Drained the trans fluid out of my car for about the 3rd time in a week. New tcc solenoid should be coming tomorrow. Also will be reinstalling trans pan bolts with blue locktite. I'm not sure why but they keep loosening up. I torqued them to 14ft. Lbs. Yesterday before I drove to work about 15 miles. Leaked a little in the parking lot during work. Put some fluid in it before I left work to be on the safe side. Got home parked the car in the garage and thought I saw some smoke when I opened the door. Looked under the car and there was already a 8 inch circle of fluid on the floor under my car. Checked this morning and all the bolts were loose again.

What did you do to your G-Body today? [2011-2018]

- Thread starter dlo253

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Drained the trans fluid out of my car for about the 3rd time in a week. New tcc solenoid should be coming tomorrow. Also will be reinstalling trans pan bolts with blue locktite. I'm not sure why but they keep loosening up. I torqued them to 14ft. Lbs. Yesterday before I drove to work about 15 miles. Leaked a little in the parking lot during work. Put some fluid in it before I left work to be on the safe side. Got home parked the car in the garage and thought I saw some smoke when I opened the door. Looked under the car and there was already a 8 inch circle of fluid on the floor under my car. Checked this morning and all the bolts were loose again.

Hang in there. You are close. Once you get the bugs worked out you are going to really enjoy that overdrive.

Hang in there. You are close. Once you get the bugs worked out you are going to really enjoy that overdrive.

I'm definitely enjoying the overdrive already!! I've drove the car more in the last week than I did all last summer. I'm just getting sick of my garage floor having trans fluid and oil dry on it. Something as easy as putting a pan on with a gasket is beating me bad so far. I think after I drop the pan to put the new tcc solenoid in I'm going to double check that the pan is still flat and go back to a cork gasket. Blue locktite on the threads when I put the pan back on and pray it doesnt leak.

I've always preferred a rubber gasket for the trans pan. Are you using a stock pan? I understand your frustration. I hate leaks.

I've always preferred a rubber gasket for the trans pan. Are you using a stock pan? I understand your frustration. I hate leaks.

Yes im using a stock pan. I have a rubber gasket in it right now but I guess I can't really tell if it's the gasket or not becsuse the bolts keep coming loose

Are you certain your torque wrench is accurate? Is 14 ft. lbs. off of its scale? I don't see anything wrong with thread locker but I've never had to use it on a trans pan. Maybe tighten the bolts, let it go through a heat cycle and the re-tighten. If you do use thread locker I wouldn't use the high strength stuff.

The torque wrench I used I borrowed from work. It's actually a preset inch lbs torque wrench with a range from 50-250 in lbs. I set it at 170in lbs. We have torque testers that we use for calibrating the torque wrenches so I know the wrench was right. I was going to use the medium strength thread locker on it because at the rate I'm going I'll have to pull the pan off again for something in another week. ☺

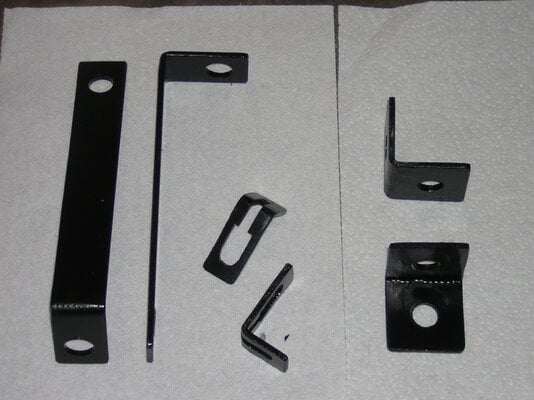

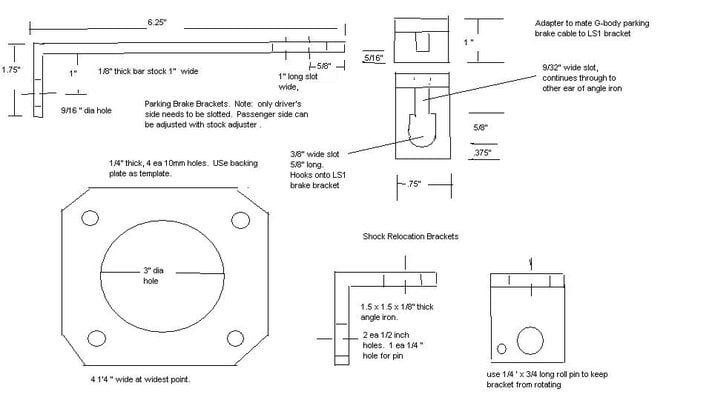

is that a 2wd blazer rear disc set-up? looks nice. what are your plans for the parking brake?Finally finished the GN axle modifications. After 14 months, the coupe is on four tires again. Finished the disc brake installation, bent new brake lines and bolted the axle in place. (Oh, how I hate flaring brake lines.) Put in spherical bushings from Speedway, per a Forum recommendation to try to reduce the chance of bind-up with the old-school Hotchkis control arms.

The shock relocation brackets I made from the Forum drawing put the bolt heads almost touching. A millimeter of clearance. Set the bracket angle, and drilled a roll pin hole to keep each one oriented, per the instructions.

Now I need to shorten the driveshaft an inch to account for the swap to the GN axle. I might just get a whole new one made. If so, I'll have for sale a driveshaft with new U-joints for a T-5, 200-4R or 700-R4 Malibu conversion...

The rear brakes came form a 2000 Camaro. I made brackets made from a pattern I found on the Forum. There are two L-shaped pieces that have a slot in them - they fit over the P-brake levers in the backing plates - and I think I can use the stock Malibu P-brake cables with just a little re-routing. The installed photo is from the Forum post - I have not hooked up the cables yet.

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 264

- Views

- 13K

- Replies

- 393

- Views

- 20K

- Replies

- 107

- Views

- 5K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.