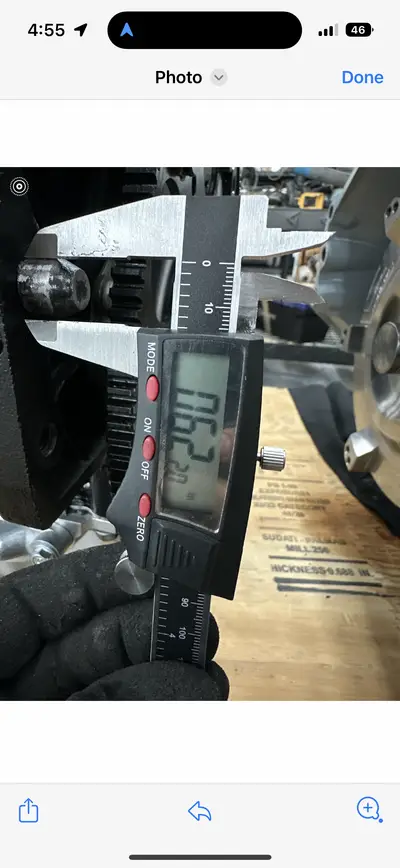

Gm, been running into all sorts of dumb problems and this is the latest. i went to mate the trans to block and it wouldnt get flush, pulled out some sanding paper and sanded the dowel hole on trand and the dowel pins, then i used a digital caliper and found that the dowel pins (engine) are .6215 and the dowel pin holes (trans)are .6115 . I called a few places, trans builder, engine builder even jegs. apparently no ones ever seen this. i cannot get a smaller dowel or it wont fit the block so what i am planning on doing is reaming the hole with a 5/8 ream (closest to what the dowel should be (.6250) my question is this. If the dowel doesnt fit super snug, is that an issue? i dont think itll have a ton of play but it may not be too snug.

4l80e dowel hole smaller than the 6.0 block dowel

- Thread starter johnnunez29

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Dowel pins aren't typically tight fitting as a rule. Some are and some aren't. Theoretically, a 35 thousandths of an inch bore difference once you open up that hole isn't going to hurt you. That's a spark plug gap. I'm guessing you're using a transmission that originally wasn't for an LS block? Just asking, I don't mess with LS and transmission combos. The bolts are keeping it tight. The dowels are simply for ease of alignment for assembly. The bolts, when properly torqued, are going to keep your transmission tight to the block.

Trans was supposed to have come off the same ,a 6.0 block. If I use a 11/16 bit then it’s too small. So 5/8 is the closest I can get. You basically said what I was hoping to hear.Dowel pins aren't typically tight fitting as a rule. Some are and some aren't. Theoretically, a 35 thousandths of an inch bore difference once you open up that hole isn't going to hurt you. That's a spark plug gap. I'm guessing you're using a transmission that originally wasn't for an LS block? Just asking, I don't mess with LS and transmission combos. The bolts are keeping it tight. The dowels are simply for ease of alignment for assembly. The bolts, when properly torqued, are going to keep your transmission tight to the block.

Drill with a 15.5mm drill (.6102") preferred or a 39/64" (.6094") drill.

Drill with a 15.5mm drill (.6102") preferred or a 39/64" (.6094") drill.

How is that going to allow a .6215" dowel pin inside?

Thank youTrans was supposed to have come off the same ,a 6.0 block. If I use a 11/16 bit then it’s too small. So 5/8 is the closest I can get. You basically said what I was hoping to hear.

sh*t 80.00 to possibly ALMOST make it inDrill with a 15.5mm drill (.6102") preferred or a 39/64" (.6094") drill.

Great point. Yeah, my brain wasn't even engaged with that. If your centerline is too messed up between the engine/trans, it could be problematic for the bearings in both engine and transmission. May want to hold off on just hogging out the holes.I wouldn't ream the trans - bad juju will happen if you're off by .005-.010".

All I can say is there's either the wrong dowels in the engine or something is amiss with the transmission holes. I've never heard of this issue before between engines/transmissions that supposedly are made for each other. Ever.

Not much of an option. What else could I do? I sanded the dowels and the hole to get the paint out and Thai is what I got.I wouldn't ream the trans - bad juju will happen if you're off by .005-.010".

Attachments

sh*t that’s the same thing I heard from the engine builder AND the trans guy. Engine builder checked a bunch of ls he had and they were all different. I’m kinda stuck. Need to do something.Great point. Yeah, my brain wasn't even engaged with that. If your centerline is too messed up between the engine/trans, it could be problematic for the bearings in both engine and transmission. May want to hold off on just hogging out the holes.

All I can say is there's either the wrong dowels in the engine or something is amiss with the transmission holes. I've never heard of this issue before between engines/transmissions that supposedly are made for each other. Ever.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 17K

- Replies

- 5

- Views

- 2K

- Replies

- 18

- Views

- 2K

BUILD THREAD

84 Regal back half/caged/mini tubbed lq4/4l80e build

- Replies

- 73

- Views

- 10K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.