Also put in fresh VR1 10W30 and a Wix 51258 oil filter. The Wix Protec filter looks identical inside to the NAPA Gold 1258 filter inside. My new oil filter cutter worked way better. Some metal but less than the last oil change Those oil pressure numbers in the video are the fresh 10W30, still really good.

1970 Olds Cutlass S Rat Rod Style

- Thread starter olds307 and 403

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

There are going to be multiple short oil changes. I have two six packs of VR1 10W30 on hand.

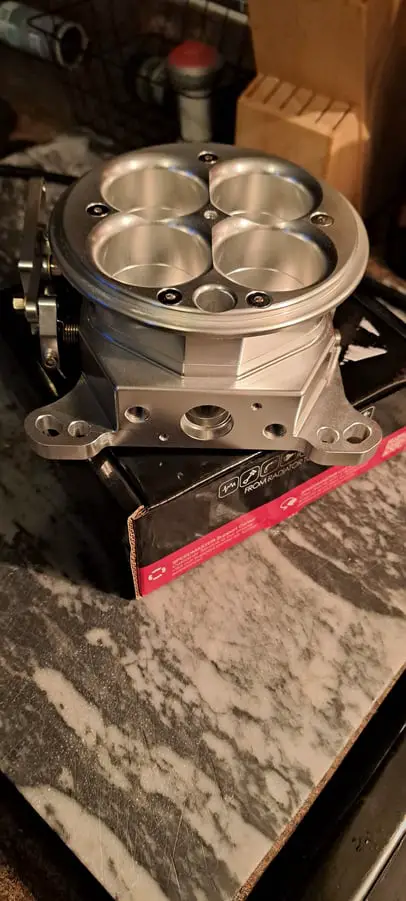

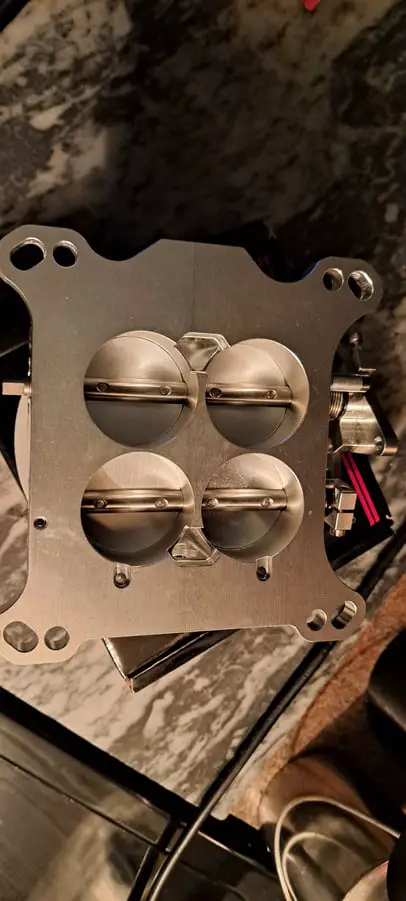

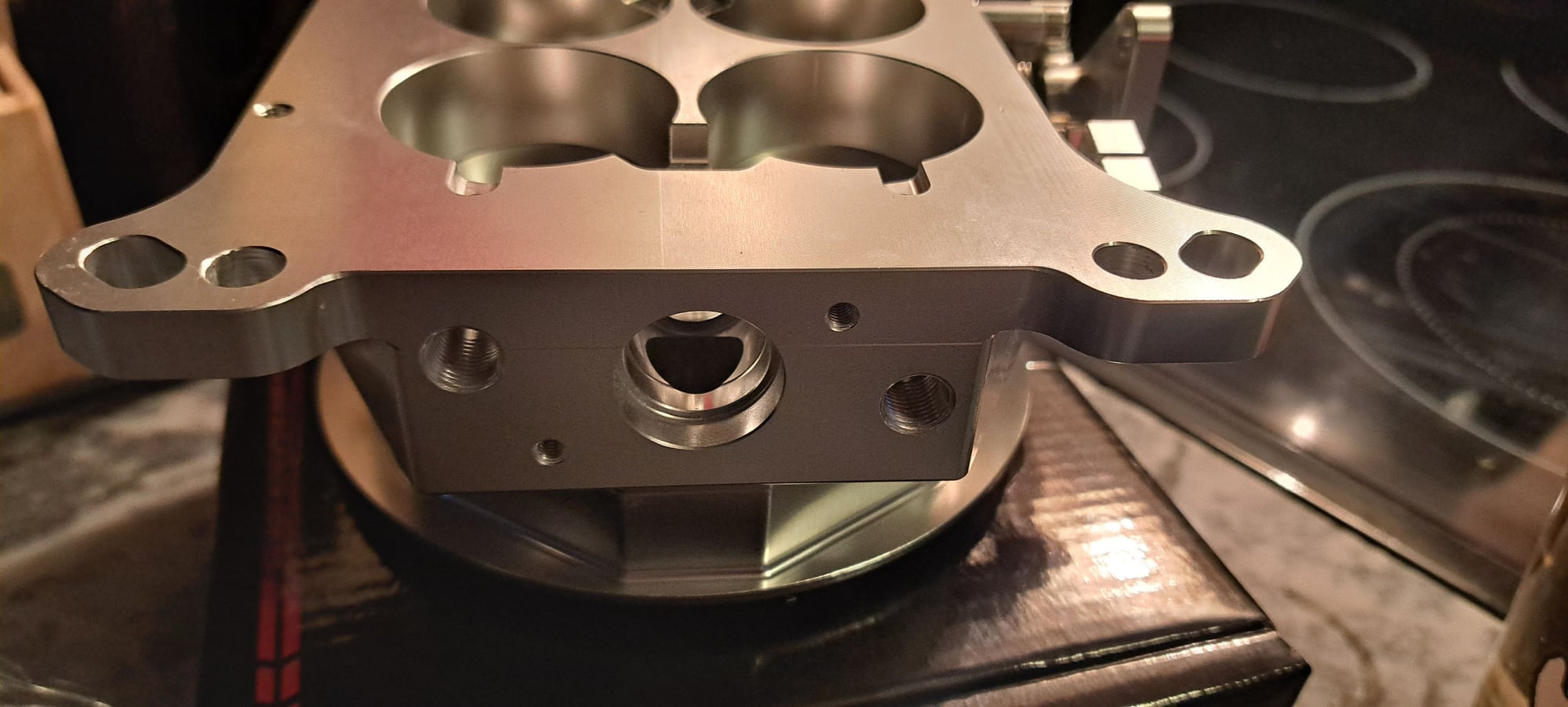

Ok so the Speedmaster 1200 cfm throttle body showed up. I still need the TPS and adapter. It is a nice looking and operating throttle body. I did have to tap the map sensor port for a plug and had to tap the throttle cable stud to 1/4" fine for my stud. I adjusted the throttle cable and relocated a drilled an extra hole for the kick down. I also reviewed the first piece of the puzzle for the TKX swap.

Well, I had a small under hood fire about a week ago at the town post office. The good, on the opposite side as all the Holley Terminator X Max wiring. Only the cover on the main power wires were burnt and actual insulation on the relay for the fuel pump. The wiper washer cover and wiring burnt. The washer pump didn't work, so I need to replace, $200 on Amazon. Either way eliminating unnecessary add ons and poorly done wiring by me and the previous owner.

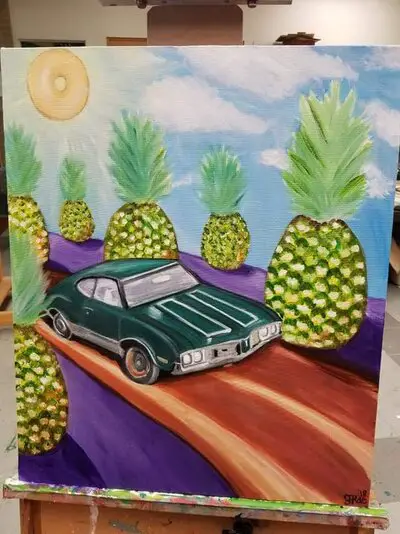

So I got everything re wired, soldered and heat shrunk with separate wire looms and grommets in the firewall. Took me all day and still isn't perfect but a bunch of crap and half *ss wiring eliminated. I also changed the positive cable end and reinstalled the battery The braided oil pressure line got toasty enough to be shooting oil on the drivers side header. Good thing I kept the line from the 88. I thought had a drain, stone dead after sitting three days. I actually moved the brake switch off the pedal, caught as I was leaving the shop. Moved the switch, all is good. In Donovan's themed picture of Olds Cool style, here is a fun painting my Daughter Faith, who is an artist, did of my 70S.

Attachments

Last edited:

Tackling the 4L80E swap. I did the 3R to 1350 conversion U joint, actually used my G body driveshaft,, it will be close but may need a bit shorter driveshaft, it is 2.5" shorter than the factory driveshaft. I got the TH350 out, I measure 3.5" difference. I got the Transdapt bellhousing adapter installed and used the orange locktite on the block to adapter and on the Speedmaster neutral balance flexplate to crank bolts, torqued to 60 ft-lbs. I also trimmed the extra aluminum on both sides to clear the headers on install.

Holy hell is the 4L80E a tight fit. The cooler lines barely fit, even with 90 degree adapters for the 6AN lines. One sensor also just touches. I forgot to start the dipstick, barely got it in. Added two more holes and stretched one for the crossmember to fit. The driveshaft is tight, hit the pinion nut. The suspension is all the way up, rear arms on stands. I will put the stands on the frame, install and see if it allows most of the travel. I threw a liter in the converter and drained the pan, nice and red, this is what was left, very happy with what I found.

Attachments

Well, I need a shorter driveshaft. Anyone have a G body 8.5" driveshaft . Extended suspension was even worse, lined up with back of the yoke. Honestly probably a 51" even driveshaft will be perfect. I need to figure out the best route. I installed the new filter, getting the old filter seal was a PIA, used a slide hammer. Reused the nice rigid core with silicone beads and torque limiters pan gasket. I installed the Amazon special steel pan with a drain plug, cleaned and reused the magnet from the stock pan. I drilled an tapped the two bottom bolts to attach the dust cover. I used the two thick hardened washers on each torque converter bolt and added one more thin on each. Good thing I removed the torque converter big snout edge. It would have hit the crank pilot edge, it just clears. The TH350 cover doesn't completely cover the bottom. I cut off a piece of a rubber 4L60E pan gasket. I installed plastic clamps and zip ties to route the braided cooler lines away from the headers. They are long enough to route well away from the exhaust. I am just using the radiatior internal cooler. I plugged in the trans wiring harness and zip tied it to stay away from the headers. Unfortunately the column shifter won't work, I have a TCI Fastgate floor shifter. The cable is pretty close to the header and cat. I got it adjusted as best as I could. It should look and work OK. Everything is done underneath except the driveshaft.

. Extended suspension was even worse, lined up with back of the yoke. Honestly probably a 51" even driveshaft will be perfect. I need to figure out the best route. I installed the new filter, getting the old filter seal was a PIA, used a slide hammer. Reused the nice rigid core with silicone beads and torque limiters pan gasket. I installed the Amazon special steel pan with a drain plug, cleaned and reused the magnet from the stock pan. I drilled an tapped the two bottom bolts to attach the dust cover. I used the two thick hardened washers on each torque converter bolt and added one more thin on each. Good thing I removed the torque converter big snout edge. It would have hit the crank pilot edge, it just clears. The TH350 cover doesn't completely cover the bottom. I cut off a piece of a rubber 4L60E pan gasket. I installed plastic clamps and zip ties to route the braided cooler lines away from the headers. They are long enough to route well away from the exhaust. I am just using the radiatior internal cooler. I plugged in the trans wiring harness and zip tied it to stay away from the headers. Unfortunately the column shifter won't work, I have a TCI Fastgate floor shifter. The cable is pretty close to the header and cat. I got it adjusted as best as I could. It should look and work OK. Everything is done underneath except the driveshaft.

I think I found a drive shaft. Of course it would help if every place measured centerline to centerline. My current drive shaft is a hair under 60" with a long yoke. A 1996 to 2005 Chebby Blazer has a 3.5" diameter, 3R joints and should be a 27 spline output and is 58.87", so 2" shorter. I will measure tonight but it should work. One inch might just clear and have minimal clearance, 2" should have plenty of engagement and no chance of destroying the rear housing under hard driving. I already have the conversion U joint on this driveshaft. It will be around $300 through Amazon. The 2.5" Fast Shafts in the right length with 2 conversion joints would be $500 CAD plus shipping and still only 2.5" in diameter. If I can get away without a custom price, would be great.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 10

- Views

- 158

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.