So haven't really done a ton of work on the garage itself lately. Still waiting on overhead doors which is getting really frustrating. Order early October and was supposed to be 4-8 weeks delivery (early December). Then it was Dec 30th. then mid Jan. Now they just keep telling me "soon". First the issue was availability of the torsion spring, then waiting on the panels. Then weather related issues, now it's weather stripping. Just holding up so much stuff about moving into the new garage.

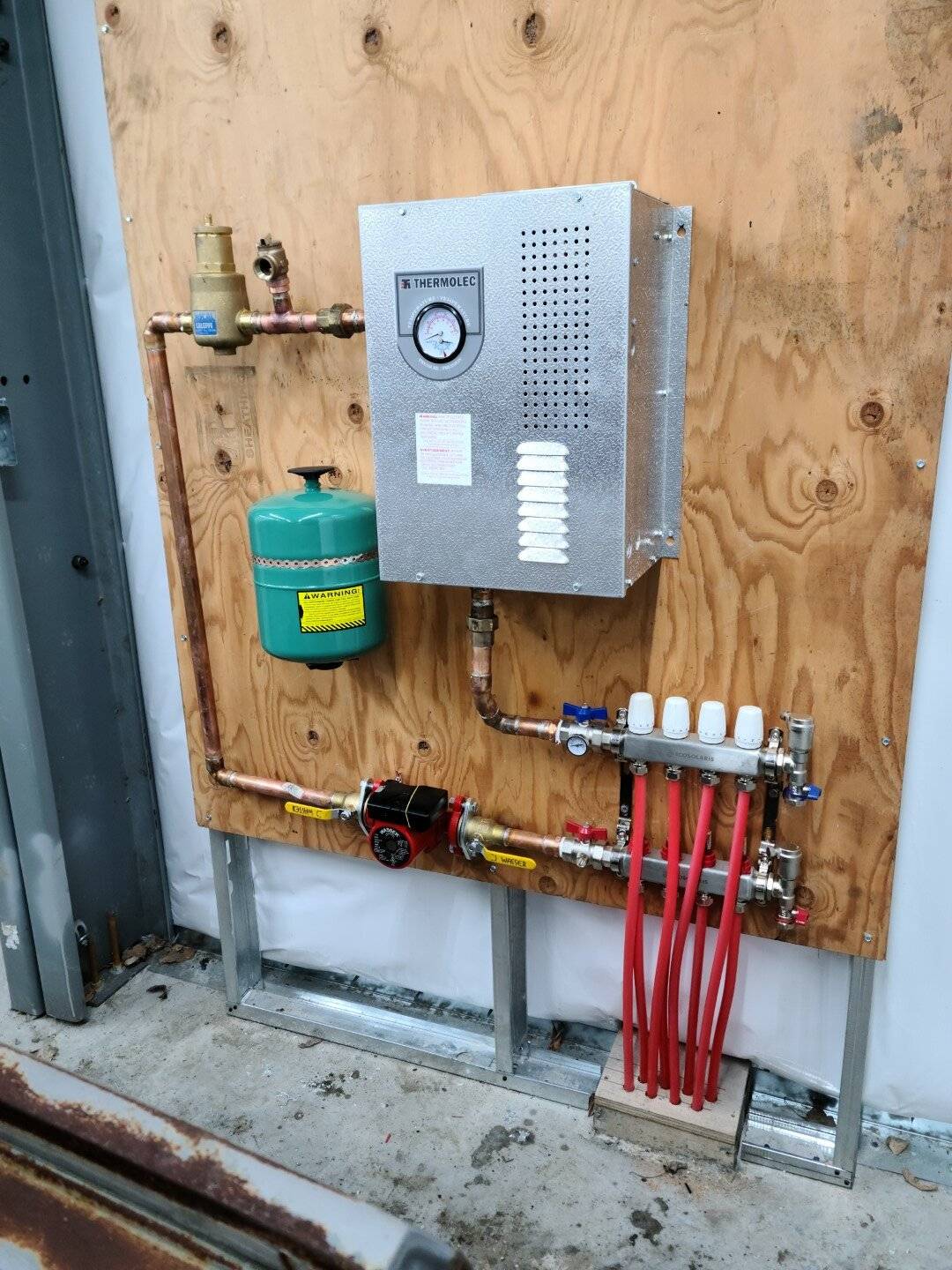

What I have been able to do is get some outlets installed and been working on getting the heating system installed and running. I have to say, routing wires and mounting stuff in a metal building is a huge pain in the *ss. Anyway, put up a couple metal studs and a piece of plywood to mount all the radiant heat stuff to it. So there's an 11 kW boiler, pressure relief valve, auto air release valve, expansion tank, circulating pump and then hot and cold manifolds. The manifolds have air release valves and drain/fill ports on them. Everything is on a single zone with 4 loops of about 250' each. Not shown in the picture below is the wiring (6/3 AC90 or BX for you southern folks), wiring from the pump to the boiler, the thermostat (which has a slab sensor), and the piping for the bottom of the auto air release valve to the expansion tank plus an additional drain/fill port with valve.

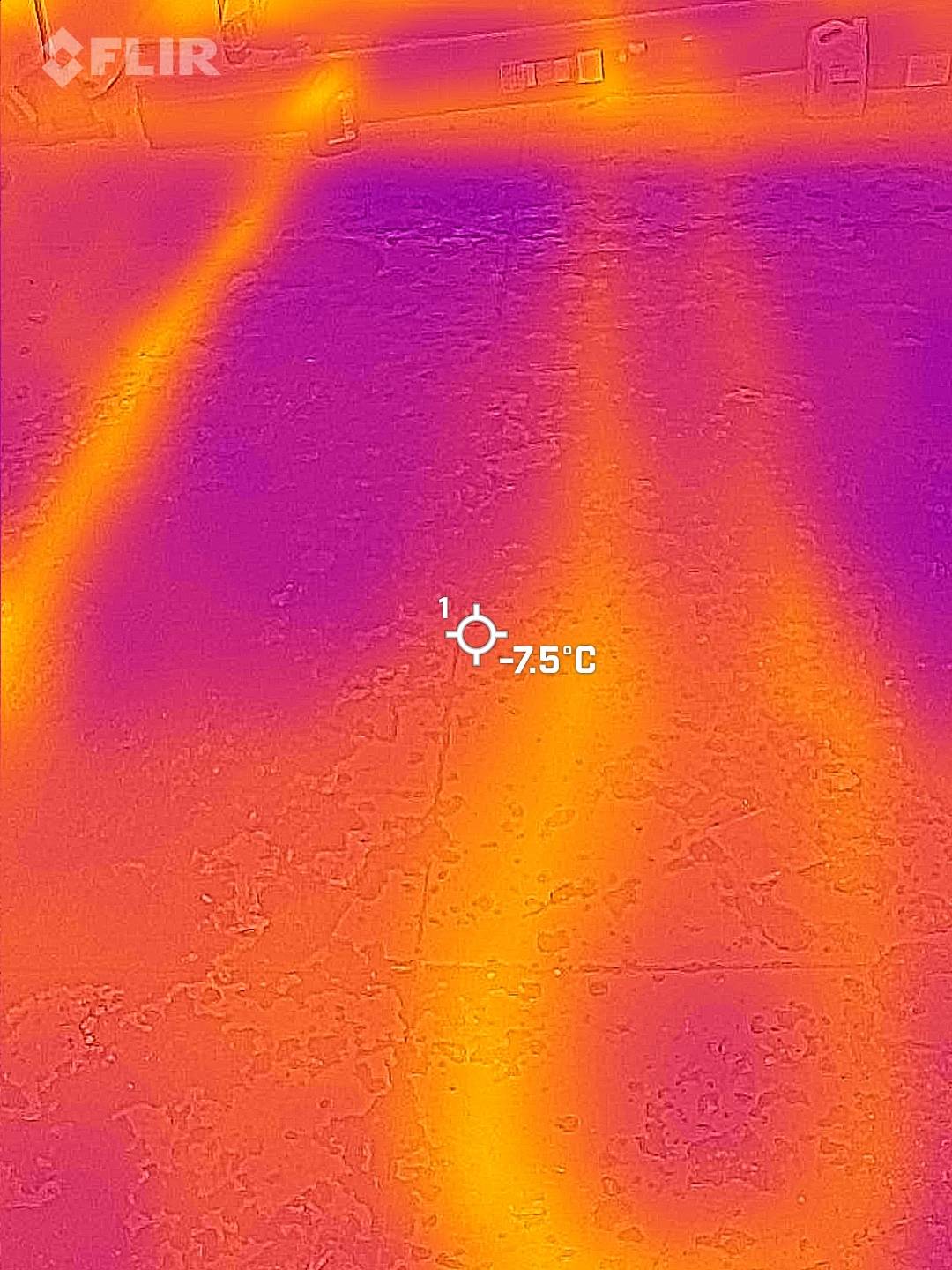

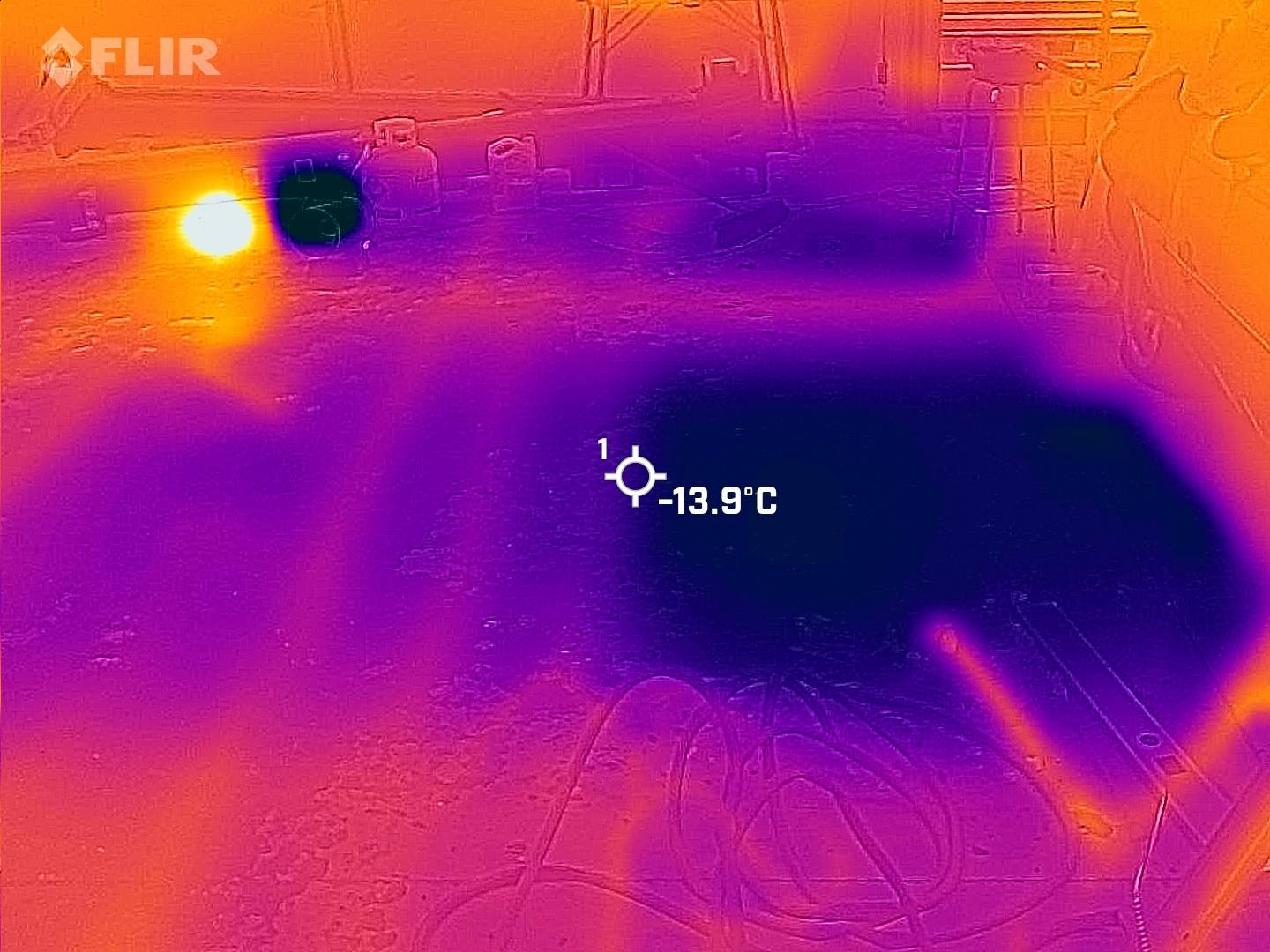

The heating system has been filled with ~35% glycol mix which should provide burst protect down to ~-40C/F. It'll get slushy before that, but it's more for just piece of mind if we ever get an extended power outage and really cold weather. Been able to get the pressure up to about 12 psi and did some quick tests. Seem to have good flow through 3 of 4 loops. I think I may have had pure water in that 4th loop that has frozen and is causing a blockage. I'd like to get the slab up to temp first before I get too worried about it. I did test each loop before hooking up the manifold just by blowing through them, which was pretty easy. I heard some gurgling through one of them and I'm pretty sure it's on the loop that's not flowing. Then we got a wicked cold spell so pretty sure I just have an ice plug in there. Right now the slab, according to the embedded temp sensor ,is ~-13C (8.5F) and night time temps have been around -25C (-13F) for several nights. I've run the system for a few hours and have seen the slab temp start to increase by a couple degrees over a few hours. Not much point leaving it running since, you know, NO DOORS. I'd just be throwing money away. But it did give me confidence that the system is working, and was able to purge a bunch of air out of the loops that ARE circulating.

But I am REALLY looking forward to getting the doors so I can really start using this damn garage and get back to working on my Cutlass (which I've now had over a year and really haven't done much to it other than rip it apart)

View attachment 191092