switched at a hydraulic hose place but I think napa can do the clamping if you can saw the old crimps off with a cut off wheel.#5 some one is saying spme things about the title on the end of the spline coupler you shaft clamps to the title in question is not on the jeep splined input in fact there's no provision on the factory spline input to where it even centers to shfts hollow but the title on a factory box input will hit on some universal shafted assemblys ( therefore saw such t*ts ( pilot)off) ok for procedure tips used some oil to lube shaft telescoping area the coupling bolts on the coupling steering shafts upper and lower (clamps bolts).... oil the pitum large 34mm nut under the pitnum arm and oil the ends of the saganaw box to frame bolts to make easy removal . I personally used a long cast iron 1 inch by 26" pipe to hit the top of the old pitnum arm after I had tighten the pitnum arm removal tool as tight as I though it would sustain pressure without springing it( to much) I might of had 65 to 70 ft lbs I don't know?.. the thought being that while it was attached and having a lot of pull weight that some hammering would assist in vibrating the pressed fit for removal...after pounding the pipe I held to the top several times with a hammer I returned underneath to add some final turns to the pitnum puller tool this worked, for me ( hopefully for others) .... OK I did leave the pitnum arm in the car still attached to the steering drag link as it seemed practicle...as far as reinstaling and hooking the shaft couplers I found one important fact you do align it by the splines ( teeth) you align the couples ( on rag joint) by the flats set the couple by the flats there us a flat spot on the input shaft ( nubb) and it has to match the flat spot on the couple so don't expect the steering wheel to be sitting the same it will be( sitting different) from the old way it looked youl have pull the wheel later ( really) or live with it!..you can mark the top of the shaft with nail polish if you forgetful..( top side) turn the key on so you can locate the rag joint to where both flat places are exactly correspondingly..I suggest you pry the clamp apart some like 1/16"inch for the rag end 1/32 for the upper steering colum end ( if you even bother this) if you take the whole shaft out to look at it be advised the upper end near the firewall has finer teeth and aligns by the little flat spot ( place with no teeth on bottom of view you have to make a mark were the little blank spot is) if the flat spot isn't lined clockwise you aint getting it on" so you probly don't need to take yhat end off unless you got anouther shaft with extra universal joints .( more steps) th attachment bolts on my old 78 saganaw unit where 5/8" the pressure fitting is 18mm wrench . I moved the brace from out of the way to take pitnum nut off and pushed it sideways it had a 15mm bolt the clamp lock bolt on yhe rag end was 7/16"( Probly different sizes) you might want to get a machine shop to removed you jeep pitnum arm certainly be careful of any hammering or possibly cut diagonally through the side of the pitnum arm just enough to weak in the grip.ok befor installing the newer saganaw unit turn the input back and fourth several times count what turns I think mine was just 3 .25 turns that meant center was 1 and a half turn plus 1/8 a turn to split ( devide)the .25 ( you have to find center)I practiced it a couple times and noticed the 4 flat places on splined sector shaft were at the same spots ( yes) I was now ready to put it in reverse order the input end shaft flat spot will be off by say 1/10 a turn as it has less turns in the ratio ( yes) therefore the different steering wheels position ( or better explanation)...out side of this I recomend Dexron mercon the red stuff although you may decide to check the chrysler dealer for info ( jeep?) Thanks for listening hope it's not to confusing

Took the regal to get groceries, it died halfway there. Spitting and sputtering and breaking up. Has to be a bad module. Called grandma for a ride back home (we live within a few blocks of eachother) to get a module i thought i had hanging on the wall, couldn't find it. Screamed internally for a few minutes, then grabbed two spare distributors (one brand new from TA, one is my original unit from my first buick 350, so its almost 50 years old), a screwdriver, sand paper, and brake cleaner.

Swapped modules. Fired up and finished the shopping. called grandma to tell her im good, she worries.

Swapped modules. Fired up and finished the shopping. called grandma to tell her im good, she worries.

Sounds like a ride to dinner or an ice cream in the car for a thank you to granny 😁Took the regal to get groceries, it died halfway there. Spitting and sputtering and breaking up. Has to be a bad module. Called grandma for a ride back home (we live within a few blocks of eachother) to get a module i thought i had hanging on the wall, couldn't find it. Screamed internally for a few minutes, then grabbed two spare distributors (one brand new from TA, one is my original unit from my first buick 350, so its almost 50 years old), a screwdriver, sand paper, and brake cleaner.

Swapped modules. Fired up and finished the shopping. called grandma to tell her im good, she worries.

its far too low and loud for her, but i go over and mow her lawn and do stuff for her when she needs it.Sounds like a ride to dinner or an ice cream in the car for a thank you to granny 😁

I would think the chatter valve and spring mite be realative: I'm keeping my fingers crossedWow that's a lot, and thank you for all of it. I'd like to offer up a small tip though: if you want you can just use the Jeep pump. Really. Short of that I highly recommend taking the fitting from the back of the Jeep pump (that the hose fitting threads into), as it will thread directly into your Saginaw pump- those threads are the same. The orifice size is important to the Jeep gear box line pressure being absolutely correct. Then you can also utilize the Jeep pressure hose without modification.

naw, I bet grandma came over and made him a home-cooked meal and cookies.... 😆Sounds like a ride to dinner or an ice cream in the car for a thank you to granny 😁

- Status

- Not open for further replies.

Similar threads

- Replies

- 226

- Views

- 9K

- Replies

- 310

- Views

- 16K

- Replies

- 99

- Views

- 4K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.