So tonight was a bit of a 'squirrel!' day.

Ran after work trying to find the tap drill for the 5/8-18, a 37/64. Non existent. Nobody stocks anything but 1/16 sized above a 1/2. Great. I've got loads of Morse taper lathe tailstock bits but not a 37/64... I need to see if I can find one from Fastenal or order it if McMaster I guess.

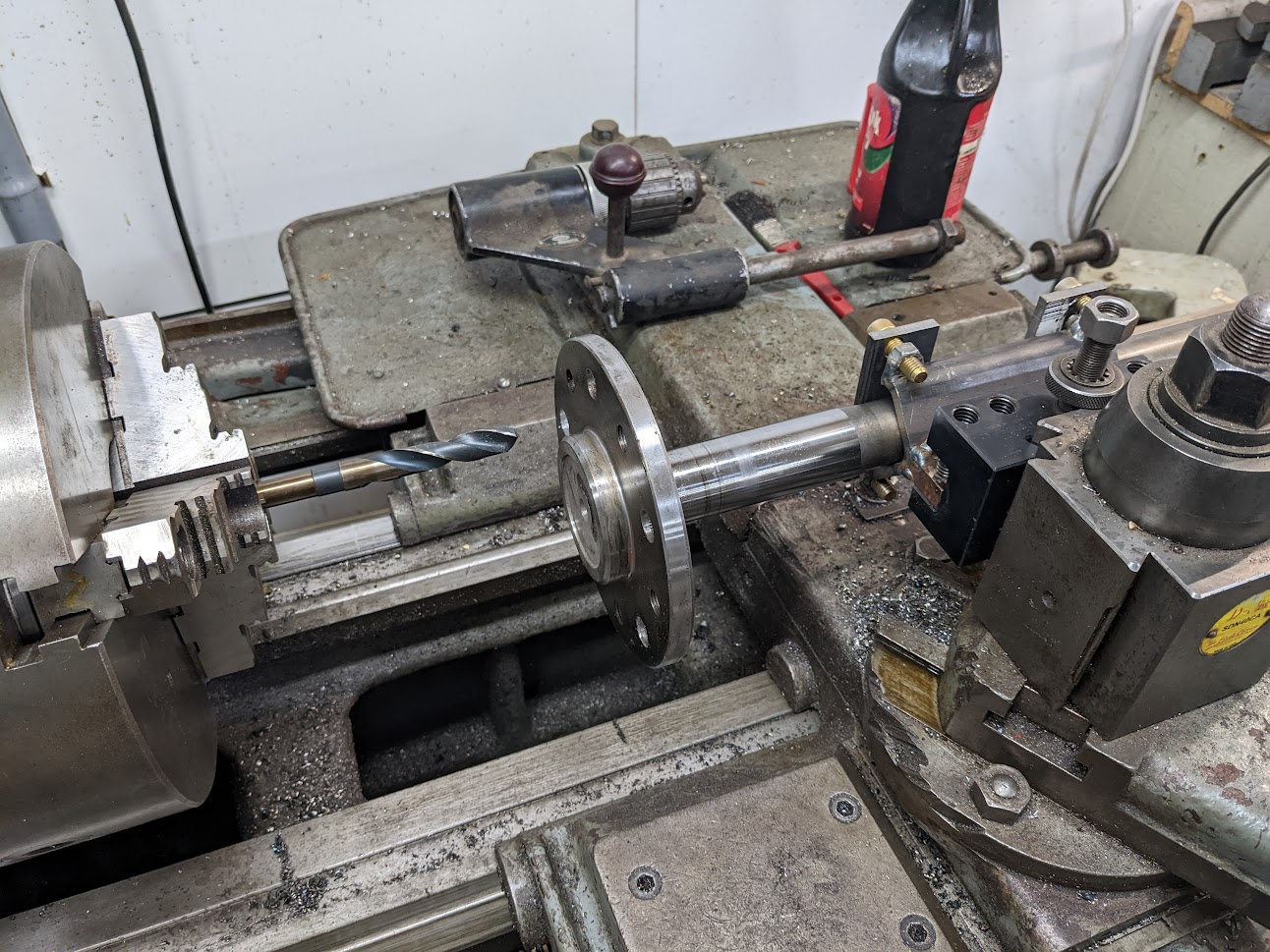

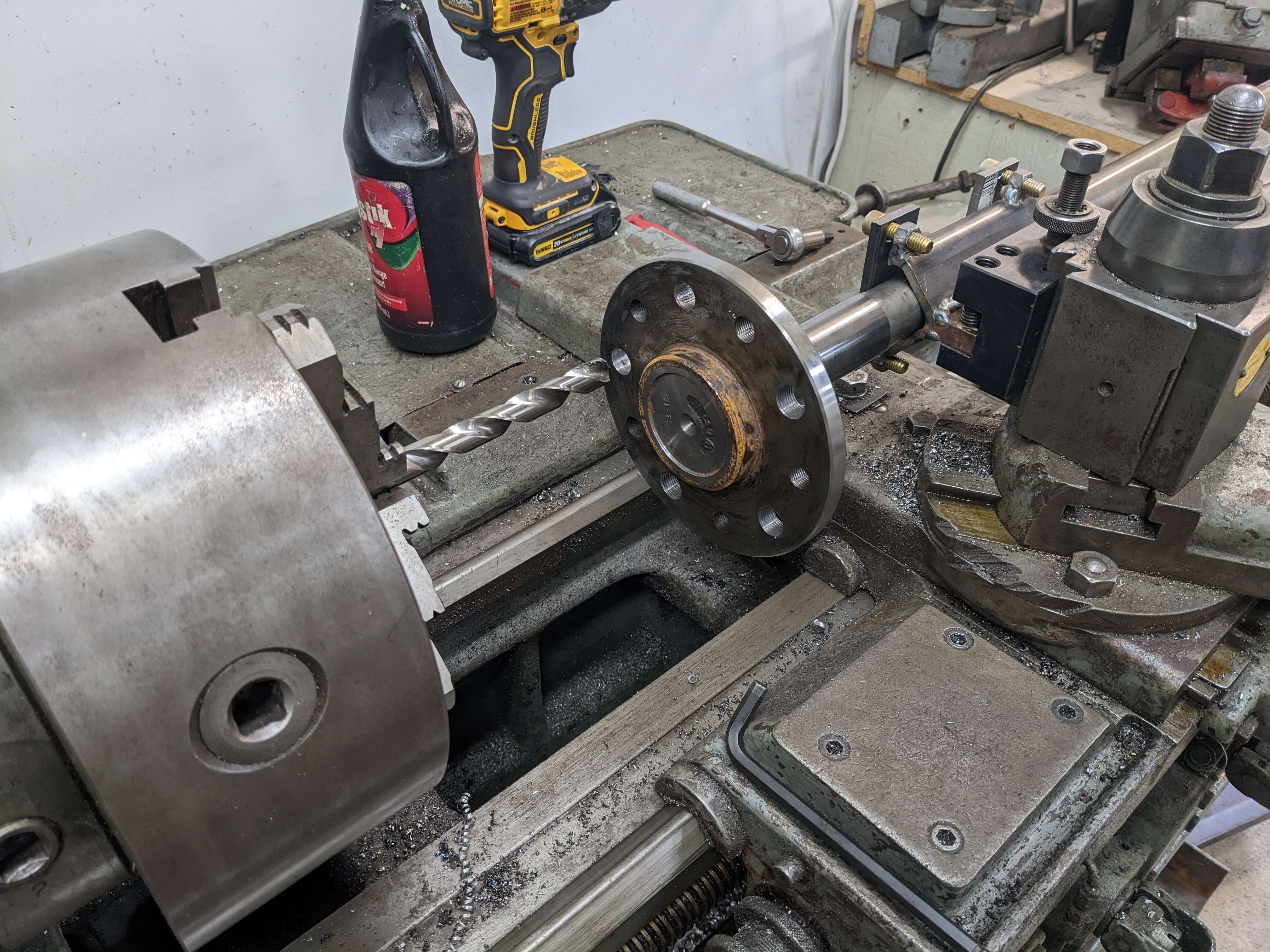

So I got started building a mount so I could put my axle into the lathe carriage and put the drill and tap into the lathe chuck. Then I just need to rotate the axle 72 degrees for each hole and bam, ready to go back in.

Dug through my scrap pile and put something together

Cut some 2" square tube in half

Welded nuts and cut some tabs

Really hot glue gun. Put the mounting bar into the tool post and aligned the V block into a 1" piece of cold rolled.

So now I have a roll cage tubing notcher and a axle pattern redrilling fixture.

But then I thought does the axle fit into the headstock?

Yes. Shoulda checked that first.

And I pulled my live tooling starter kit that I stole from dad who's had it for probably 30 years. Great, this is spiralling out of control...

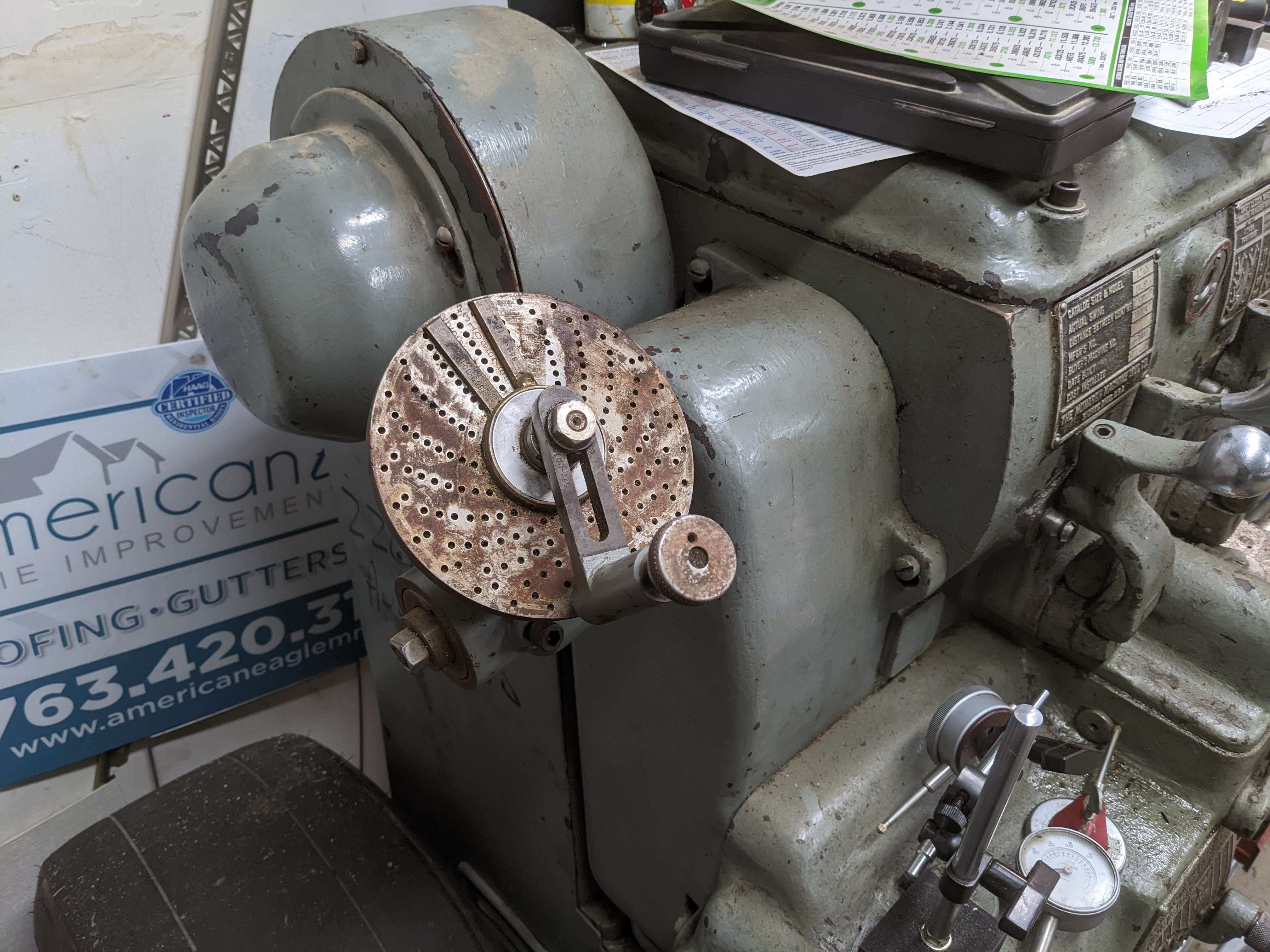

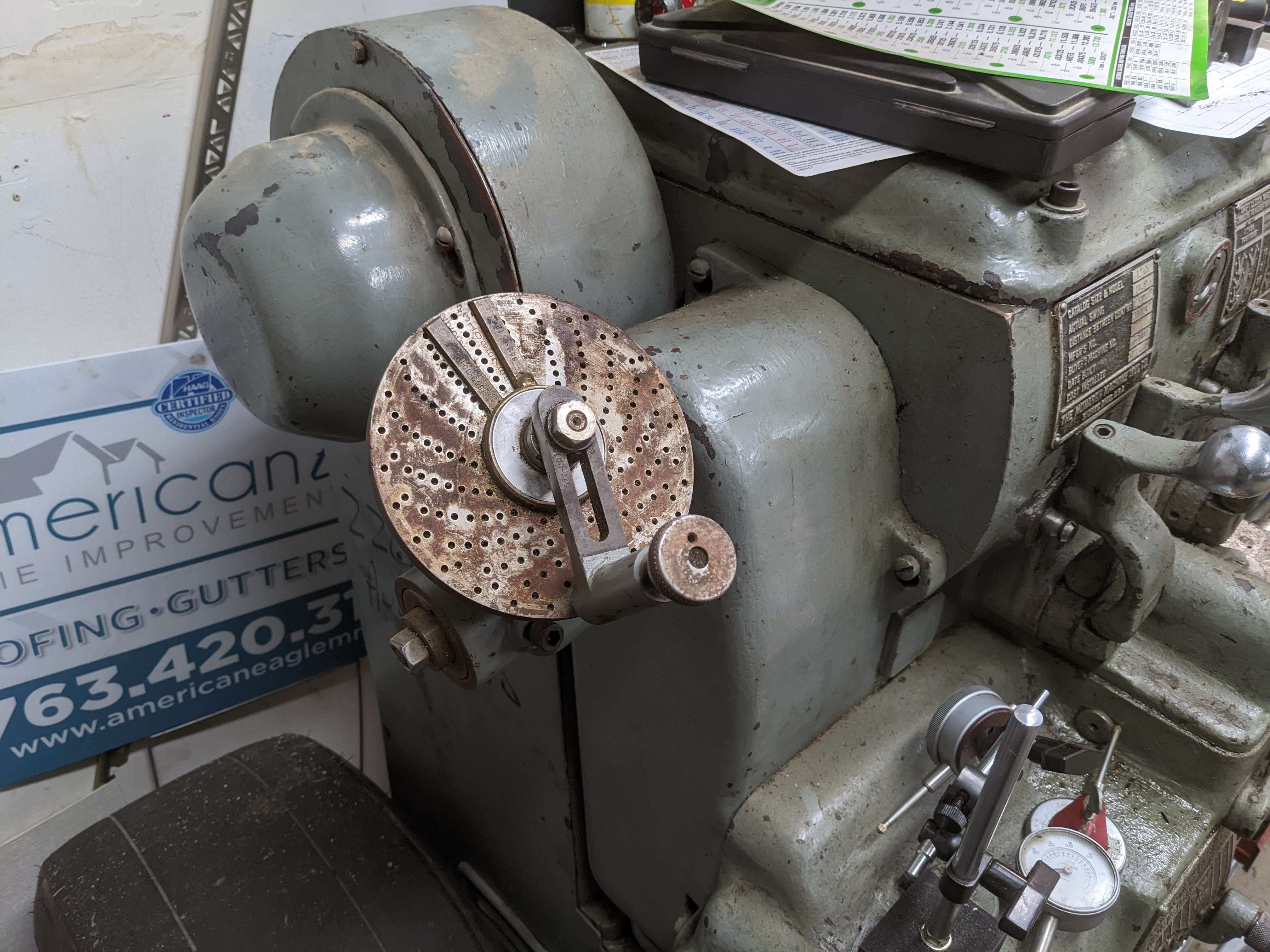

And I have a headstock indexer, I just need to build an adapter bushing. It's a 40:1 gearbox with anything from a 15 to 40 indexer plate on it so I can go down to .225 degree, 1/1600 of a full rotation resolution.

So, I should just do my best to get the 5/8 studs tapped and 99% chance it will be fine, but I've got all the crap to index the axle and do hole patterns, cut splines, etc., I just have to do the machining to make it work. Once this is done I can pop the axle in and drill and tap with really good accuracy in 10 minutes so....

Follow along on my side quest!

Ran after work trying to find the tap drill for the 5/8-18, a 37/64. Non existent. Nobody stocks anything but 1/16 sized above a 1/2. Great. I've got loads of Morse taper lathe tailstock bits but not a 37/64... I need to see if I can find one from Fastenal or order it if McMaster I guess.

So I got started building a mount so I could put my axle into the lathe carriage and put the drill and tap into the lathe chuck. Then I just need to rotate the axle 72 degrees for each hole and bam, ready to go back in.

Dug through my scrap pile and put something together

Cut some 2" square tube in half

Welded nuts and cut some tabs

Really hot glue gun. Put the mounting bar into the tool post and aligned the V block into a 1" piece of cold rolled.

So now I have a roll cage tubing notcher and a axle pattern redrilling fixture.

But then I thought does the axle fit into the headstock?

Yes. Shoulda checked that first.

And I pulled my live tooling starter kit that I stole from dad who's had it for probably 30 years. Great, this is spiralling out of control...

And I have a headstock indexer, I just need to build an adapter bushing. It's a 40:1 gearbox with anything from a 15 to 40 indexer plate on it so I can go down to .225 degree, 1/1600 of a full rotation resolution.

So, I should just do my best to get the 5/8 studs tapped and 99% chance it will be fine, but I've got all the crap to index the axle and do hole patterns, cut splines, etc., I just have to do the machining to make it work. Once this is done I can pop the axle in and drill and tap with really good accuracy in 10 minutes so....

Follow along on my side quest!