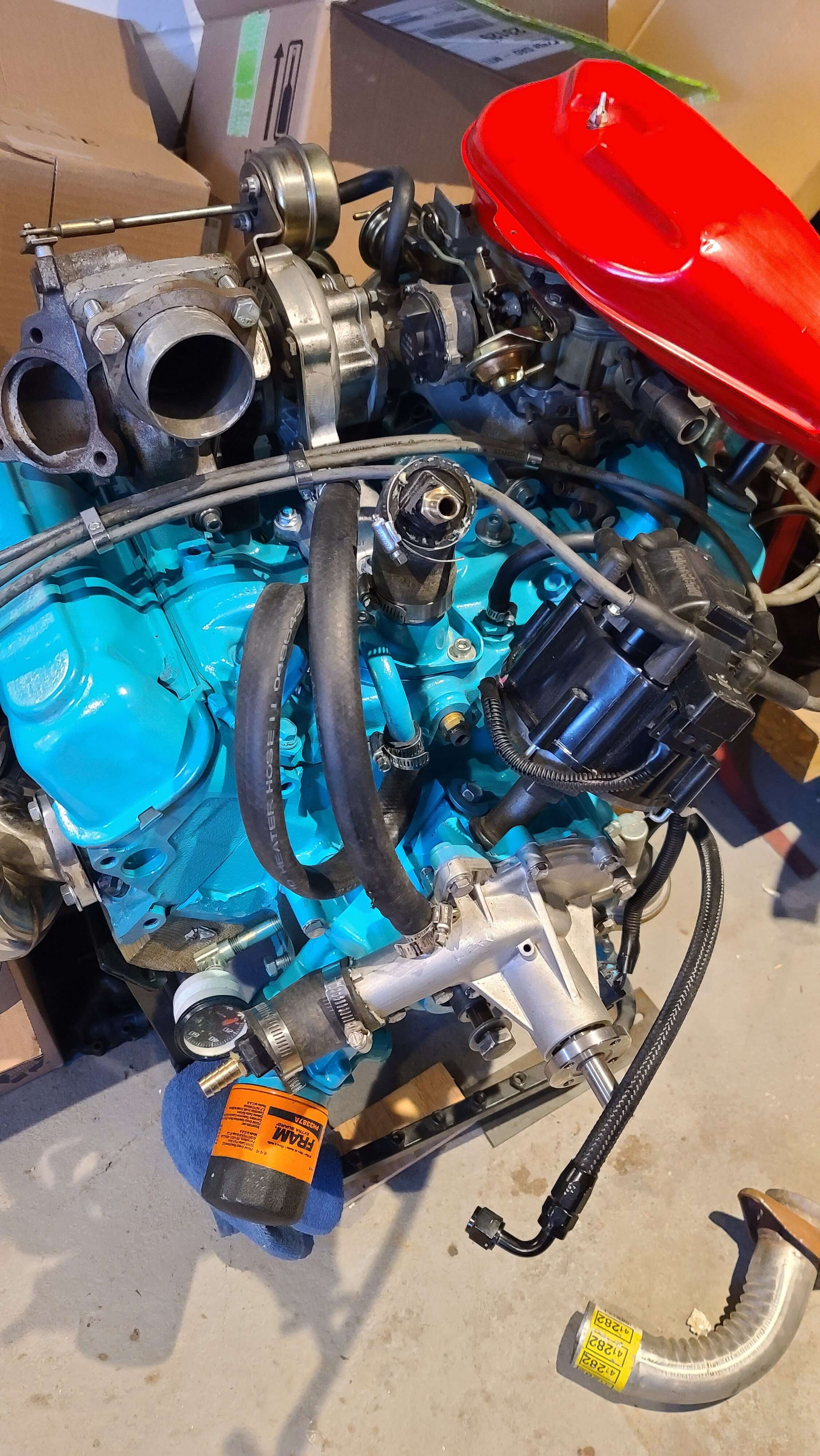

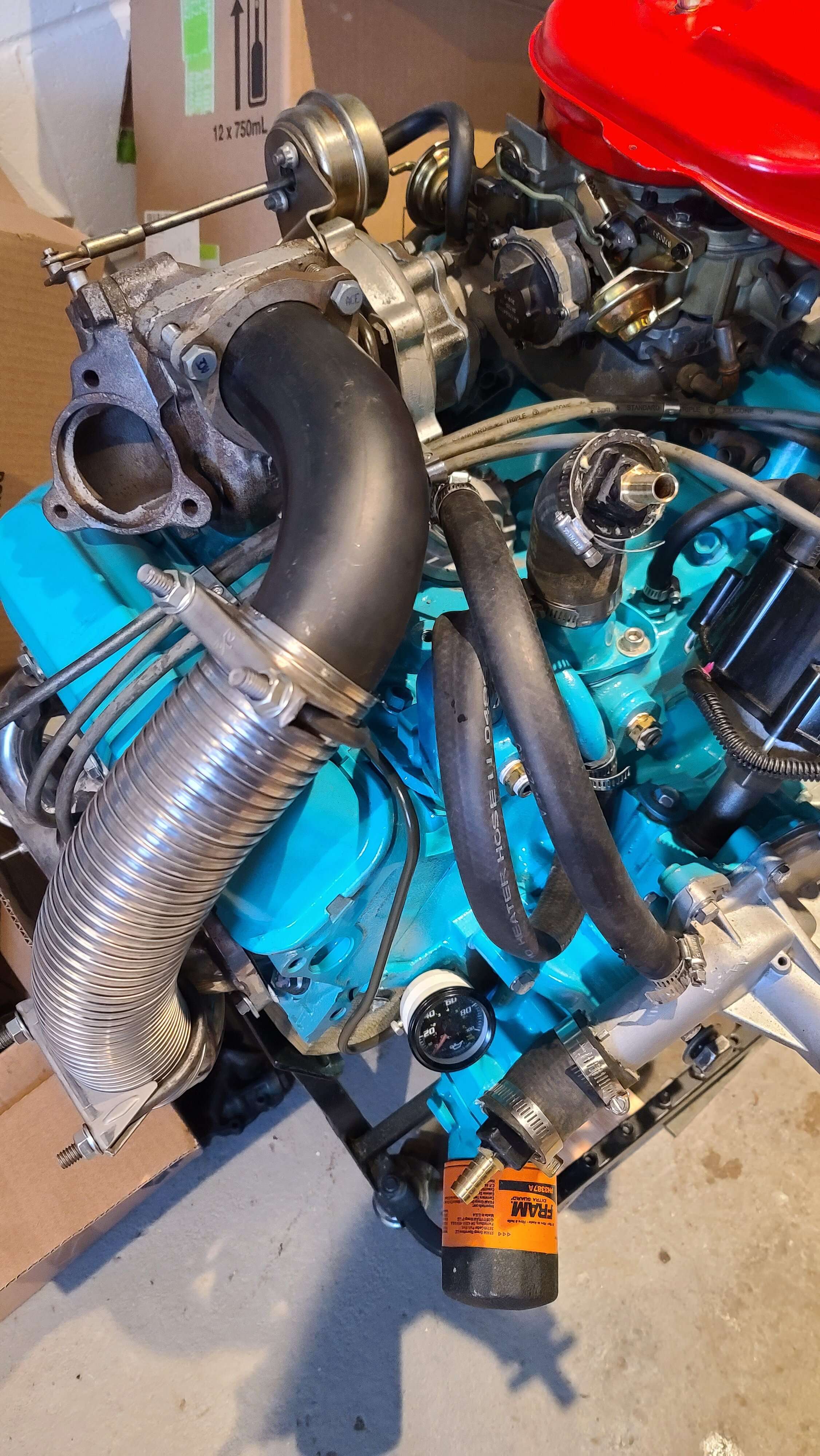

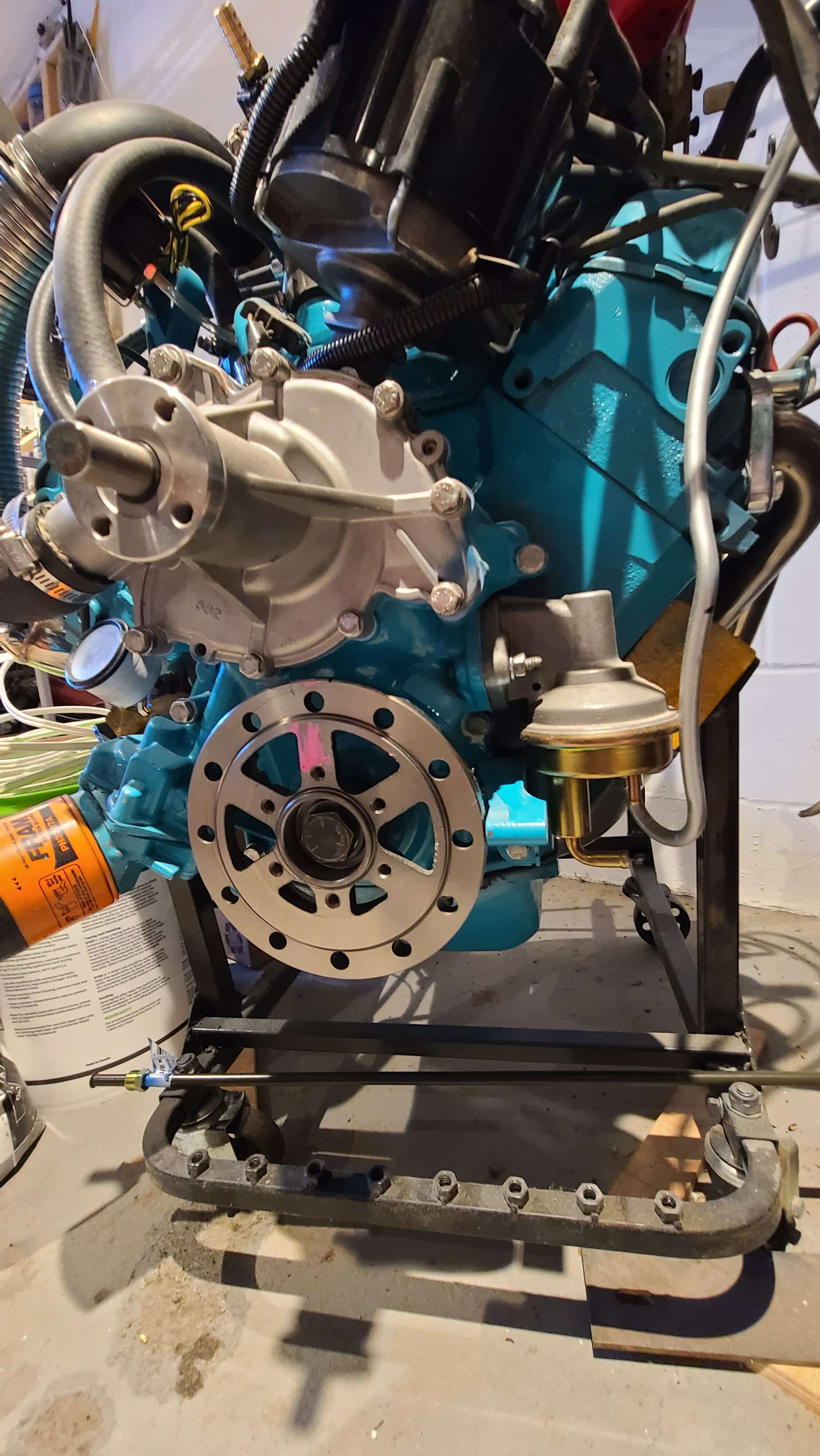

Looks good except throw that oil filter in the bush!

Seconded.

Looks good except throw that oil filter in the bush!

Ahah, I see you don't like FRAM ?Looks good except throw that oil filter in the bush!

Yes, to the poorly constructed, orange can of doom. The latest Tough Guard and the Ultra Synthetic are very good filters. I got Wix and Purolator Pure One filters off Amazon for cheaper than that POS at Walmart or Canadian Tire. It might be fine for the initial fire up of this motor, then switch to something better.Ahah, I see you don't like FRAM ?

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.