You could build a basic version of this in a day, or find a donor for the frame and smash a box on it.

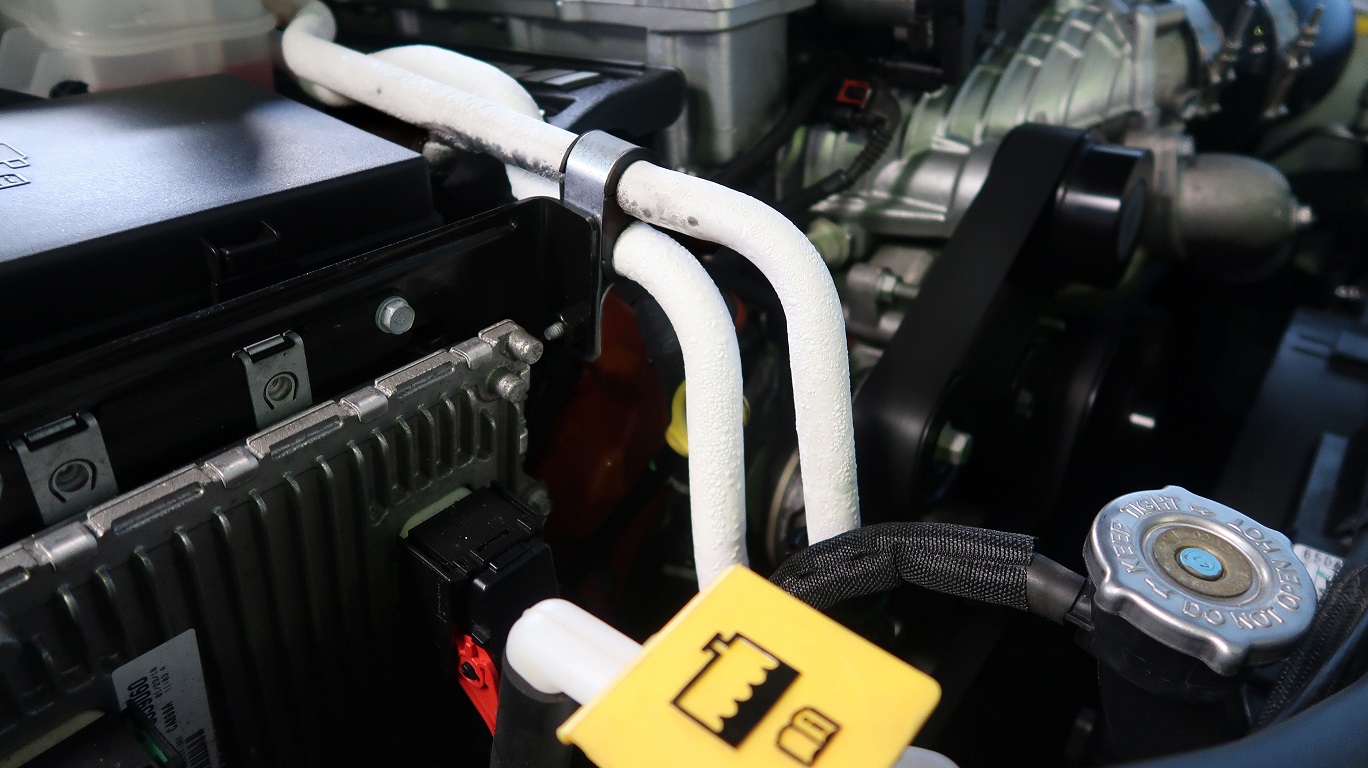

Yeah the more I see the more I realize how low of timing I actually was running. I do have 317's, I didn't know about the burn rate on cathedral port vs. square port stuff.

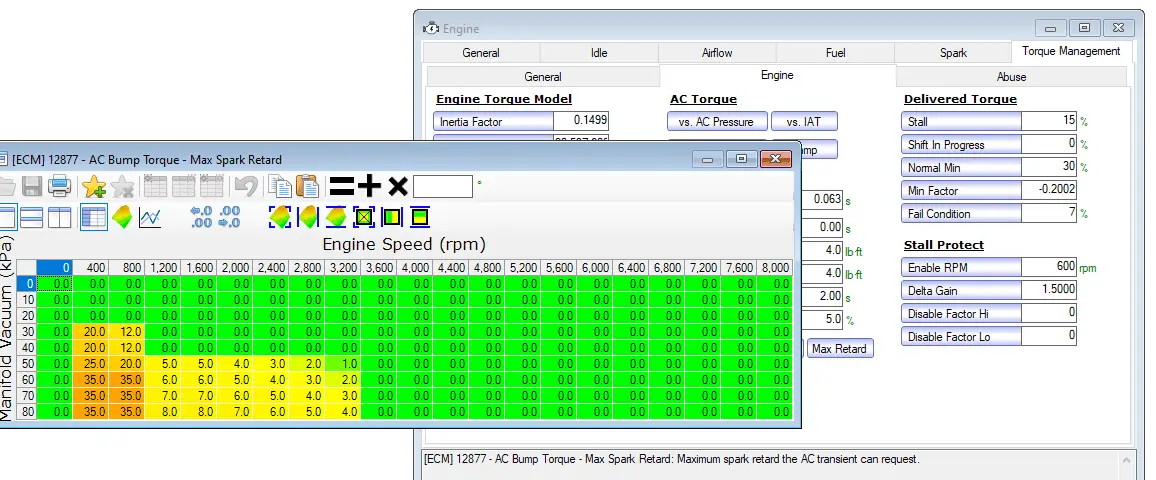

8-14 does seem pretty reasonable for 91 on a realistic heat soaked setup. I have been digging around on LSA forums and they say 6* of knock retard is pretty common with 140 IAT on the stock tune on 91/93 which puts it essentially RIGHT in that 8-14 range. Max torque at 4200-4600 rpm. 12ish PSI.

General consensus says 20 degrees seems possible if it's cool and on 93 octane, or spraying some alky. That stock LSA 14-20 high octane table does make sense for an engine that is not heat soaked and on 93.

24-26 on E85 seems like the general consensus so another 5 degrees over gas, which kinda aligns with the Holdener gas to E85 test he did where he went from 18 on gas to 23 on E.

I'm going to dial the fuel in on this 8-14 tune and once it's more settled (there are still some holes due to the fuel pressure change when I went to twin pumps) I think I will throw the 2.55 pulley I have on and see what that does to my boost. It should get me to 12-13psi and I will dial the fueling in there. If my IAT's aren't crazy I will look into creating a slightly more aggressive timing table to try at the track. Probably 12-18 degrees and do an A to B comparison at the track to see if I pick up any MPH.

Speaking of IAT's my brain started thinking about building my own interchiller/demon style aftercooler water chiller off my AC.

Long story short, the math on these systems doesn't add up to me. It just seems like a gimmick to me. It seems like it works but once you put a pen to paper they don't. Ice has just shy of 80X the specific heat of water, so if you have 1gallon of ice and melt it that same amount of energy will heat up a gallon of water about 80F.

How did I make that decision?

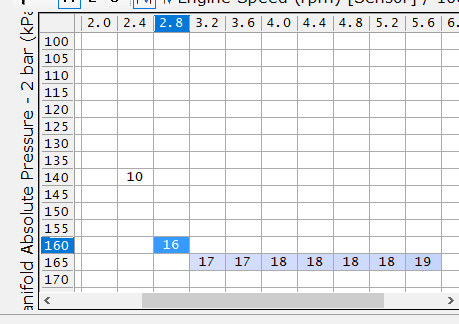

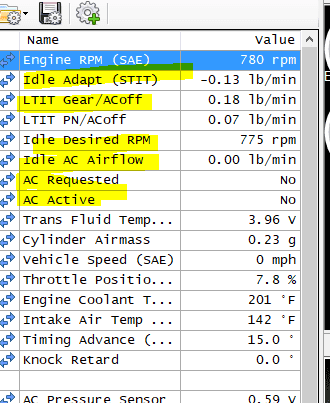

My current IAT tops out at 140F on a cool, non heat soaked setup with reasonable 60-70F ambient temp. It climbs up to 160F when it is heatsoaked and the ambient temp is 90F+.

The heat exchanger does a good job, I log the temp and it scrubs all the heat out of the system with maybe a 5F temp rise over ambient. The post aftercooler temp rises about 25F, so if it's 65F outside the water temp coming out of the aftercooler is 80F.

I also see about 50F of IAT temp rise compared to whatever is coming out of the aftercooler, so if the post cooler temp is 80F the IAT is about 130F. Heatsoak adds maybe 10F.

My problem is if its 90F outside, my IAT's are going to be 160-165F.

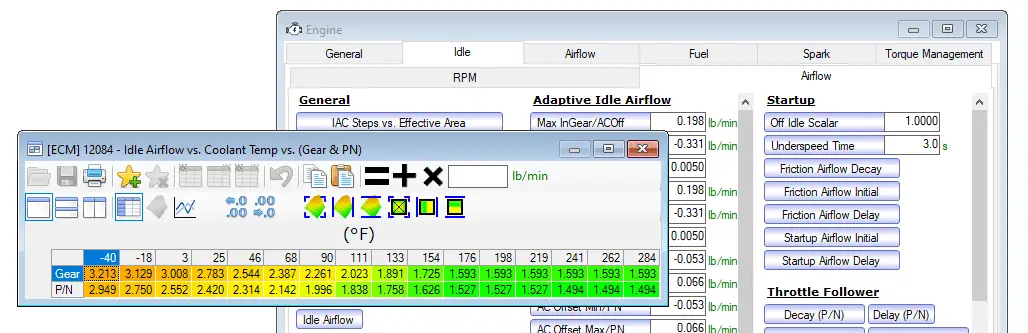

So best case if I can get my water temp down to 40F, I can probably get my IAT's down to 110-120F. I did some math and if the intercooler pump flows 4gpm and I want to keep the water cool for 30 seconds and allow a 10F temp rise (40 to 50F), I need ~2megaJoules of energy stored in the water.

The problem is that is 12 gallons of water. The blower puts out enough heat that in 30 seconds to heat 12 gallons of water from 40F to 50F. Even if I would only want to cool the air for 15 seconds (2-4 seconds to cool-soak the aftercooler post burnout plus the 10-11 second run that would still be 6 gallons of water and I don't want a 5 gallon bucket reservoir hiding under the inner fender of the car.

If I were to put an ice tank in I would need about 13 pounds of ice per run, or basically 2 gallons of ice, so I would need a 5 gallon tank in the trunk and drain 2 gallons of water every pass to add more ice. Granted my IAT's would always stay at whatever rise over 32F, but still. The math is starting to make sense on why people burn so much ice per pass if they have an ice tank.

So I am just going to live with 160F IAT's and heat soak! The amount of cool water I need in a reservoir too much to make an interchiller system work.

Automotive AC systems are 20k BTU/hr at max, so to cool my warm 50F water to 40F to scrub the 2MJ of energy the blower added for the 15 seconds, I would need to run my AC pump for 6 minutes.

Running the AC pump during the pass makes zero sense also. It only puts out 5BTU/sec best case which is 0.005MJ/sec. Ouch. The blower makes 133MJ/sec of heat according to my sensors.

So no interchillers for me!

Demons and Redeyes et al would disagree.

Jeep Trackhawk Interchiller Review

www.hellcat.org

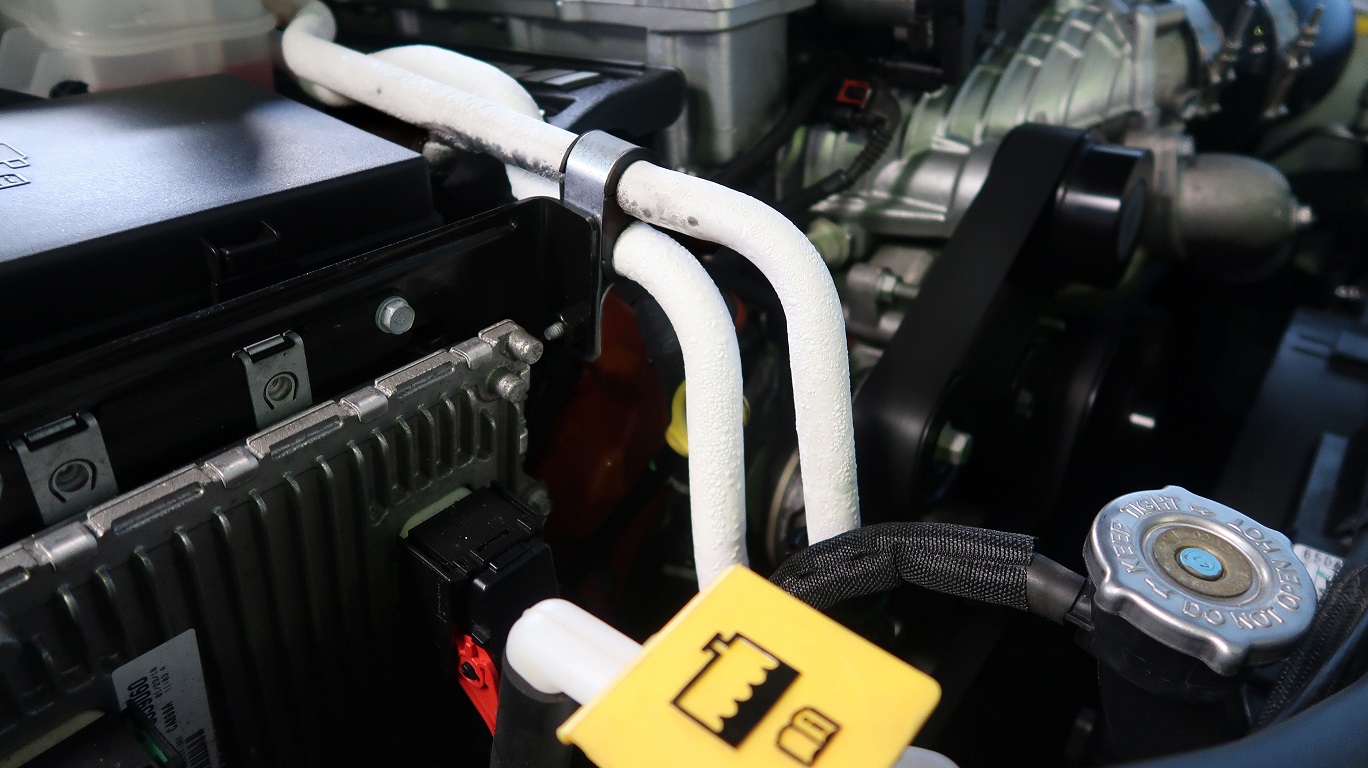

Those lines look pretty frosty. The high capacity systems (on both the AC and intercooler HX side) seem to be the difference makers.

Interesting. I guess they do get the water a lot cooler than I thought. I assumed they only got the water to 40F but they get it down to sub 10F. Might be worth addressing after all. Potentially the newer AC pumps are bigger and more efficient than the Sanden style I have also? Lots more water volume also possibly? Probably a back shelf project, but I did pull it out of the trash. FI interchillers seems very quiet about their systems as far as providing tech info.

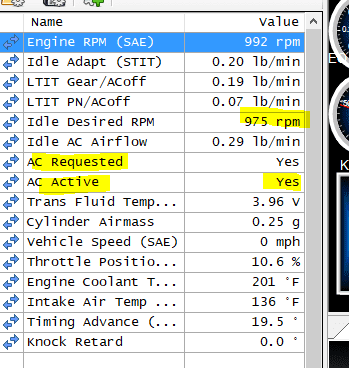

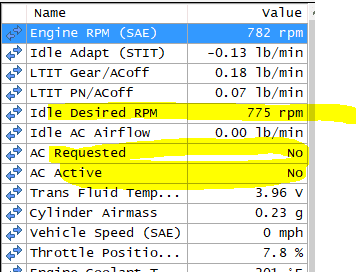

Butt dyno confirms there are more Llama thrusts on tap with new timing?

Damn, he sure threw the warranty out of the picture fast lol.Because I like looking at both sides of a problem, here is an interchiller/trunk ice tank delete to just a 3 gallon ice box swap:

Stinkeye Challenger build....

Holy crap cakes ! [emoji44] Sent from my BBF100-2 using Tapatalkwww.hellcatforum.org

Granted this is not a street car (ie. pushed to the line), and is chasing extreme weight savings. So, it's apples to oranges.

Here's the car they are referring to:

Damn, he sure threw the warranty out of the picture fast lol.

Interesting. Ill have to digest that a bit.

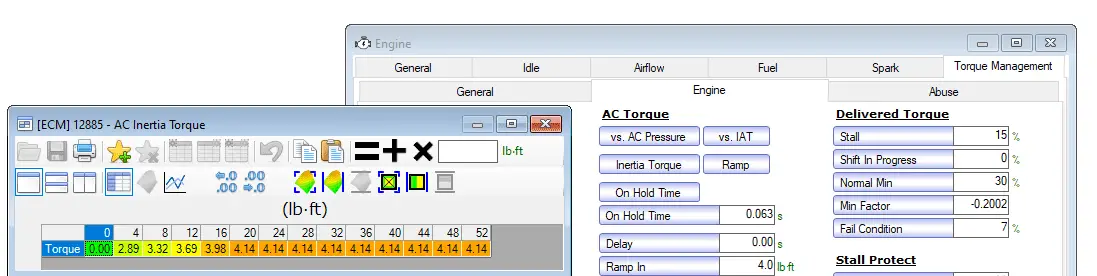

Butt dyno is out of calibration but HPT is in cal 🙂 The answer is yeah.

Little apples to oranges since at the track I have 275/60-15 DR's and street is 275/40-17 so the true vs HPT mph is a little off due to tire height. The car is actually moving faster than HPT says it is on DR's so it's going to look slower at the track because of the speed error.

All my checks were in 3rd gear because the car won't hook in 2nd not on DR's.

4380-5660 RPM pull on street tires (70-94 llamas/hour), 2.27 seconds

same pull range on DR's, 2.801

So a little over 1/2 second faster from 70-94 llamas/hr.

Did the same range but starting from a higher RPM

2.6s on low timing and 1.89s on high timing. So about 0.7s faster.

And for an apples to apples comparison (I trust this a lot more)

2500-5250 pull, 4.485s on low timing and 4.077 on high timing. So basically 0.4s faster.

Damn, he sure threw the warranty out of the picture fast lol.

Interesting. Ill have to digest that a bit.

I wouldn't like putting tires in the back seat. I like your caddy way better.Older picture of the 2+2 from '18 drag weekend popped up (the first time I blew my rear axle lol) and raised the question, should I go back to the tool box and tire caddy on the trailer hitch or keep with storing the tires in the back seat.

I bottomed out HARD when I did this with the stock springs in '18 but it was really convenient to keep all my tools locked up and tires outside the car. It made loading and unloading the car much easier. The caddy has some fold down legs so I just pull into the spot at the track, fold the legs down, pull the hitch pin and pull forward. Putting gas on was kinda a PITA.

I have 5409 rear springs now and spring seat height adjusters so the car shouldn't bottom out like it used to so roading should be more pleasant.

However, I found totes that fit into my trunk so I can get all my tools into the trunk. Sliding the tires into the back seat is a pain however.

Options!

View attachment 180933

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.