About 20 years ago, I found a 36mm sway bar on a 3rd Gen WS6 T/A in the Junkyard. These bars weigh 10 lb less than the stock 32mm and I was trying to run mid 11's stock appearing, so I was looking for any weight saving I could find. I remember buying some bushings and it bolted right on. Later, when my dad had the the car torn apart to be repainted, I told him to swap the 36mm bar onto the 2+2, and he put the 32mm back on the T-type.

Recently I bought another 3rd gen 36mm for the T-type and when it didn't just bold right on, I figured I'd better make a thread to go through What I did to make it fit.

Turns out my T-type had dealer installed brackets/urethane bushings on the factory bar, that made installing the 36mm bar easier than the factory brackets.

Here are the things that the thread will go into:

1) Frame Bushings

2) Frame Mounting Bracket Mods

3) Frame Bracket Shims

4) Frame mods.

5) Link length

6) Misc

Completed Install:

1) Frame Bushings

The options for frame bushings are the factory rubber or aftermarket urethane

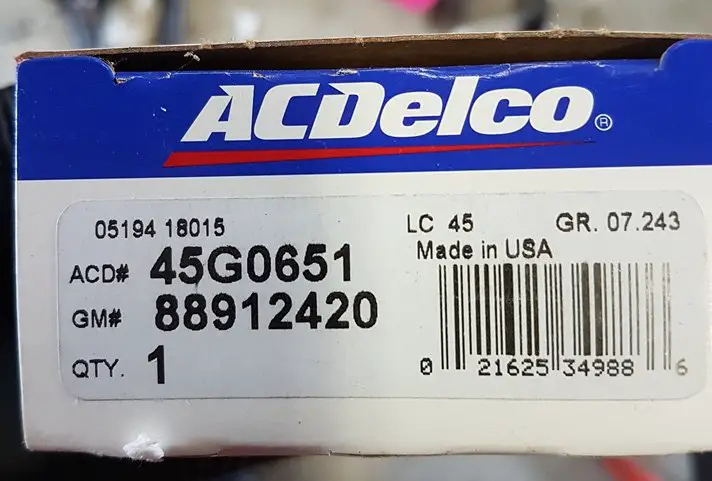

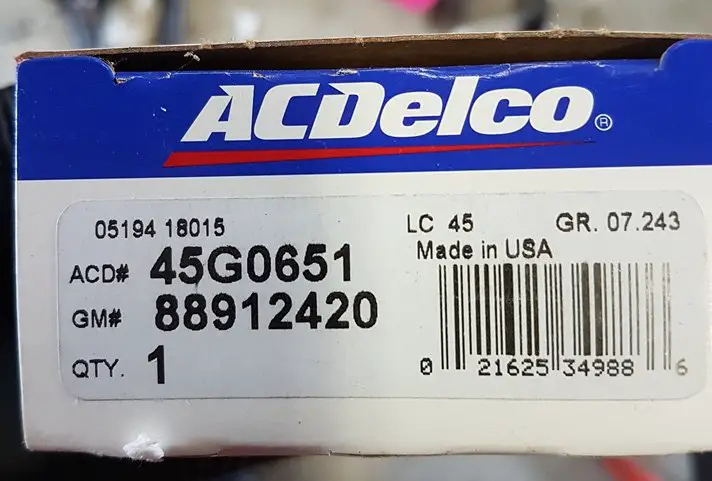

Moog K6459 and AC Delco 45G0651 are equivalent to the factory 88912420 Rubber Bushings (use the factory brackets). My QTY: 1 box contained 2 bushings.

Energy Suspensions 3.5213 greaseable 36MM kit may work, but will probably need some mods, because it is for GM trucks that have a .3" larger distance between mounting bolt centers

2) Frame Mounting Bracket Mods:

Here are the 3 different types of Frame Mounting Brackets:

Stock (Left), F-body (Middle), Aftermarket (for urethane) Right

If reusing the Factory G-Body Frame Mounts, they will need to be modded for use with the factory 36mm rubber frame bushings. The rear outside of each bracke will need to be opened up for clearance. (note the F-Body Mounts above have completely open sides.

The F-body 36MM Brackets have offset mounting holes and 3" spacing and there isn't much meat there to drill a new hole - maybe it can be done, Modding the factory brackets is probably a better option.

Aftermarket brackets won't need this mod:

3) Frame Bracket Shims

Note in the picture above, that bushing extends 3/8" below the bracket. The Bolts can probably be cranked down to crush the bushings, but the swaybar should rotate freely in the bushings, so this would be bad. Its best to shim the bracket away from the frame about 1/4" - 5/16". Ideally, some Aluminum plate would be best. I used my $10 Harbor Freight cut off wheel to cut some shims out of an old non vented Miata rear disk rotor:

After Sanding/Painting (Extreme Close-up)

How the Shims Fit:

4) Frame Mods

The LCA bump stop plate and excess weld on the frame can rub the bar during its travel. The $10 Harbor Freight Cut off wheel makes short work of these:

I may touch the voiding up with a MIG welder later, but for now...

5) Link Length

The Ideal link bolt length is a 7" with a 2.75" to 3" sleeve. Poly Bushings may need a 7.5" bolt to start, with a 3" sleeve.

I go buy real shoulder bolts from the hardware store.

I used to have a lot of thread failures with the necked down hardware on OEM and Aftermarket Sway bar links.

Real Grade 5 or Grade 8 bolts, not so much.

6) Misc

If you need new frame bolts, the Frame bracket bolts off of a Tahoe/Suburban/Yukon work great with the factory brackets. These have a 6 point 10mm head and a larger washer surface than factory. Regular bolt heads with this thread will be too large and be too close to the bracket to use a closed end whench/socket.

7) Installation

Installing the Bar is a littles easier than the factory 32mm (because its 10lbs lighter, but there are a few tricks:

1) The U-bend in the middle goes down. Think of the bar smiling back at you and not frowning.

2) Install the Frame Brackets/Spacers loose on both sides, then...

3) Push the arms of the bar as high up as they will go, to center the bar in the frame brackets.

4) Now tighten the Frame brackets (I use a tiny 1/4" drive ratchet so its hard to cross thread/strip anything)

5) after the frame brackets are tight, make sure the bar moves without much resistance and that it is still centered on the frame.

Recently I bought another 3rd gen 36mm for the T-type and when it didn't just bold right on, I figured I'd better make a thread to go through What I did to make it fit.

Turns out my T-type had dealer installed brackets/urethane bushings on the factory bar, that made installing the 36mm bar easier than the factory brackets.

Here are the things that the thread will go into:

1) Frame Bushings

2) Frame Mounting Bracket Mods

3) Frame Bracket Shims

4) Frame mods.

5) Link length

6) Misc

Completed Install:

1) Frame Bushings

The options for frame bushings are the factory rubber or aftermarket urethane

Moog K6459 and AC Delco 45G0651 are equivalent to the factory 88912420 Rubber Bushings (use the factory brackets). My QTY: 1 box contained 2 bushings.

Energy Suspensions 3.5213 greaseable 36MM kit may work, but will probably need some mods, because it is for GM trucks that have a .3" larger distance between mounting bolt centers

2) Frame Mounting Bracket Mods:

Here are the 3 different types of Frame Mounting Brackets:

Stock (Left), F-body (Middle), Aftermarket (for urethane) Right

If reusing the Factory G-Body Frame Mounts, they will need to be modded for use with the factory 36mm rubber frame bushings. The rear outside of each bracke will need to be opened up for clearance. (note the F-Body Mounts above have completely open sides.

The F-body 36MM Brackets have offset mounting holes and 3" spacing and there isn't much meat there to drill a new hole - maybe it can be done, Modding the factory brackets is probably a better option.

Aftermarket brackets won't need this mod:

3) Frame Bracket Shims

Note in the picture above, that bushing extends 3/8" below the bracket. The Bolts can probably be cranked down to crush the bushings, but the swaybar should rotate freely in the bushings, so this would be bad. Its best to shim the bracket away from the frame about 1/4" - 5/16". Ideally, some Aluminum plate would be best. I used my $10 Harbor Freight cut off wheel to cut some shims out of an old non vented Miata rear disk rotor:

After Sanding/Painting (Extreme Close-up)

How the Shims Fit:

4) Frame Mods

The LCA bump stop plate and excess weld on the frame can rub the bar during its travel. The $10 Harbor Freight Cut off wheel makes short work of these:

I may touch the voiding up with a MIG welder later, but for now...

5) Link Length

The Ideal link bolt length is a 7" with a 2.75" to 3" sleeve. Poly Bushings may need a 7.5" bolt to start, with a 3" sleeve.

I go buy real shoulder bolts from the hardware store.

I used to have a lot of thread failures with the necked down hardware on OEM and Aftermarket Sway bar links.

Real Grade 5 or Grade 8 bolts, not so much.

6) Misc

If you need new frame bolts, the Frame bracket bolts off of a Tahoe/Suburban/Yukon work great with the factory brackets. These have a 6 point 10mm head and a larger washer surface than factory. Regular bolt heads with this thread will be too large and be too close to the bracket to use a closed end whench/socket.

7) Installation

Installing the Bar is a littles easier than the factory 32mm (because its 10lbs lighter, but there are a few tricks:

1) The U-bend in the middle goes down. Think of the bar smiling back at you and not frowning.

2) Install the Frame Brackets/Spacers loose on both sides, then...

3) Push the arms of the bar as high up as they will go, to center the bar in the frame brackets.

4) Now tighten the Frame brackets (I use a tiny 1/4" drive ratchet so its hard to cross thread/strip anything)

5) after the frame brackets are tight, make sure the bar moves without much resistance and that it is still centered on the frame.

Attachments

Last edited: