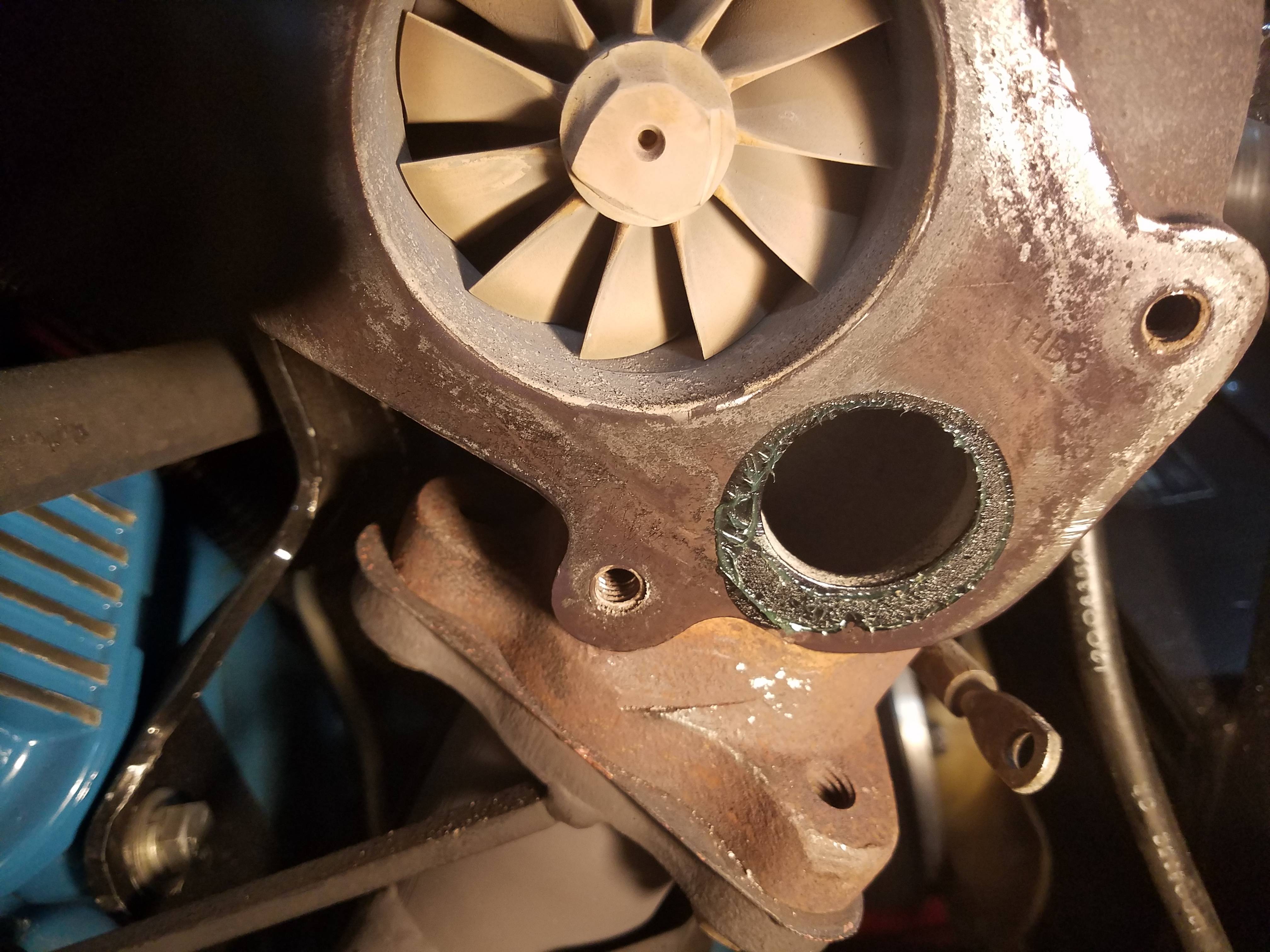

Not right now anyways. The WG hole in this turbo is bigger than a stock Grand National turbo. So the TH down pipe puck is a little too small and sloppy. So it doesn't seal very good I think.Are you going to port the WG hole to match?

Suck N Blow Monte

- Thread starter Turbo Zach

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Not right now anyways. The WG hole in this turbo is bigger than a stock Grand National turbo. So the TH down pipe puck is a little too small and sloppy. So it doesn't seal very good I think.

Then you are already ahead of the game.

I have flirted with the idea of getting an external gated pipe, but I think this should work good for my needs. I did cut the one in my pipe and rewelded it to line it up better, but it was not much bigger than the hole.Then you are already ahead of the game.

Can you take some photos when you change this?I tweaked on the tune a little the other day. Still needs some work, but I have all summer to make it better. I did take it for a cruise today. About 30 miles. Filled it up with magical corn fuel. I like how it runs on E85. I also like the 17psi of boost. I did get my oversized puck in the mail last week. View attachment 174440 This will hopefully make my turbo lag better. The puck I have now dosen't always seal the best and I believe that is why the boost fluctuates so much. I would like to see how it reacts after this. Then I am going to turn it up some more.

Yes sir I will.Can you take some photos when you change this?

Per your request. I took the down pipe off last night and cut the old puck off. Tonight I ported the flange to fit the new puck and filed the flange flat. I then put the new puck in the pipe.Can you take some photos when you change this?

As long as it seats flat on the housing it’ll work.

A perfectionist would make it centered and have it work exactly the same as what you have now.

Once you bolt that back together I won’t be able to see it from my house - run it.

A perfectionist would make it centered and have it work exactly the same as what you have now.

Once you bolt that back together I won’t be able to see it from my house - run it.

Per your request. I took the down pipe off last night and cut the old puck off. Tonight I ported the flange to fit the new puck and filed the flange flat. I then put the new puck in the pipe.View attachment 175884View attachment 175886View attachment 175885View attachment 175887 If you look close you can see the marks on the exhaust housing. It looks like the puck might have been leaking? There was a even mark on the puck all the way around though.View attachment 175888 I test fit the pipe with some greese.View attachment 175889 I am not really happy about the fit. Problem is I welded the tab on already to the shaft. I should have test fit it before I welded it. It has a good eighth inch coverage at the thin spot. Should be enough. The puck needs a longer lever to be centered. Not sure what I will do about it? Might just run it?

It'll work fine. The most important part is that the puck sits flush against the turbine housing. I chased a slow spool issue for years due to that problem after installing a very expensive aftermarket downpipe on my Buick. The moment I lightly bent the puck arm to align it, and it sealed, the car (finally) got into the 11s on a humid August day.

Leaks are bad.

Thanks Mike for commenting. I have checked the puck with a straight edge to the flange. A few years ago I rewelded and aligned the old puck with the gasket I was using. It seemed the puck was a little too small for the hole and was loose. Per your advice I am not going to use a gasket this round. The copper gasket will not fit now anyways.It'll work fine. The most important part is that the puck sits flush against the turbine housing. I chased a slow spool issue for years due to that problem after installing a very expensive aftermarket downpipe on my Buick. The moment I lightly bent the puck arm to align it, and it sealed, the car (finally) got into the 11s on a humid August day.

Leaks are bad.

I put the exhaust back together Saturday night. I changed the O2 sensor for the PLX gauge, but it still doesn't work. I need to look into that some more. Sunday morning I washed the car and went to Fort Dodge to car show. I ended up having the wrong date and place for the show. So there was no car show in Fort Dodge. I got something good to eat for lunch and Drove to Boone where I knew there was a car show. I took some fun roads and did some spirited driving. Car ran pretty good. It doesn't seem to be spooling any faster and now I am only making 7-10 psi of boost. I need to shorten my waist gate rod to get it back up. I figured it would be off. Probably good it was not the other way. I probably would have blown it up with 20 psi of boost? I drove it over a 100 miles yesterday. I did not enter the car show in Boone. Parked outside the gate and check out the cars. Nice little car show and good to get the car out and enjoy it.

Some of the cars that caught my eye.

Some of the cars that caught my eye.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 311

- Replies

- 0

- Views

- 181

- Replies

- 16

- Views

- 295

- Replies

- 0

- Views

- 91

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.