was it as cold as the new motorheadmike rating scale? the one where he says the ground is c*ck-solid cold? 🤣Spent another two hours cleaning, sorting and rearranging in the shop yesterday. It's cold today (probably not by Northern-Canadian standards), so it will be later in the afternoon today before I get back in there. I will post a couple of pics this evening to show where I am now.

What did you do to your shop today?

- Thread starter RecklessRegal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is that the one where, if you do happen to be outside and you whip it out and smack it against something hard, your willy will shatter on impact??

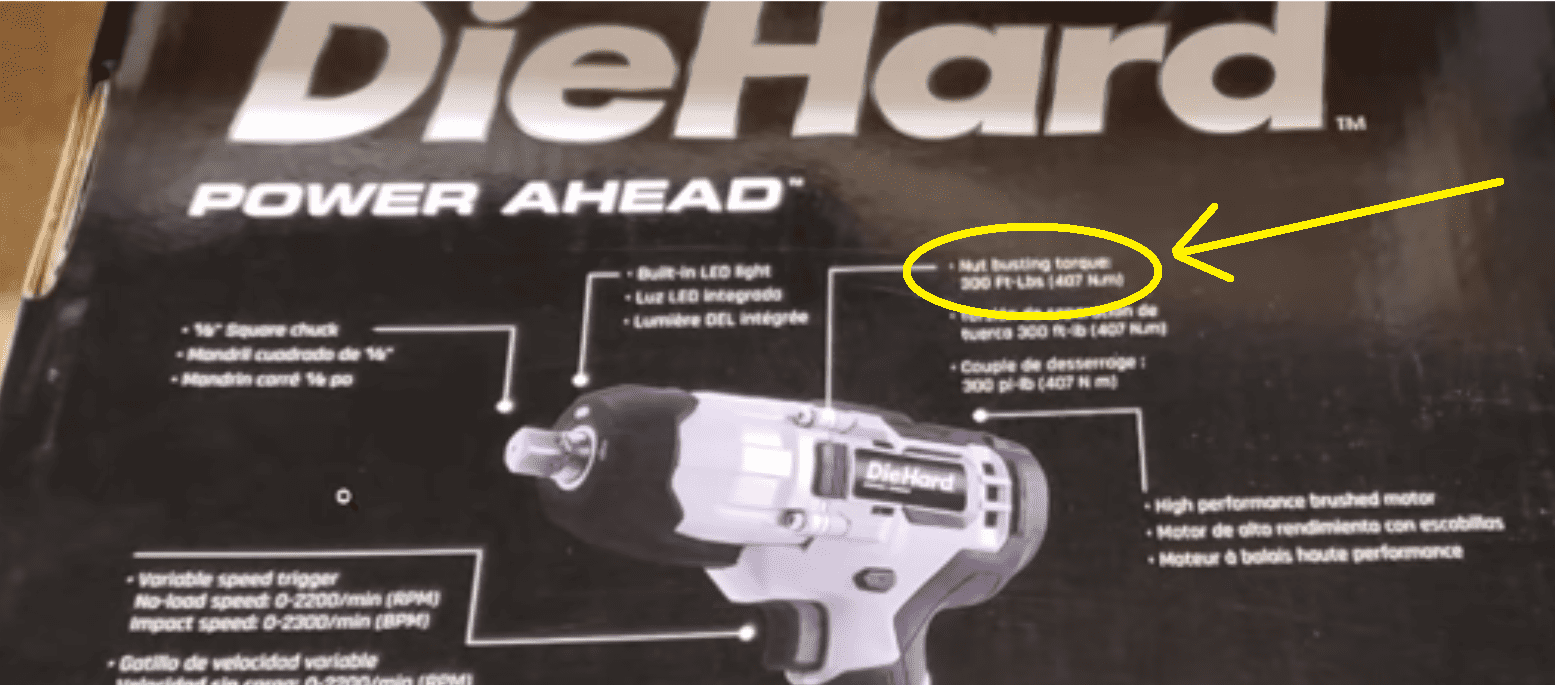

is it like the Diehard cordless impact wrench? it has a Nut-Busting torque of....300ft-lbsIs that the one where, if you do happen to be outside and you whip it out and smack it against something hard, your willy will shatter on impact??

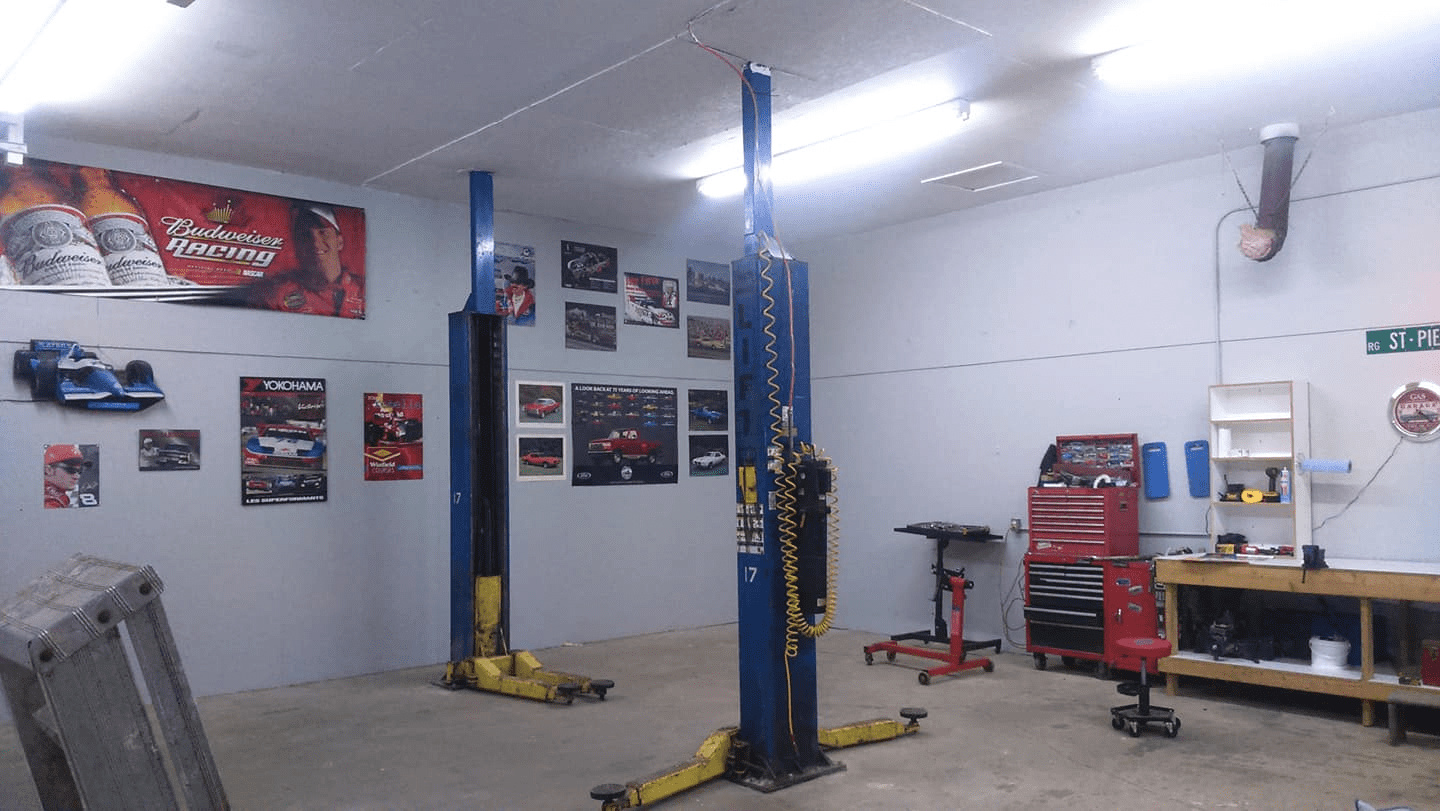

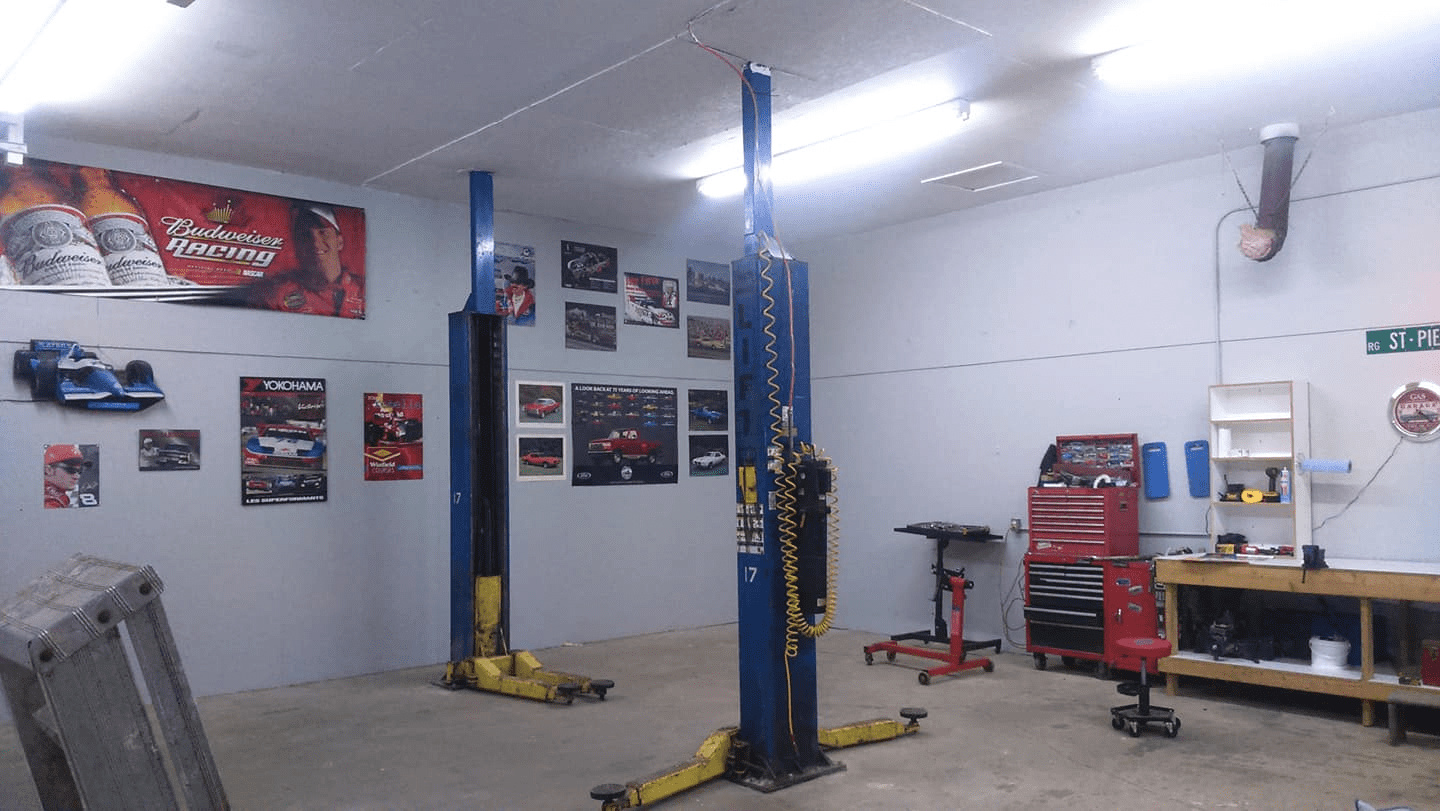

I'm a little late to the shop party but here goes. Mine is 32X36 with heat and a/c. I just added a 12 ton press for all the pressy stuff and added a few more pictures/vintage adds on the wall. Lift wise it's a 9k lbs american made ALM 2 post. Picks up a 2500 diesel silverado without breaking a sweat. It ain't new works perfect.

Spent most of Sunday and Monday finishing the insulation/plywood walls in my carport-turned-storage shed. Next, if I can get to it, is the ceiling.

So today became the day to Foam the Door. The 3000 pound elephant in the road was my Non G-Body G-Body Van. It needed to move ahead about four feet to give me some ladder room but, of course, that brought up another problem; four feet would slam the front bumper up tight against my welder and the 5.3 on its stand with about two feet still to go.

The solution was to carefully extract both the welder and the engine stand and move them over by the tool chest and the inner door skin on its bench. That gave me about 5 feet of floor to use. After that it was just a question of popping the van into neutral, slithering in between the rear doors of the van and the main door to the garage and becoming a human push cart to "encourage" the van to roll forward. It did and I had my room.

As I sort of suspected, the foam tubing was just sort of floating over the cleft between the door skin and the header so it was more of a decoration than an asset.

I had paid a visit to the local Bulk Hardware store and scored a 3 pack of spray bomb foam for insulating cracks and crevices and that became my remedy of choice for this exercise. Only thing is that this stuff sticks to everything including people and is hard to get off. I did not want to make this a permanent cure because I have the Door Dudes coming in early May to replace the upper door seal so the trick was to make it work but make it removable.

For the removable, what i did was to take two foot lengths of Wax Paper, cut them lengthwise to get two equal panels, fold one long edge over to to give me about an 1-1/4" of margin; made about 8 of these to use as forms.

Then, one by one, took each form/panel up the ladder with some masking tape and the foam, and, one by one, attached the forms to the upper door edge with the masking tape, using the margin I bent as a guide, then rolled the rest of the form down into the crevice between the door skin and the header to create a wax paper channel, and taped that down as well. With a form secured more or less in place, I then filled it with a pass of insulating foam in a can. Made one, pass, checked it for how well it sank into the paper channel, gave it some 'encouragement" to sink if it hadn't, added more foam to top the fill off, and sprayed it with water to encourage it to set. (Hey don't ask me, them's the destructions on the can))

Lather, Rinse, Repeat, for the subsequent 6 out of 7 panels that I had created for this and then checked it all again just to be sure and spritzed a little more water at it and back to terra firma for me.

Gave it all a few minutes to set while I figured out how to get some overspray off my left hand. (Turns out that CFC free Brake Cleaner works about the best but you do need a stiff bristle brush to go with it) and then turned the lights out to see how things had progressed.

AND I AM BACK IN BLACK!@!!!

(Caution: This type of activity requires being up on ladders, using nasty chemicals with smelly fumes, and has a fun factor of -100 on the "YEE_HAW" scale.)

So why the Wax Paper? Well, if I was to just spray in the foam it would have stuck to the header and the door just fine; the trick would have been to remove the stuff in the spring; that falls into the wire brush or wire wheel category. So, while the foam sticks to the wax paper, having the paper as a liner keeps it from sticking to the door skin or the header. Come spring, up the ladder i go, pull the tape, and out pops the foam. (At least that is the theory) See this was never meant to be permanent-permanent, only to last as long as winter and early spring. I don't plan to just yard it out and trash it, the plan for that is to remove each section on a section by section basis, number and tag it for location and store them. Should it prove that the new door gaskets and resetting the tension rail don't solve the problem, I have my foam inserts ready and waiting to use. JUst me.

Nick

The solution was to carefully extract both the welder and the engine stand and move them over by the tool chest and the inner door skin on its bench. That gave me about 5 feet of floor to use. After that it was just a question of popping the van into neutral, slithering in between the rear doors of the van and the main door to the garage and becoming a human push cart to "encourage" the van to roll forward. It did and I had my room.

As I sort of suspected, the foam tubing was just sort of floating over the cleft between the door skin and the header so it was more of a decoration than an asset.

I had paid a visit to the local Bulk Hardware store and scored a 3 pack of spray bomb foam for insulating cracks and crevices and that became my remedy of choice for this exercise. Only thing is that this stuff sticks to everything including people and is hard to get off. I did not want to make this a permanent cure because I have the Door Dudes coming in early May to replace the upper door seal so the trick was to make it work but make it removable.

For the removable, what i did was to take two foot lengths of Wax Paper, cut them lengthwise to get two equal panels, fold one long edge over to to give me about an 1-1/4" of margin; made about 8 of these to use as forms.

Then, one by one, took each form/panel up the ladder with some masking tape and the foam, and, one by one, attached the forms to the upper door edge with the masking tape, using the margin I bent as a guide, then rolled the rest of the form down into the crevice between the door skin and the header to create a wax paper channel, and taped that down as well. With a form secured more or less in place, I then filled it with a pass of insulating foam in a can. Made one, pass, checked it for how well it sank into the paper channel, gave it some 'encouragement" to sink if it hadn't, added more foam to top the fill off, and sprayed it with water to encourage it to set. (Hey don't ask me, them's the destructions on the can))

Lather, Rinse, Repeat, for the subsequent 6 out of 7 panels that I had created for this and then checked it all again just to be sure and spritzed a little more water at it and back to terra firma for me.

Gave it all a few minutes to set while I figured out how to get some overspray off my left hand. (Turns out that CFC free Brake Cleaner works about the best but you do need a stiff bristle brush to go with it) and then turned the lights out to see how things had progressed.

AND I AM BACK IN BLACK!@!!!

(Caution: This type of activity requires being up on ladders, using nasty chemicals with smelly fumes, and has a fun factor of -100 on the "YEE_HAW" scale.)

So why the Wax Paper? Well, if I was to just spray in the foam it would have stuck to the header and the door just fine; the trick would have been to remove the stuff in the spring; that falls into the wire brush or wire wheel category. So, while the foam sticks to the wax paper, having the paper as a liner keeps it from sticking to the door skin or the header. Come spring, up the ladder i go, pull the tape, and out pops the foam. (At least that is the theory) See this was never meant to be permanent-permanent, only to last as long as winter and early spring. I don't plan to just yard it out and trash it, the plan for that is to remove each section on a section by section basis, number and tag it for location and store them. Should it prove that the new door gaskets and resetting the tension rail don't solve the problem, I have my foam inserts ready and waiting to use. JUst me.

Nick

Last edited:

So way back in December I posted about having to create a special socket to deal with the fact that my after market balancer mounting bolt had come with a head thickness that the throat in the stock engine crankshaft rotating tool was too shallow to accept. It hit bottom and the tool was just sort of "floating".

As I subsequently noted, it turned out that that tool had been hardened or made from hard steel and it was giving me grief when i tried to cut the cap away from it to harvest the foot with its fingers.

Anyway, this is what I was aiming to create, in its final finish welded form. The adaptor is because the default broach for the socket was 3/4 drive and i decided to hang on to that. With the adaptor in place, when installed, the fingers, aka the "duck foot" line up with the mounting bolts for the crank pulley and the tool can be used with a large Johnson bar to rotate the engine to set valve lash or when priming the engine with oil to guarantee that all the journals and bearings get oil before I even think of dropping the timer and whacking the key.

However, it has another trick up its sleeve. if, before it is secured in place using the pulley bolts, a 6 point impact socket is placed on the head of the center bolt, then the tool is able to fit over the socket, the adapter gets removed and a 1/2 drive extension gets inserted down inside the tool body to pick up the socket, the Johnson bar gets moved over to the outboard location and a torque wrench can be attached to the extension to properly torque down the balancer bolt! No more getting close and then having the engine try to rotate.

Granted that the torquing purpose of the tool is something of an atypical capability; not what it would get used for most of the time, having the option is nice. Post welding I did visit some of the passes with a couple of warding files and a chainsaw chain file. They all can cut and shave welds where a normal file might bounce. it wasn't so much about the pretty as it was to remove a few high spots and chamfer a couple of sharp edges and generally shape/shave the welds down to a bit lower and smoother profile that would let the user handle it without tearing up or cutting their fingers or hand while holding it.

Nick

Last edited:

The delays on the Monte's bodywork have been for a good reason. I had to get these tools out of my dreams and into my life.

Made myself a 24" brake and a t-dolly.

Been wanting to make these for years. Built out of scraps, leftovers, and a few borrowed parts from other tools. I suppose I could have bought them... but where is the fun in that? FWIW, the brake comes off with just 5 bolts.

Made myself a 24" brake and a t-dolly.

Been wanting to make these for years. Built out of scraps, leftovers, and a few borrowed parts from other tools. I suppose I could have bought them... but where is the fun in that? FWIW, the brake comes off with just 5 bolts.

Just one small afterthought on the foam. Don't let a bright day scare you. Turns out that this particular version dries/sets/hardens translucent. Means that in daylight you see some reflected sunshine. Don't sweat it. It was overcast today and I was out in the shop today for a brief minute and the upper door panel was dark. No light showing.

Nice home build on the brake. Mike. Now if I just had another shop to put it in..............

Nick

Nice home build on the brake. Mike. Now if I just had another shop to put it in..............

Nick

I'm probably going to borrow some of those ideas.... Nicely done!The delays on the Monte's bodywork have been for a good reason. I had to get these tools out of my dreams and into my life.

Made myself a 24" brake and a t-dolly.

View attachment 190809View attachment 190810View attachment 190811View attachment 190812View attachment 190813View attachment 190814View attachment 190815View attachment 190816

Been wanting to make these for years. Built out of scraps, leftovers, and a few borrowed parts from other tools. I suppose I could have bought them... but where is the fun in that? FWIW, the brake comes off with just 5 bolts.

Similar threads

- Replies

- 80

- Views

- 3K

- Replies

- 116

- Views

- 5K

- Replies

- 185

- Views

- 12K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.