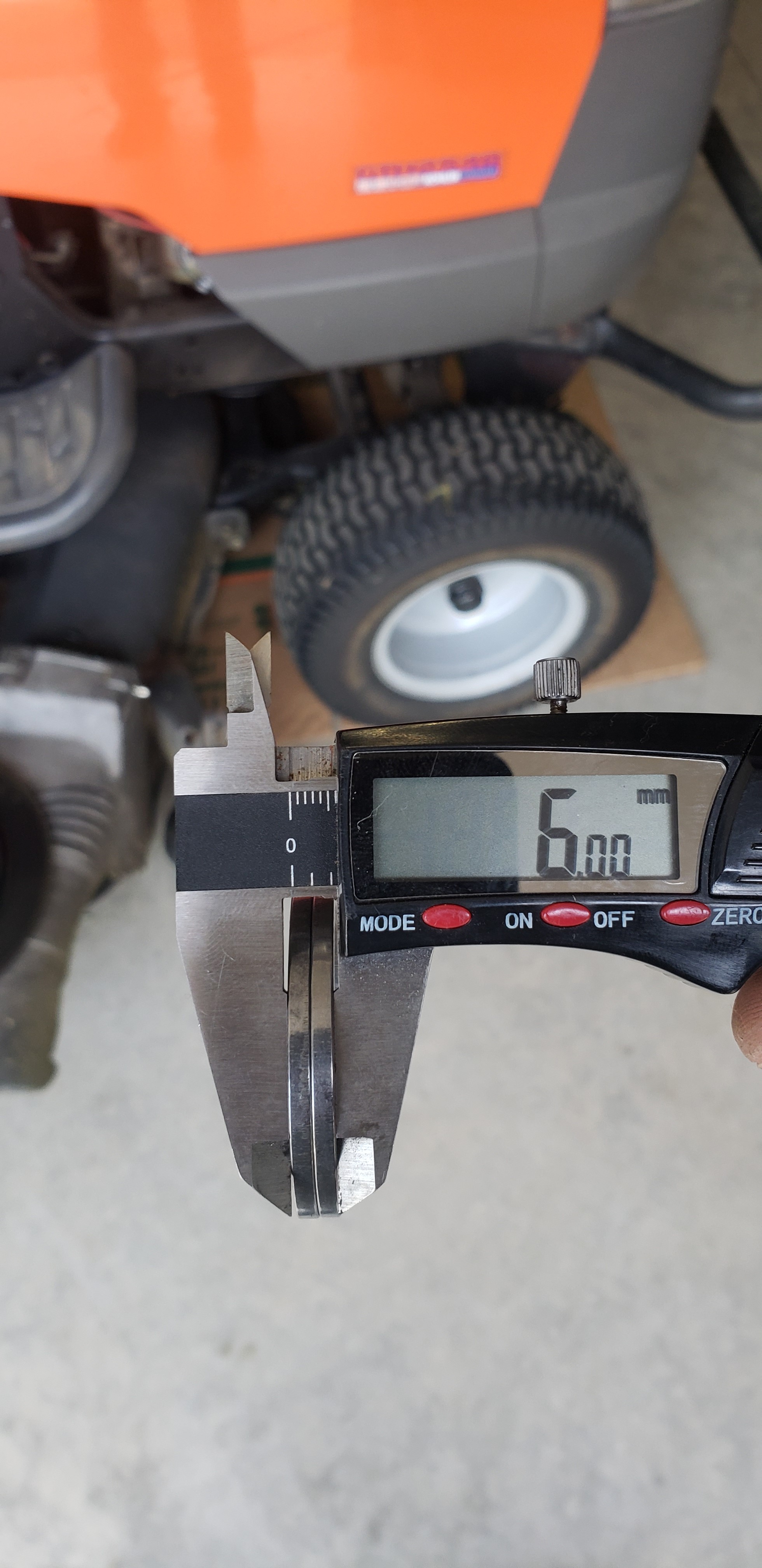

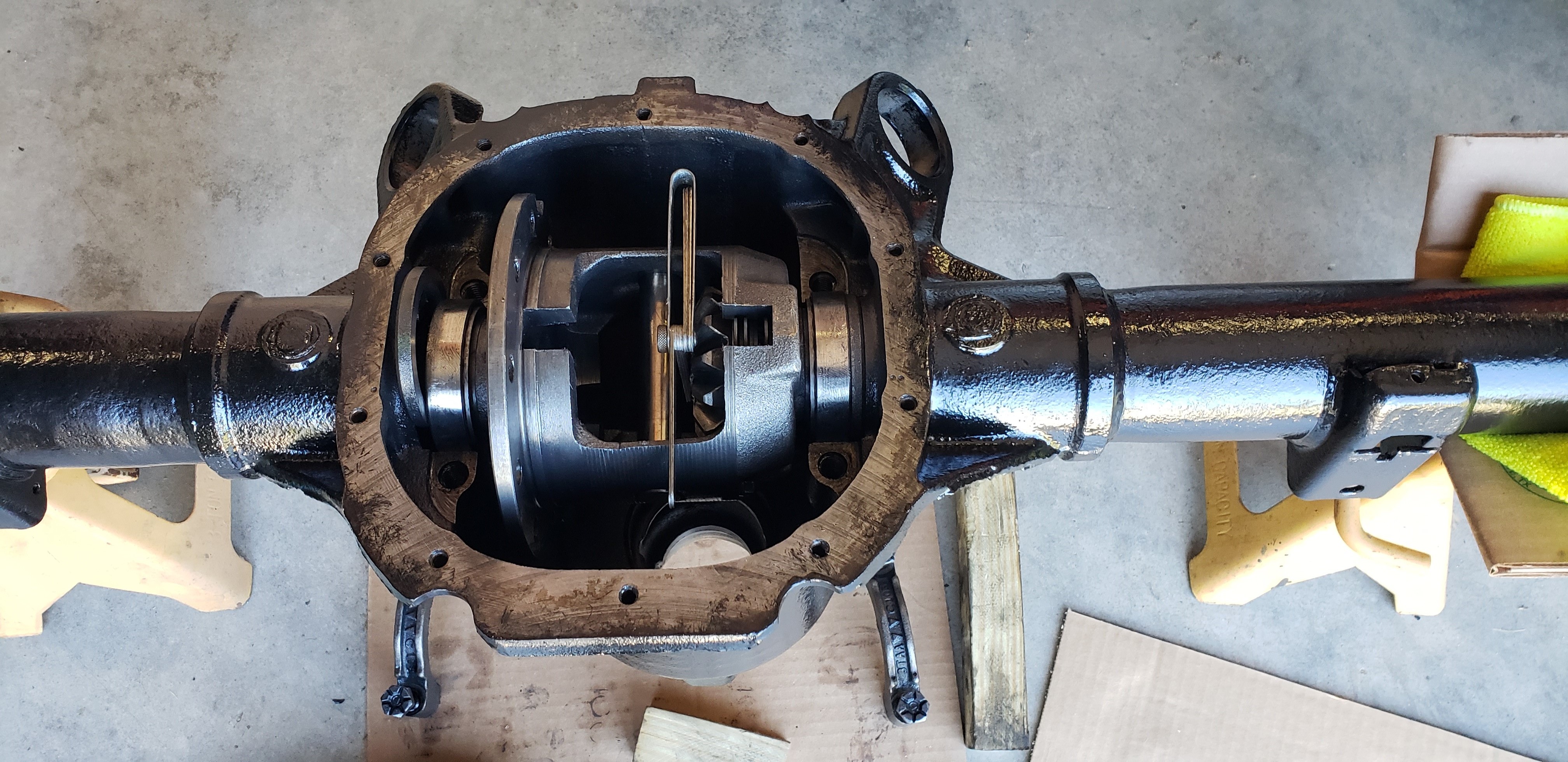

Does anyone have the upper control arm bushing housing bore measurement off of a 64-88 GM A/G body. I need the bore measurement along with the thickness of the ear on the housing.

Hi, I don't have the ear specs for the A body rear end but rockauto usually shows specific info on parts. This has helped me out on so many occasions when I did not have the specs on something. I went to 1969 Chevelle and for the rear bushings they show ....

Outside Diameter 1.850 in.

Length 2.40 In.

Inside Diameter 0.510 in.

https://www.rockauto.com/en/moreinfo.php?pk=356242&cc=1038877&jsn=682