Alright, Little bi-weekly update lol.

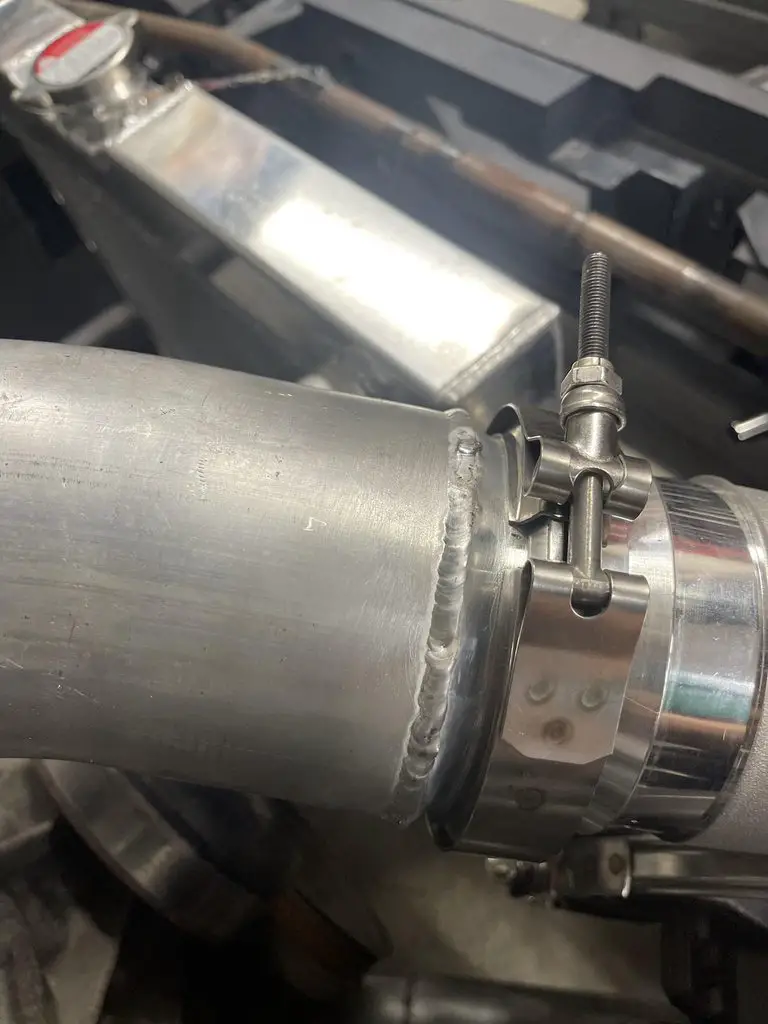

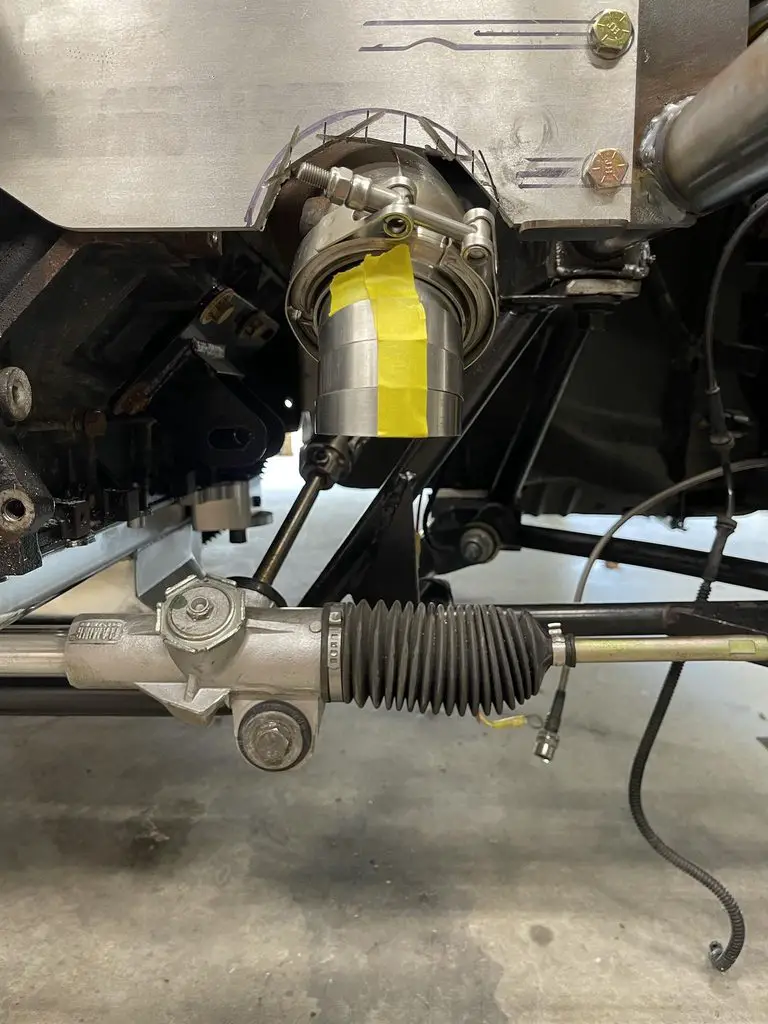

Buddy got his waste-gate pipe in, so we mocked them up cut the pipe to match the cope and then tacked them on for presentation. I'm worried a little bit about the passenger side placement priority, but at the end of the day i have twin 44MM waste-gates so it should cover any boost spikes.

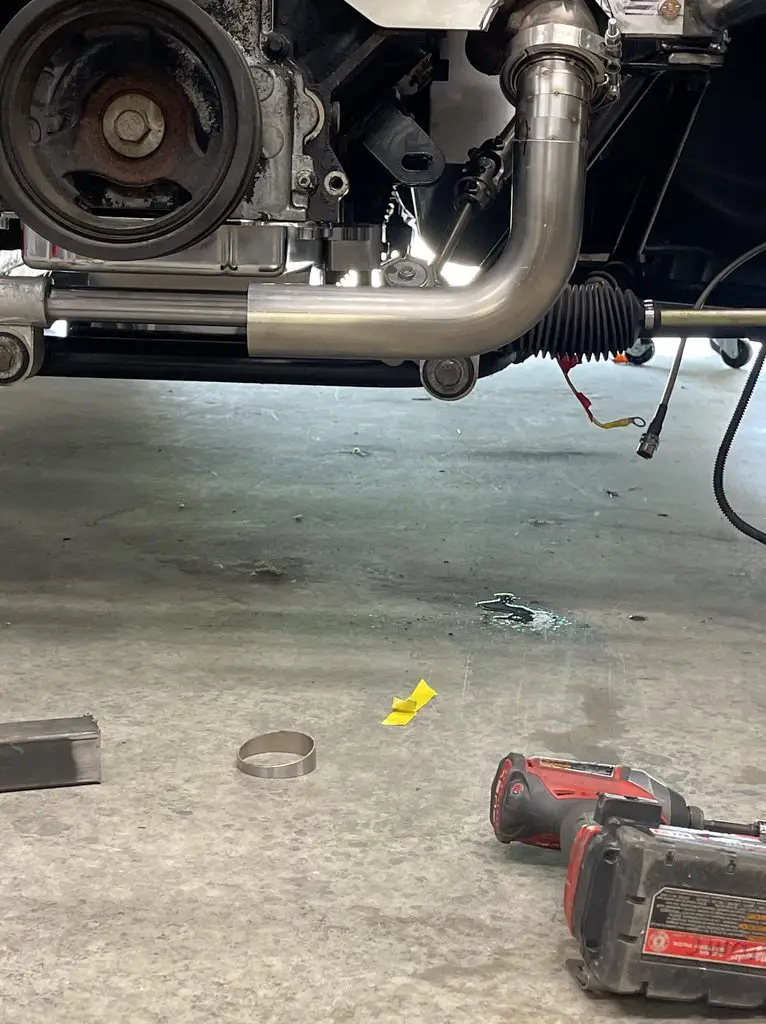

Never welding aluminum before i raided my stash of ebay inter-cooler pipe to practice on before committing to welding the v bands onto the charge pipe.

Not pretty but it works.

My new lower finally came in, hello dual fuel rails!

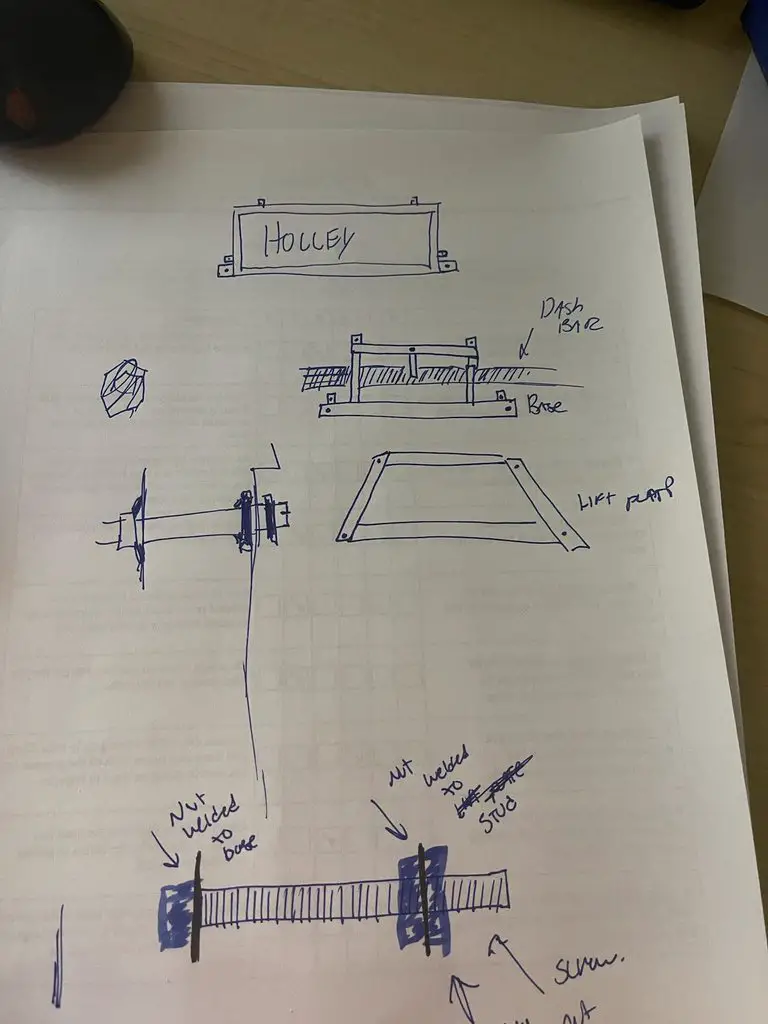

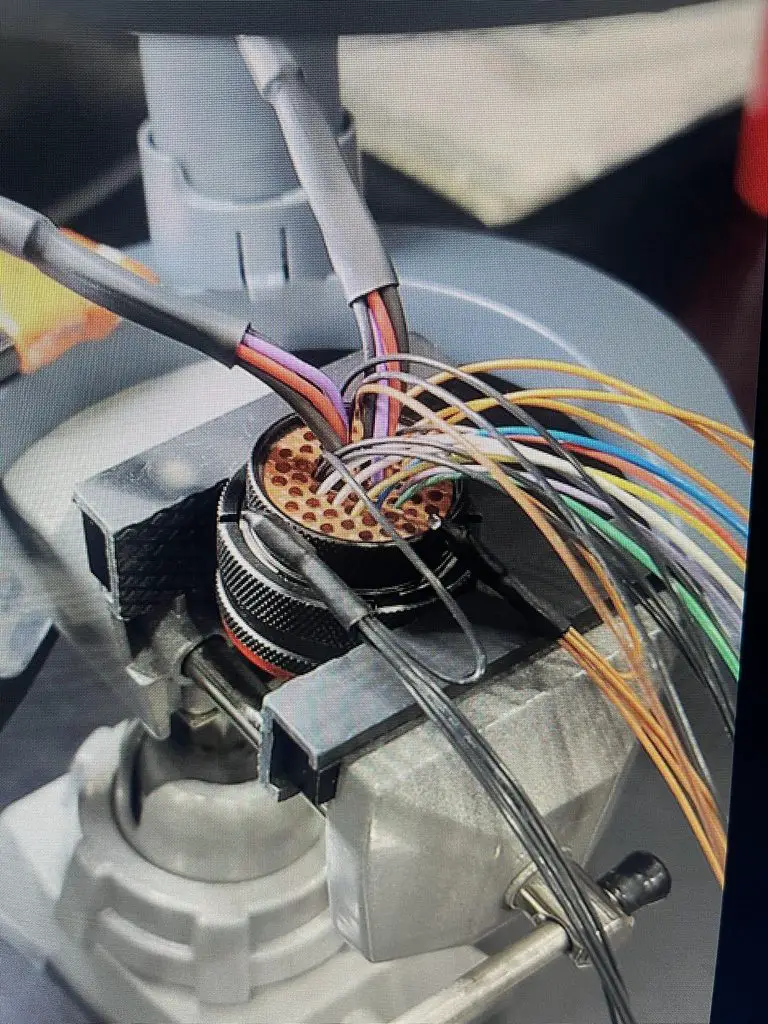

Some goodies came in the mail. Davis Craig EWP 150 - This will be used on the intercooler ice tank, its used but it wont get very much continuous use so it should be okay. Also got a Holley boost control solenoid for a deal with it. And finally got some Johnson short travel lifters prior to the price increases.

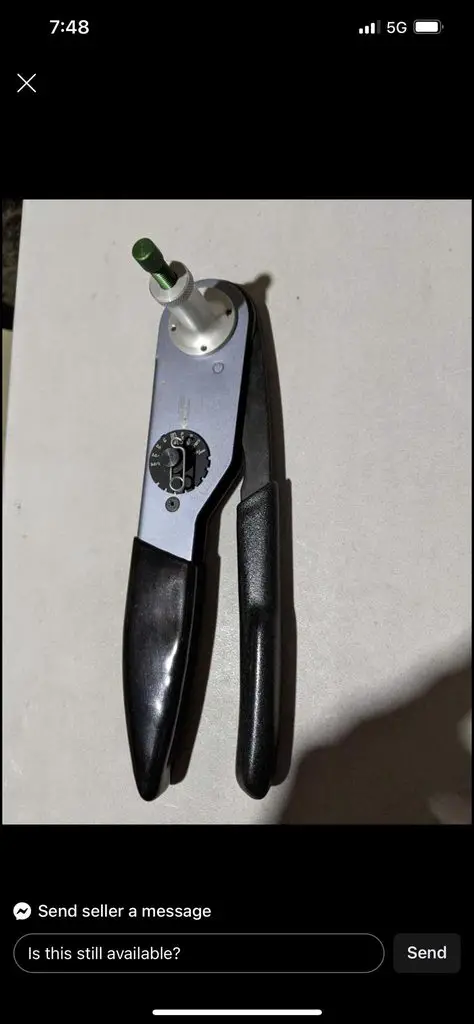

Scored some TE crimpers for pretty damn cheap, should make solid barrel contacts easy peasy.

Didn't like my steering wheel, so thanks to Doug Cook at Motion Raceworks i got this nice steering wheel.

Then while waiting on my buddy to get her to help rip out his motor i started to look into how im going to sheet metal the rear quarters. The car came with some really nice Scott Rod pre-fabricated panels. But due to whoever made this cage, the door pillar to main hoop bar is way to close to squeeze it in. Talking to a few people, it looks like ill have to source a company that does tin work to drop it off too.

NOW i did skip some steps here, but in building my buddies car we wished we would have made the charge pipe first to somewhat anchor the position of the turbo. So that's what we started on first, its a little more forward than id like it to be but it had to be this way in order to clear the water-pump accessories. The radiator is sitting there for reference, it still needs to go over another 2" which i have the room for. I don't see any concern with the inlet being behind the radiator at all.

I'm going to start working on the hot side this weekend/next week. I have to order another regulator and fill another bottle so that i can back purge the stainless.

Thats all folks!