Very nice Jared...everything is looking like it would have been from the factory...only much much nicer!

Will be watching for more updates!

Will be watching for more updates!

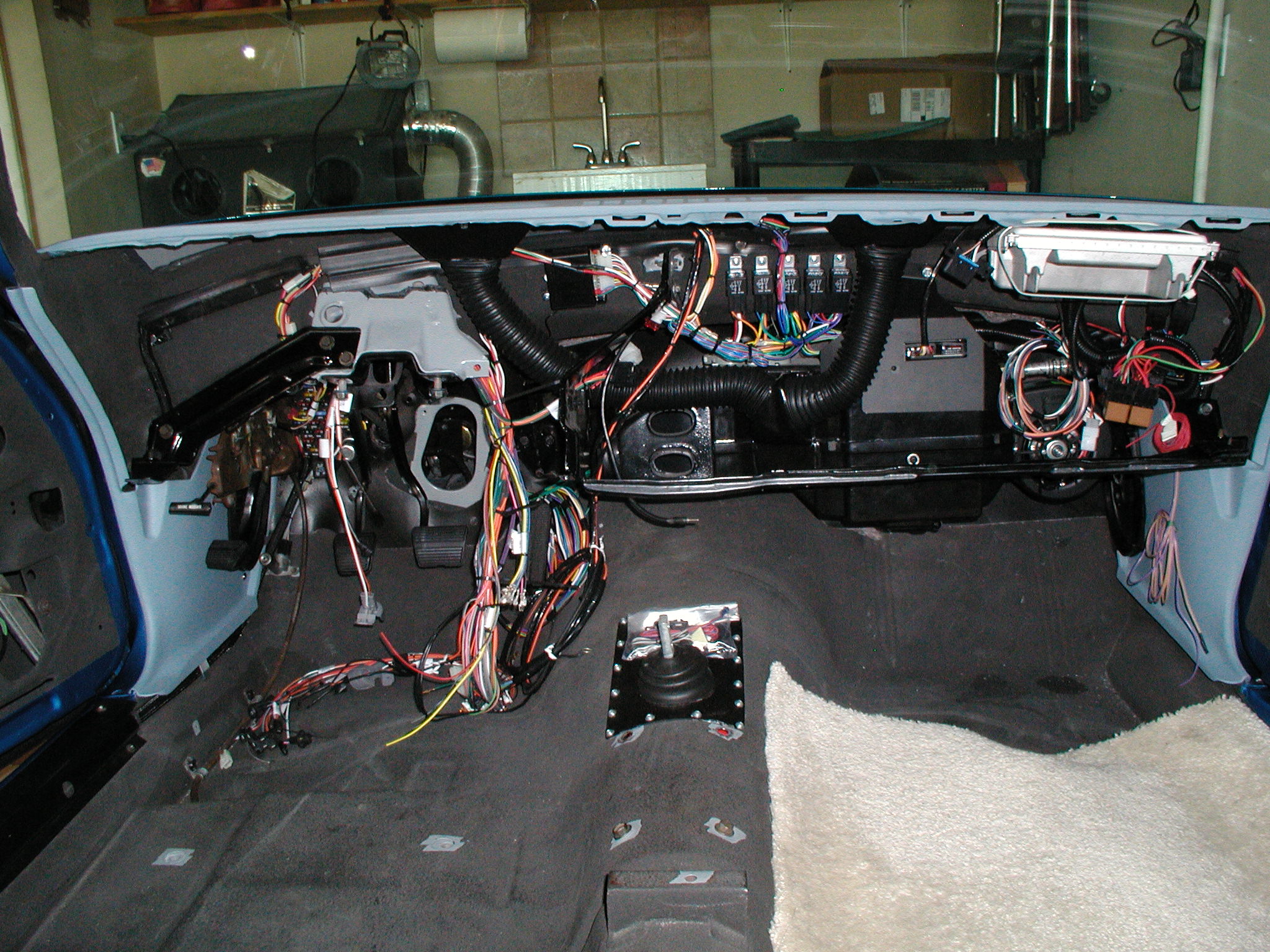

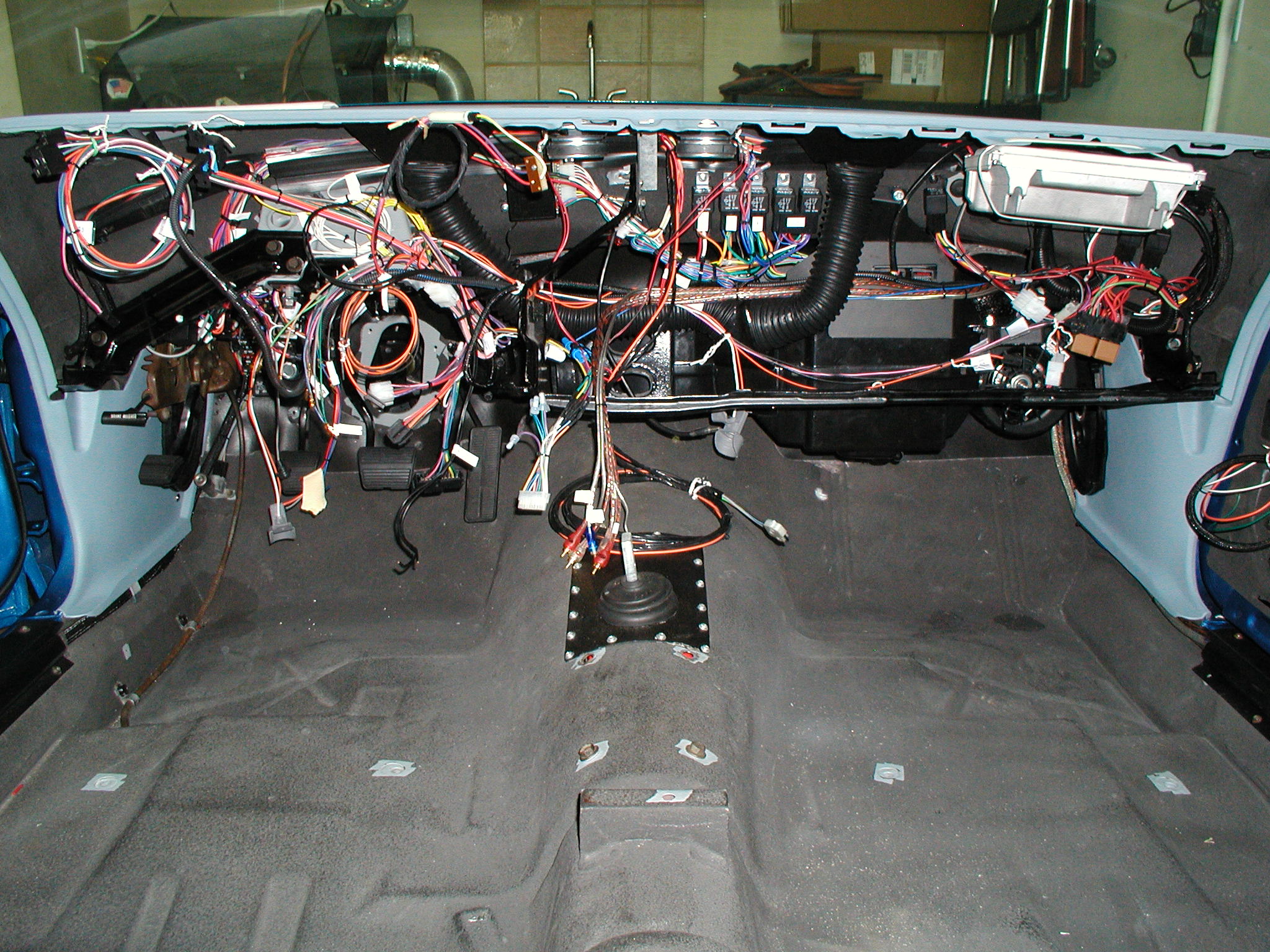

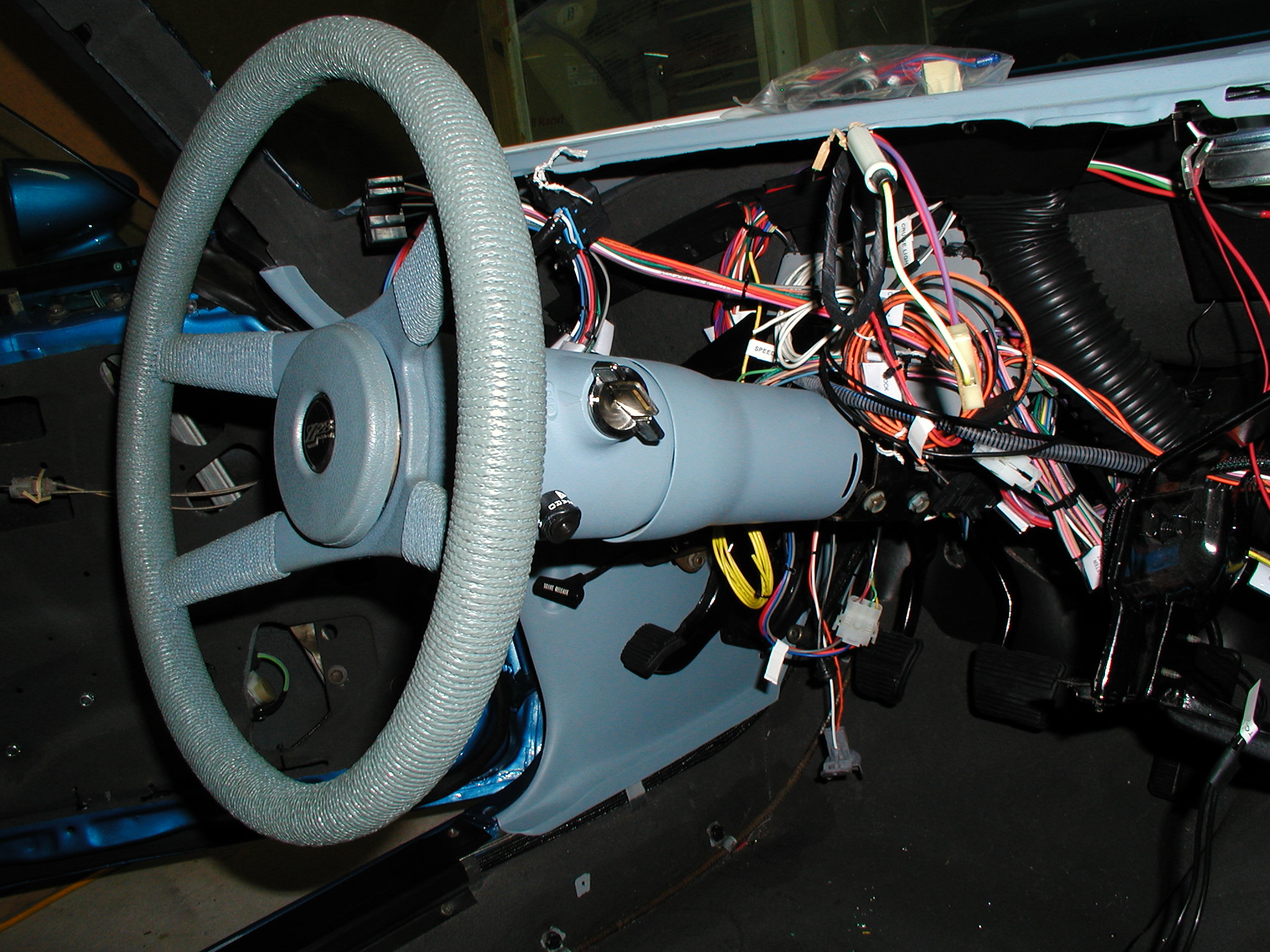

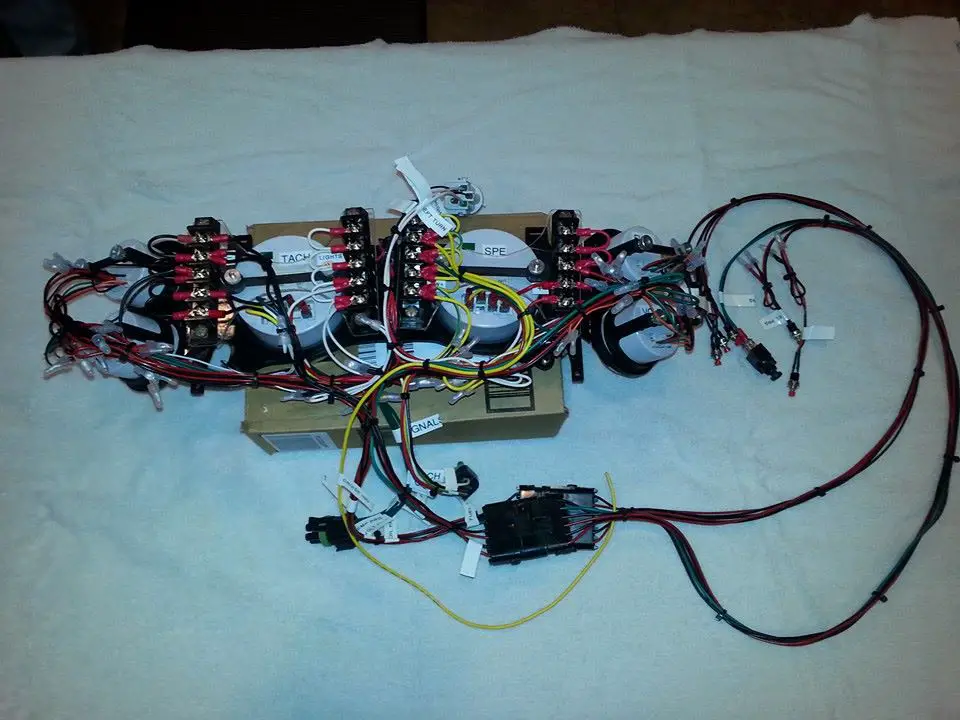

Thanks Kevin. I always appreciate the likes and the replies to the thread. We put a lot of heart and soul into the build. Not everything turned out exactly like we wanted but it is a very nice car.Very nice Jared...everything is looking like it would have been from the factory...only much much nicer!

Will be watching for more updates!

Thanks Opie. I appreciate the kind words and positive feedback. It truly does mean a lot that some of you guys are interested.This thread is great so far Jared. You guys put a lot of work into that Camaro and it's looking really good. Great job writing all of this up. Keep up the good work!

Jared,

The work quality speaks for itself. Everything is done so methodically and sanitary. It's amazing the amount of work and detail that went into this extraordinary build.

How well does the F-body fans work? The reason I ask is that I have the same fans in my garage that I was originally planning to use on my car, but went back to using a mechanical clutch fan.

Thanks for the kind words Jack. It's been fun reliving the project by creating this thread. Its funny how you forget how much you've done and what a journey it has been.

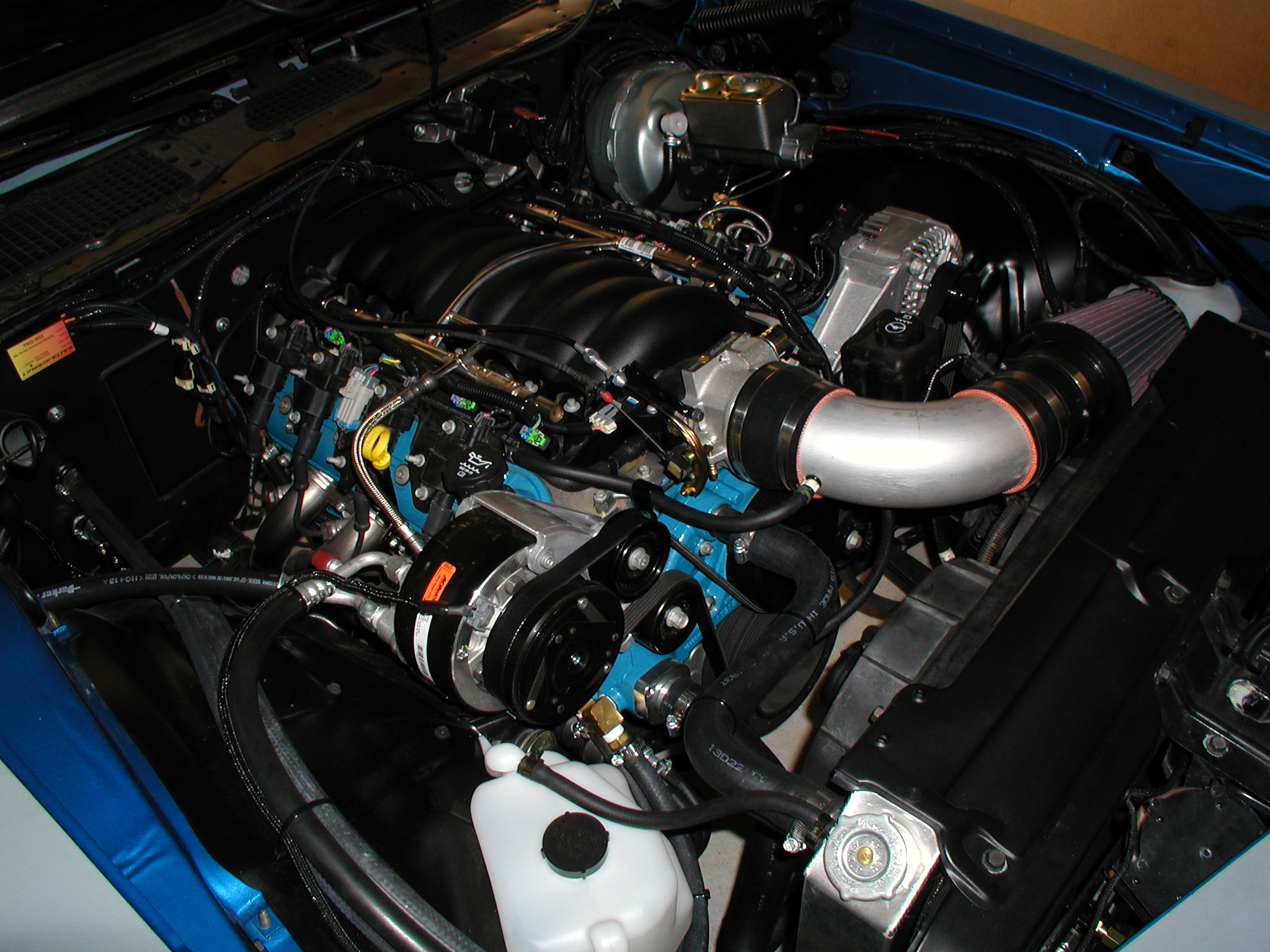

The F-body fans work and fit terrific. Believe it or not, the whole thing is a used setup off of Ebay. One thing I forgot to mention is that we have it installed upside down to make it fit the way it does in the Camaro. As I recall, when we tried to put it in right-side-up, there was interference with the left side fan and the power steering gearbox. We have each fan on its own relay and both are controlled by the PCM. The 'high temperature' fan is also controlled by a pressure switch on the high side of the A/C system. Once it reaches a certain pressure, that fan kicks on, regardless of temperature. For our cars, if not LS swapped, I personally prefer the look of the clutch fan and shroud. I know some on here think I am a dinosaur for it. I'm not going to run my car at sustained high speeds so the clutch fan is fine for me and gives me the look I want. On Sean's car, we used the Corvette front accessory drive and used the production PCM so going with electric fans was a no brainer and matched the look or theme of the engine compartment.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.