Generally I shoot for around 28-3200. But you were on the right track with your limiting screw. You can fill in the rotor pin slots with epoxy and then file them to get enough travel to see 16-18 degrees advance and then set your initial higher and go from there. It sucks because its a trial and error thing unless you know someone with a distributor machine.Total at what Rpm?

With the pieces i have on hand. My two options (with 18-20 idle) were all in a 2400 or (one step up on the springs) all in at 4500+

All in at 2400 will not work as a road test revealed pining under a light load

Dumb timing question

- Thread starter Baker7888

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Can i mix/match springs? For example 1 light spring 1 medium spring. This would probably put my all in around 3200Generally I shoot for around 28-3200. But you were on the right track with your limiting screw. You can fill in the rotor pin slots with epoxy and then file them to get enough travel to see 16-18 degrees advance and then set your initial higher and go from there. It sucks because its a trial and error thing unless you know someone with a distributor machine.

YesCan i mix/match springs? For example 1 light spring 1 medium spring. This would probably put my all in around 3200

Ok ill can give it another shot with 1 light and 1 medium spring. If i cant get all in by 3200 i will keep my current setting of base 13 all in at 3000…

Just confirming you are doing this with vac can unplugged. And then plugging vac can to manifold after timing is set.

Also wondering how much i stand to gain with a higher initial. I would think total in at the lowest possible rpm without ping (3000) would be more valuable

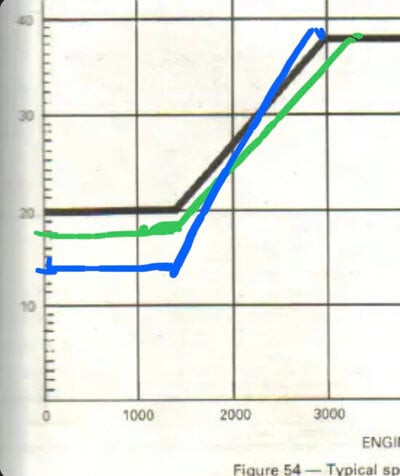

I just took the graph posted earlier and drew (roughly) over it

BLUE (non limiter screw) is 13 initial and 23 mechanical in at 3000.

GREEN (limiter screw setup) is 16 initial and 16 mechanical in at 3200. This is contingent on 1 light and 1 medium spring getting me to 3200.

Correct me if im wrong but the current blue setup is a better curve and the only thing i stand to gain by running more initial is a better idle but a weaker performance curve.

BLUE (non limiter screw) is 13 initial and 23 mechanical in at 3000.

GREEN (limiter screw setup) is 16 initial and 16 mechanical in at 3200. This is contingent on 1 light and 1 medium spring getting me to 3200.

Correct me if im wrong but the current blue setup is a better curve and the only thing i stand to gain by running more initial is a better idle but a weaker performance curve.

Attachments

I feel like you have tried this but on my BBC I have a kill switch on the ignition and I would get it cranking first then flip the ignition on this eliminated the flexplate and starter issues I had.I tried the locked out thing, and it idled great but I didn't have the set up right and damaged the starter and flexplate over time.

I did but I think my issue was the start retard box I had. I would crank it like you say but mine had a 10 or 25 degree retard. I went right to 25 and I had all my issues. Being I couldn’t go back to 10 I was stuck but I had people tell me after the fact that 10 works better.I feel like you have tried this but on my BBC I have a kill switch on the ignition and I would get it cranking first then flip the ignition on this eliminated the flexplate and starter issues I had.

I would go with more initial always. The 200 rpm difference will be insignificant . Better idle and throttle response will run betterI just took the graph posted earlier and drew (roughly) over it

BLUE (non limiter screw) is 13 initial and 23 mechanical in at 3000.

GREEN (limiter screw setup) is 16 initial and 16 mechanical in at 3200. This is contingent on 1 light and 1 medium spring getting me to 3200.

Correct me if im wrong but the current blue setup is a better curve and the only thing i stand to gain by running more initial is a better idle but a weaker performance curve.

Correct me if im wrong but the current blue setup is a better curve and the only thing i stand to gain by running more initial is a better idle but a weaker performance curve.

Definitely a ‘no’ imo.

For performance you only need to be concerned about getting the ‘all in’ as soon as your motor can handle it. And getting the correct amount of timing at your all in rpm.

Everything that goes on below the all in rpm is fuel economy and street manners. Tuning those two are completely separate from performance above 3000rpms. And if you want maximum performance with the best possible street manners, then it will take some fiddling with the dizzy and the carb.

I get a sense from your responses that you don’t want to have it idling at 16-20 degrees? Is that so? If yes, then why?

Thanks. Ok so i will have to experiment with the springs to see if low 3000s is achievable with what ive got on hand. Thinking one light spring and one medium spring will get me closeI would go with more initial always. The 200 rpm difference will be insignificant . Better idle and throttle response will run better

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 152

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.