Getting the 250 twin swap on the 125 drift trike project together. Mocked up experimental triple x-pipe exhaust with Werks performance and gsxr 600 parts. using welding helmet for headlight visor/ wiring coverup.. making the old el camino bedcover hold opens I made into mirror brackets, Got alligator look vinyl to cover things. Still in mock up stage, have to blow apart and properly weld up all the big tack & partial welds. Long ways to go. lots of hand fab work. Designing cable operated handlebar shifting. Bike was in working condition with the 125 engine to both drift on plastic sleeves and wheelie onto wheelie bar

What did you do to your non-G body project today? [2023]

- Thread starter Wraith

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BEWARE THE RED CAN!! The red format can be a visual cue that the can contains CFC's and generated Chlorine Gas if subjected to heat after being sprayed on a rusted or damaged component.

Was digging around in one of the scrap piles and happened to come across a section of cabin panel from the S-10 that I had cut away during a cabin corner/sponson replacement. Put a micrometer to it and discovered that it was about a .001 thinner than the metal in the indian fender that I have been tinkering with in my spare, spare, spare?? time. Brought it in and down to my basement shop, did some cutting and trimming on it for fit and added some curve to it for shape and it lands fairly nicely against the edge on the existing fender from which the damaged fender tip had been cut away.

Plan now is to walk it out to the main shop and throw some tacks at it to create a preliminary joint. That will let me do some more shaping and see what I get. It does land long against the outer leading edge of the jig that I had created a couple of years back now but the plan was always to go long and then trim it back to where it looks like factory again. This is very much a subjective exercise on my part as I have no patterns or pictures of what it ought to look like if original and intact. The lack and cost of replacements often forced riders to cut or clip away the damage from an accident or incident and just go with a bobbed fender. By estimated measurements, my own fender is missing as much as 7 inches of length after the front or leading fender mounting bracket. This loss, for me, makes this just another case of make versus buy and since buy is mostly a non-starter unless I can find a donor in worse shape that still has its sheetmetal intact, make, it has to be.

Nick

Plan now is to walk it out to the main shop and throw some tacks at it to create a preliminary joint. That will let me do some more shaping and see what I get. It does land long against the outer leading edge of the jig that I had created a couple of years back now but the plan was always to go long and then trim it back to where it looks like factory again. This is very much a subjective exercise on my part as I have no patterns or pictures of what it ought to look like if original and intact. The lack and cost of replacements often forced riders to cut or clip away the damage from an accident or incident and just go with a bobbed fender. By estimated measurements, my own fender is missing as much as 7 inches of length after the front or leading fender mounting bracket. This loss, for me, makes this just another case of make versus buy and since buy is mostly a non-starter unless I can find a donor in worse shape that still has its sheetmetal intact, make, it has to be.

Nick

Now that's just sick!Getting the 250 twin swap on the 125 drift trike project together. Mocked up experimental triple x-pipe exhaust with Werks performance and gsxr 600 parts. using welding helmet for headlight visor/ wiring coverup.. making the old el camino bedcover hold opens I made into mirror brackets, Got alligator look vinyl to cover things. Still in mock up stage, have to blow apart and properly weld up all the big tack & partial welds. Long ways to go. lots of hand fab work. Designing cable operated handlebar shifting. Bike was in working condition with the 125 engine to both drift on plastic sleeves and wheelie onto wheelie bar

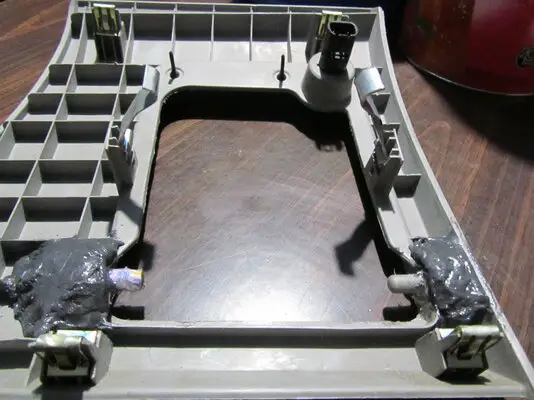

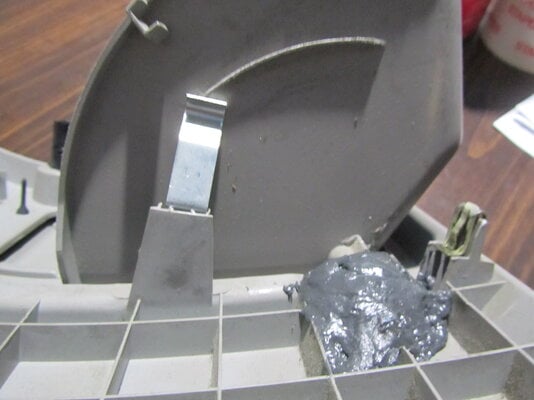

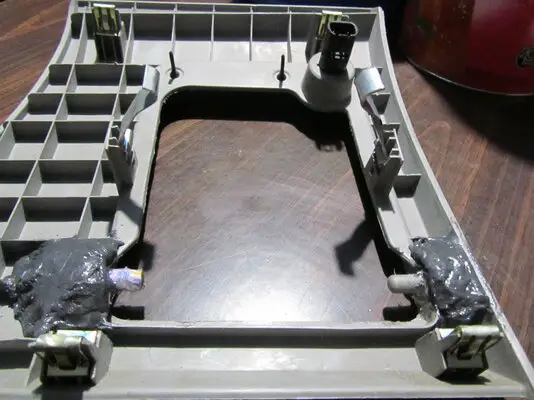

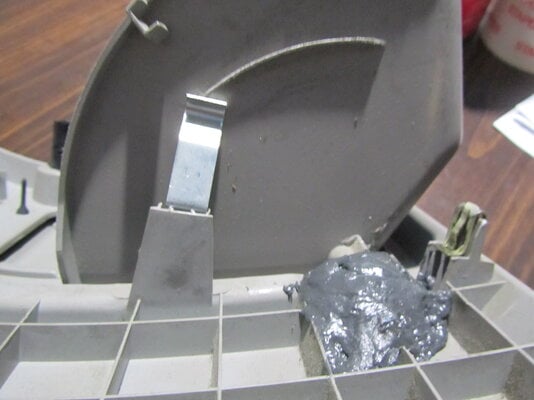

2005 Cobalt. Cheap-azz plastic knee bolster cuddy tray fell out and parts were busted/missing. The whole assembly is discontinued, Fleabay prices are insane, so it's fix-it time. One plastic tit was missing and the other almost broken off. I measured it and it was 5/16". I found a pencil that is 5/16" so I cut a small length and epoxied it in place of the missing one. Then I epoxied the broken tit back in position. I think there was a missing steel spring tensioner because there are two mounting posts but only one tensioner was left. It miked up at .025" thick and I found a .030" steel strip so I fabricated a copy. The tray fitted well on the tit and copy, and the spring tensioners added a lot of stability to the whole tray. Now it stays in place either open or closed or in-between. That is some fugly epoxy work but it will be hidden. And it will be STRONG!!!!!!!!!!!!!!!!!!!!!!!!!

Want to know how great this site is? I got two thumbs up on THIS site- and ZERO on the Cobalt site. This site ROCKS!!!!

You got my thumbs up because I feel the cheap cobalt interior pain. Every time I touch anything in the cheap daily I worry its about to explode.Want to know how great this site is? I got two thumbs up on THIS site- and ZERO on the Cobalt site. This site ROCKS!!!!

Does the front end sound like it is fitted with coffee cans full of rocks? What a rattle-trap!!!!I worry its about to explode.

Surprisingly tight still and it has about 290K km on it. It's all the interior plastics that rattle in rough roads. The electric power steering makes an awful groaning sound and sometimes causes the gauges to go completely insane bouncing around wildly with warning chimes. If you unplug it for a week it's usually good for a month or two before it acts up again.Does the front end sound like it is fitted with coffee cans full of rocks? What a rattle-trap!!!!

I was about to buy a yellow SS fully loaded to the gills back when they were new and had them playing with the bouncing balls with the vettes in the commercials. Car was on the showroom floor at a low-volume dealer (aka few fingerprints and lookie loos) but a car jumped the curb, smashed the window that was just a sidewalk width away, hit the car.Surprisingly tight still and it has about 290K km on it. It's all the interior plastics that rattle in rough roads. The electric power steering makes an awful groaning sound and sometimes causes the gauges to go completely insane bouncing around wildly with warning chimes. If you unplug it for a week it's usually good for a month or two before it acts up again.

Then I couldn't find one similarly equipped. So I passed. Aside from that whole gm key thing they weren't bad cars for the price and mileage you could get out of them IMO.

Similar threads

- Replies

- 385

- Views

- 20K

- Replies

- 106

- Views

- 5K

- Replies

- 256

- Views

- 12K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.