Suck N Blow Monte

- Thread starter Turbo Zach

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I have been pissing around with the car this week. I decided to paint my carb hat black. Took four trys, but I got it painted. First time it turned out ok and then I dropped it in the rocks and dirt. Scuffed it wiped it down with paint prep and painted it. This is what happened.

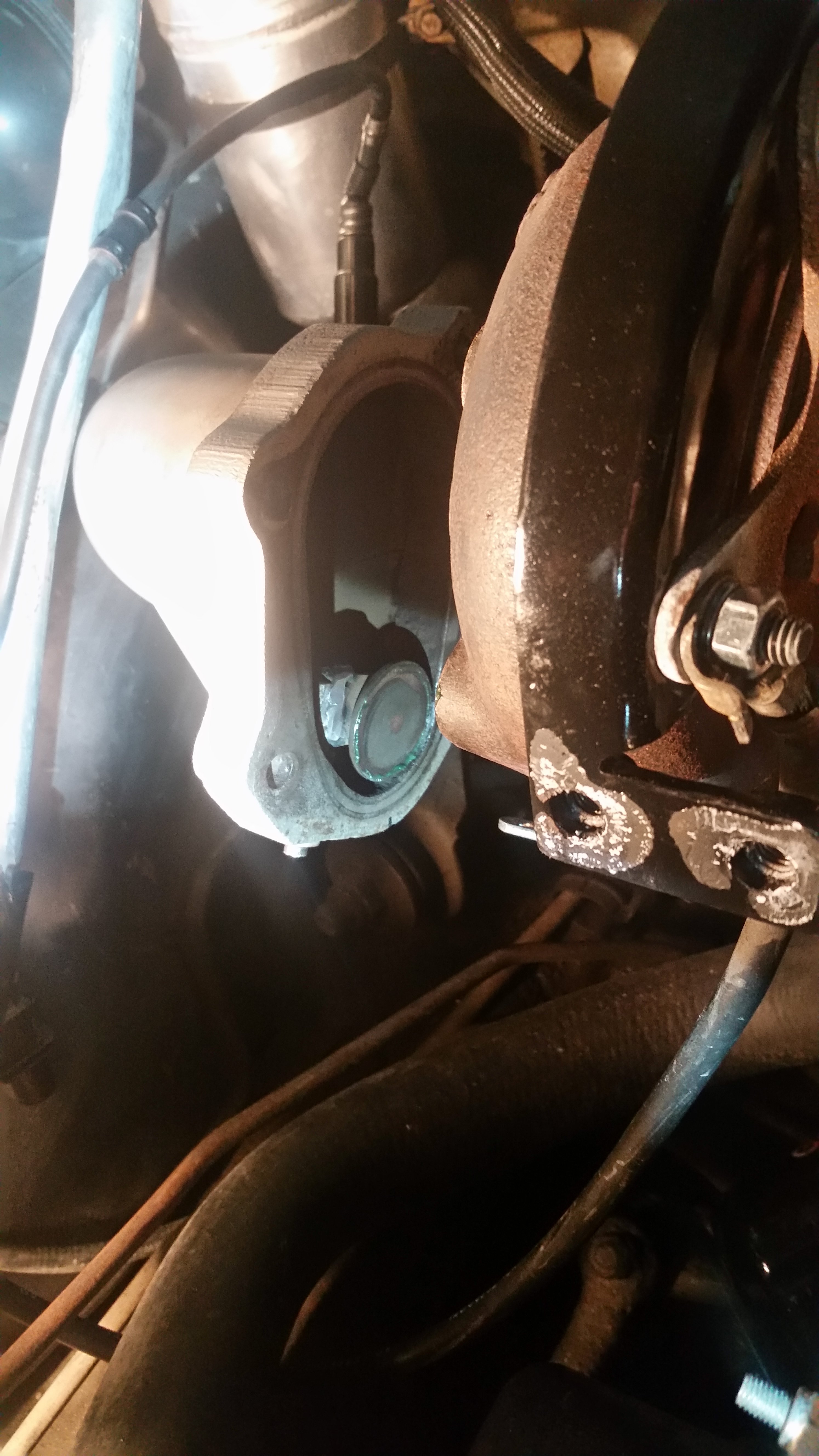

I stripped it back down and painted it again. Same thing happened. Scuffed it again, wiped it down with a paper towel, and painted it. It turned out ok now. I just about chucked that sucker across the shed! For some reason I can only make about 10- 12 psi of boost. So I decided to look into that. Checked the waist gate actuator with a blow gun and a air regulator. Takes 20 psi to move the actuator. So that is not it. Checked the headers for cracks, leaks, and loose bolts. That all looked good. I decided to check my waist gate puck on the down pipe before I put the heat shield back on. I took the down pipe loose from the turbo. Put greese on the turbo. Put the down pipe back on and moved the puck. Took it back apart and this is what I found.

I stripped it back down and painted it again. Same thing happened. Scuffed it again, wiped it down with a paper towel, and painted it. It turned out ok now. I just about chucked that sucker across the shed! For some reason I can only make about 10- 12 psi of boost. So I decided to look into that. Checked the waist gate actuator with a blow gun and a air regulator. Takes 20 psi to move the actuator. So that is not it. Checked the headers for cracks, leaks, and loose bolts. That all looked good. I decided to check my waist gate puck on the down pipe before I put the heat shield back on. I took the down pipe loose from the turbo. Put greese on the turbo. Put the down pipe back on and moved the puck. Took it back apart and this is what I found.

The puck is not covering the hole right. I took the down pipe off the car. I then made a template out of cardboard. Laded the template and gasket on the down pipe.

The puck is not covering the hole right. I took the down pipe off the car. I then made a template out of cardboard. Laded the template and gasket on the down pipe.

So it definitely is not sealing right. Now I need to cut the puck apart, move it, and reweld it. That is were I quit for now. I was going to drive it to work tomorrow, but I guess not now. I think an external waist gate is a better deal than a internal waist gate like I have.

So it definitely is not sealing right. Now I need to cut the puck apart, move it, and reweld it. That is were I quit for now. I was going to drive it to work tomorrow, but I guess not now. I think an external waist gate is a better deal than a internal waist gate like I have.

I had the same problem with my Buick for years - spooled like crap. I had a big dollar 3" downpipe so I never figure that to be the problem. Yet, one day I decided to do the grease test and found it wasn't sealing correctly. I planed both mounting surfaces with a fine file to true them up - that achieved nothing. I literally just bent the wastegate puck swing arm toward the turbine housing and this solved the problem.

Careful with any gaskets between the downpipe and turbine housing as that can upset the tolerances.

Careful with any gaskets between the downpipe and turbine housing as that can upset the tolerances.

Mine is a true TH downpipe. I may try heating and bending before I cut it apart. It is off more than the pictures show and the pitch is off. I have a copper gasket. With out the gasket the pitch is better, but still off. Did you not use a gasket on yours?I had the same problem with my Buick for years - spooled like crap. I had a big dollar 3" downpipe so I never figure that to be the problem. Yet, one day I decided to do the grease test and found it wasn't sealing correctly. I planed both mounting surfaces with a fine file to true them up - that achieved nothing. I literally just bent the wastegate puck swing arm toward the turbine housing and this solved the problem.

Careful with any gaskets between the downpipe and turbine housing as that can upset the tolerances.

Mine is a true TH downpipe. I may try heating and bending before I cut it apart. It is off more than the pictures show and the pitch is off. I have a copper gasket. With out the gasket the pitch is better, but still off. Did you not use a gasket on yours?

Nope, no gasket. I just trued up the flanges and sealed it with copper RTV or muffler cement.

Well I did some work this week. First I cut my waist gate puck all apart.

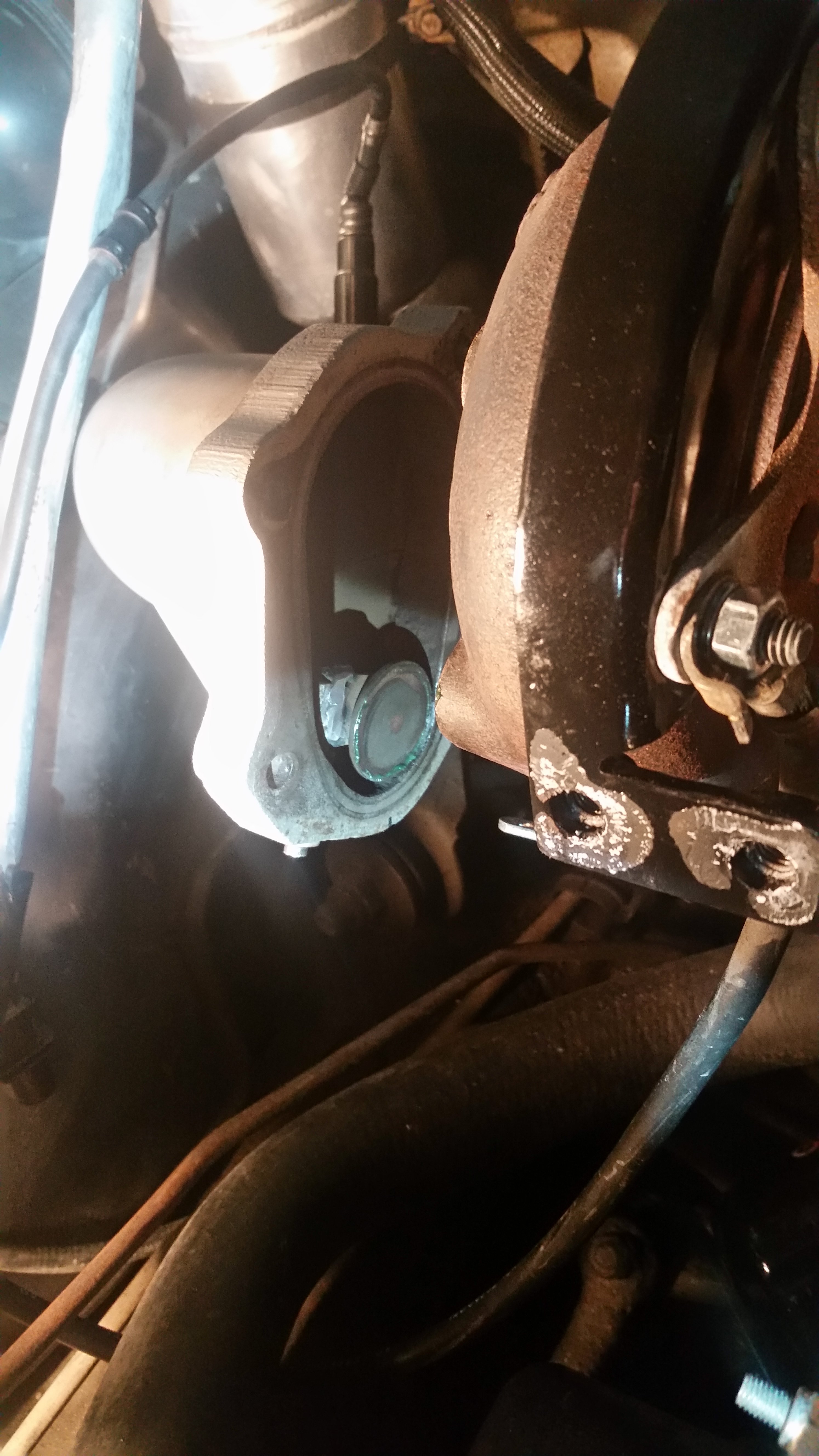

Lots of trial and error. This is the improved waist gate puck.

Lots of trial and error. This is the improved waist gate puck.

It looks more simple than it is. You have to locate it rite, pitch angle, and keep it from catching on the exhaust hole. I filed the edge flat. It was worped some.

It looks more simple than it is. You have to locate it rite, pitch angle, and keep it from catching on the exhaust hole. I filed the edge flat. It was worped some.

Now it is sealing better.

Now it is sealing better.

I put my new heat shield and black painted carb hat on. I think it looks a lot better and more factory now. What do you guys think?

I drove the car to work Friday. After work I washed it and went to a drive in car show.

I drove the car to work Friday. After work I washed it and went to a drive in car show.

All I can say is whole crap this car is quick now boarder line fast! It spools a lot faster and is getting about 17 psi of boost. I did play with my fuel and timing settings. I am getting some knock, but I think most of it is false knock. No set pattern to the knock. This car is so much fun to drive. MrSonny better get his sh*t together if he thinks he can stand a chance with this car!

All I can say is whole crap this car is quick now boarder line fast! It spools a lot faster and is getting about 17 psi of boost. I did play with my fuel and timing settings. I am getting some knock, but I think most of it is false knock. No set pattern to the knock. This car is so much fun to drive. MrSonny better get his sh*t together if he thinks he can stand a chance with this car!

Don't make me bring the Pig out there!

Glad to see you got it sorted out better.

Glad to see you got it sorted out better.

I would not want to upset you! You definitely need a turbo. Turbo's are so much fun.Don't make me bring the Pig out there!

Glad to see you got it sorted out better.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 281

- Replies

- 1

- Views

- 128

- Replies

- 14

- Views

- 345

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.