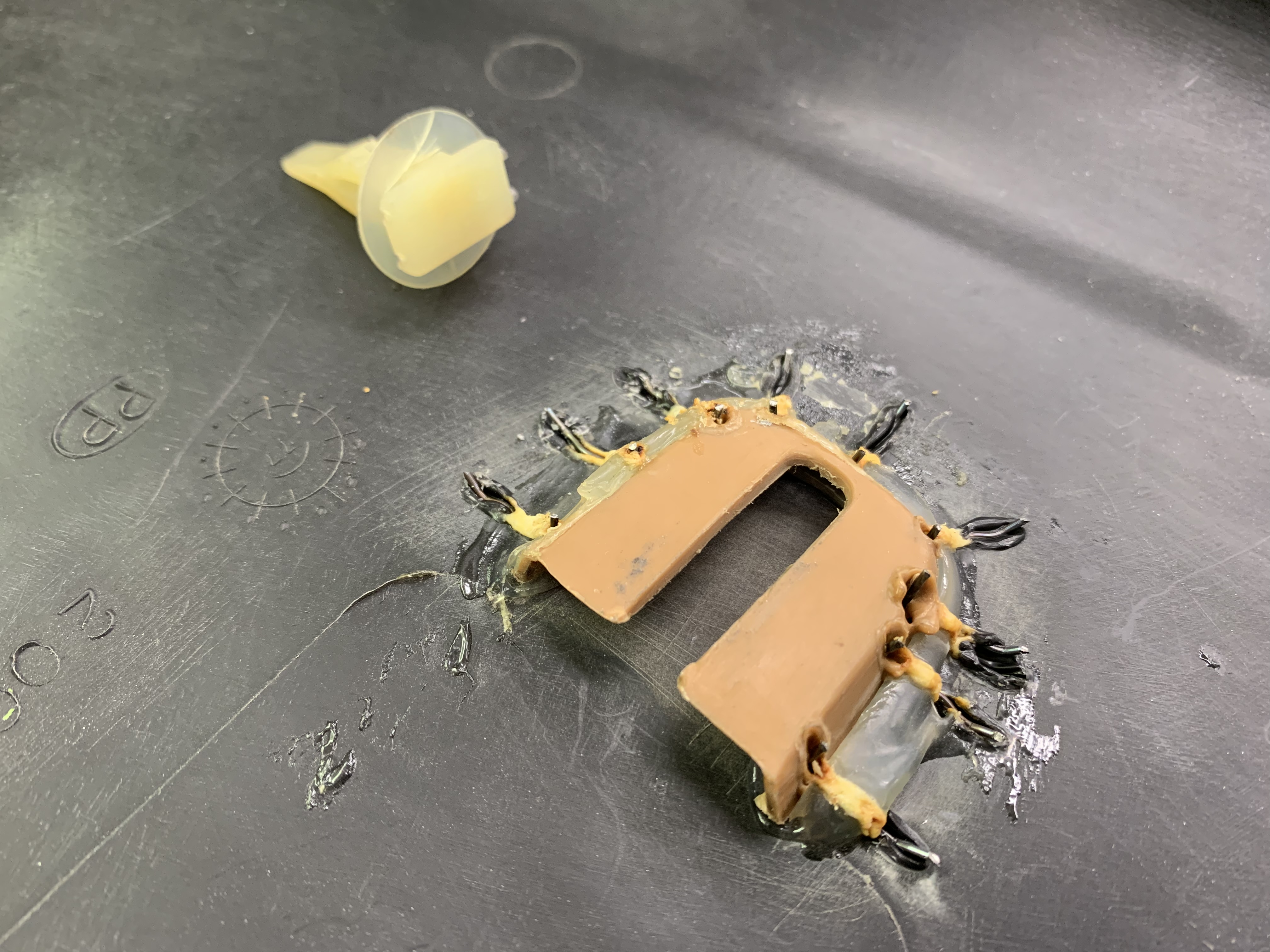

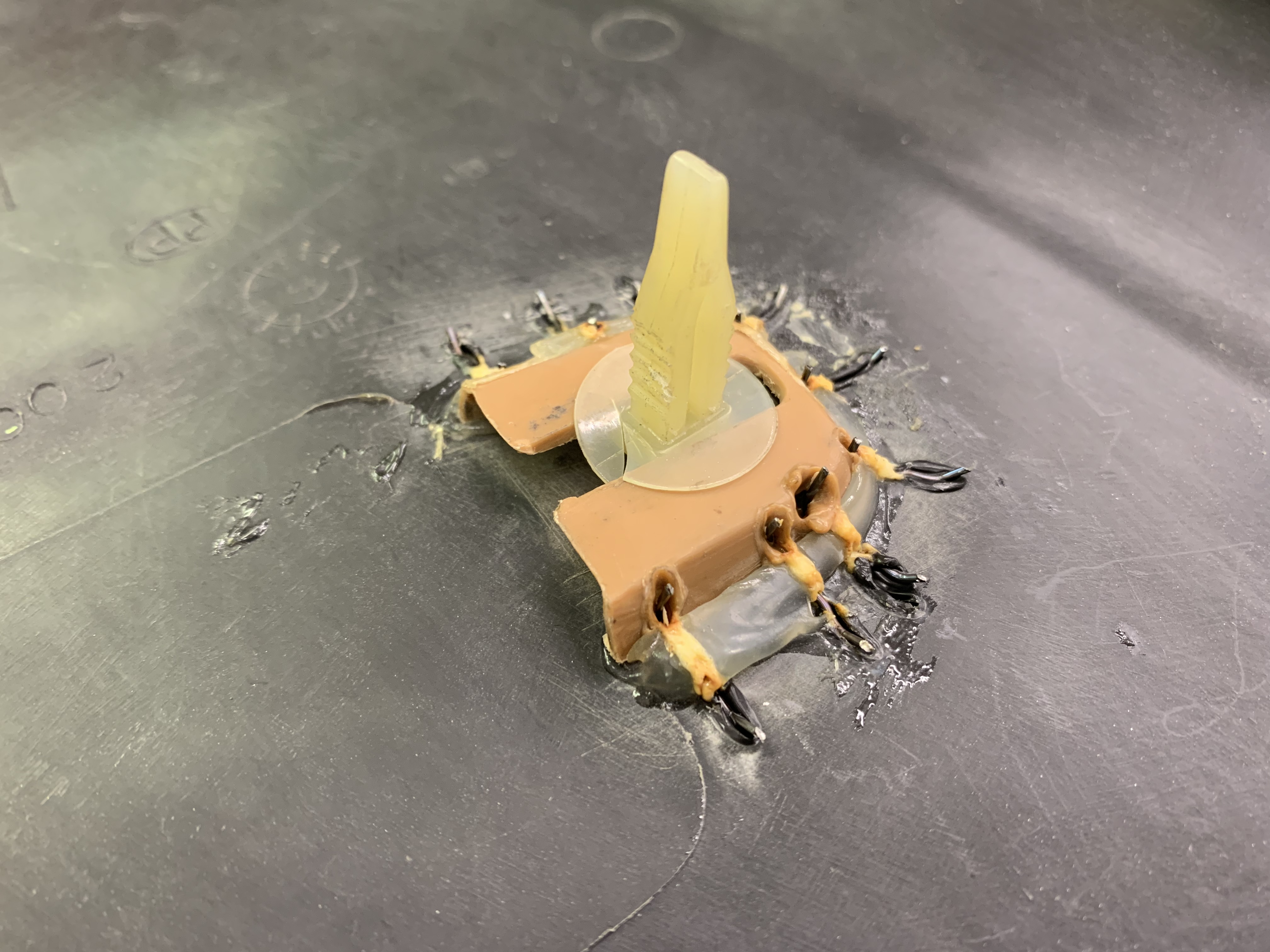

Same here, it would make sense that it should work fairly well. By melting the staples into the plastic, they become one with the panel and put the necessary strength back into it. I’ll report back once I have a chance to play around with it a bit.

Correct. Each type of plastic has its own unique properties, and you have to be sure of what it is you’re working with beforehand. ABS plastic for example, can be welded back together with solvent, I have some of that already. But polypropylene and polyethylene cannot. PP and PE have relatively low melting points however, so they can be fused back together with heat pretty easily.

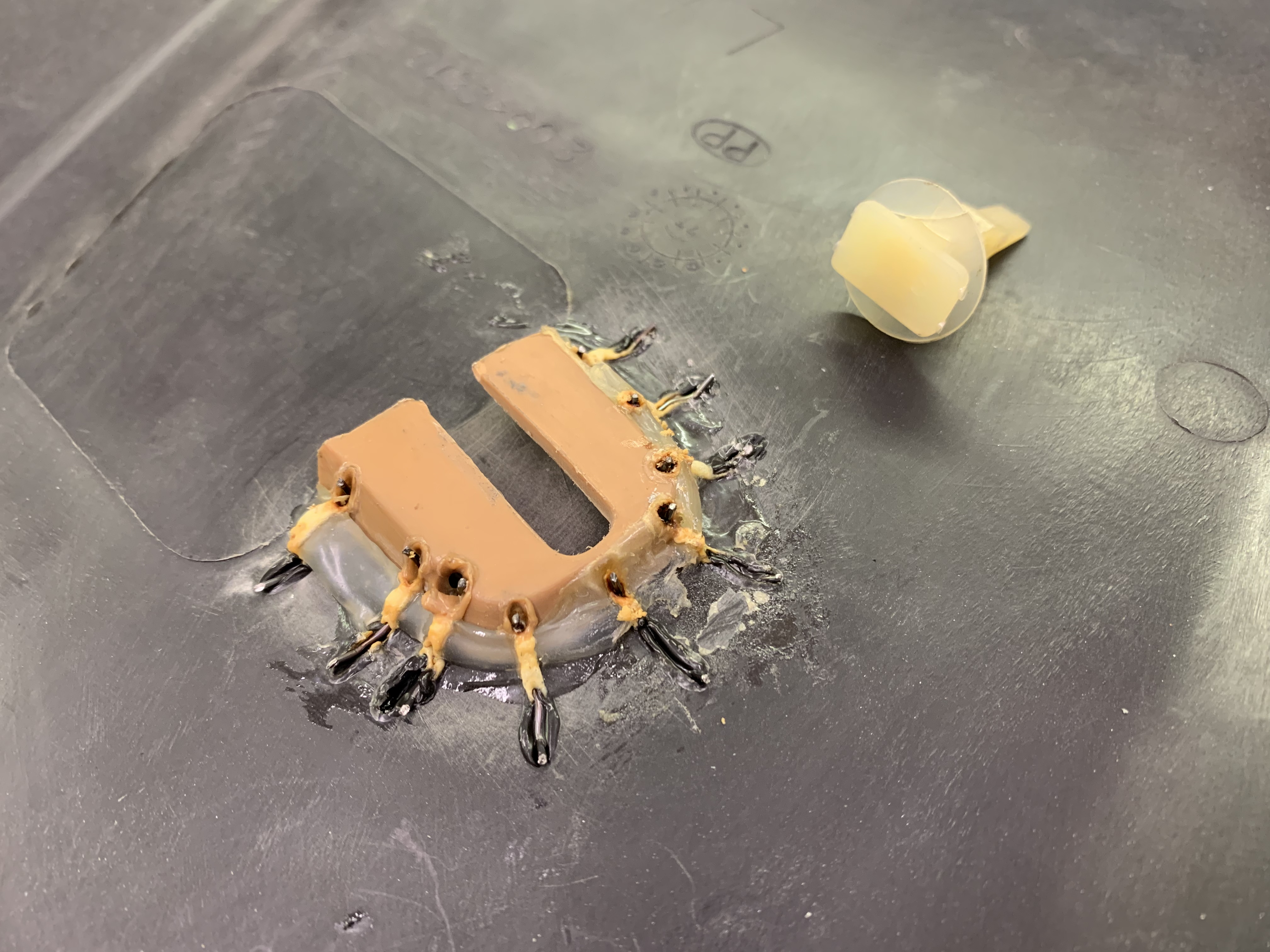

The panel I have to repair is polypropylene, so my only option is plastic welding. The staple method I plan on trying will work better than trying to infuse new plastic filler rod, but that is the other option. A simple pencil style soldering iron and the appropriate plastic filler rods is all that’s needed for that type of repair.

Yet another job for zip ties 🙂