That was at the rear end correct? If so I'd say it's normal lash on gears.

BUILD THREAD 87 Cutlass EFI build: 9/13/23..NEW STUFF!

- Thread starter Injectedcutty

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I'd also add that pinion angle isn't the answer and someone correct me if I'm wrong. It's pinion angle in relation to drive shaft angle. And it shouldn't matter if you check it with the rear wheels up on a ramp or jack stands under the rear end. The difference in angle will be the same. I've always looked for -2 to -3 degrees between them. When you accelerate the pinion will move up slightly closer to zero.

If I'm wrong someone let me know.

If I'm wrong someone let me know.

Yes, but the "clunk" is coming from the front. I'll check the front later when I get back home.That was at the rear end correct? If so I'd say it's normal lash on gears.

It depends on the suspension set-up.I'd also add that pinion angle isn't the answer and someone correct me if I'm wrong. It's pinion angle in relation to drive shaft angle. And it shouldn't matter if you check it with the rear wheels up on a ramp or jack stands under the rear end. The difference in angle will be the same. I've always looked for -2 to -3 degrees between them. When you accelerate the pinion will move up slightly closer to zero.

If I'm wrong someone let me know.

A stock leaf spring set-up? Definitely. Leafs w/CalTracs? Not so much.

An aftermarket 4-bar/4-link? Nope. The OE C4L set-ups under A/G bodies? Not so much beyond the factory flex of stamped arms & rubber bushings. Add aftermarket arms/bushings & def not so much.

The 2-3° number is off as well. The concept is/was a 3° drivetrain angle as the common number for OE carb'd set-ups & the basic go-to number for building hot-rods. EFI is more flexible on that set-point. So, if the drivtrain (motor + trans) is 3° (angled down/pointing toward the road surface), the pinion which is typically several inches below the trans would be set within 1° of that number angled/pointing-up. So 3°- 2° = 1° working angle (difference between the two joints) which is close to zero but off enough to help the needle bearings within the joint rotate for increased joint longevity. Big trucks (box trucks) w/multiple shafts & carrier bearing set-ups are a great visual of this because typically the rear end pinion is WAY below the trans output thus the 1st shaft is angled down X°; then there's a bearing, & the next shaft is angled down more to better fall within the 1° or less number/goal by the time it reaches the pinion.

Lower the vehicle to the extremes (VERY common in the truck scene) & that's where things change. That automotive standard no longer applies when the pinion C/L is equal to or above the trans output. In that same scenario I listed above, If the pinion is equal or above the trans output, you'd actually add the numbers & have 5° working angle between the joints which will wear things quickly.

This is why you need to measure the angles of each + the heights of each if things border on the aggressive side of lowering & adjust things accordingly. These G-body's are mostly mildly lowered so it's likely the pinion C/L is below the trans output C/L but one needs to understand there is a difference.

Last edited:

No problems me either but how did he do that quarter rear window because I can't seem to get that rubber out that's around the silver trim on that quarter rear windowHad a local guy powdercoat them. Sorry for the delay, haven't been on here in months

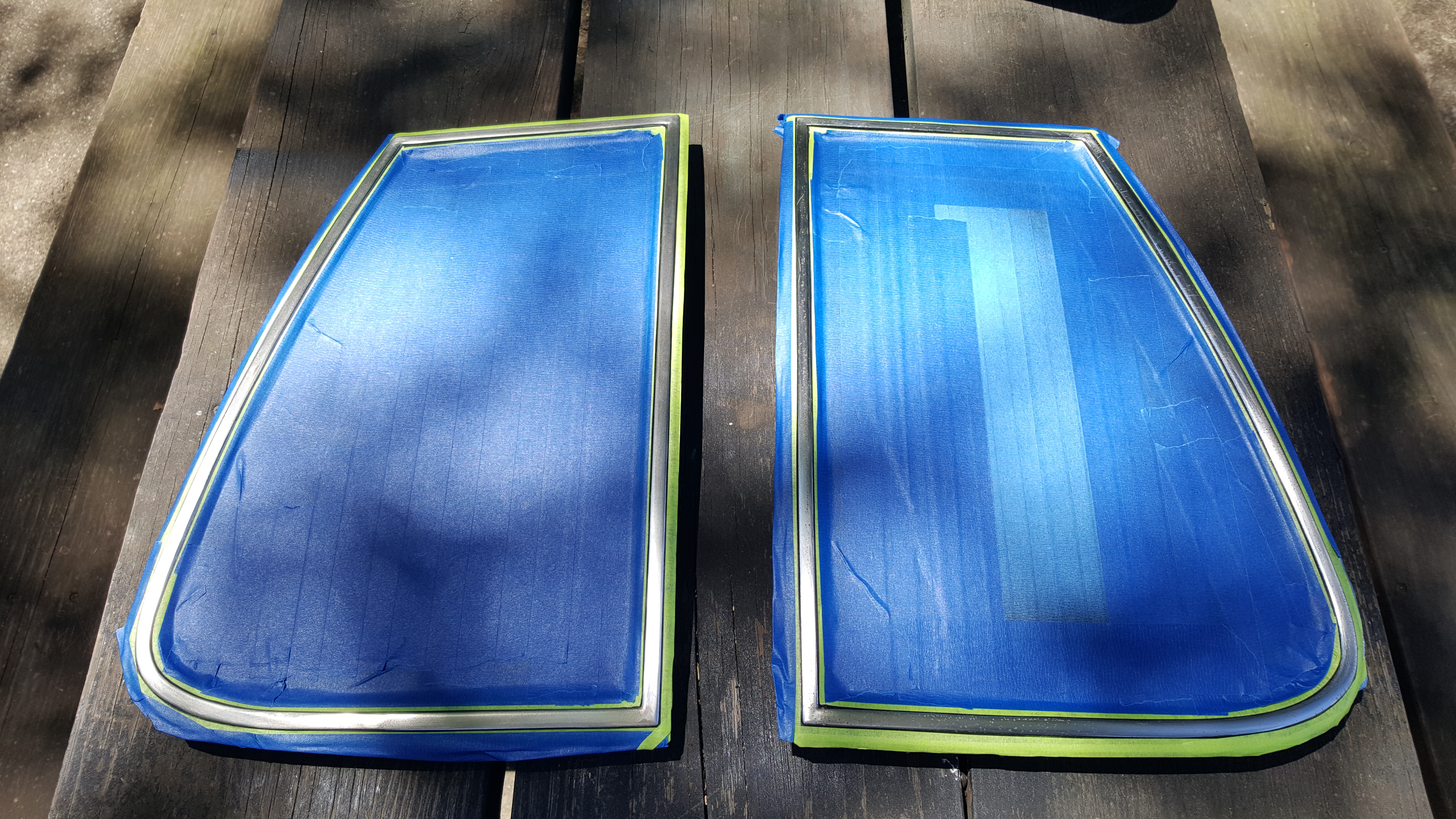

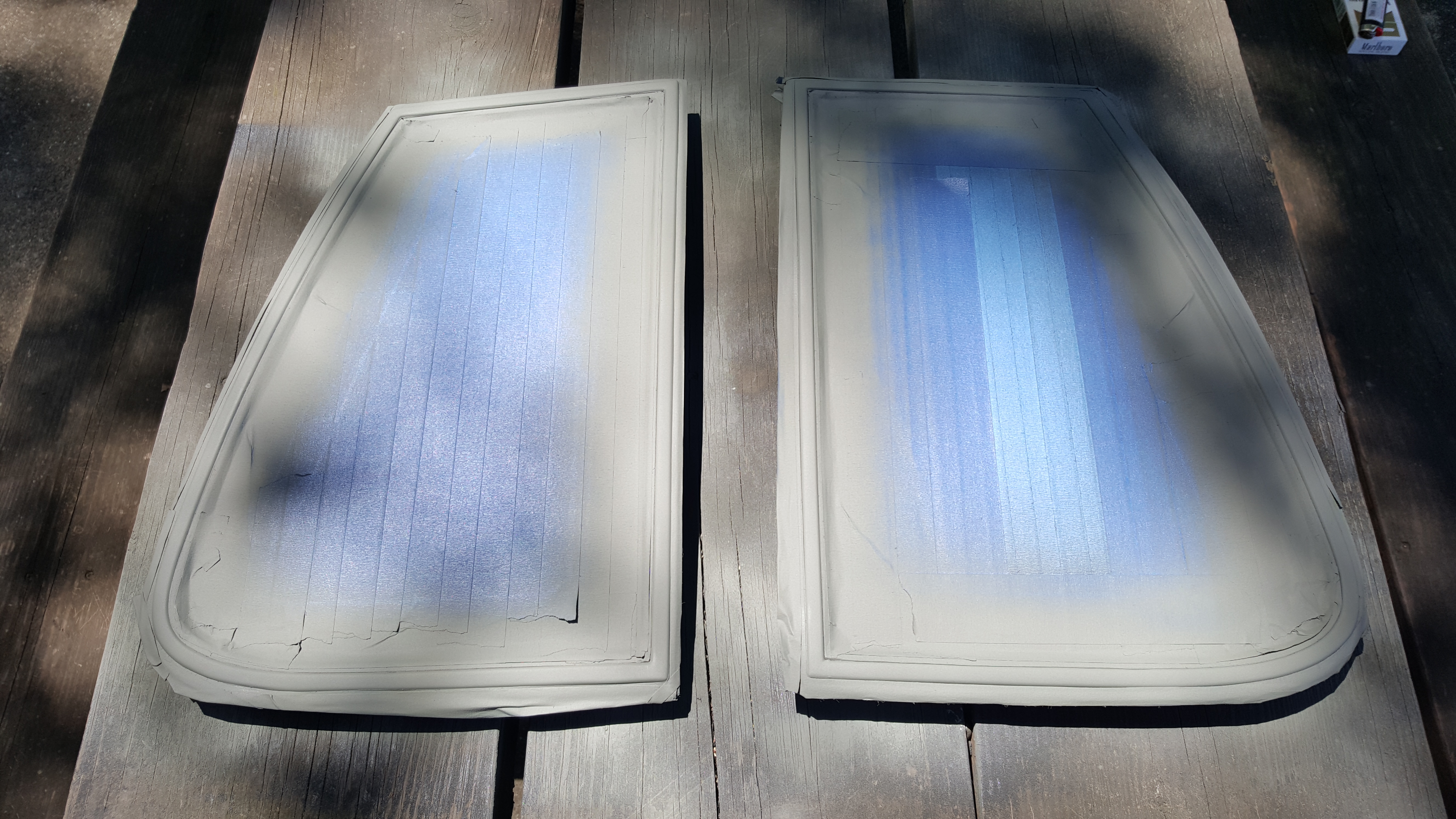

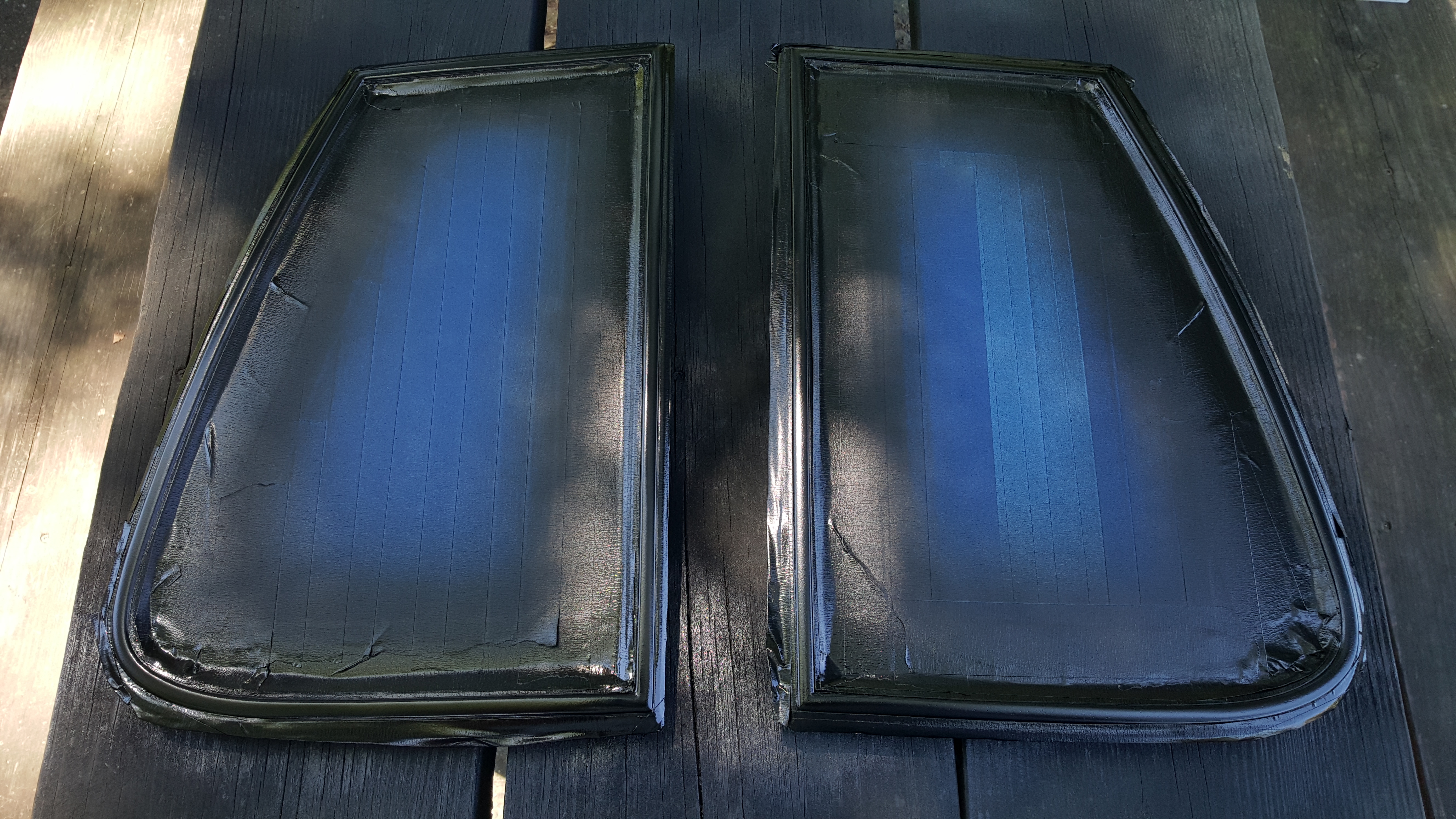

Not sure what he did but I painted mine. Clean, scuff, clean, tape and epoxy primer the color coat.No problems me either but how did he do that quarter rear window because I can't seem to get that rubber out that's around the silver trim on that quarter rear window

Oh, I painted those. Very painstakingly taped them off with only the chrome showing, prepped, untaped and retaped with clean tape. Then shot with satin black....No problems me either but how did he do that quarter rear window because I can't seem to get that rubber out that's around the silver trim on that quarter rear window

Attachments

Pypes Street ProWhat type of mufflers do you have?

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 13

- Replies

- 0

- Views

- 40

- Replies

- 1

- Views

- 95

- Replies

- 4

- Views

- 351

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.