Brake lever boots showed up yesterday. Dorman 924-243 from Amazon.

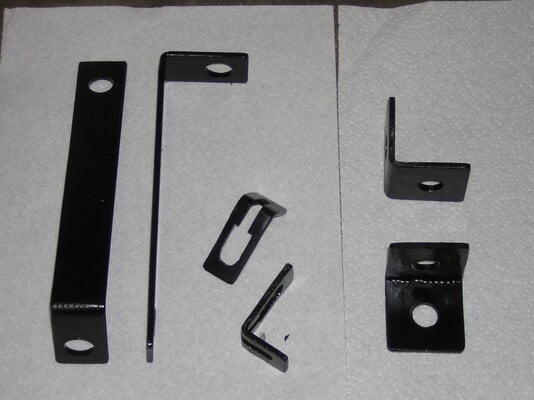

Looked high and low, then ordered a sheet of 3/32" steel via EBay to make the spacer/shims for the brake backing plates. By my calculations, this should exactly line up the caliper brackets around the rotors. Once I cut, drill, file, etc.

Looked high and low, then ordered a sheet of 3/32" steel via EBay to make the spacer/shims for the brake backing plates. By my calculations, this should exactly line up the caliper brackets around the rotors. Once I cut, drill, file, etc.