Outstanding job with the car and great write-up.

Sean's 78 Camaro Z28

- Thread starter Texas82GP

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thanks. I appreciate the praise. I've admired many of your project and wonder where you get the time and energy for them.Outstanding job with the car and great write-up.

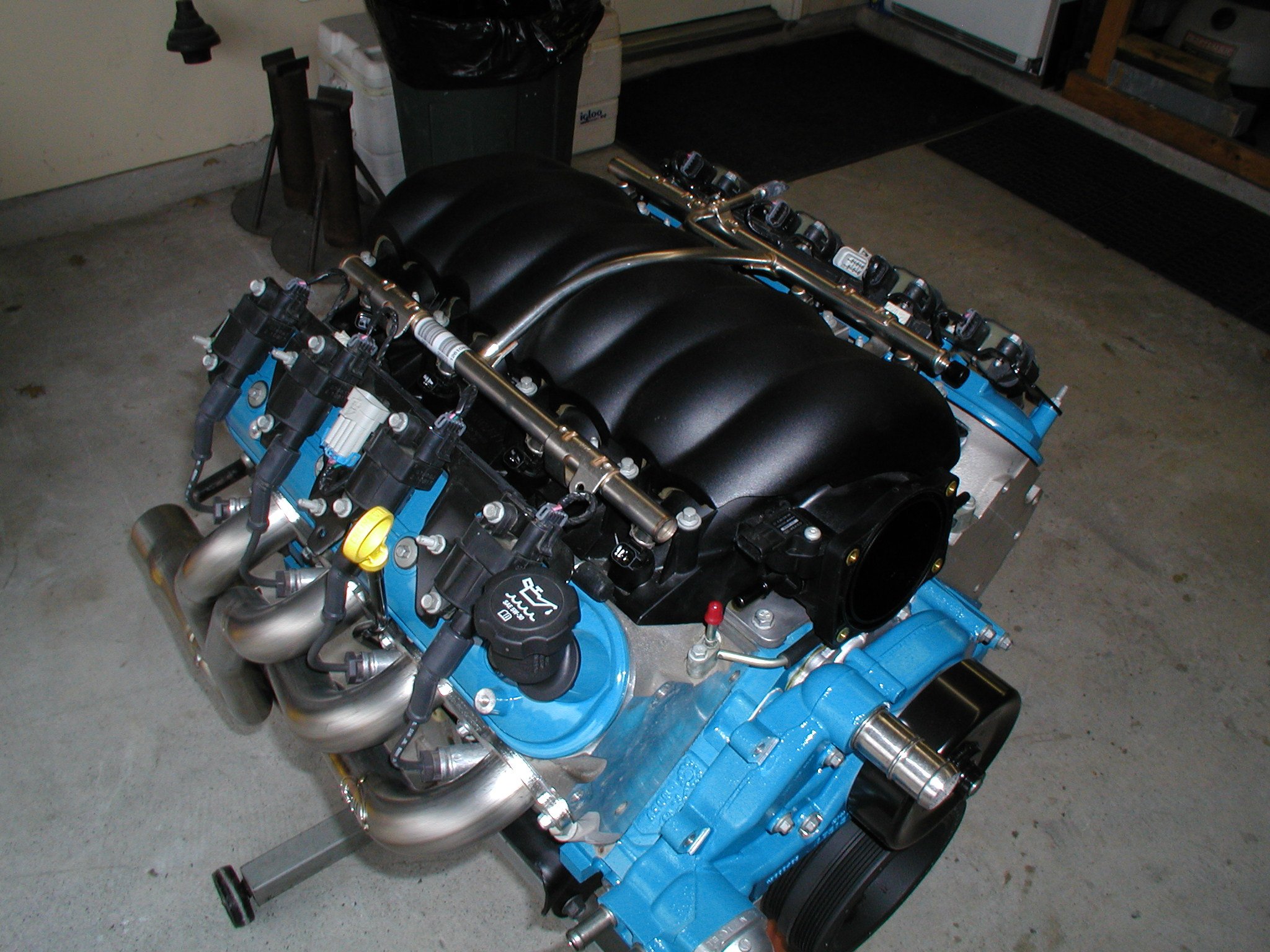

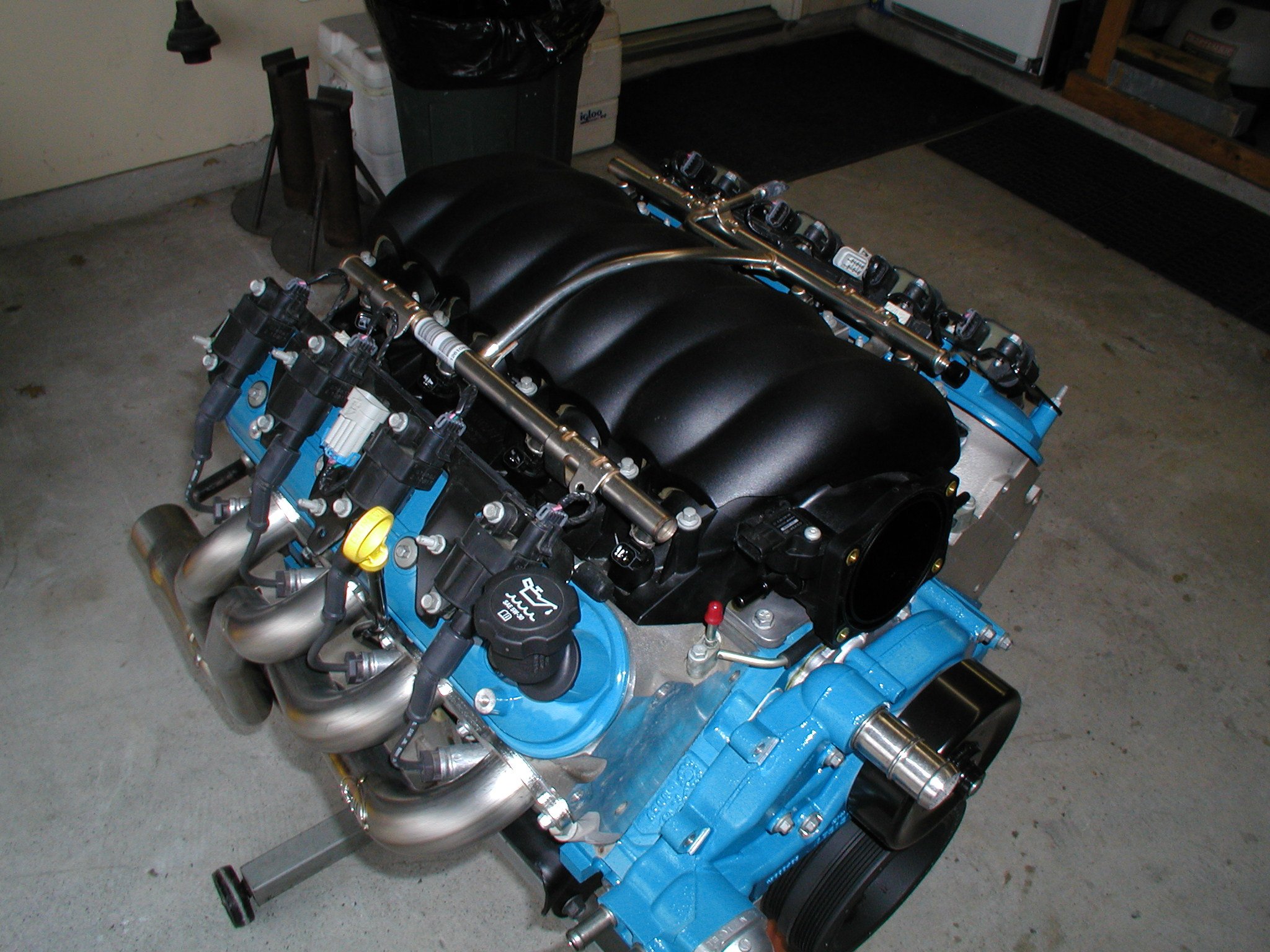

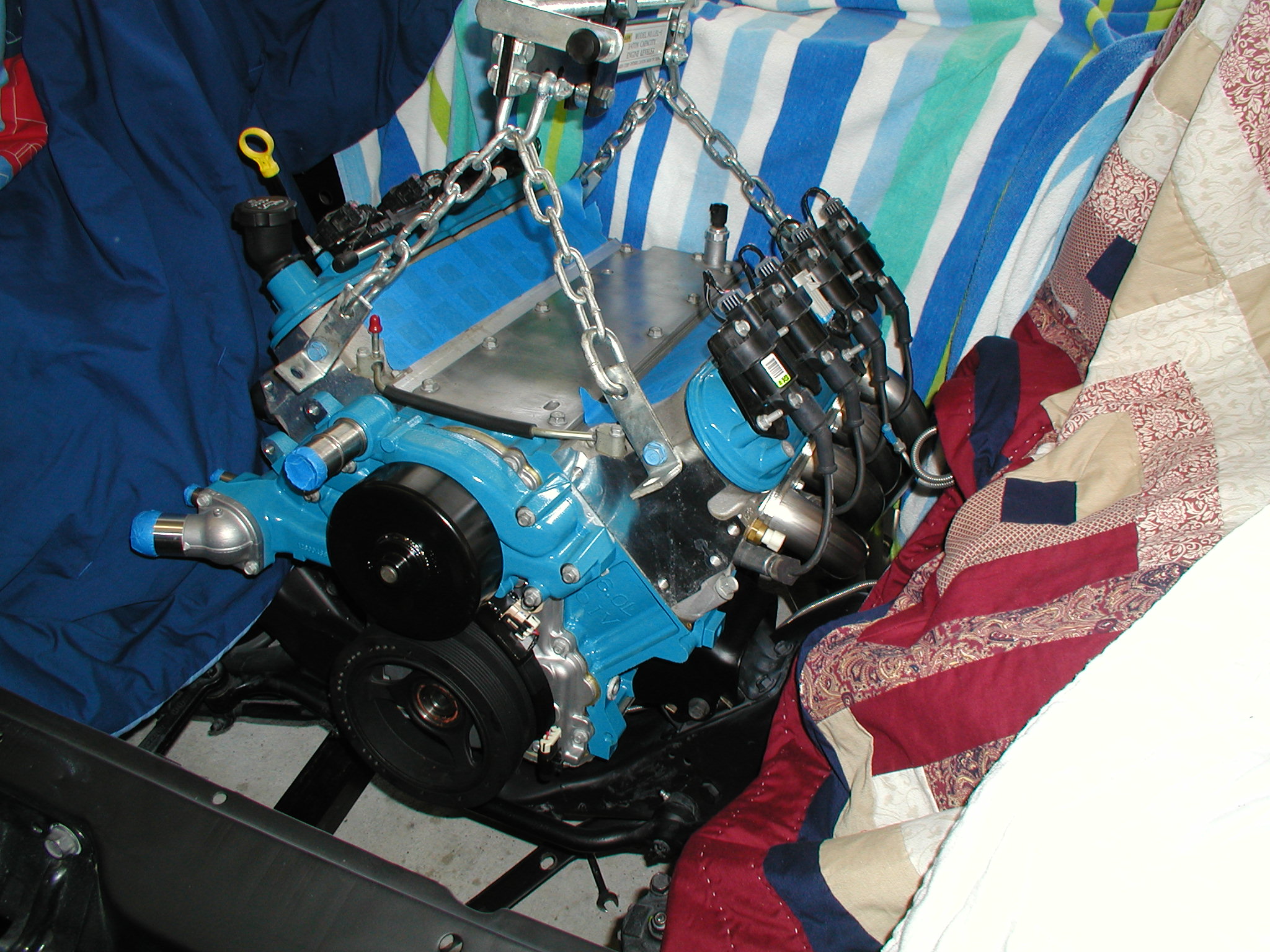

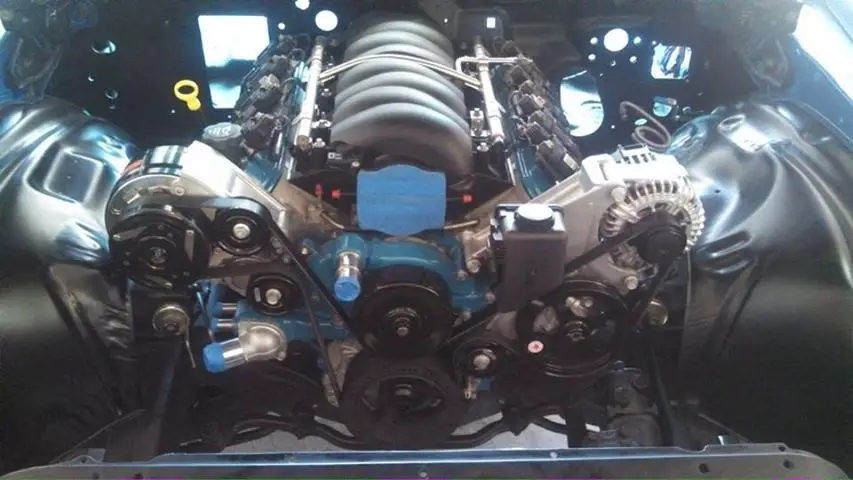

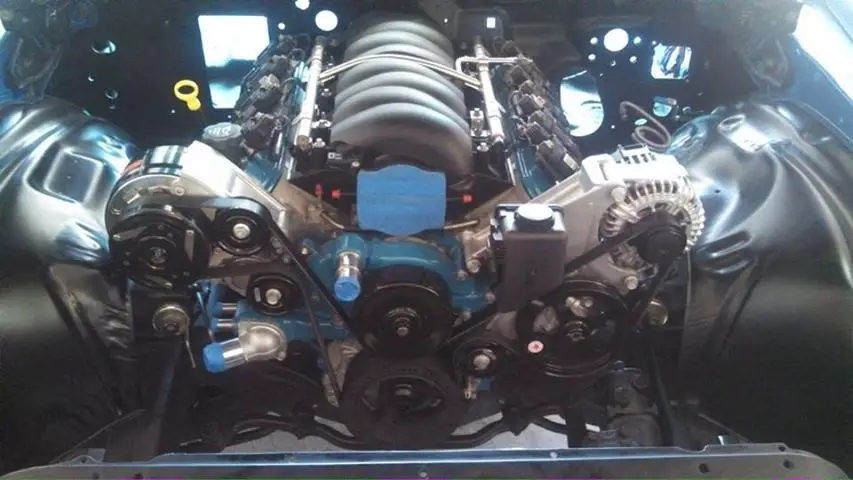

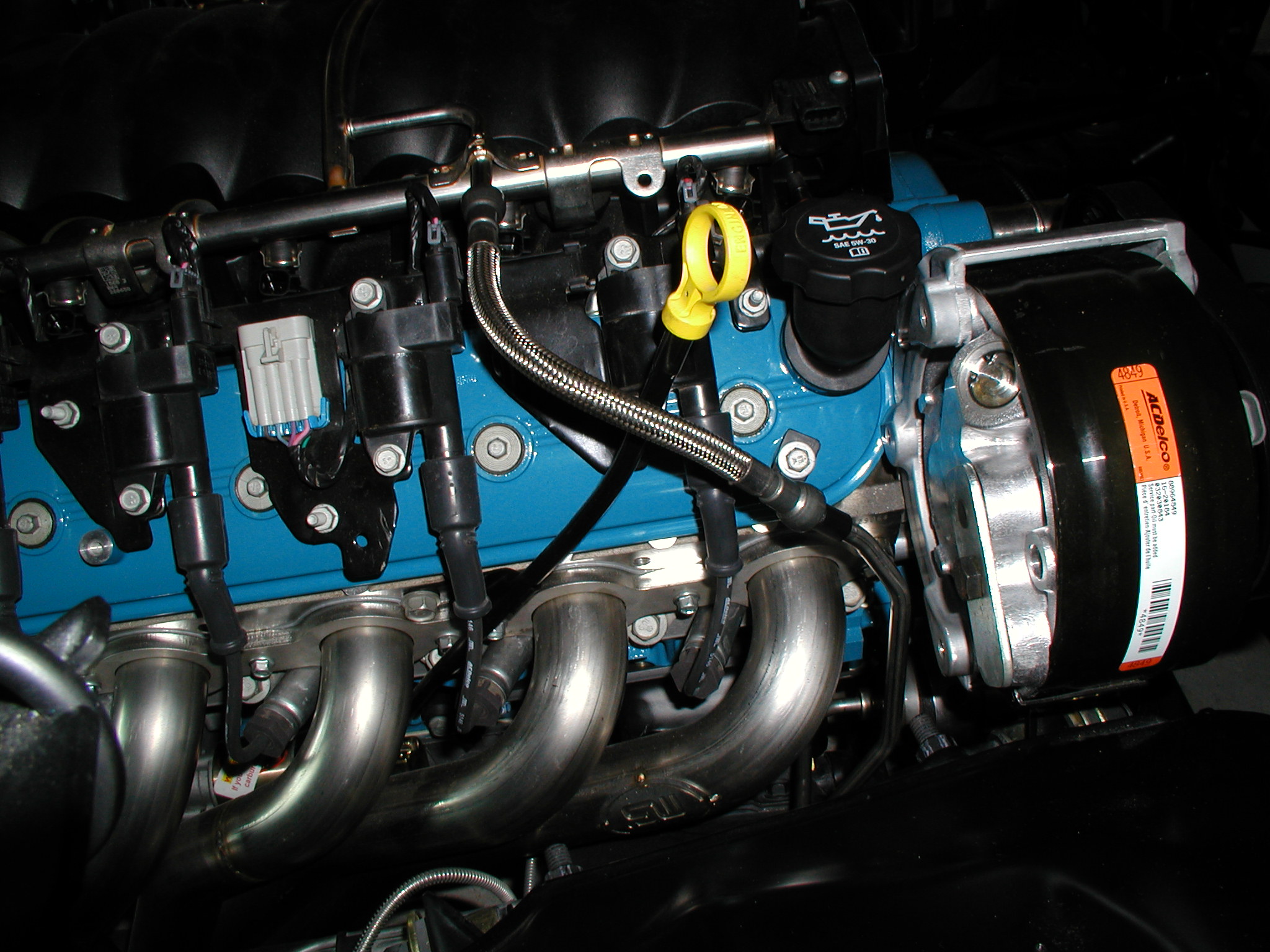

Time for an update. So now we will get back in sequence. The body has been 'jambed', the glass has been installed, the 6.0 has been purchased and has been painted, cam swapped, and ridded of the van specific equipment. Where we previously left off, the engine looked like this...

Next we painted and installed the water pump and installed the motor mounts. We used the swap plates that came with the headers. We also used the original 350 clamshells that were in the car. I don't remember grinding the A/C mount boss, but we must have done so. I don't have any pictures of it....

Next came the intake. My brother bought a take off LS3 intake with fuel rails and injectors. Note the fuel hookup is on the driver's side. More on that later. We put the intake on for a look and for mock up. It came back off later to set the engine in the car......

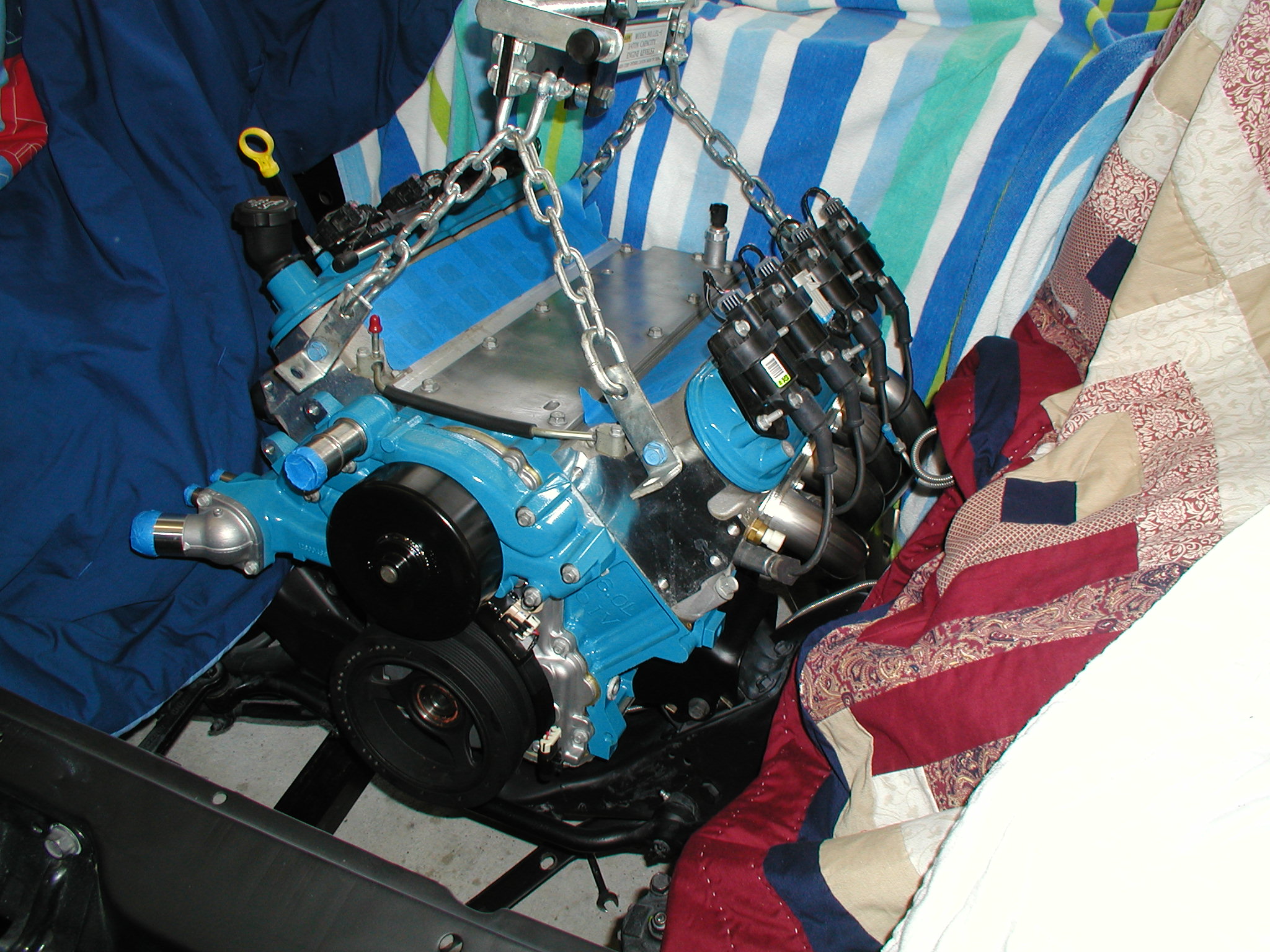

I believe we swapped out the truck steam line for the LS3 steam line at the same time. I don't think the truck line would work with the LS3 intake. This gets us to the beginning of April, and a big day for the car was April 6, 2013. That was the day we set the engine in the car. This will be pic heavy! The engine bay won't be empty for much longer....

Here's the car in position ready to accept the new heart....

Going in. Dad didn't like all of our covers that much. I wish I had seen the tennis ball in the picture. I was using the screen on the back of the camera instead of the view finder and just didn't see it so there is a tennis ball right in front of dad's face.

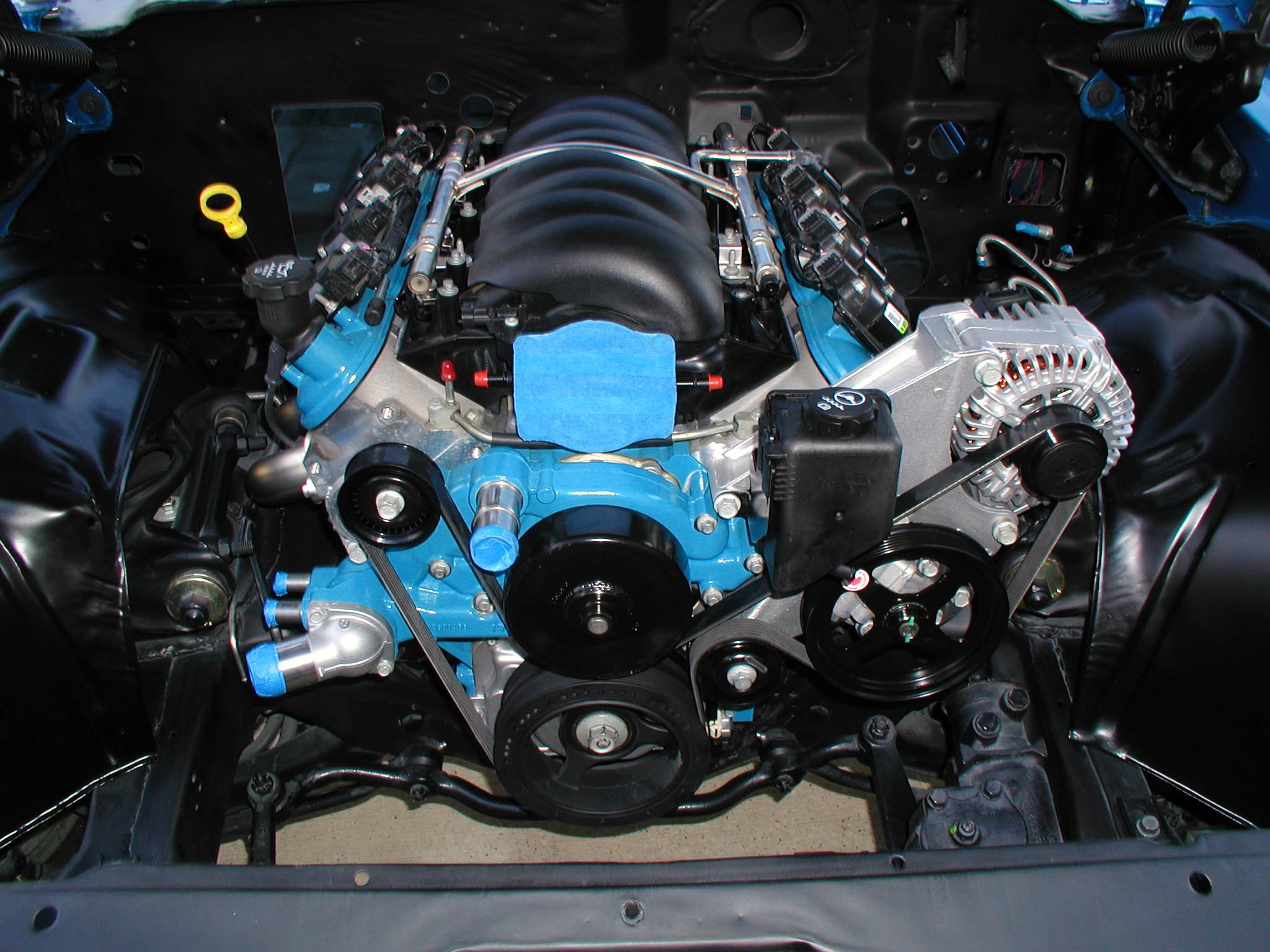

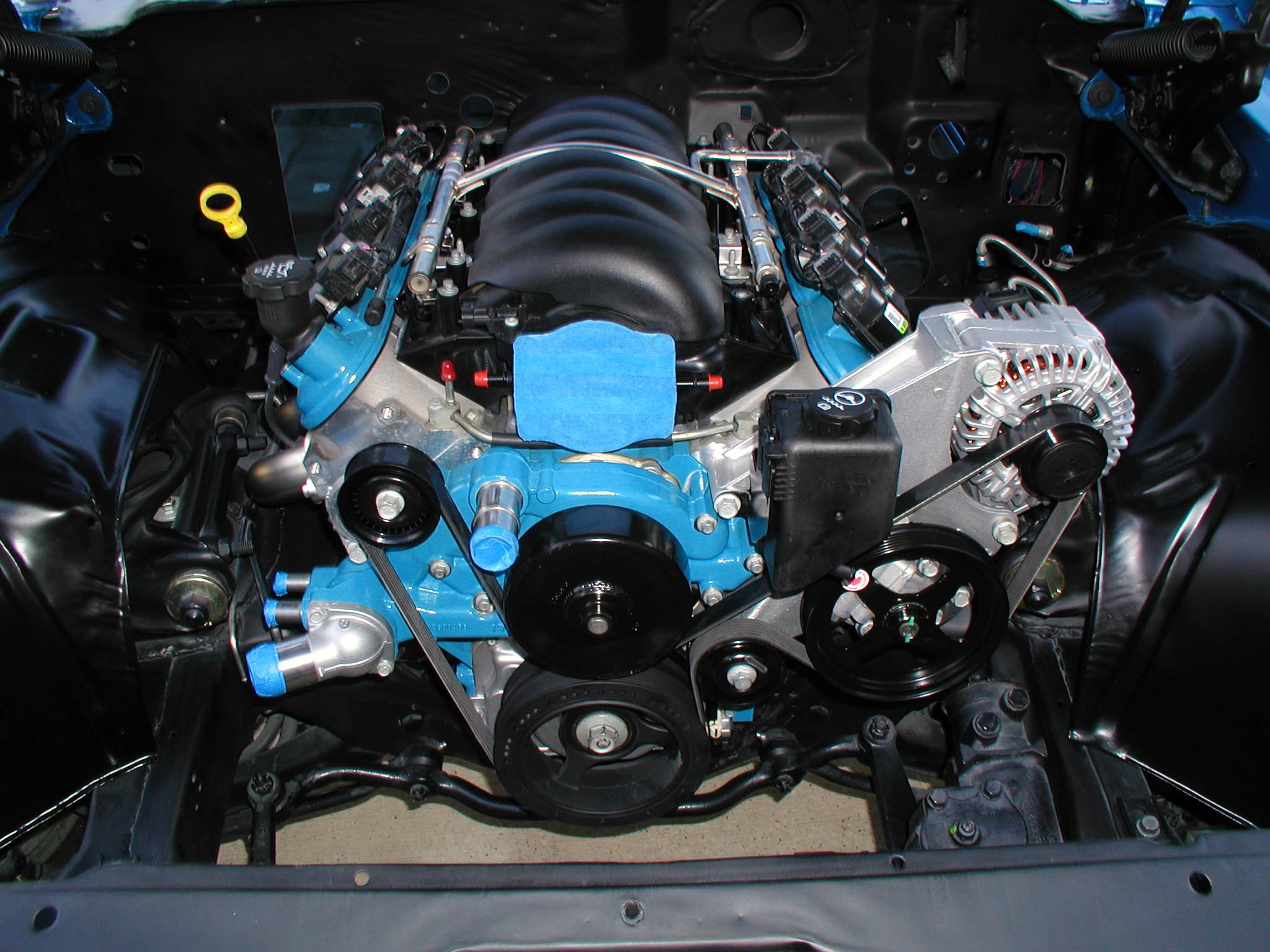

Bolted in. No issues with fitment. The engineered solution fully came through. It was like it belonged in there.

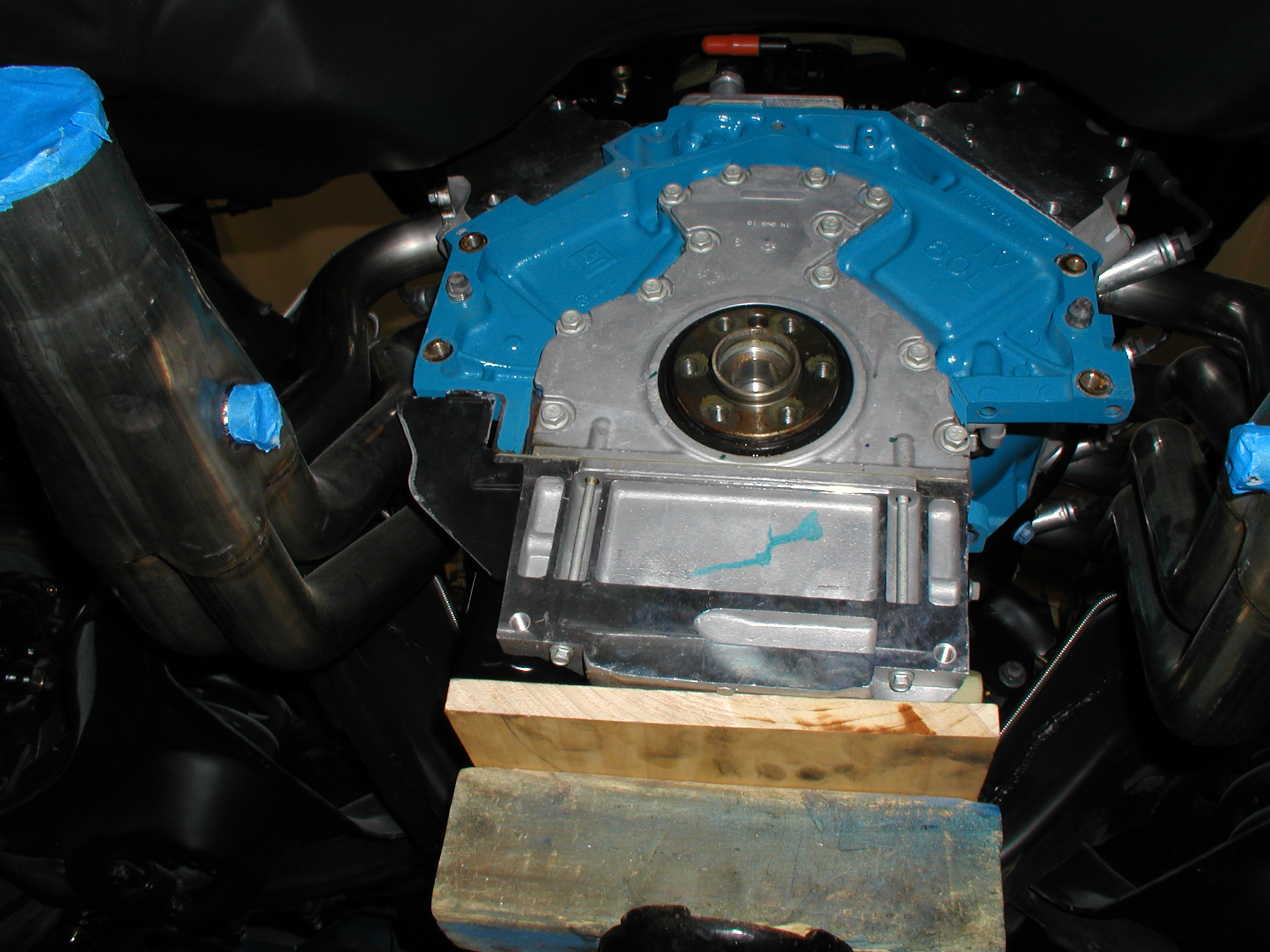

Now without the covers and the hoist. We placed a block of wood between the engine and the firewall to support it, since we didn't have a transmission yet....

And with the hood back on.....

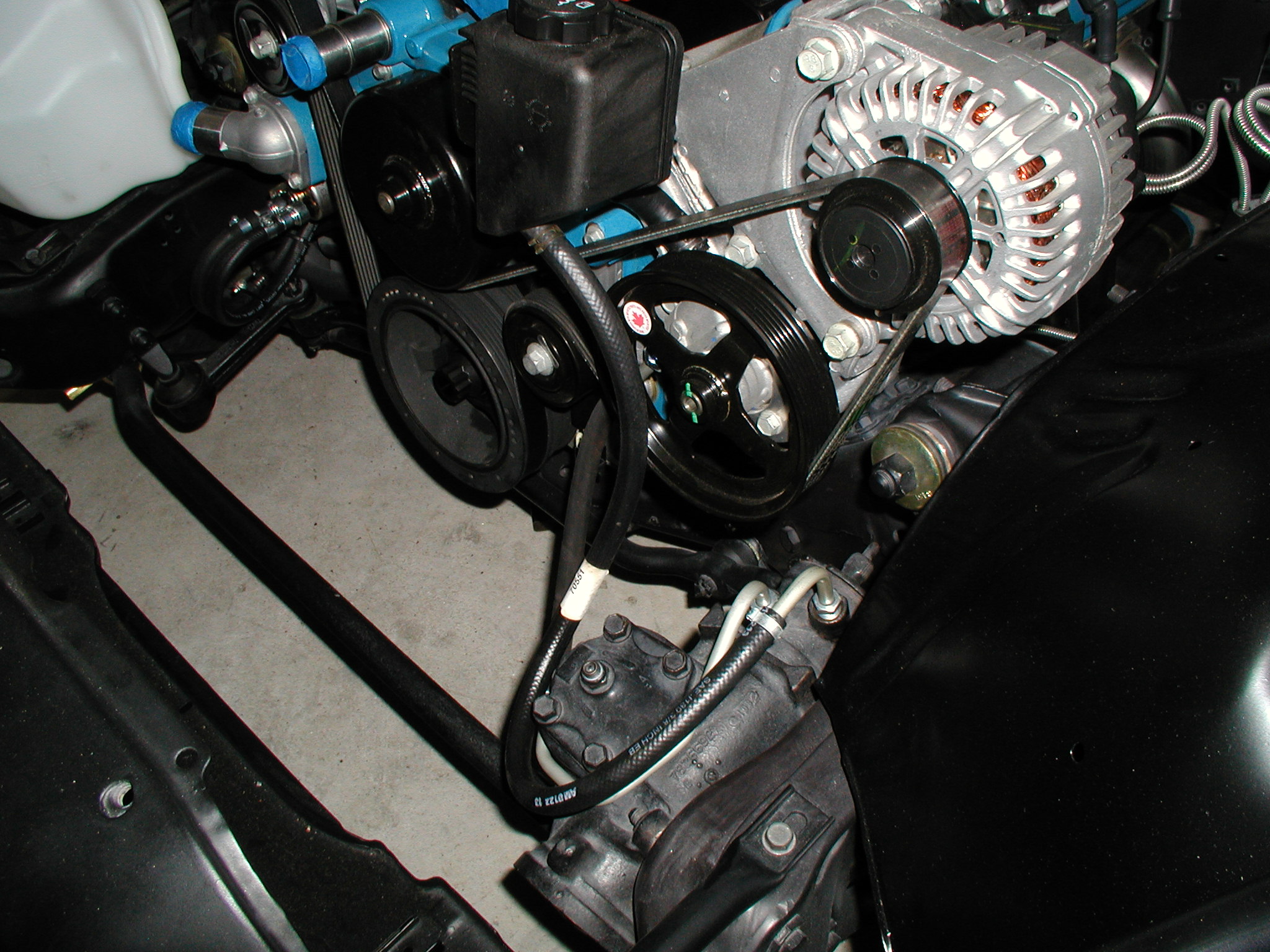

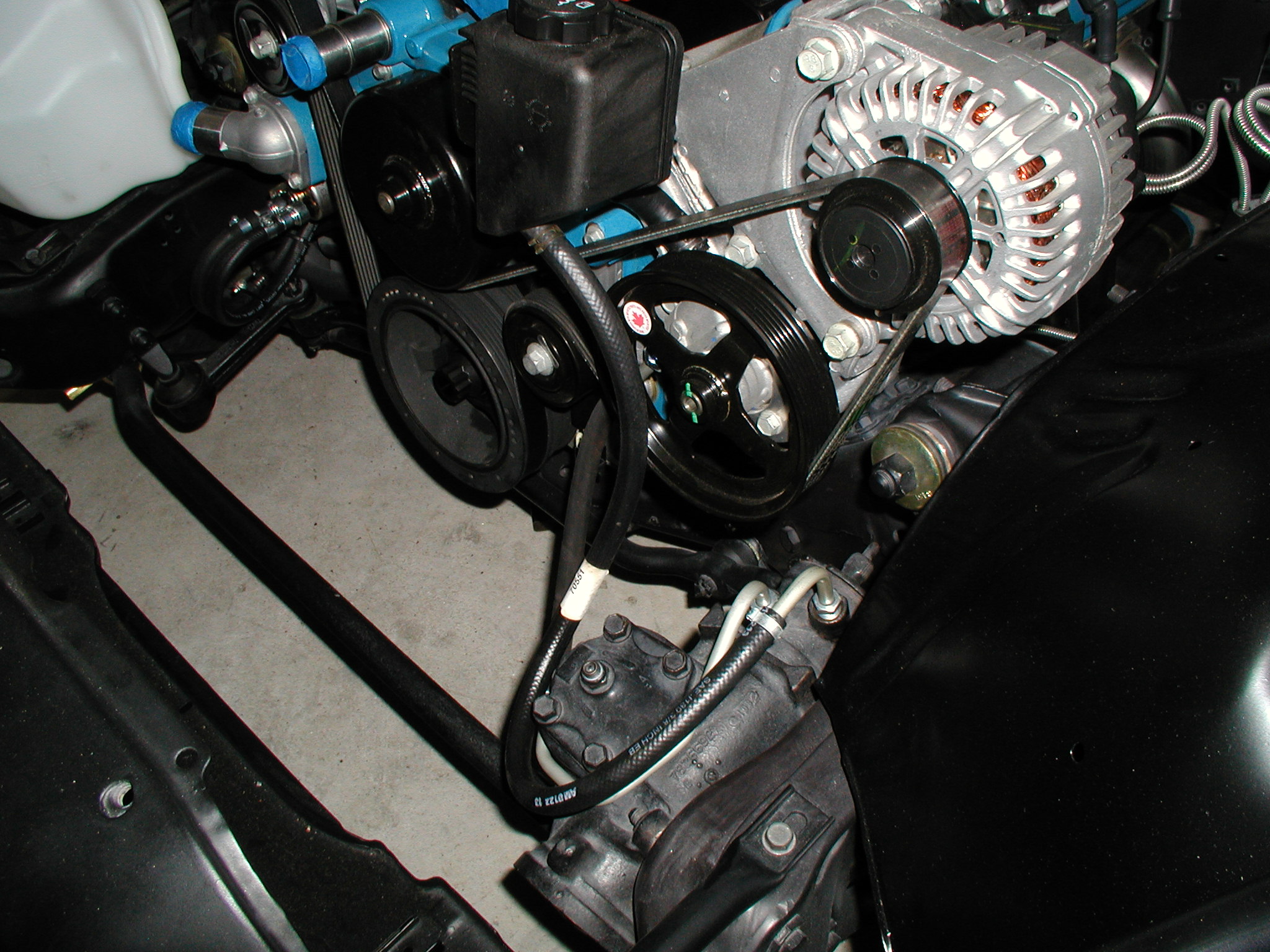

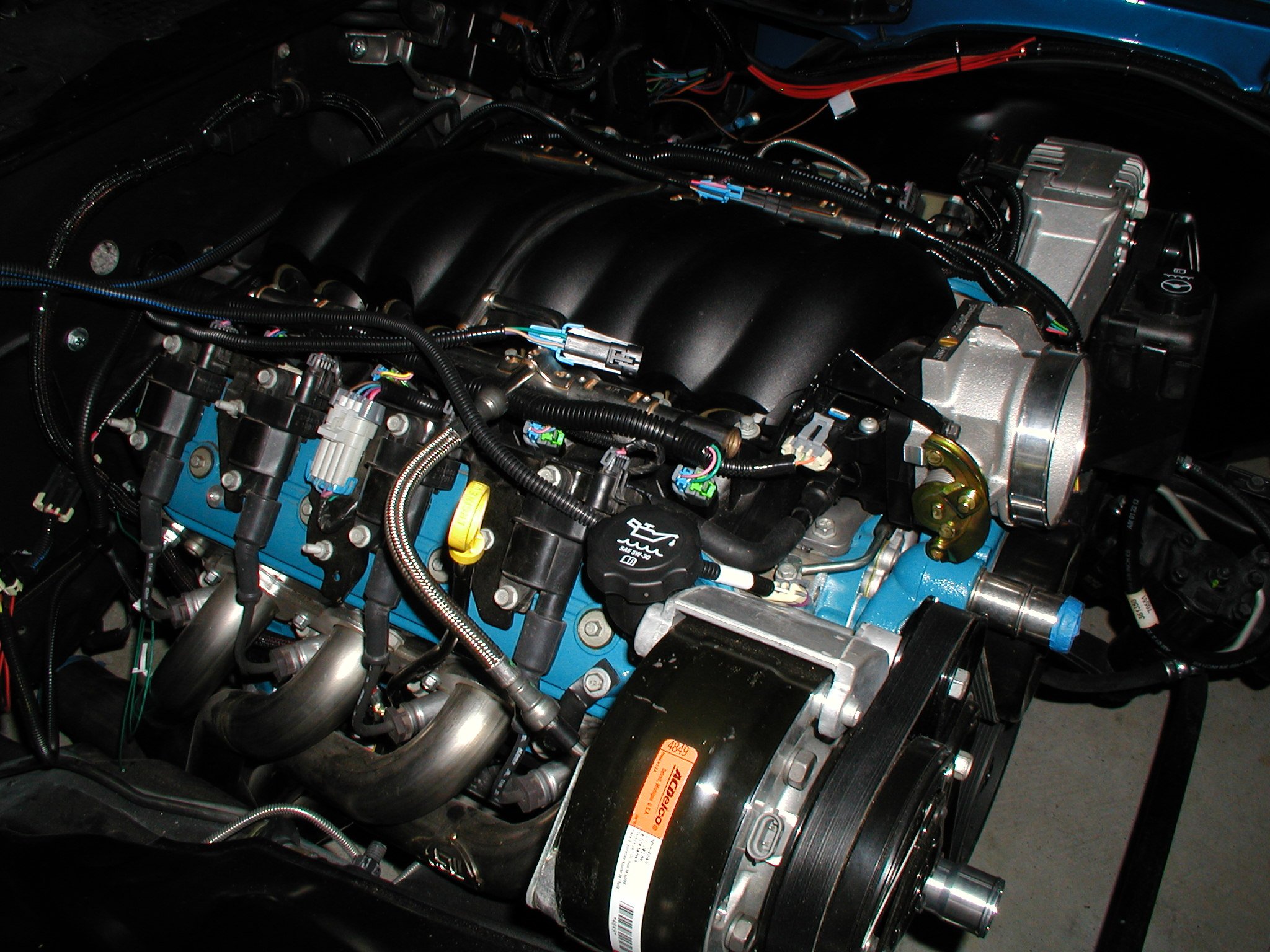

As you can imagine, we were highly enthused at this point. I immediately started putting together the front accessory drive. We used the Corvette accessory drive. It fits the engine bay like it belongs in there.....

More to come.....

Next we painted and installed the water pump and installed the motor mounts. We used the swap plates that came with the headers. We also used the original 350 clamshells that were in the car. I don't remember grinding the A/C mount boss, but we must have done so. I don't have any pictures of it....

Next came the intake. My brother bought a take off LS3 intake with fuel rails and injectors. Note the fuel hookup is on the driver's side. More on that later. We put the intake on for a look and for mock up. It came back off later to set the engine in the car......

I believe we swapped out the truck steam line for the LS3 steam line at the same time. I don't think the truck line would work with the LS3 intake. This gets us to the beginning of April, and a big day for the car was April 6, 2013. That was the day we set the engine in the car. This will be pic heavy! The engine bay won't be empty for much longer....

Here's the car in position ready to accept the new heart....

Going in. Dad didn't like all of our covers that much. I wish I had seen the tennis ball in the picture. I was using the screen on the back of the camera instead of the view finder and just didn't see it so there is a tennis ball right in front of dad's face.

Bolted in. No issues with fitment. The engineered solution fully came through. It was like it belonged in there.

Now without the covers and the hoist. We placed a block of wood between the engine and the firewall to support it, since we didn't have a transmission yet....

And with the hood back on.....

As you can imagine, we were highly enthused at this point. I immediately started putting together the front accessory drive. We used the Corvette accessory drive. It fits the engine bay like it belongs in there.....

More to come.....

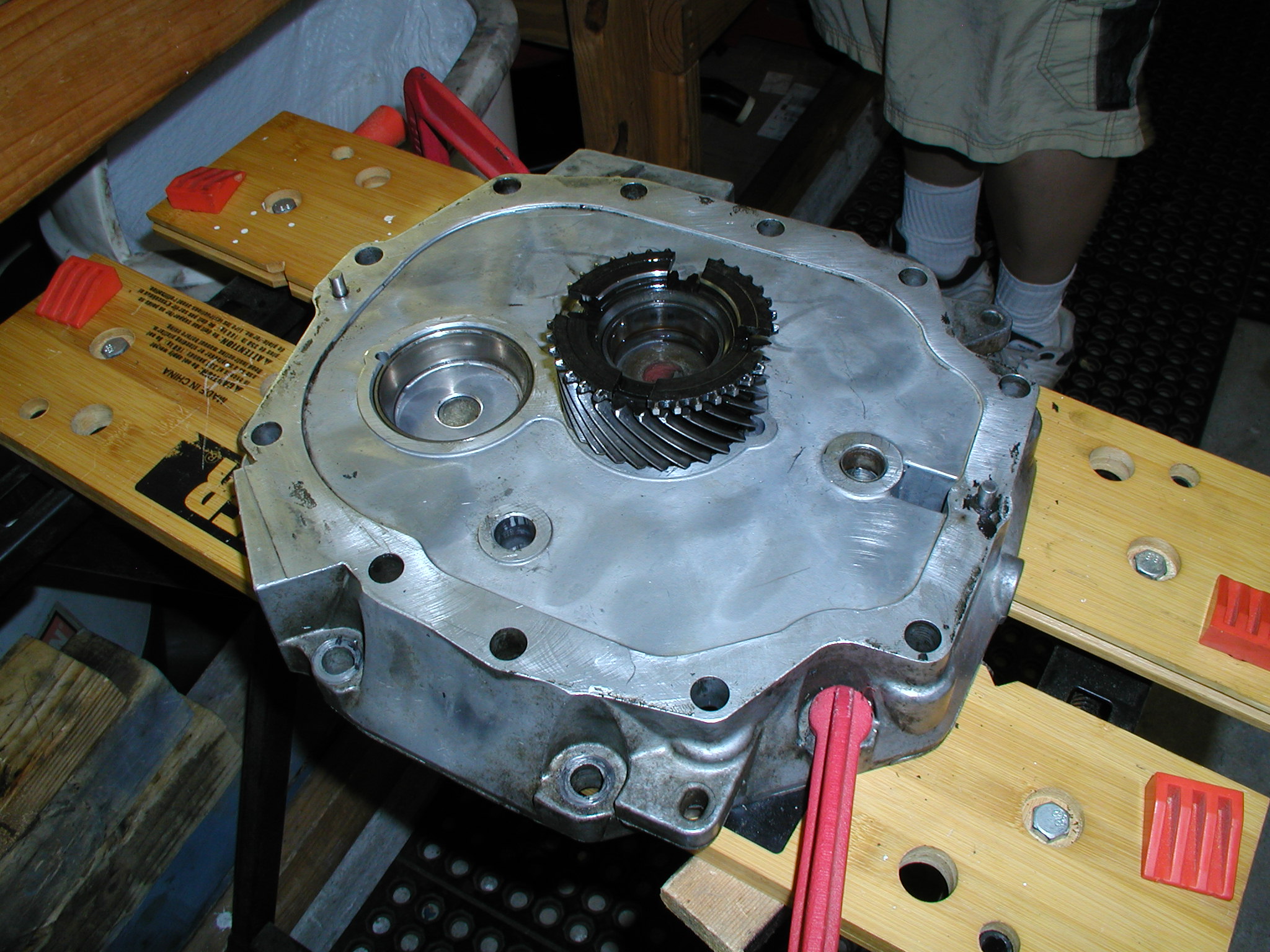

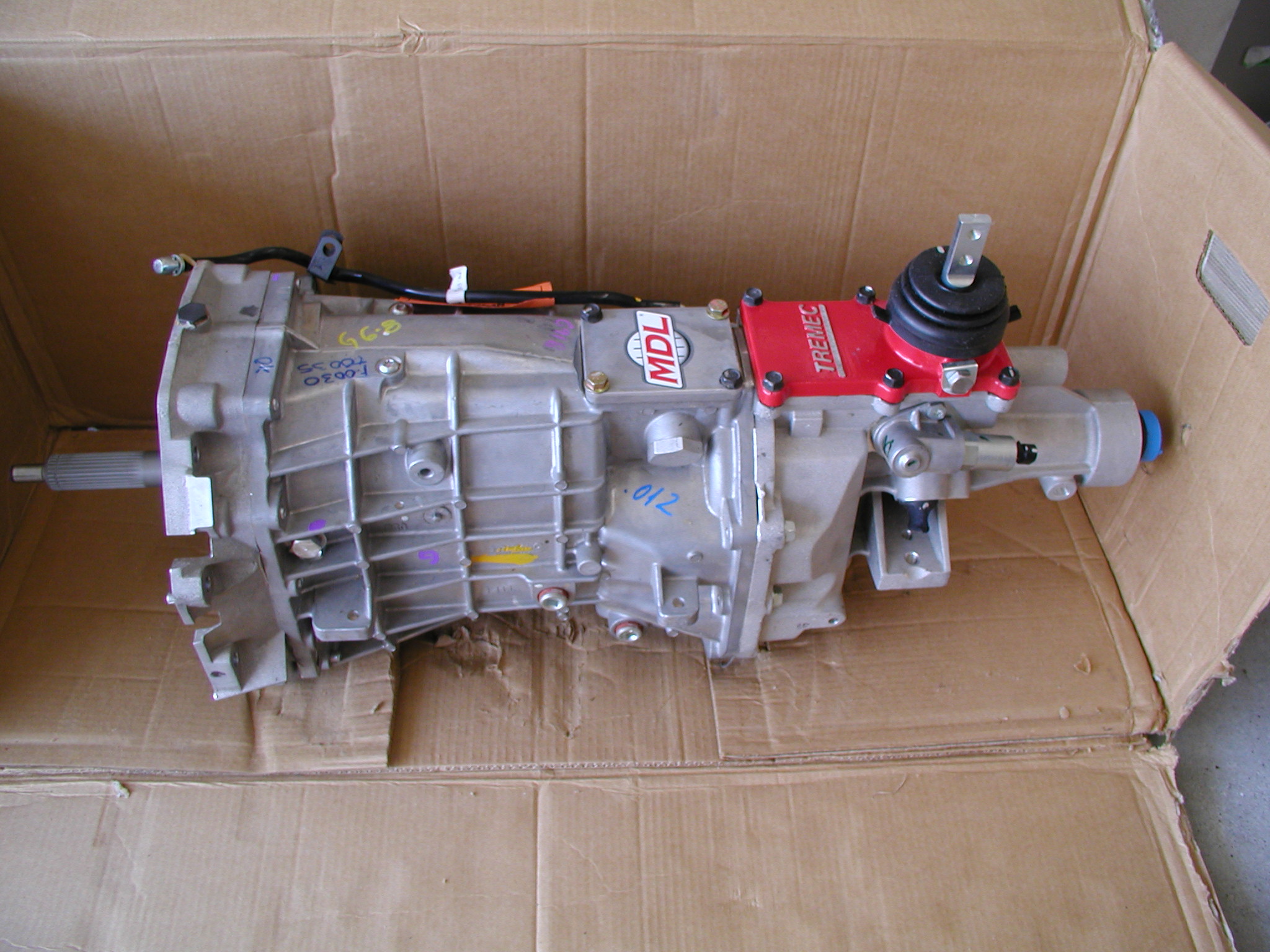

What next? We need a transmission of course! The car was originally a 350/TH350. Sean had wanted to convert it to stick in the 80's when he and dad were working towards trying to paint it. He even bought a T5 and shifter at a swap meet but lacked lots of stuff like pedals, driveshaft, etc. It never ended up happening and Dad later sold the T5 at another swap meet for him. We decided that we wanted a T56 in the car. After some searching, we found a T56 out of an 06 GTO. I think we found it on craigslist but it might have been ebay. As I recall, it came from El Paso. Here it is on the pallet the day it arrived....

And unwrapped....

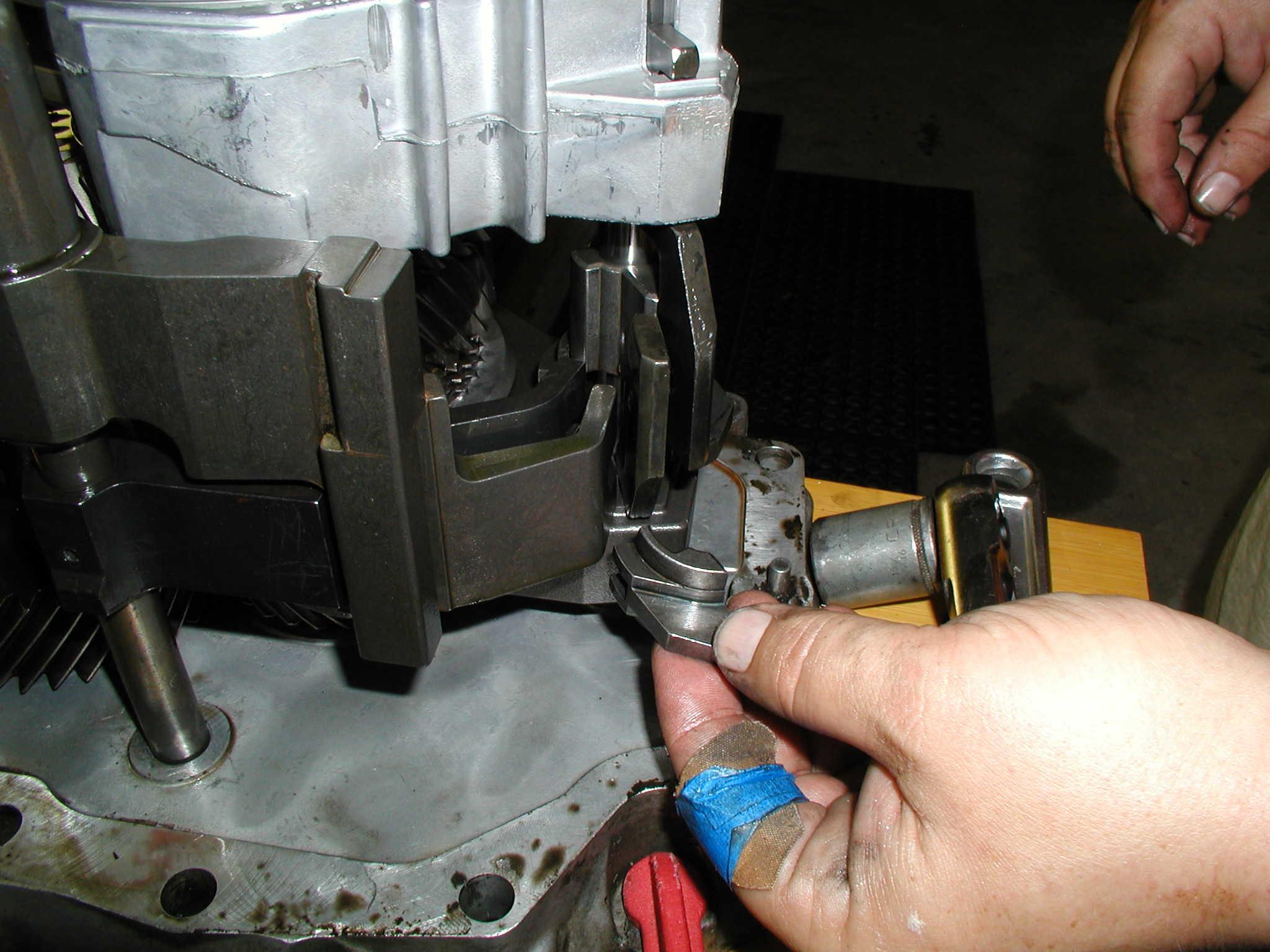

This was in June of 2013. At one point, we stood the transmission up. I forget why, but when we did, there was a loose metallic object clanking around inside. Uh-oh. I did a partial tear down of the trans to inspect it. We planned on overhauling it (as necessary) and upgrading some of the soft spots in the stock T56 like the plastic pads on the shift forks. Unfortunately, this trans was thrashed. The cluster gear was hurt....

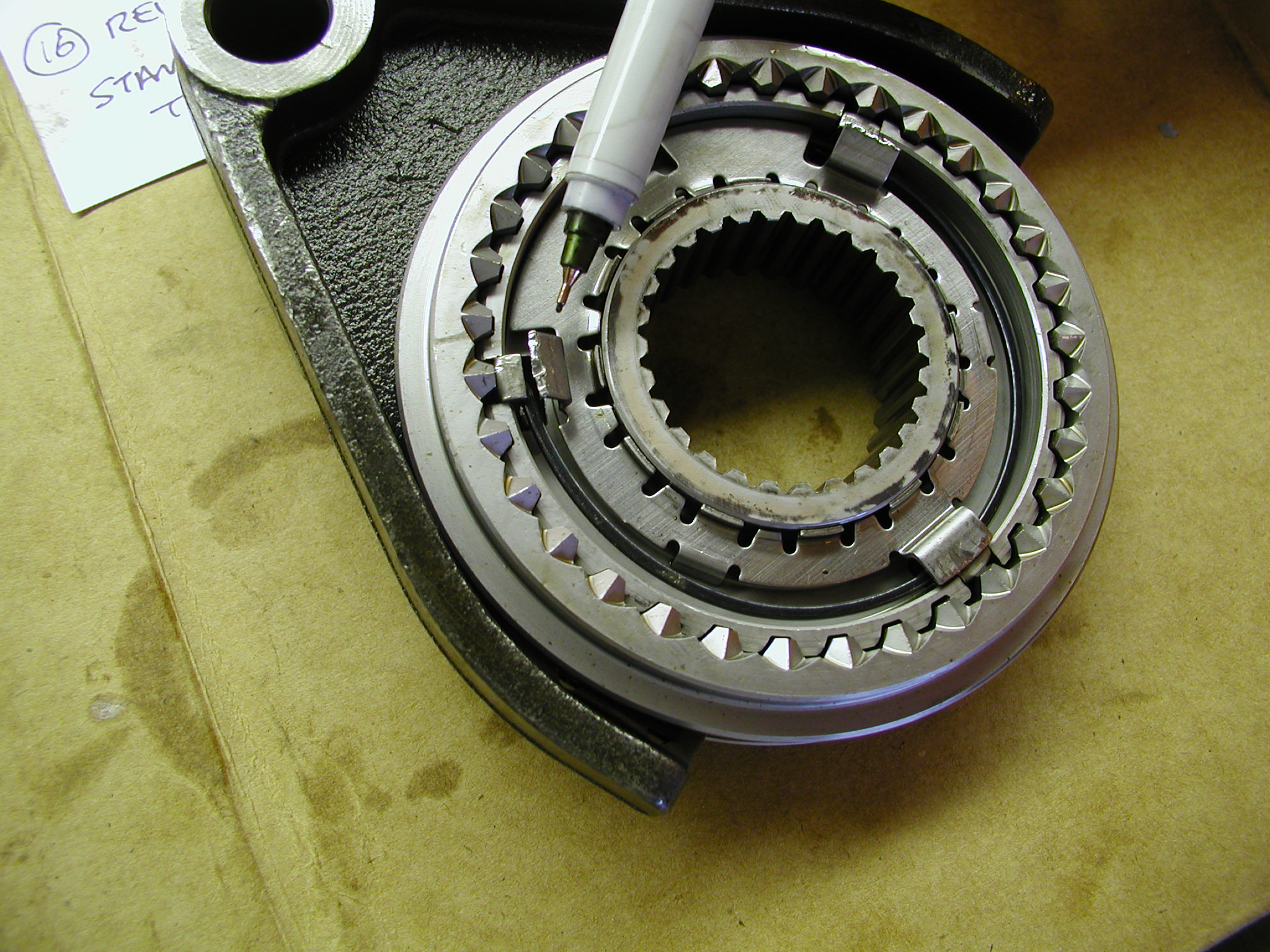

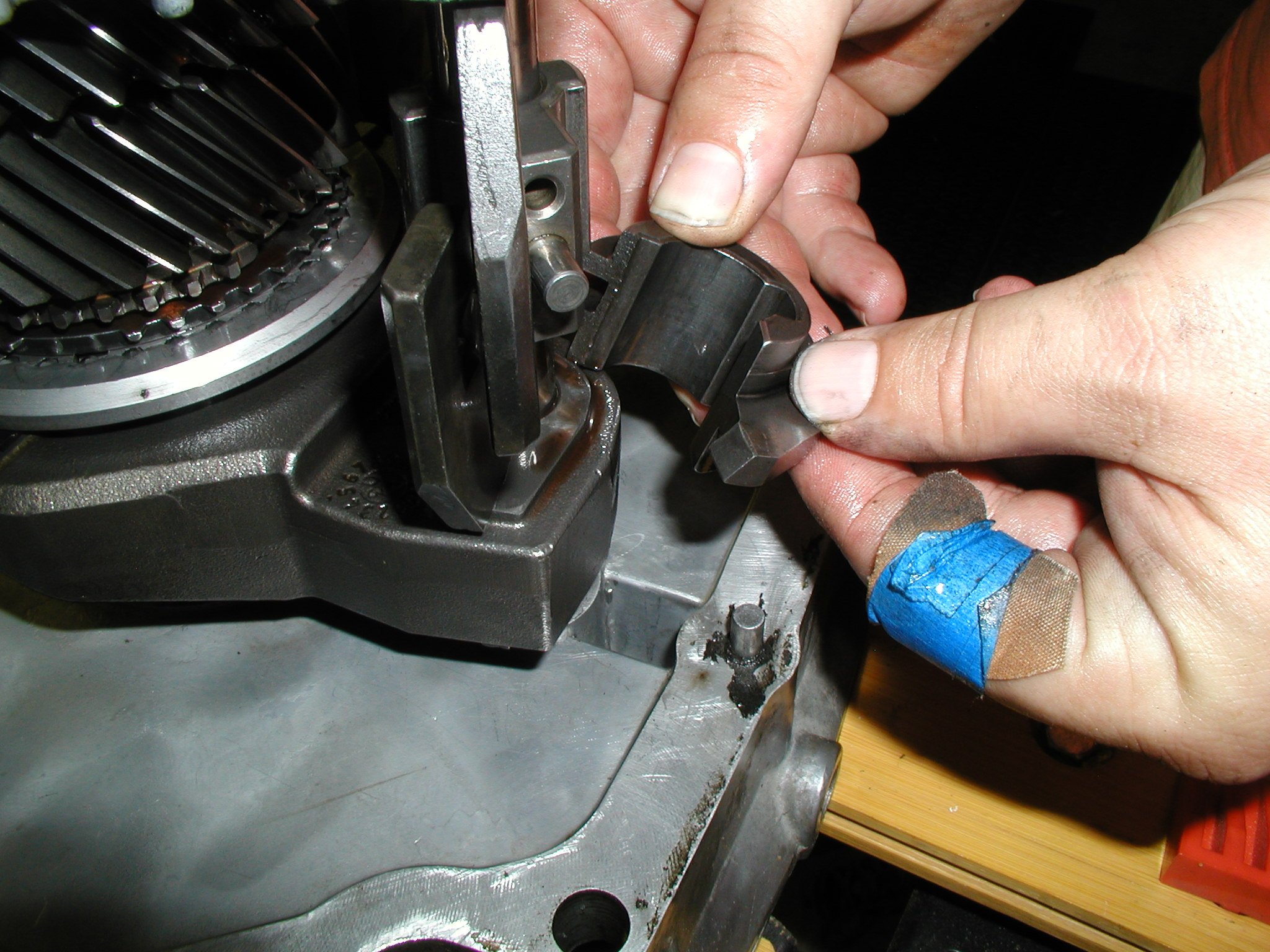

The shift interlock was busted (loose object we heard rattling around)...

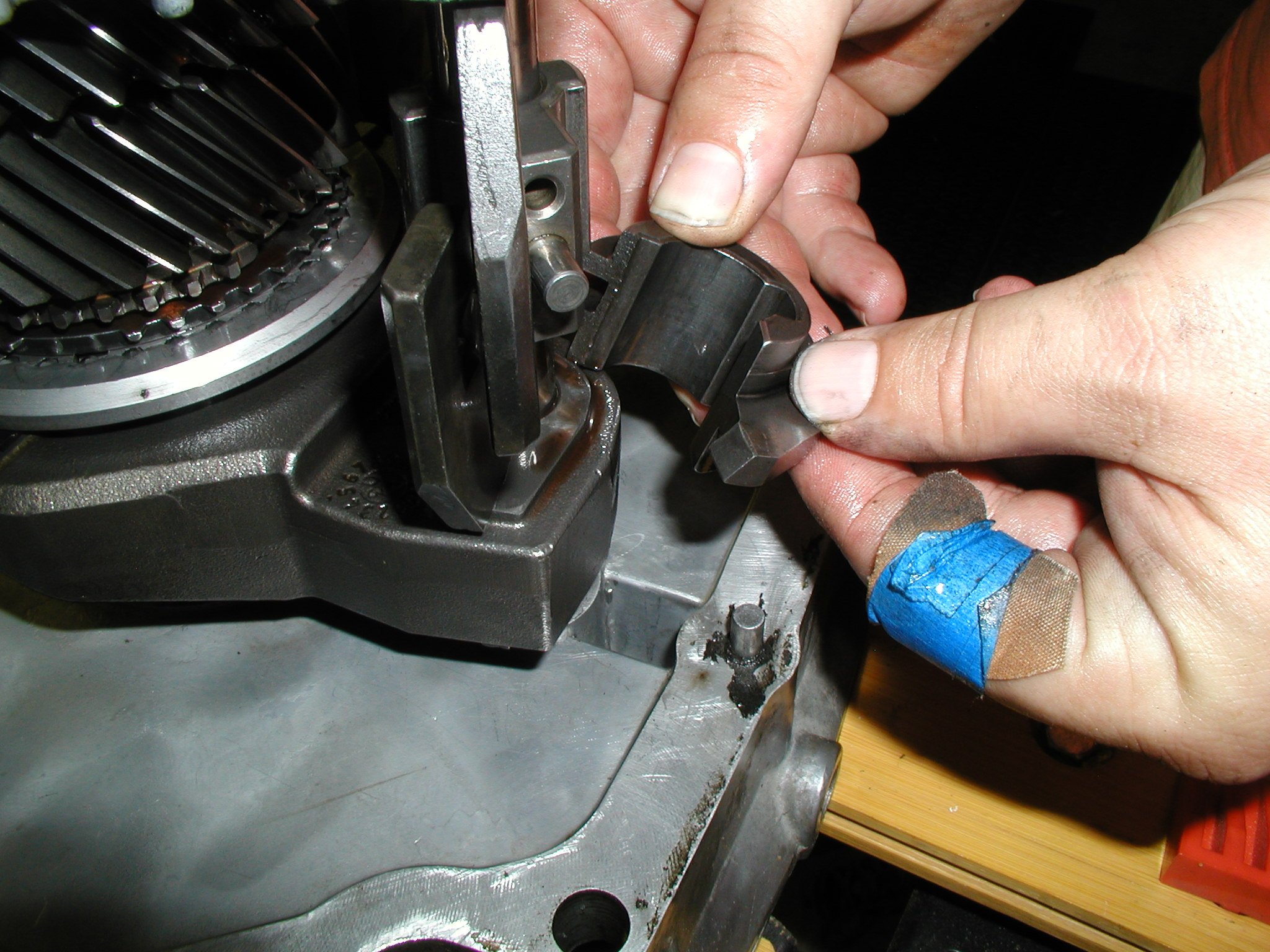

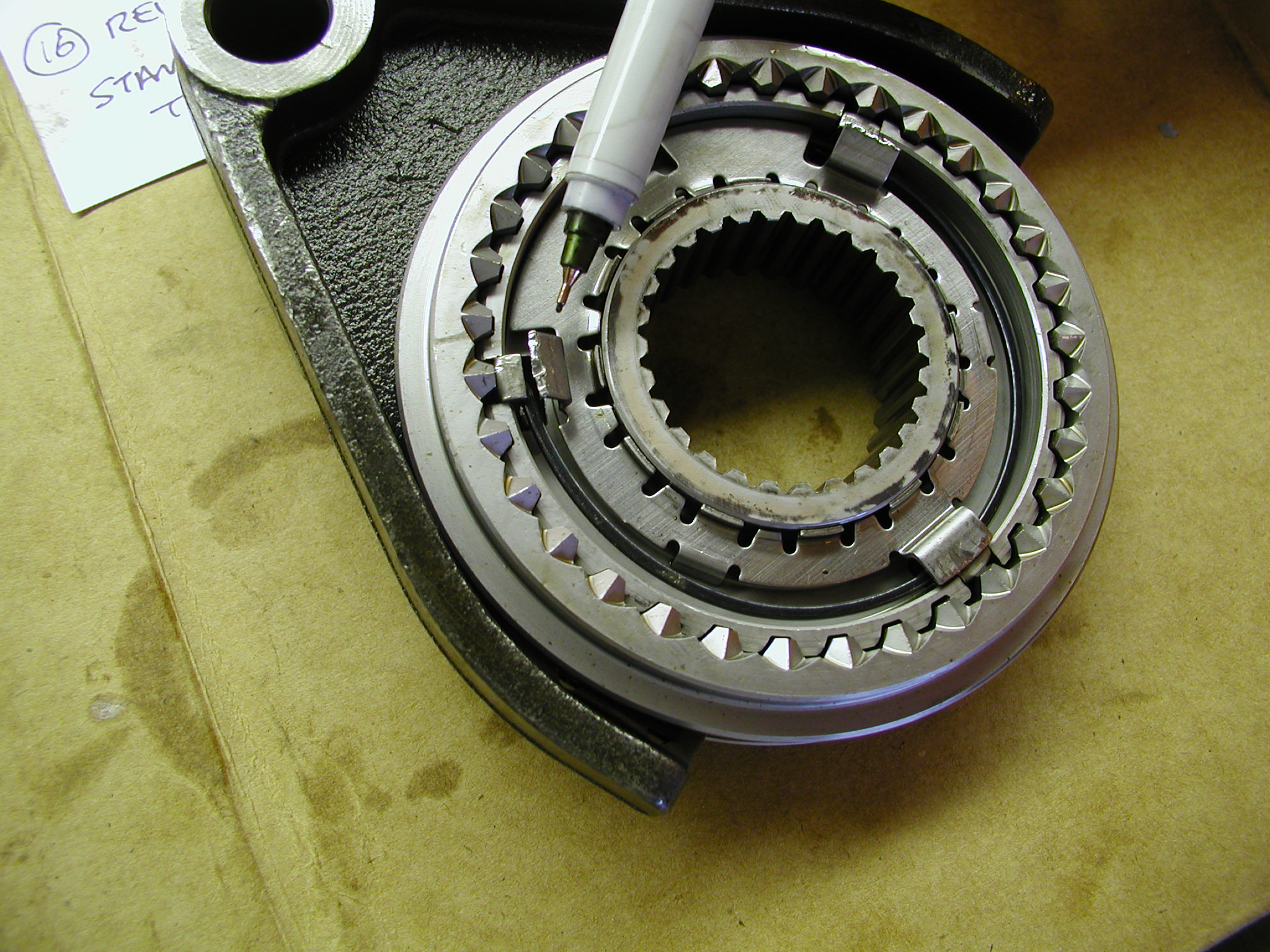

There was a lot of wear on the teeth where the slider (sychronizer) engages in the input shaft...

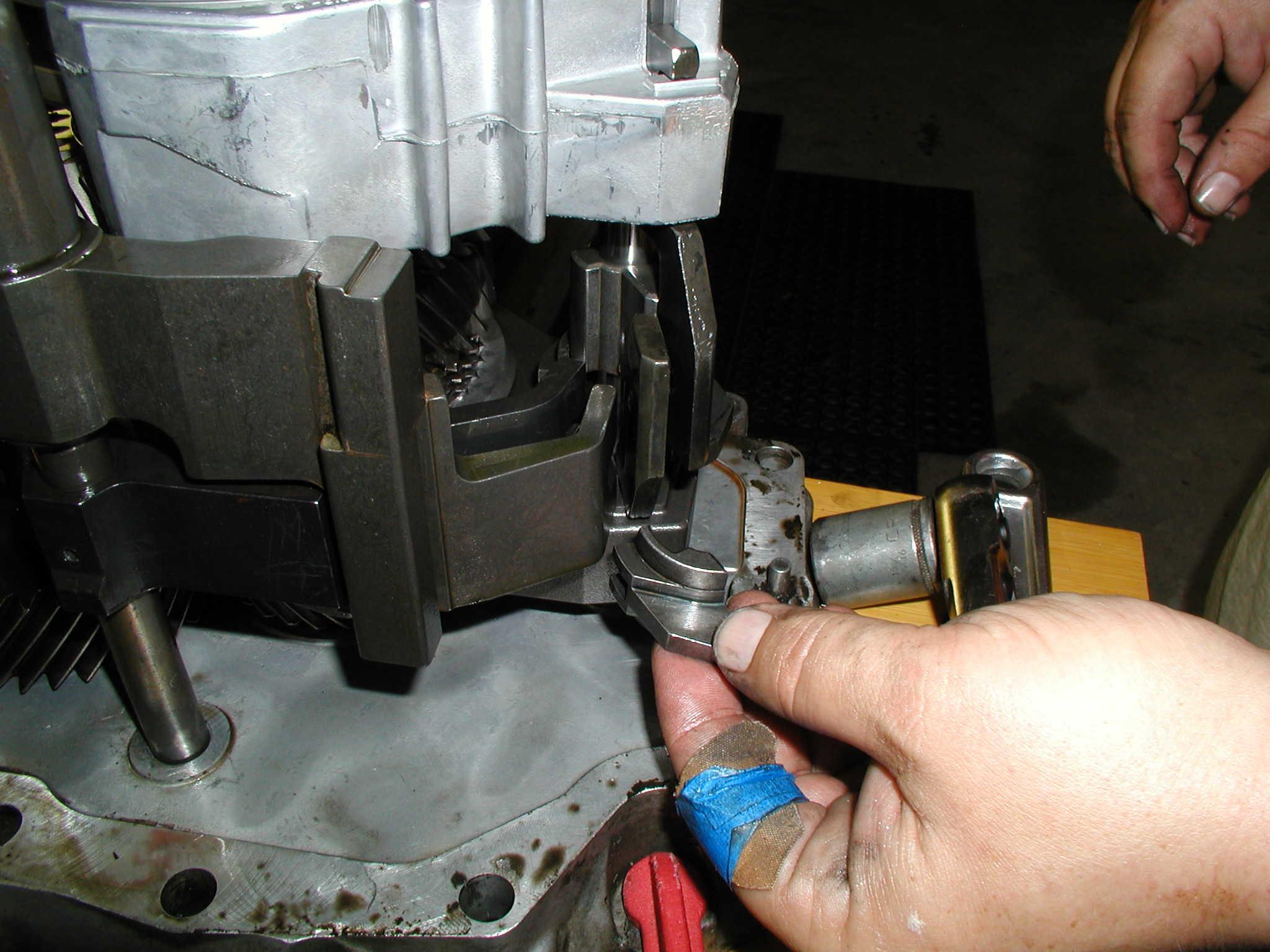

There was some damage to the reverse gear synchronizer...

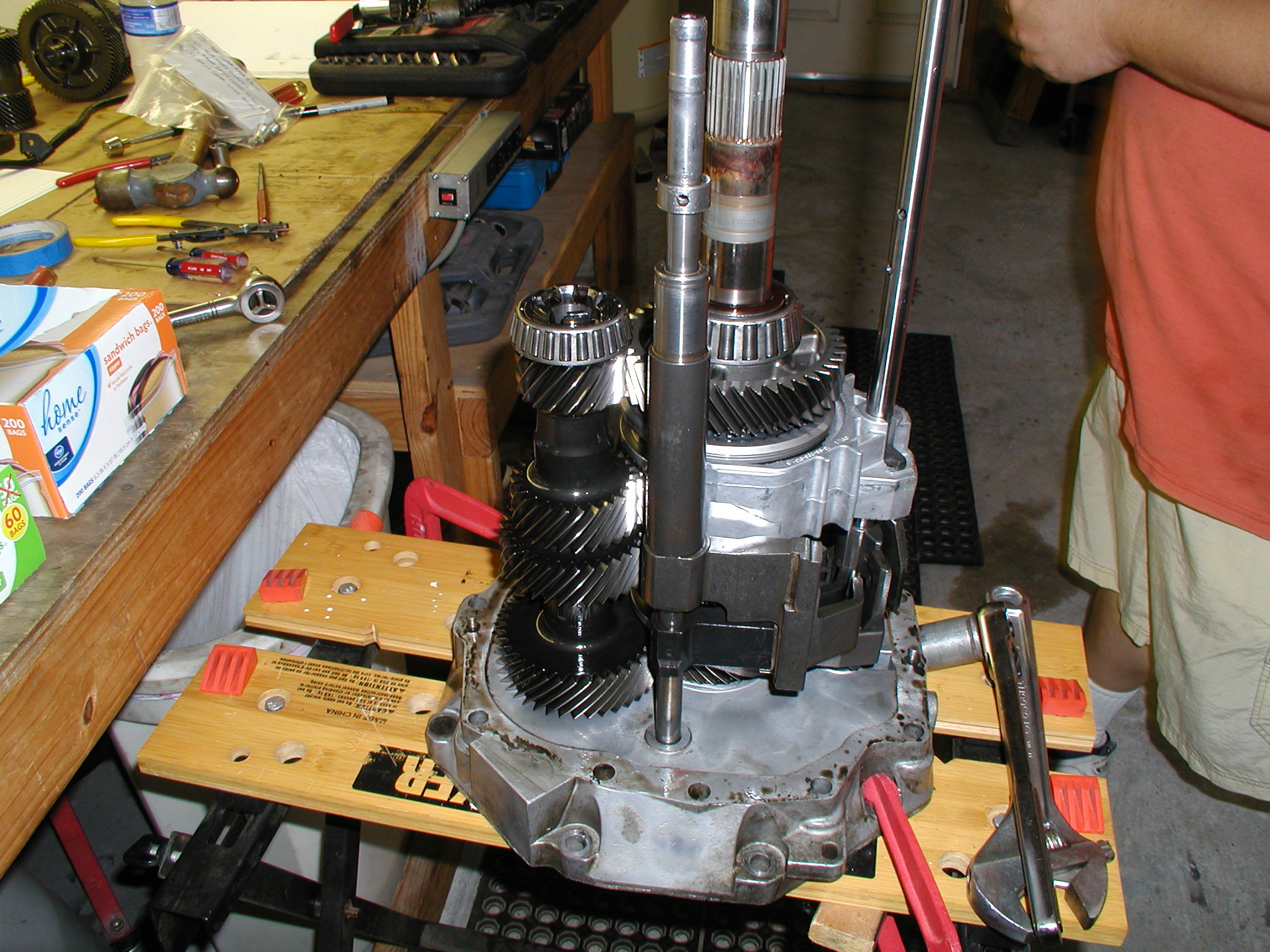

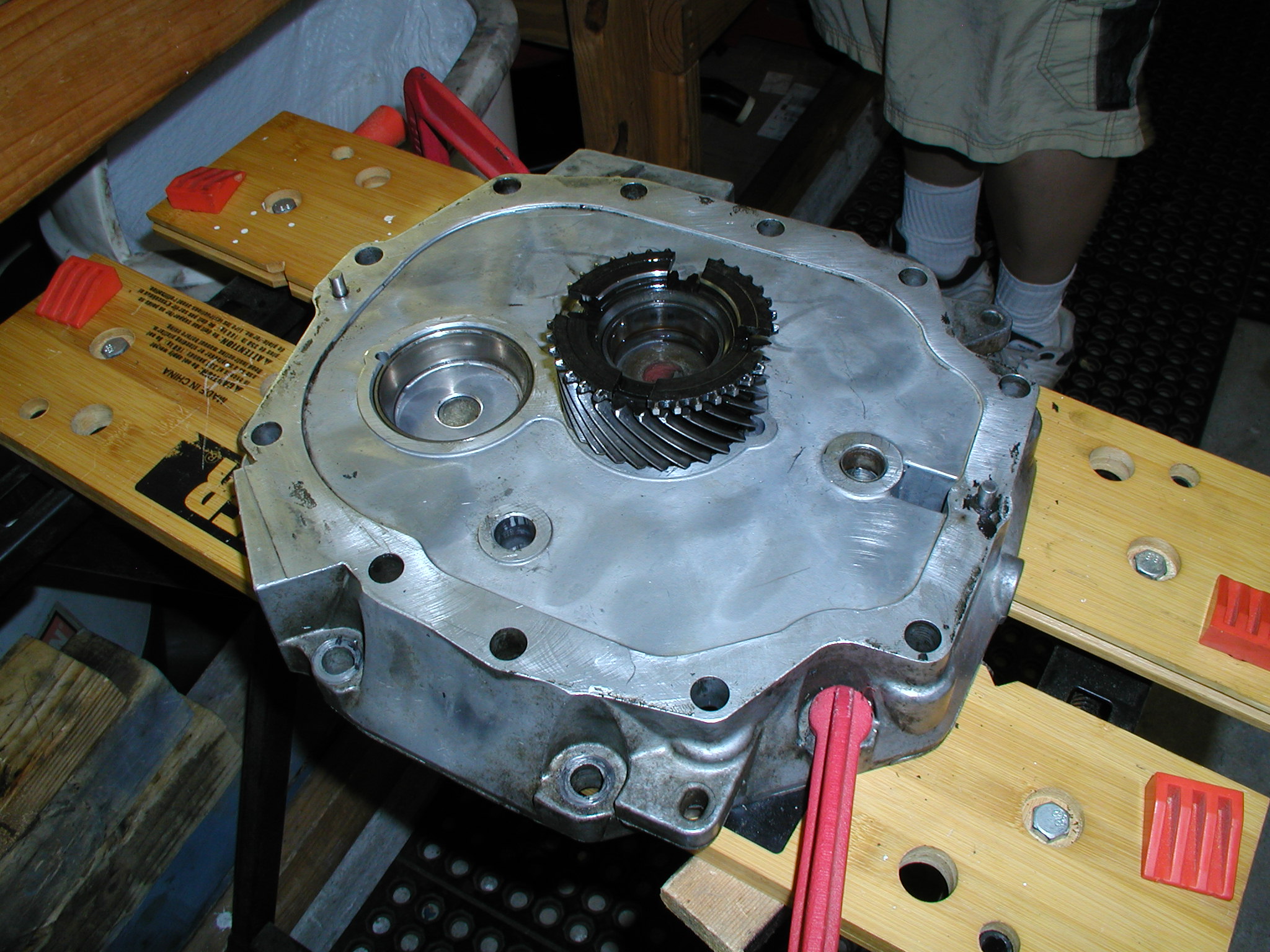

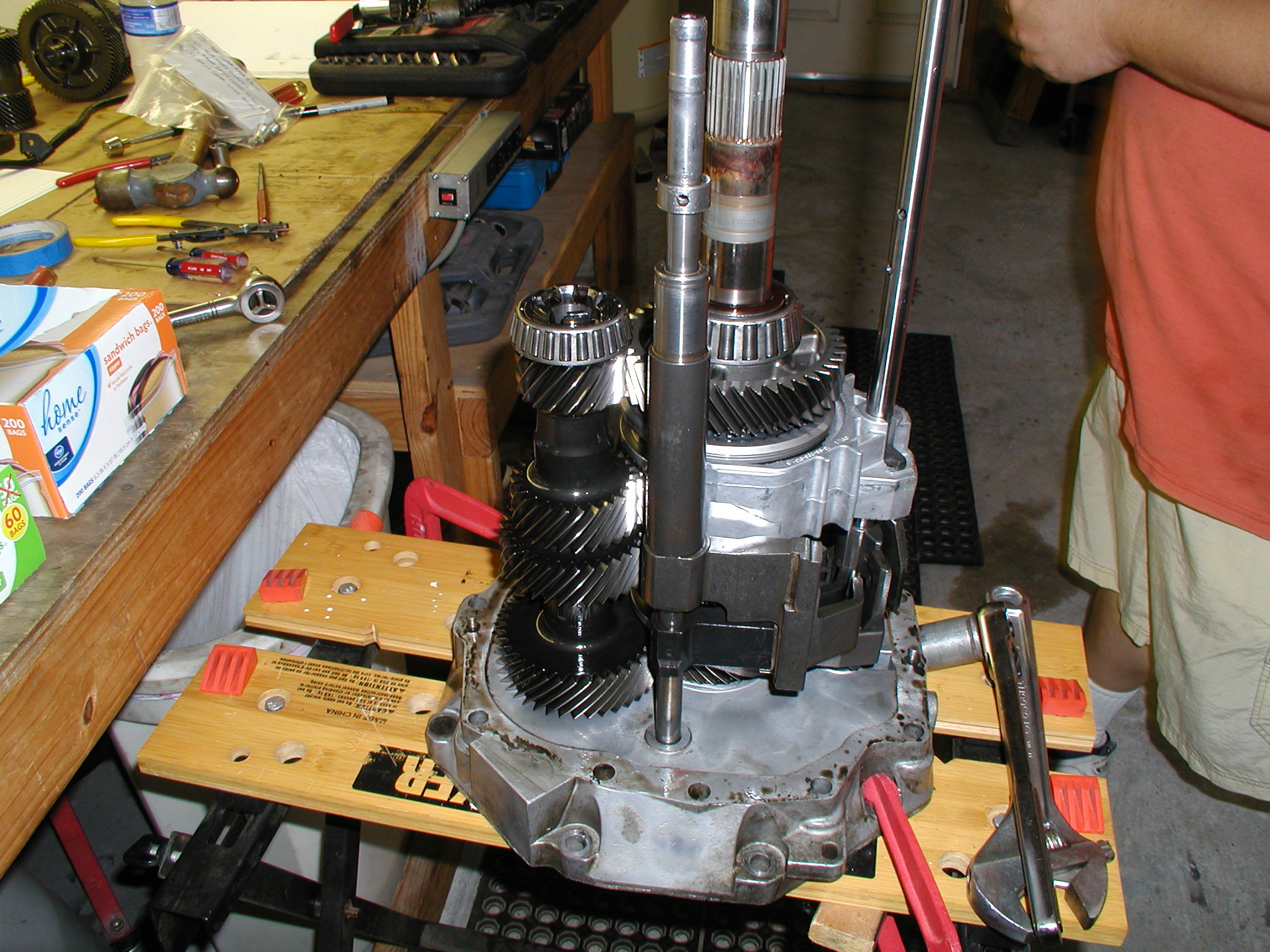

As I recall the teeth on second gear where the synchronizer engages were torn up as well. Here's a look at the main gear train and cluster gear for those of you that haven't seen the inside of a T56...

Here's all of the sub-assemblies on the bench after the teardown...

It was pretty disappointing. As I recall, the cluster gear by itself would have cost us $800 to replace. It was going to take way too much money to overhaul/repair this thing. I put it all back together. My brother ended up in a drawn out Paypal dispute with the seller. In the end, he disputed it with his bank, which almost immediately credited his account and that got Paypal off of their backside. They settled the dispute in favor of my brother and the trans got shipped back to El Paso at the seller's expense.

More to come.....

And unwrapped....

This was in June of 2013. At one point, we stood the transmission up. I forget why, but when we did, there was a loose metallic object clanking around inside. Uh-oh. I did a partial tear down of the trans to inspect it. We planned on overhauling it (as necessary) and upgrading some of the soft spots in the stock T56 like the plastic pads on the shift forks. Unfortunately, this trans was thrashed. The cluster gear was hurt....

The shift interlock was busted (loose object we heard rattling around)...

There was a lot of wear on the teeth where the slider (sychronizer) engages in the input shaft...

There was some damage to the reverse gear synchronizer...

As I recall the teeth on second gear where the synchronizer engages were torn up as well. Here's a look at the main gear train and cluster gear for those of you that haven't seen the inside of a T56...

Here's all of the sub-assemblies on the bench after the teardown...

It was pretty disappointing. As I recall, the cluster gear by itself would have cost us $800 to replace. It was going to take way too much money to overhaul/repair this thing. I put it all back together. My brother ended up in a drawn out Paypal dispute with the seller. In the end, he disputed it with his bank, which almost immediately credited his account and that got Paypal off of their backside. They settled the dispute in favor of my brother and the trans got shipped back to El Paso at the seller's expense.

More to come.....

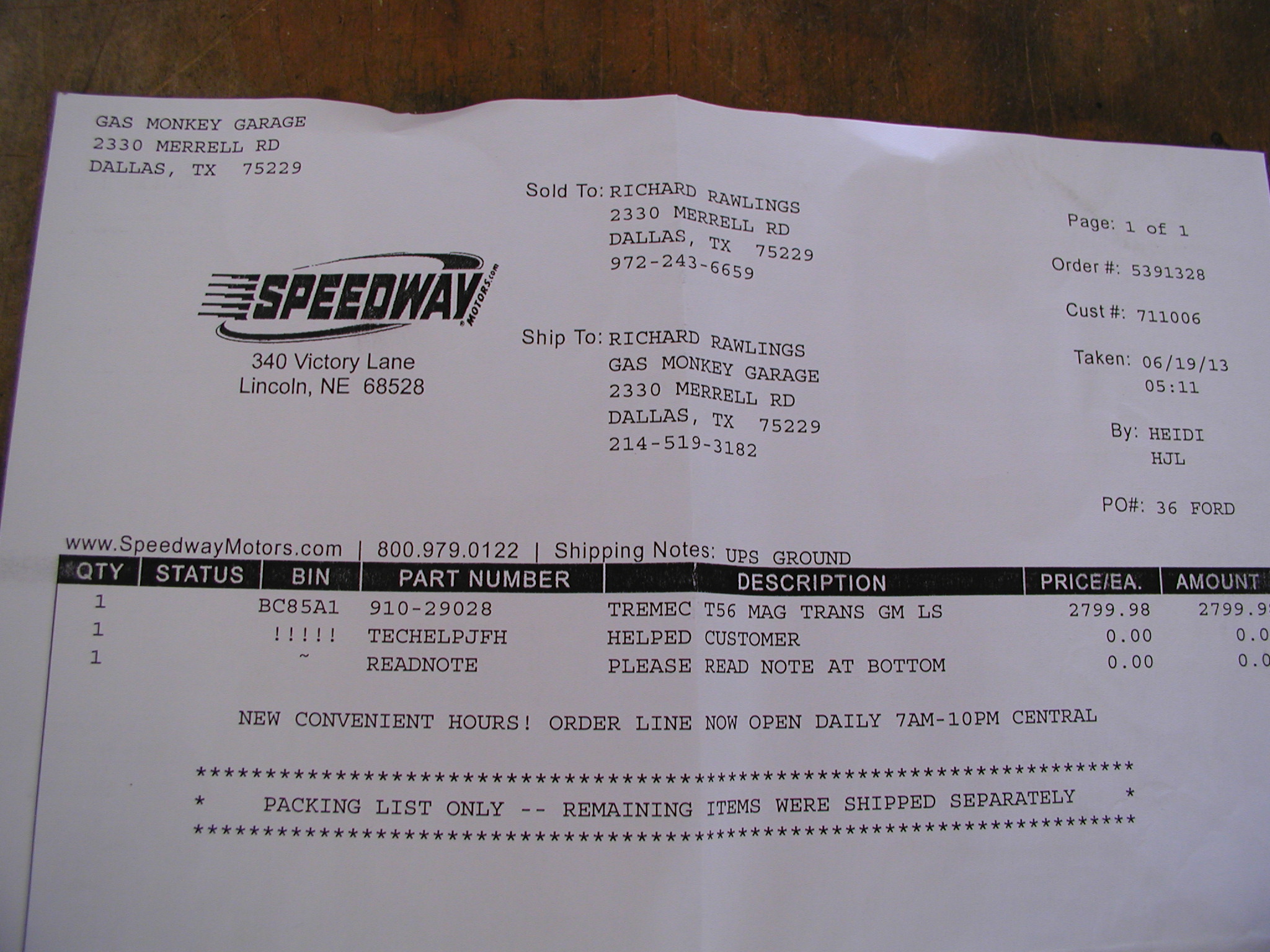

What to do? Look for another used T56 and overhaul it/upgrade it? In the end my brother decided against that. He had a bad taste in his mouth over the GTO transmission. He had me telling him that a used trans really needed to be upgraded and overhauled to survive behind that 6.0. He ended up biting the bullet and buying a brand new T56 magnum. The new trans arrived at the end of July....

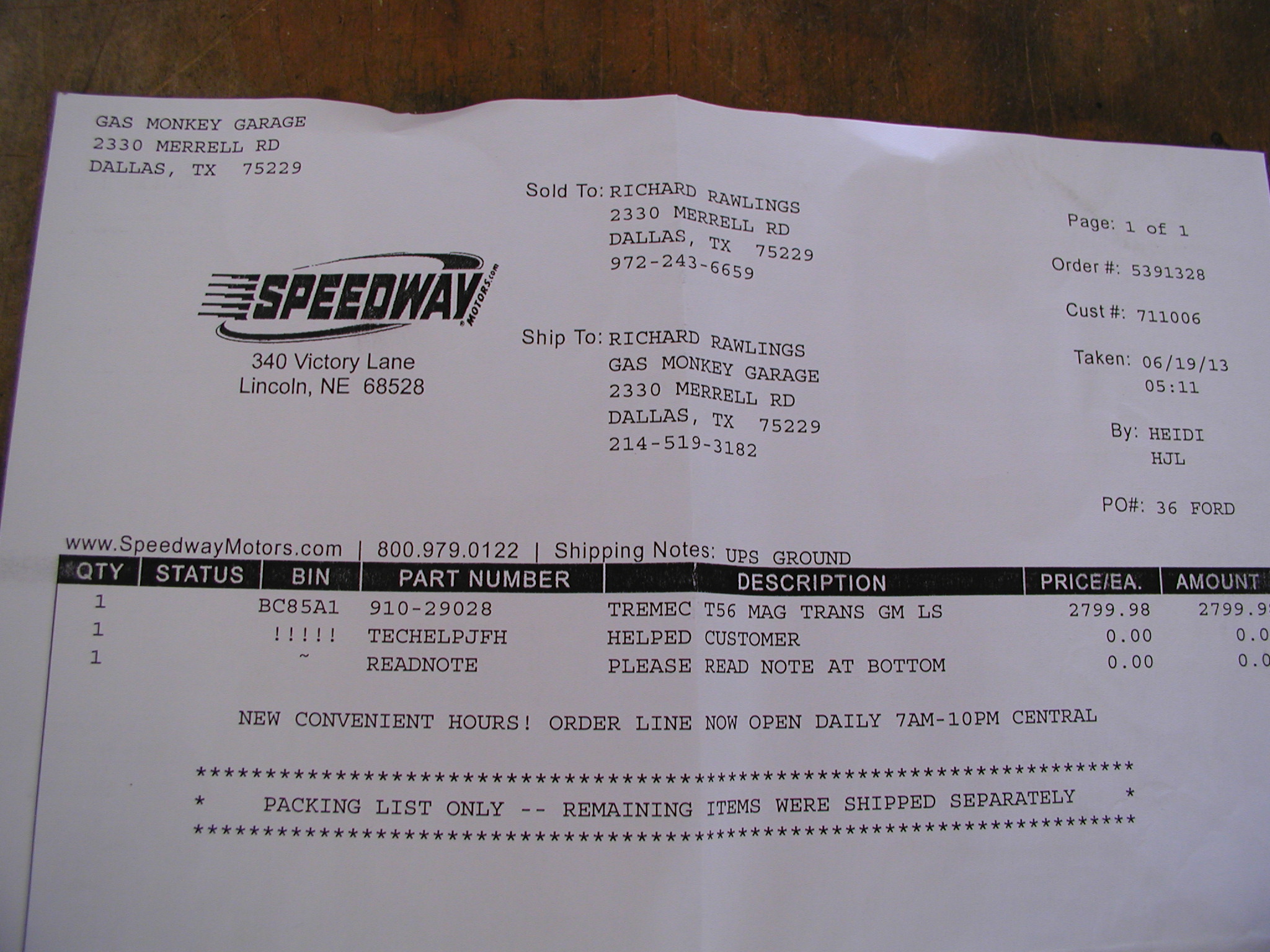

Evidently it had been previously sold to Gas Monkey Garage and then returned. I guess they didn't end up using it/needing it. We found this in the box.....

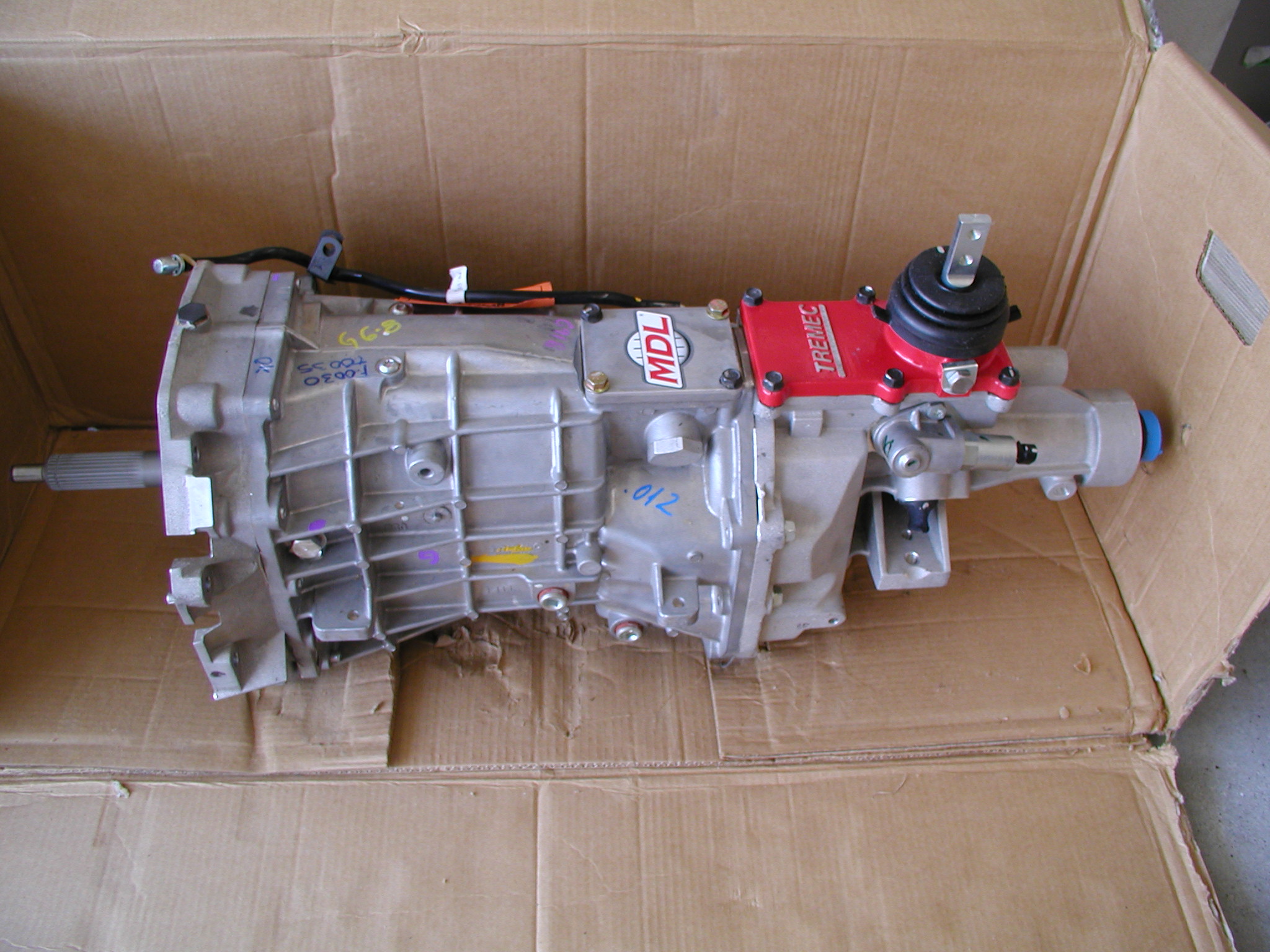

Here it is out of the box. There was no indication it had been out of the box or installed. No bolt marks. Nothing....

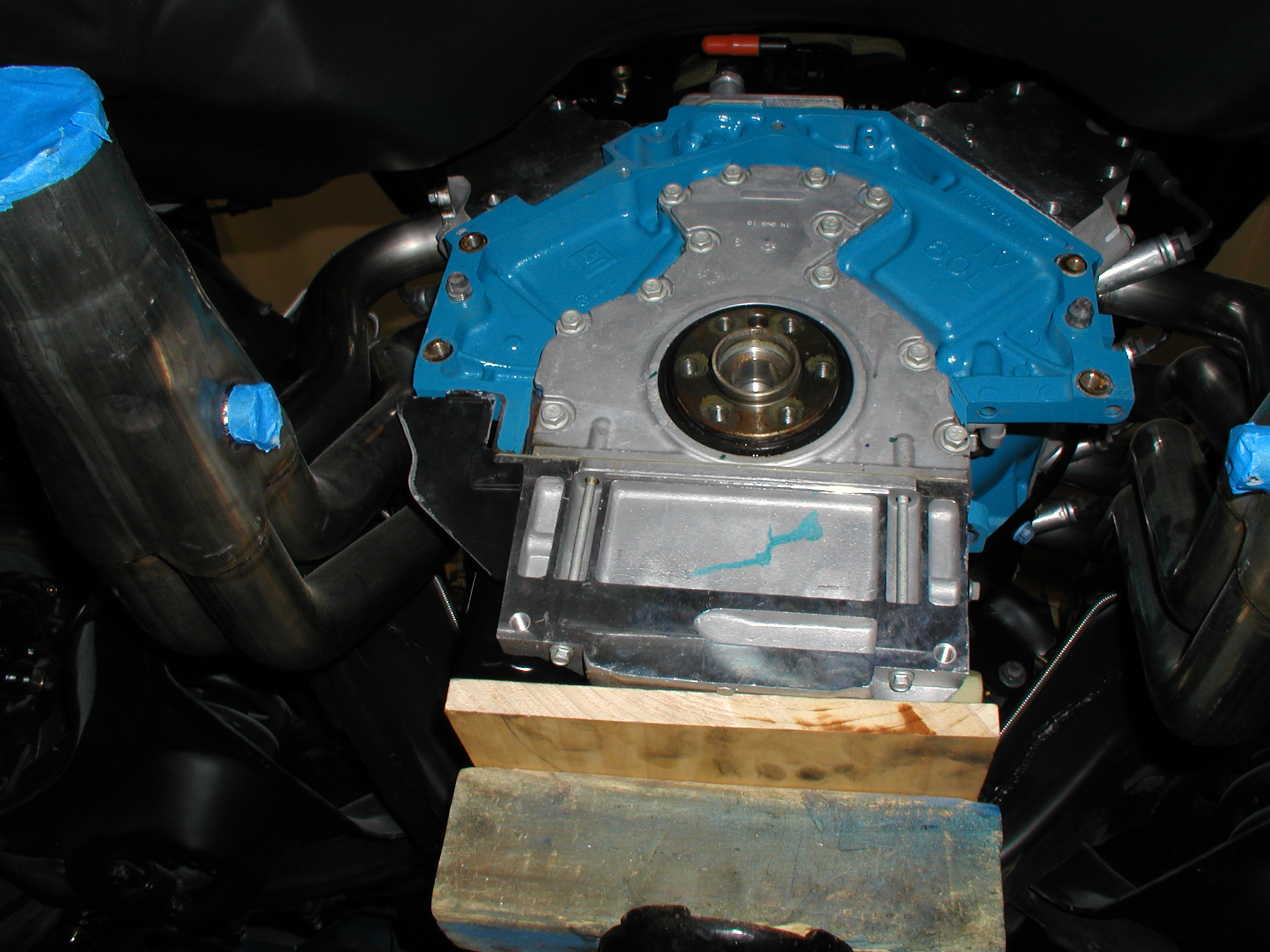

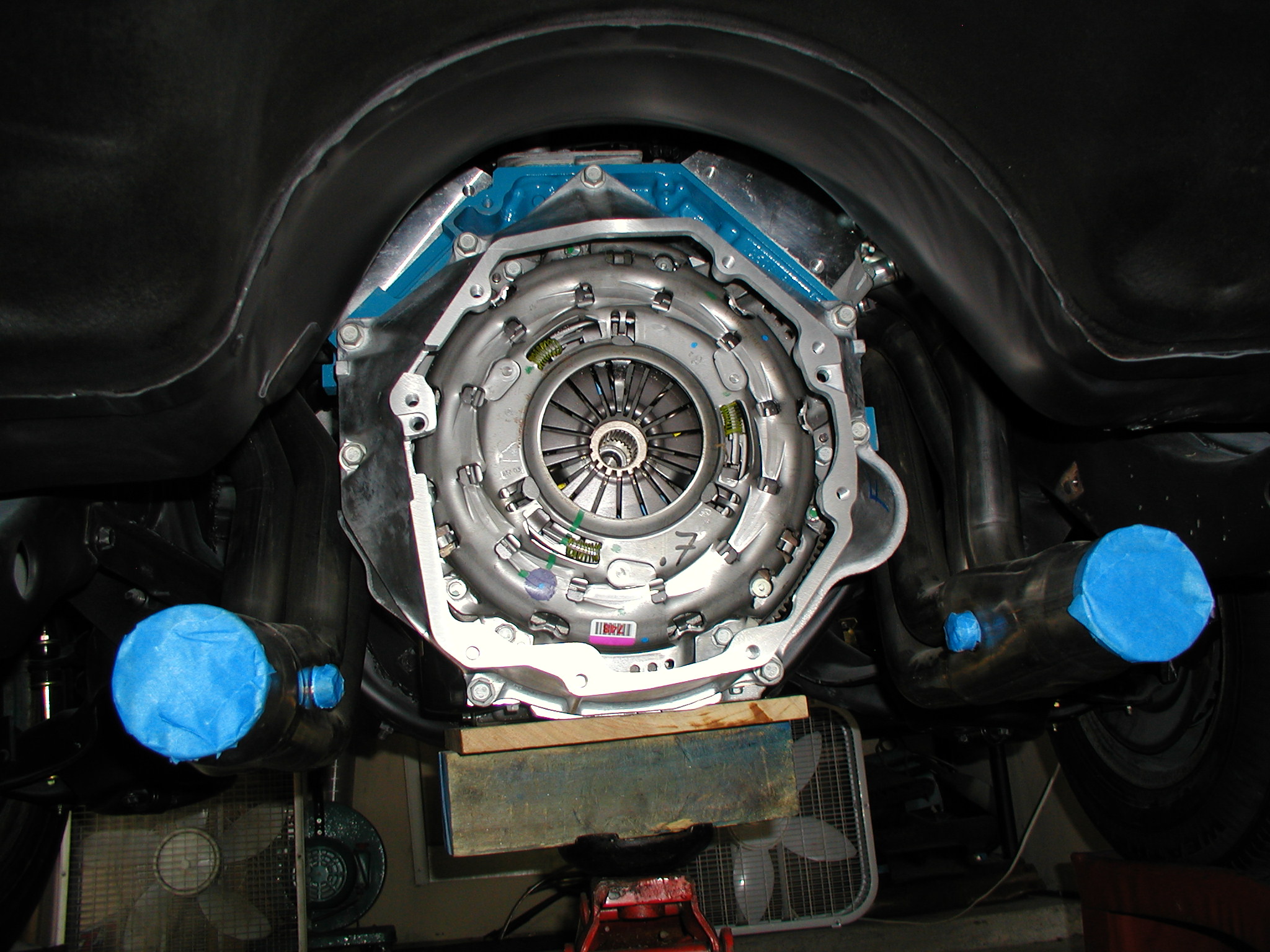

On August 4, 2013 the install began starting with the clutch and bellhousing....

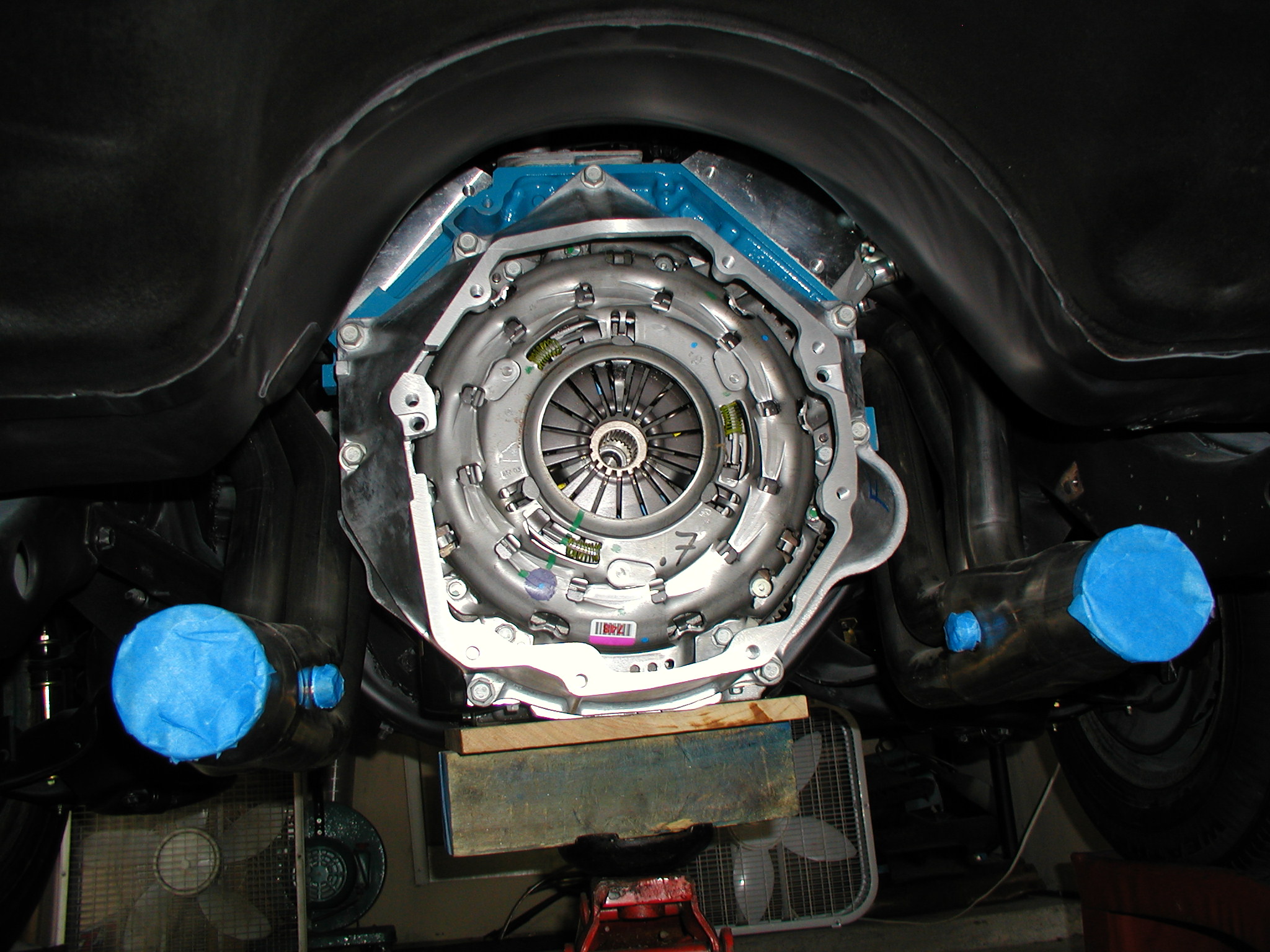

We used the LS7 clutch. Overkill for us, but why not.....

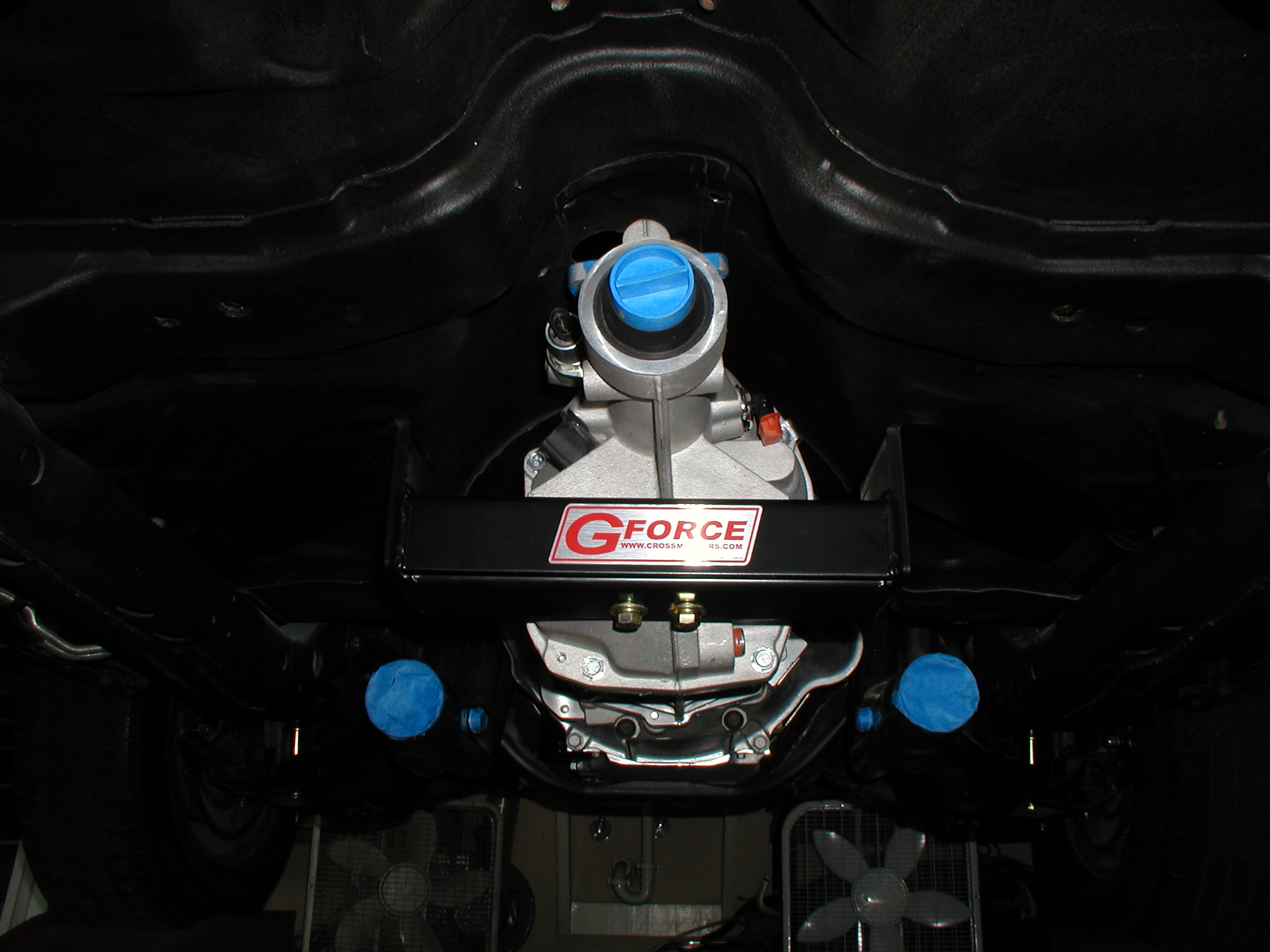

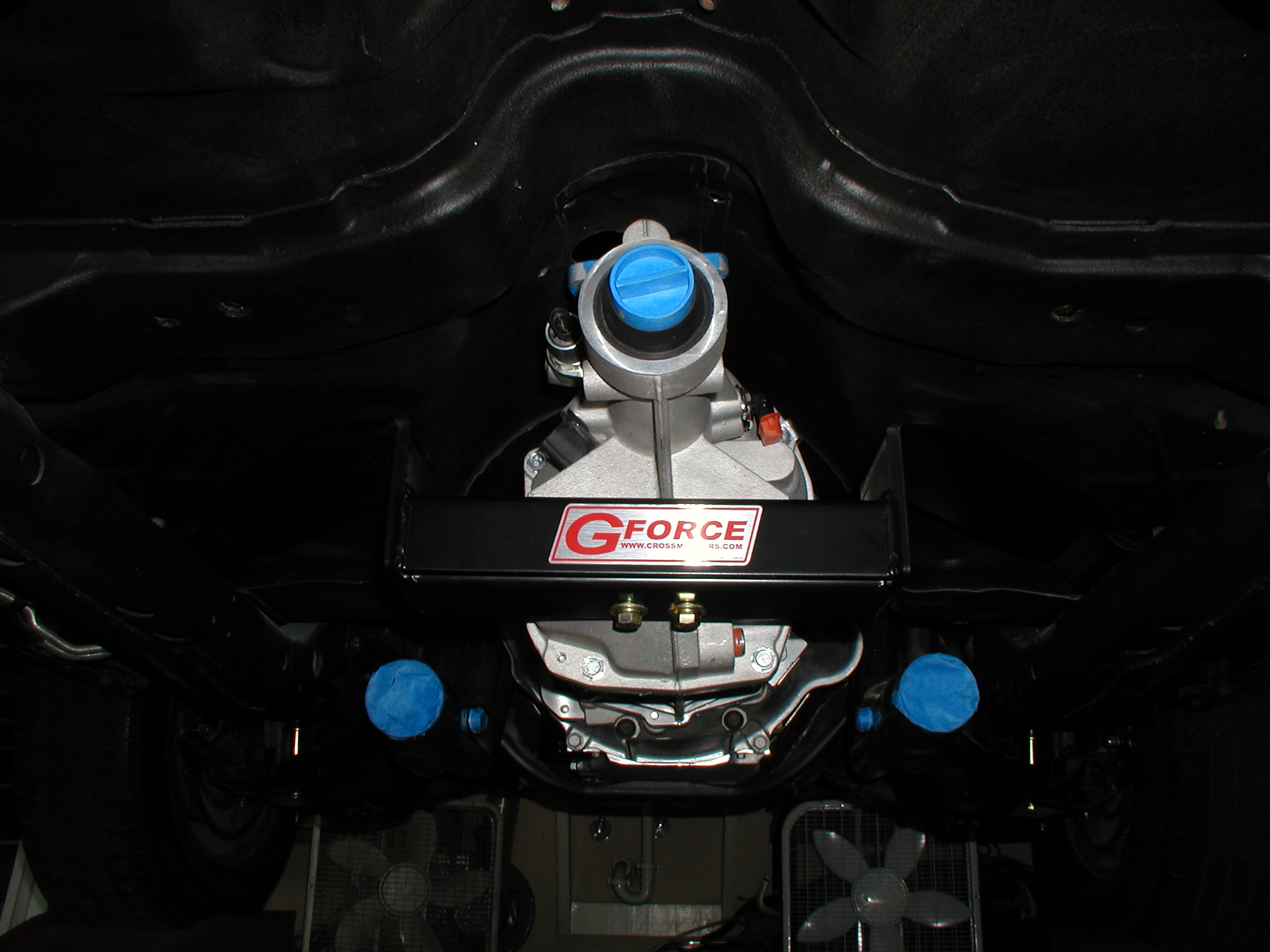

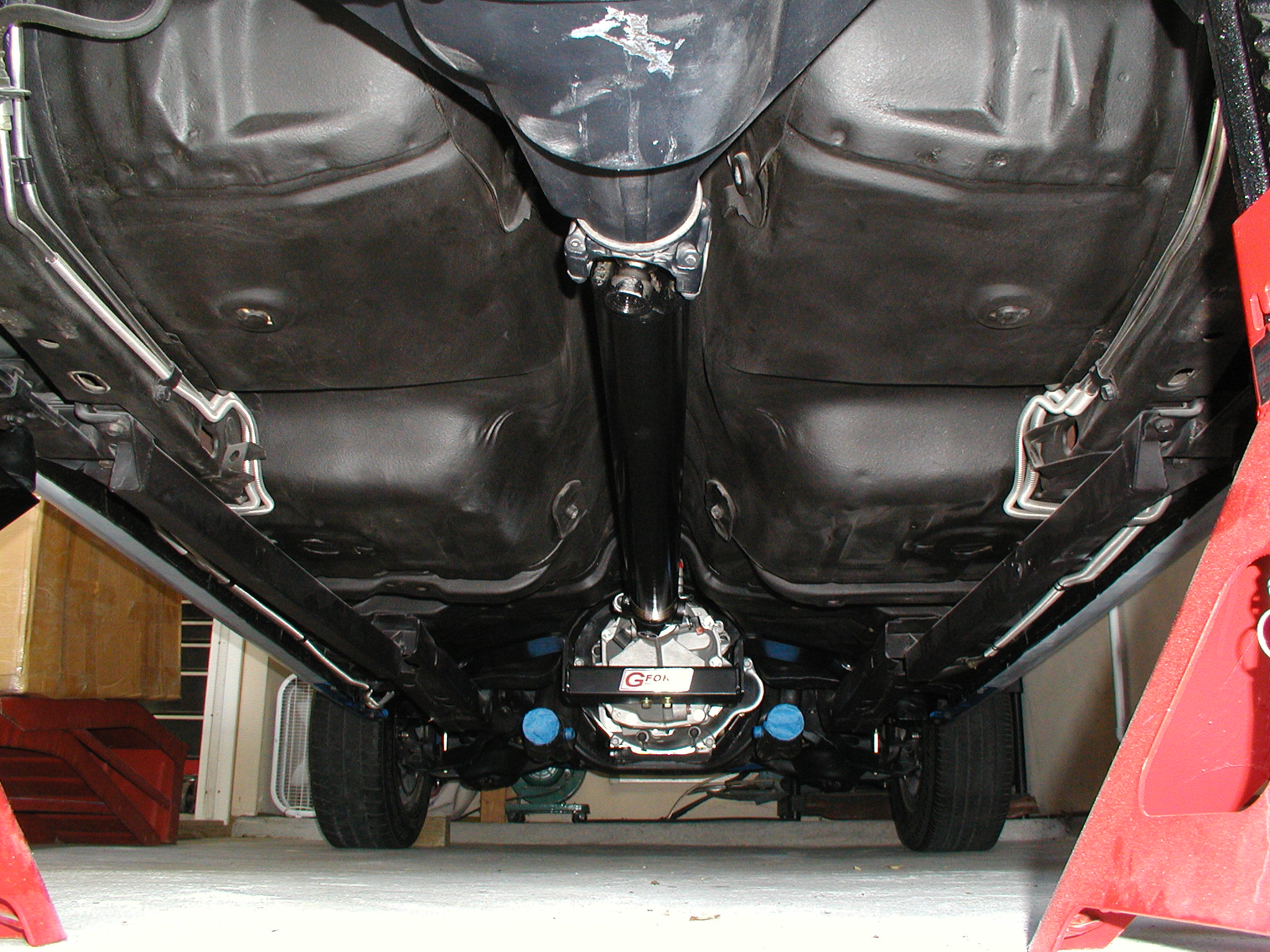

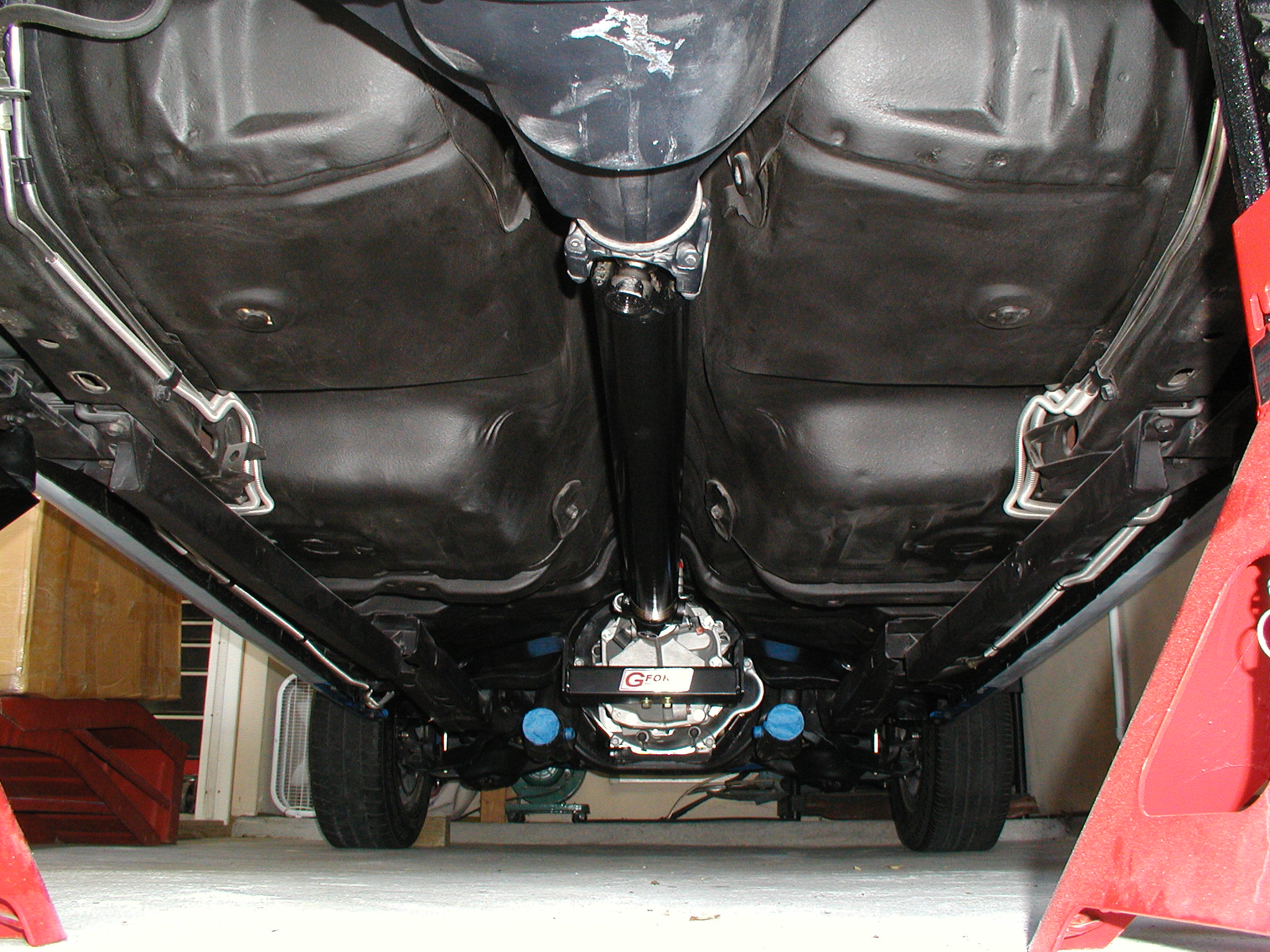

And here it is stabbed and sitting on the G-Force crossmember....

It fit like a glove. Whoever engineered the swap plates had the engine in exactly the right spot. Credit again to Stainless works on the prototyping of the headers and providing the same swap plates as the prototype car. I had found a build thread detailing the prototyping of the headers and knew there was a T56 Magnum and G Force crossmember used so that's the way we went. It all fit so well.

Here is some surgery to the tunnel for the shifter. The T56 fit the tunnel with no mods. No cutting out the tunnel. No pounding on the tunnel. It just fell in there like it belonged....

Now with the shifter installed....

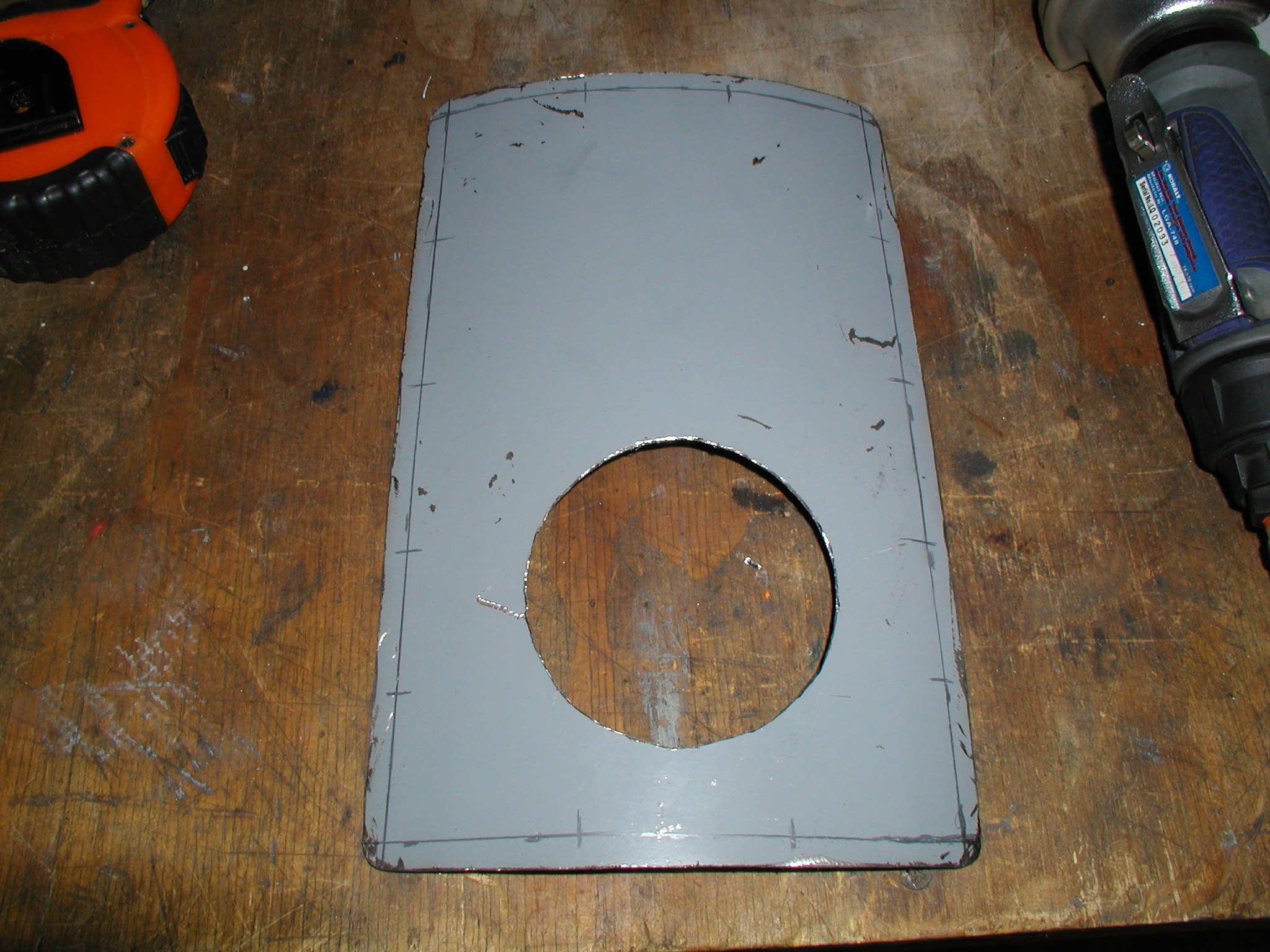

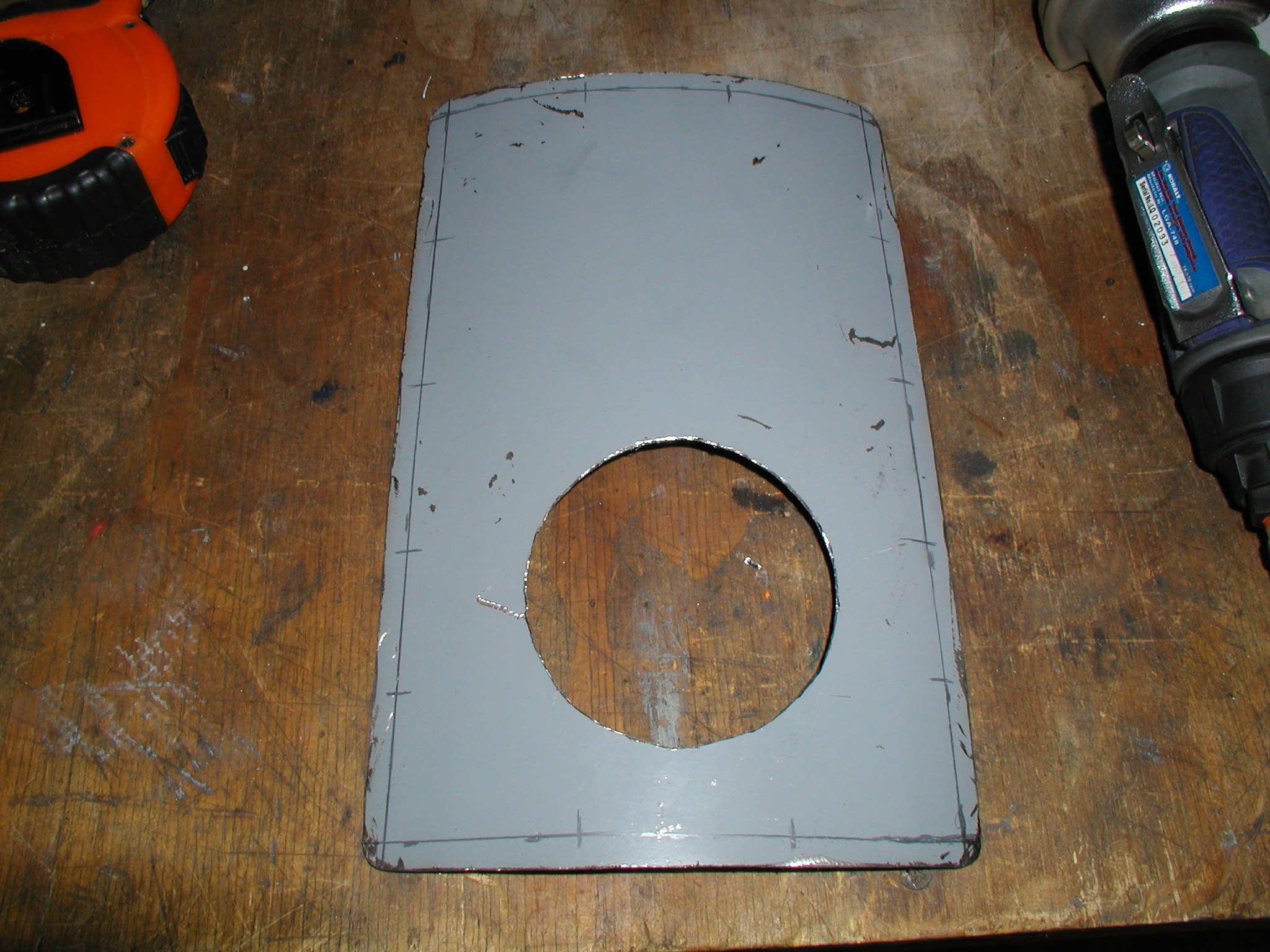

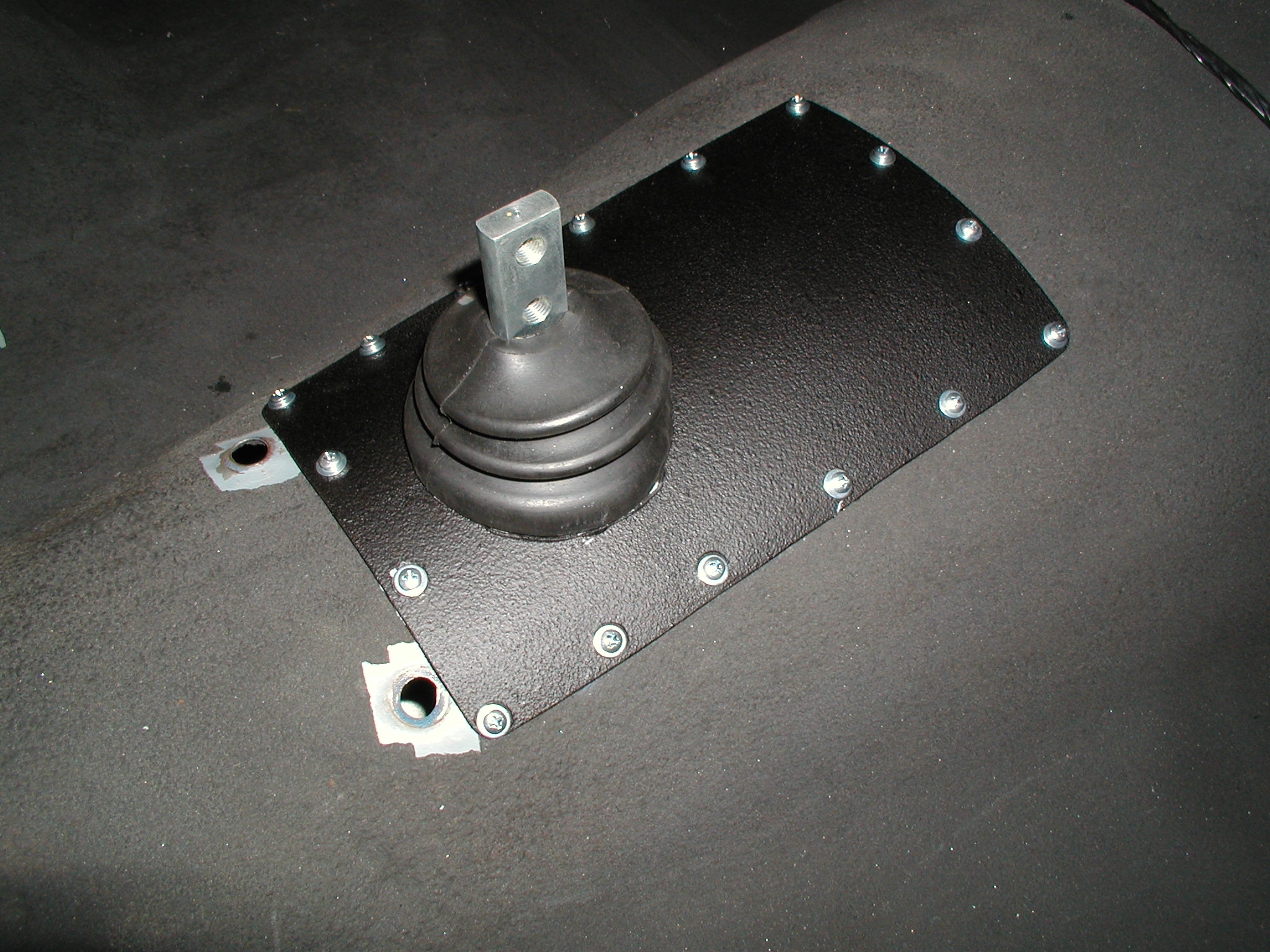

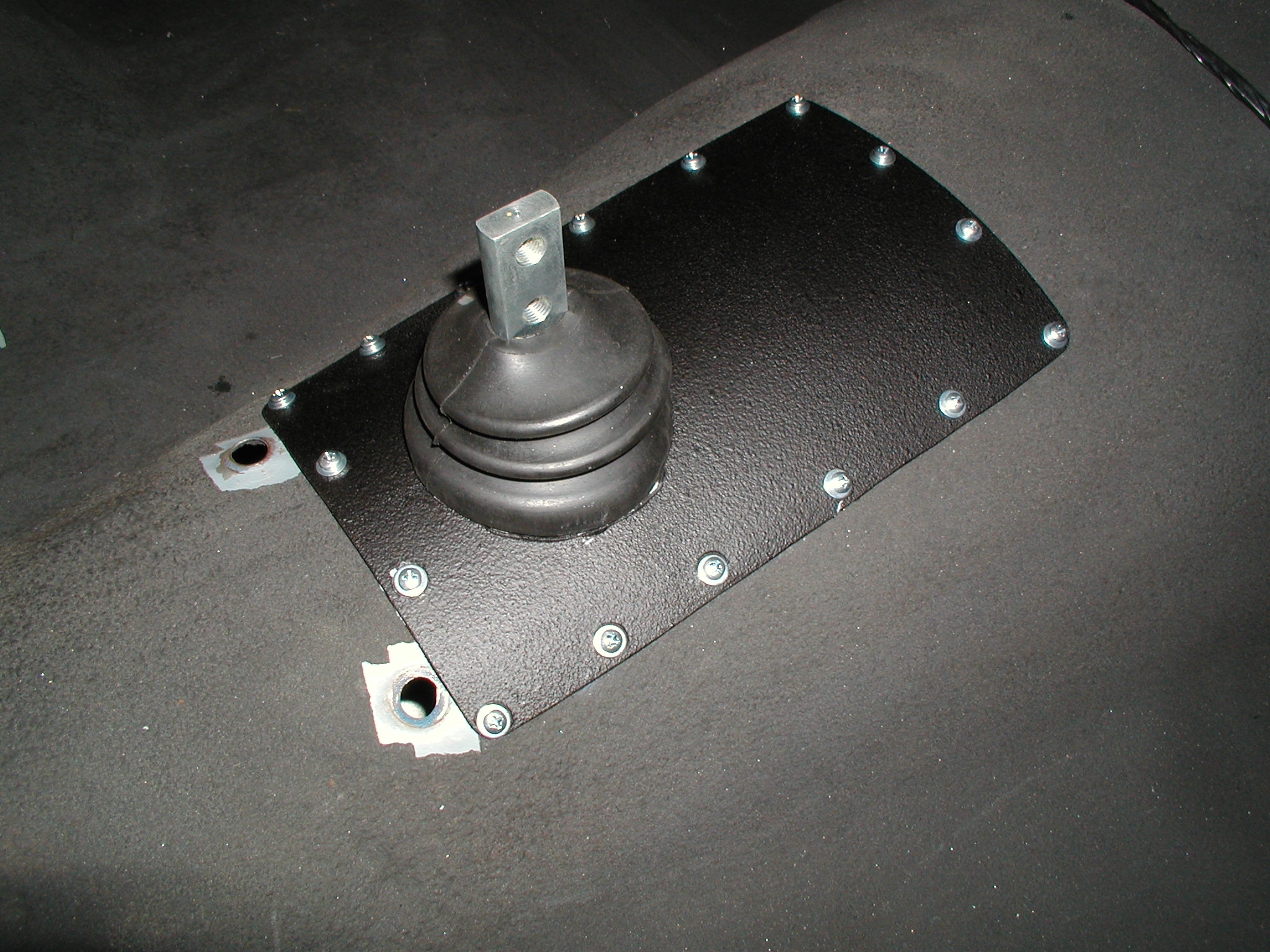

Next, my brother fabbed up a cover plate for the transmission tunnel. He used some metal we had previously cut off of the car. Note the grey epoxy primer already on it...

Stay tuned.....More to come....

Evidently it had been previously sold to Gas Monkey Garage and then returned. I guess they didn't end up using it/needing it. We found this in the box.....

Here it is out of the box. There was no indication it had been out of the box or installed. No bolt marks. Nothing....

On August 4, 2013 the install began starting with the clutch and bellhousing....

We used the LS7 clutch. Overkill for us, but why not.....

And here it is stabbed and sitting on the G-Force crossmember....

It fit like a glove. Whoever engineered the swap plates had the engine in exactly the right spot. Credit again to Stainless works on the prototyping of the headers and providing the same swap plates as the prototype car. I had found a build thread detailing the prototyping of the headers and knew there was a T56 Magnum and G Force crossmember used so that's the way we went. It all fit so well.

Here is some surgery to the tunnel for the shifter. The T56 fit the tunnel with no mods. No cutting out the tunnel. No pounding on the tunnel. It just fell in there like it belonged....

Now with the shifter installed....

Next, my brother fabbed up a cover plate for the transmission tunnel. He used some metal we had previously cut off of the car. Note the grey epoxy primer already on it...

Stay tuned.....More to come....

Here is his cover plate mocked up in the car...

Next he undercoated it to protect it and make it look like the bottom of the car on the bottom or like the Lizard Skin on the top. The two holes above are where the threaded inserts were for the automatic shifter....

Final install the next day....

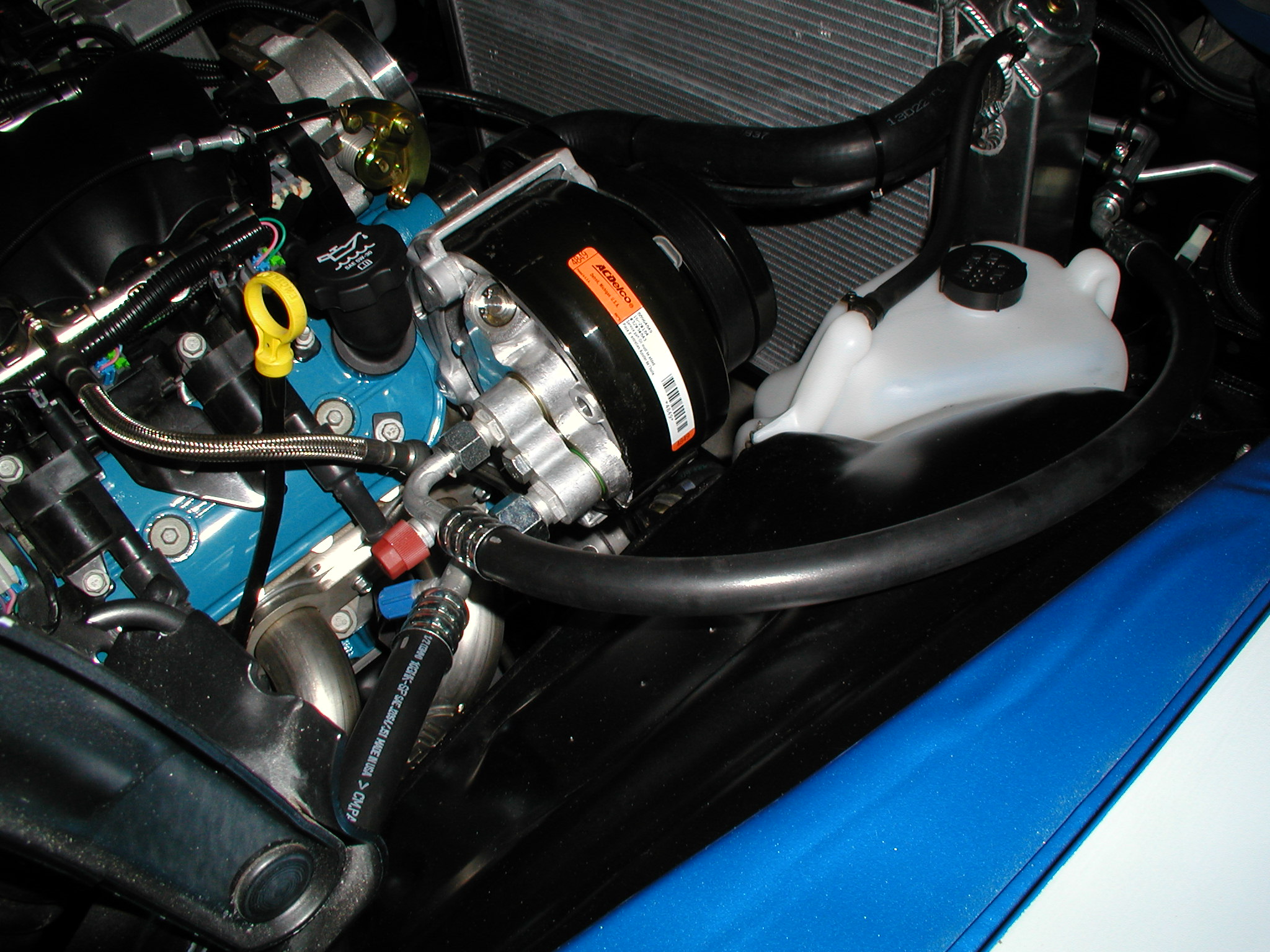

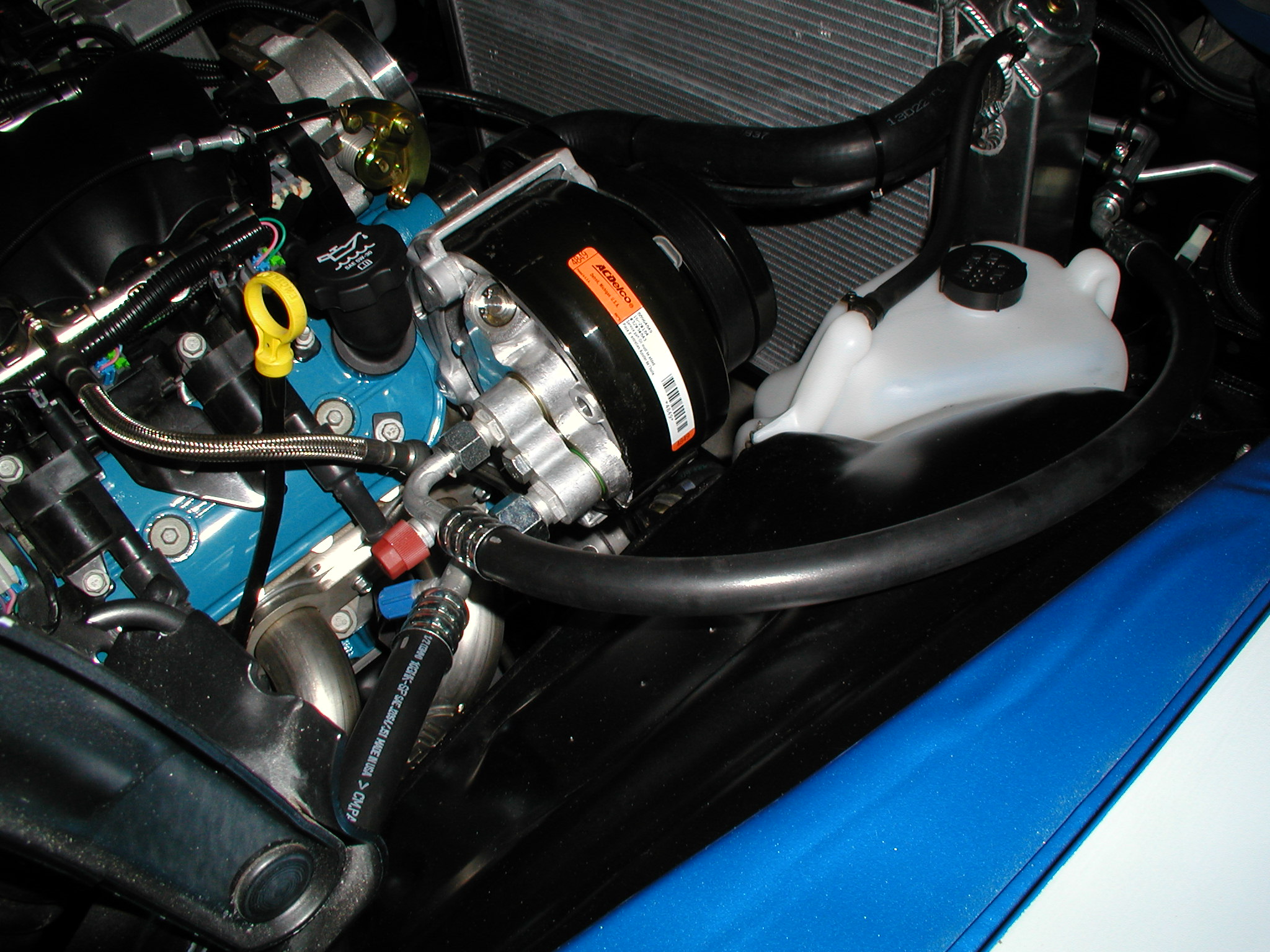

By now, my brother's wallet was smoking pretty bad. 😱 I was impatient to move on. This part of the project was the most fun for me. The way I remember it he bought the A/C compressor bracket from Holley and I got impatient and bought the compressor. Anyway, here it is installed. This was the next piece of the puzzle....

Around this time my brother came up with this mini collage that shows how far the engine compartment had come by then...

And here it is with the belt. I think it took about six trips to the auto parts to get the right one....

Around the same time, at my urging, my brother got a pair of traction bars for his birthday. We put these on at the very end of August. Love the cool factor of the traction bars. I think they were Competition Engineering, like the subframe connectors......

That gets us to the end of August of 2013. This is a good place to leave off for awhile. Thanks for following along. More updates to come.

Next he undercoated it to protect it and make it look like the bottom of the car on the bottom or like the Lizard Skin on the top. The two holes above are where the threaded inserts were for the automatic shifter....

Final install the next day....

By now, my brother's wallet was smoking pretty bad. 😱 I was impatient to move on. This part of the project was the most fun for me. The way I remember it he bought the A/C compressor bracket from Holley and I got impatient and bought the compressor. Anyway, here it is installed. This was the next piece of the puzzle....

Around this time my brother came up with this mini collage that shows how far the engine compartment had come by then...

And here it is with the belt. I think it took about six trips to the auto parts to get the right one....

Around the same time, at my urging, my brother got a pair of traction bars for his birthday. We put these on at the very end of August. Love the cool factor of the traction bars. I think they were Competition Engineering, like the subframe connectors......

That gets us to the end of August of 2013. This is a good place to leave off for awhile. Thanks for following along. More updates to come.

Tuned in, glad I took the time to scroll thru the entire thread.

Glad to see you following along and glad you are enjoying it. Thanks everyone for the likes and replies.Tuned in, glad I took the time to scroll thru the entire thread.

Time for another installment. When we left off it we were moving into September of 2013. It had been seven years since Sean bought the car back from our Uncle. The body and chassis were restored. The glass was back in the car. the engine and transmission were in. It was still largely an empty shell though. The next piece of the puzzle was the driveshaft. We had Denny's Driveshafts build us a new shaft. It was a really good experience. We measured according to their printable form and then my brother called in and placed the order. The service and guidance/advice was great. Here is the new driveshaft. It was well packed and the quality is outstanding. There's just nothing like nice new made in the USA stuff....

And here it is in the car. This also gives you a good look at the Competition Engineering subframe connectors which I've hardly mentioned...

Here's a look at the rear disc brakes, traction bar, sway bar, etc. It's amazing how dirty this stuff gets just sitting around. A lot or most of the dirt is from all of the body work.....

Moving into October, we started connecting the fuel lines to the engine. We used the factory configuration fuel supply/return/vent lines. When we installed all new stock style stainless lines we were still planning to go back with a Gen I small block. If we had planned an LS swap all along, we might have plumbed it differently. Since the LS3 fuel rail doesn't include a pressure regulator or a provision for a return line, we decided to use the C6 Corvette filter/regulator. we found a place to mount it on the lower front passenger side corner of the engine block, near where the factory fuel and return lines terminate, near where the stock mechanical fuel pump would be. We used fuel injection grade hose and clamps to connect the filter/regulator to the hard frame lines...

The next issue was that the LS3 fuel rail has it's inlet on the driver's side and our fuel lines were on the passenger side. What to do? It turns out it was as easy as pulling the fuel rail and swapping it around. It fit perfectly. Now all we needed to do was get from the outlet of the filter/regulator to the fuel rail. The stock fittings are GM push lock. On the inlet side of the filter regulator we used aftermarket adapter fittings to adapt the push lock barbs to the hose clamp barbs. We didn't want to use rubber hose from the outlet of the filter/regulator to the inlet on the fuel rail due to the proximity to the header on the passenger side. After doing some looking, we sourced a stock braided stainless fuel hose from I believe, a fourth gen LS1 F body. That left us a pretty long gap. I ended up fabbing up a hard line out of stainless to bridge the gap. I bought a really nice hydraulic flaring tool that had the dies to make these push lock flares. I wish I had a picture of the completed line off of the car but here it is installed. You can barely see where it turns to the front and stabs into the filter regulator deep down in the picture. You can also see the little bracket we fabbed up to tie the hard line to the passenger valve cover....

Next we installed a new coolant bottle....

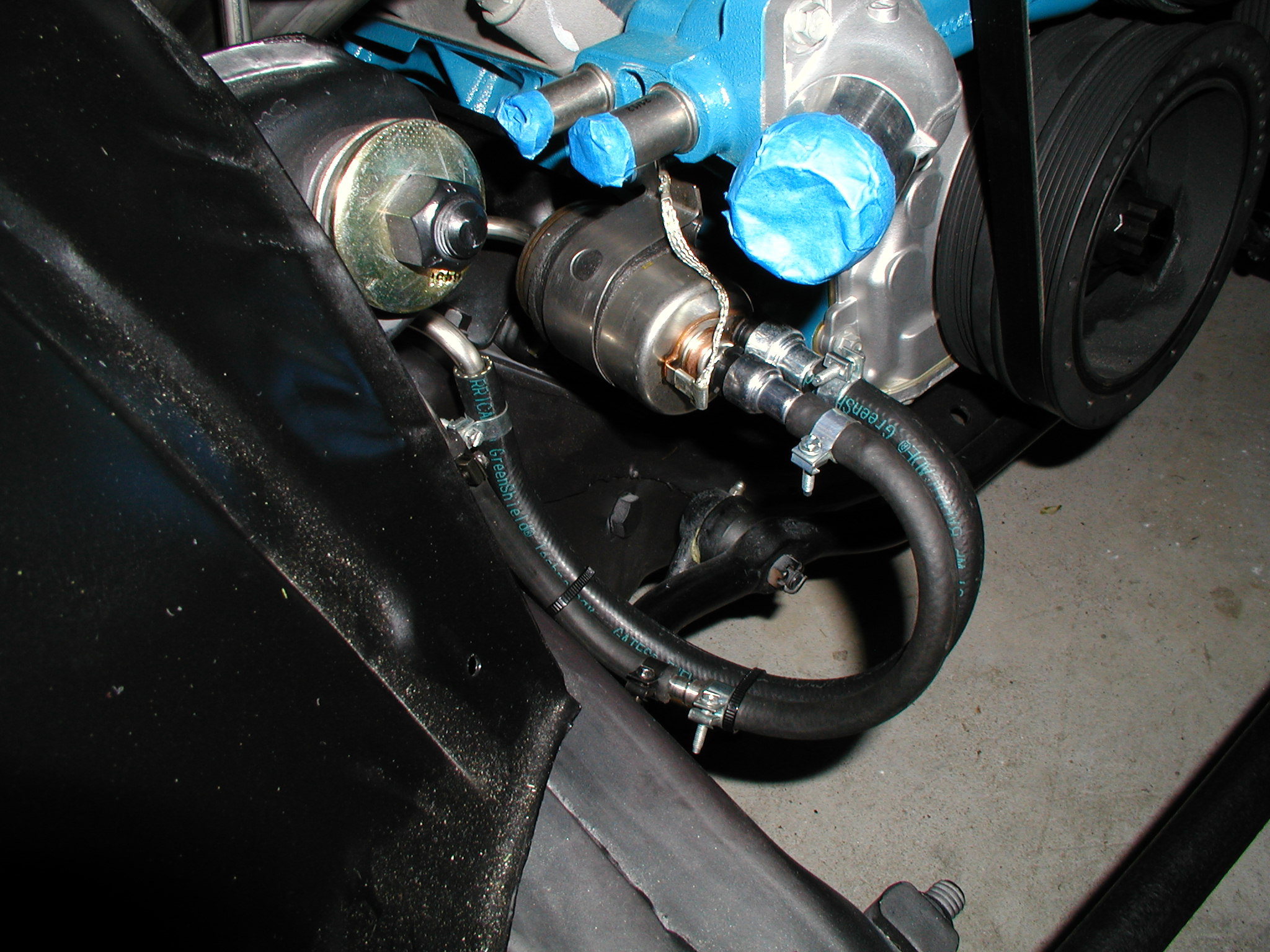

Next we worked on hooking up the power steering hoses. This was a little bit of a challenge on the pressure hose since the C6 power steering pump used a metric bubble flare fitting with o-ring and the gearbox took a good old SAE inverted flare fitting. The solution was to take a new pressure hose that was stock to the car and cut the pump end off of it. Then I used a repair fitting from Edelman that included the metric bubble flare fitting and a straight section of metal pipe. We initially installed it on the car with just a hose clamp holding the two pieces together but later took it off as an assembly and had a local shop crimp it together professionally.....

Next the new windshield washer bottle went in...

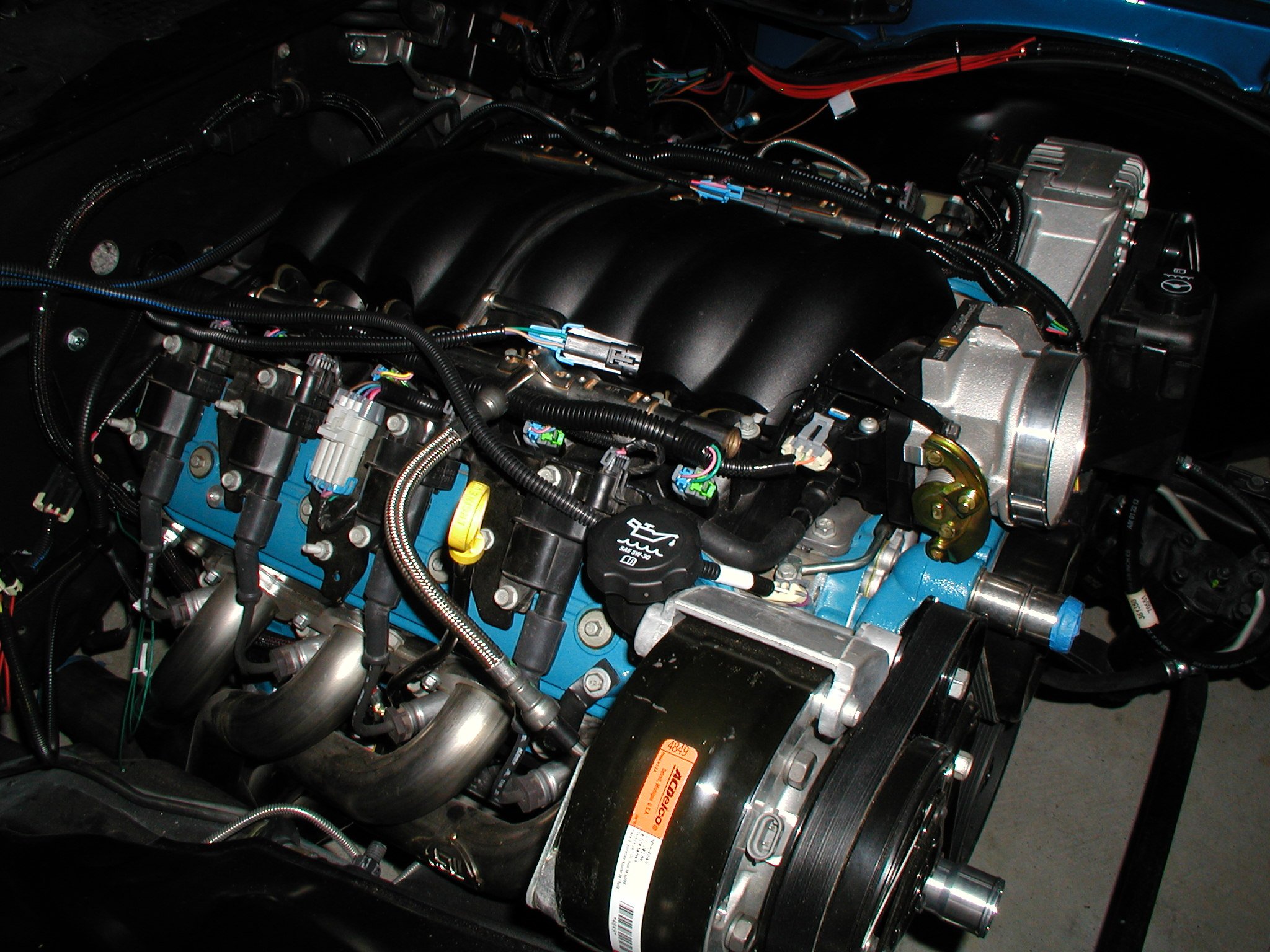

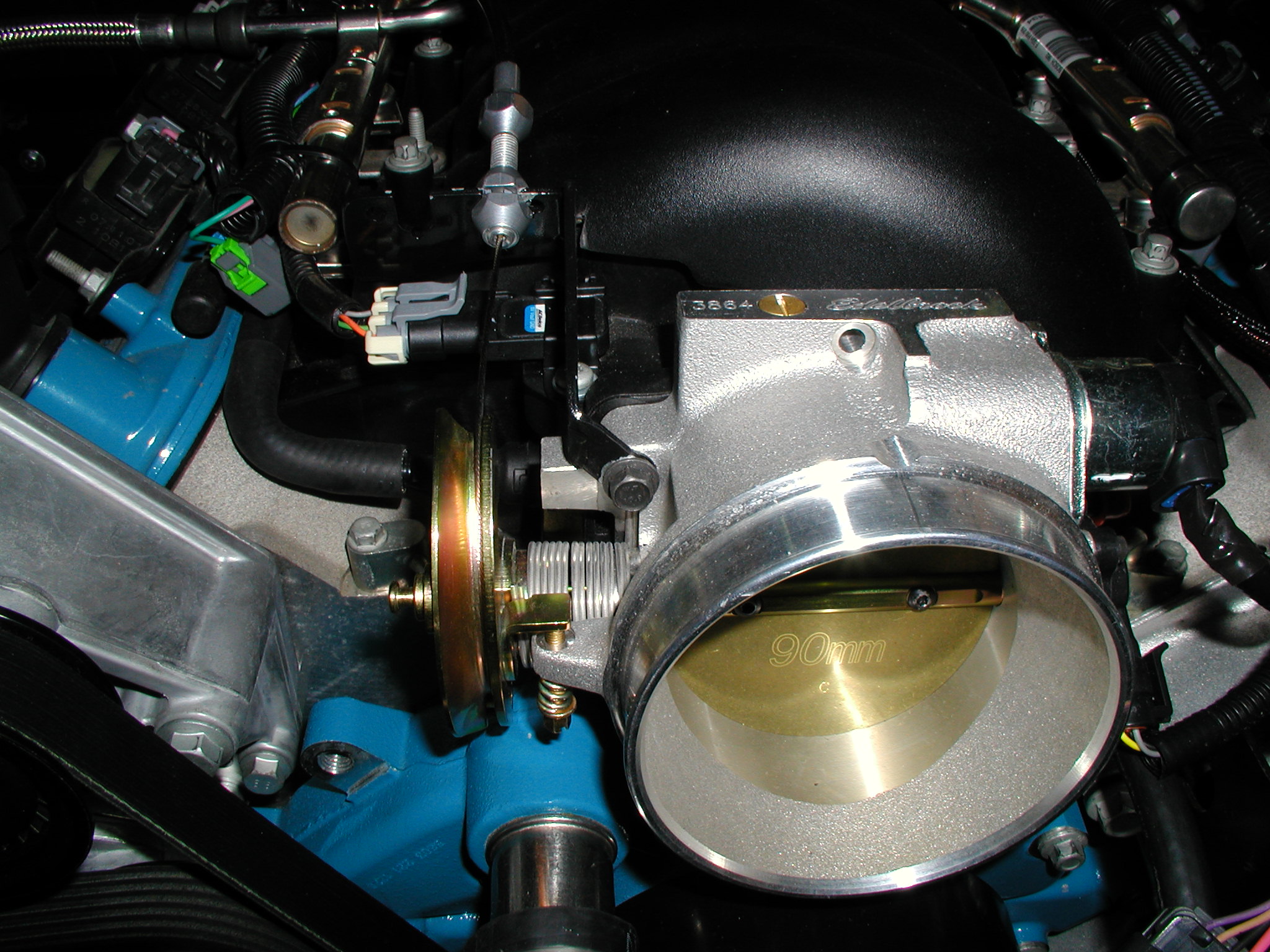

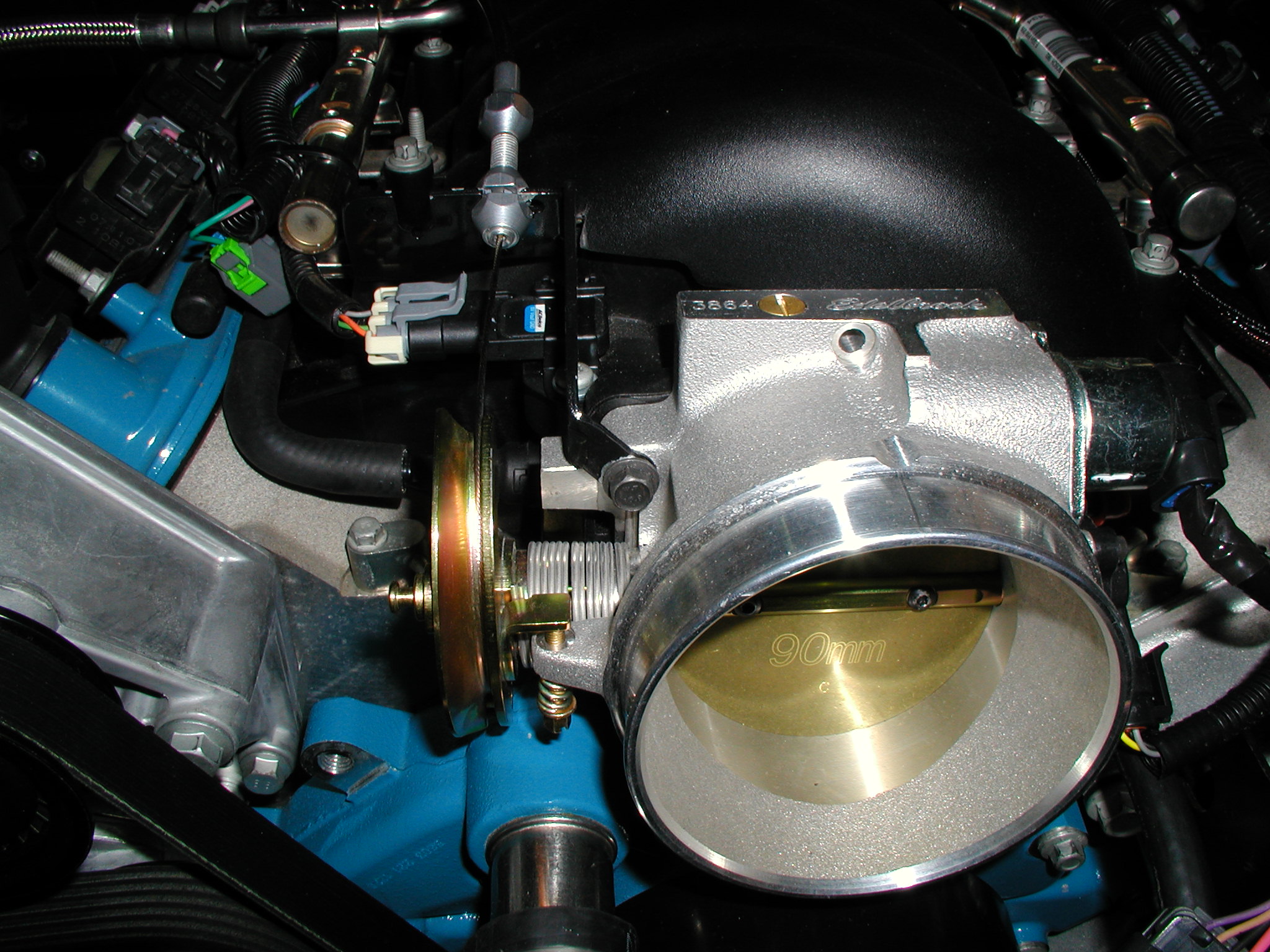

Around this time we procured and installed the throttle body. We went with an Edelbrock 90mm throttle body that had the late style four bolt pattern to fit the LS3 intake but was cable driven...

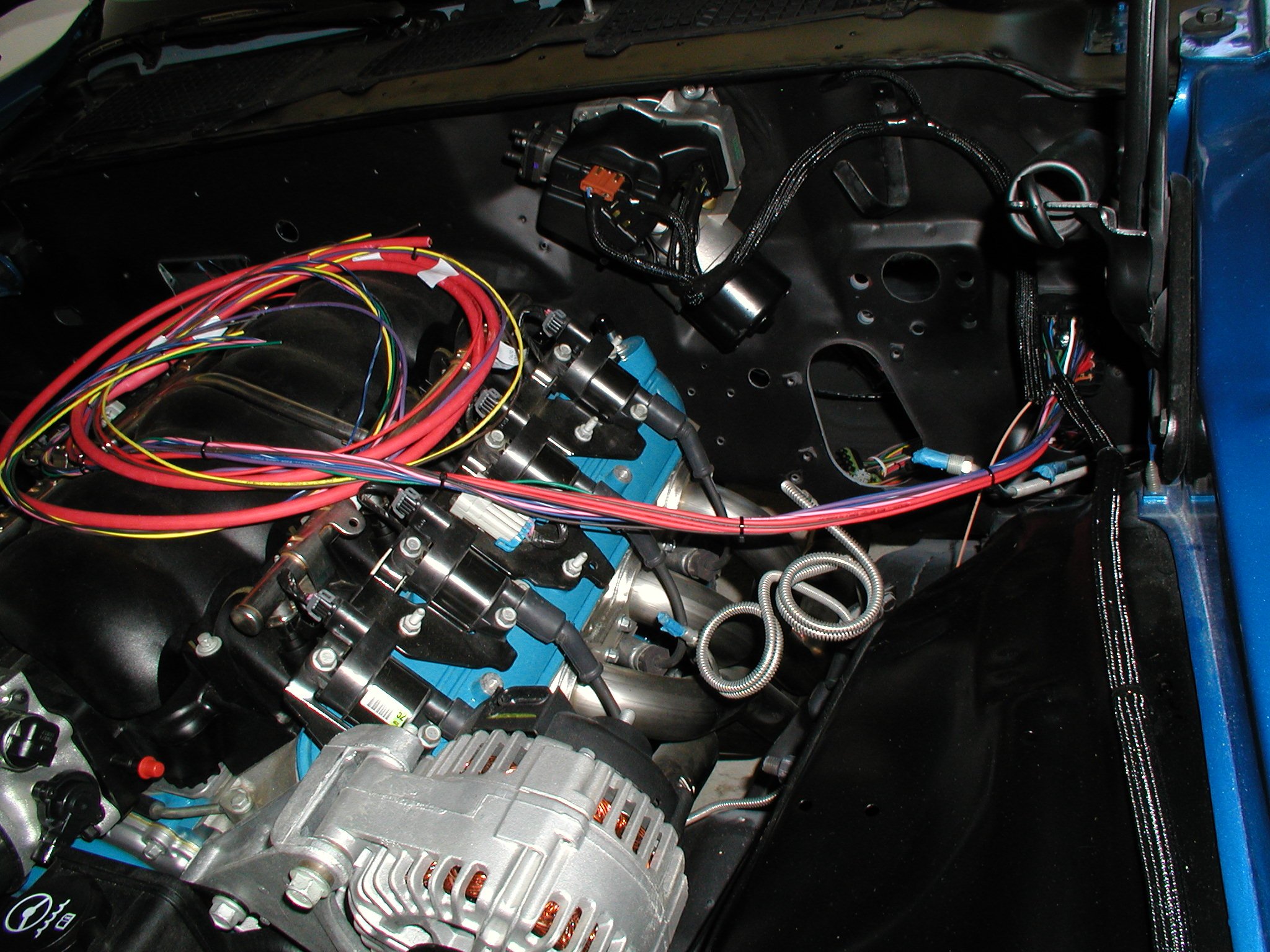

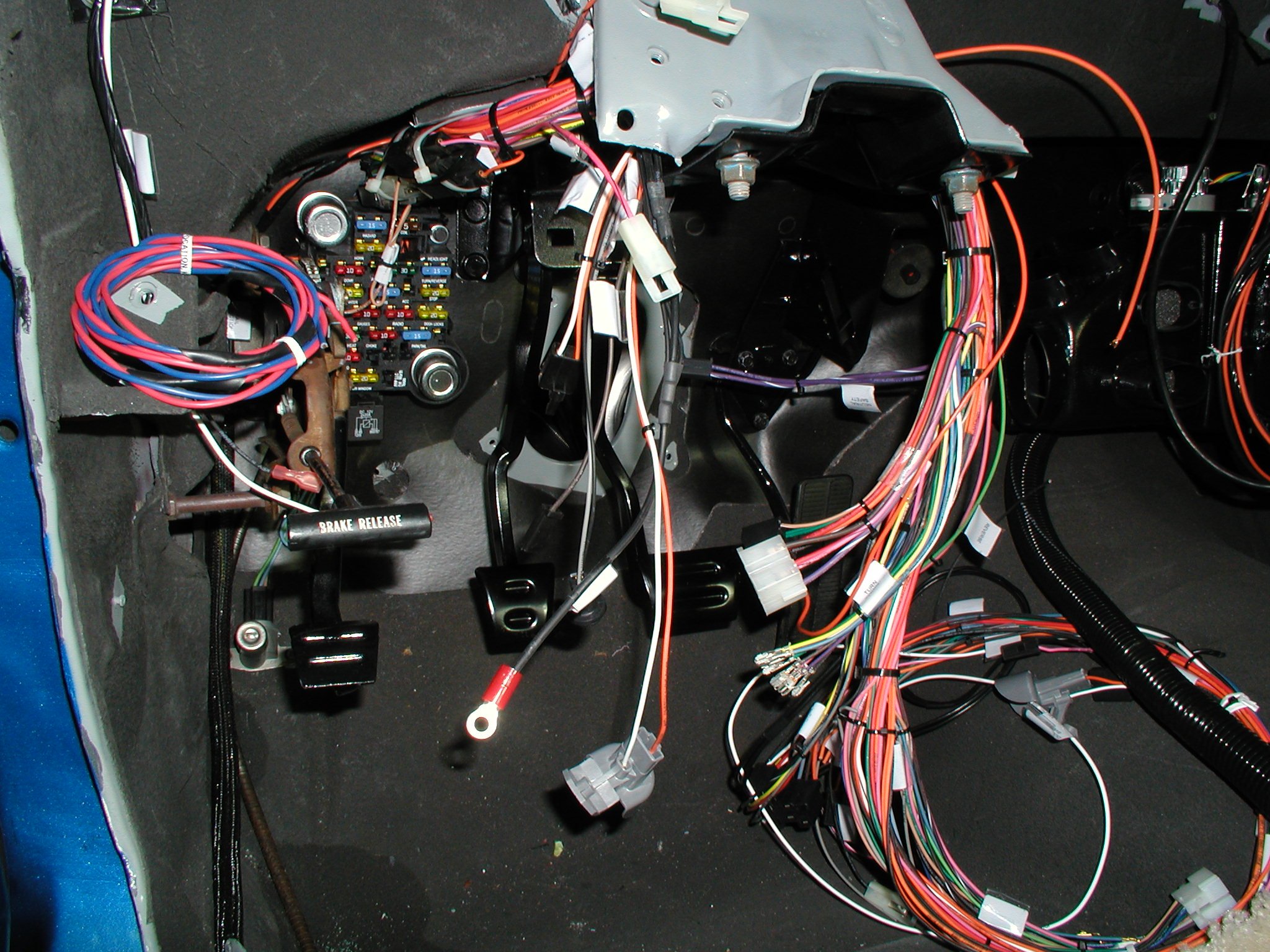

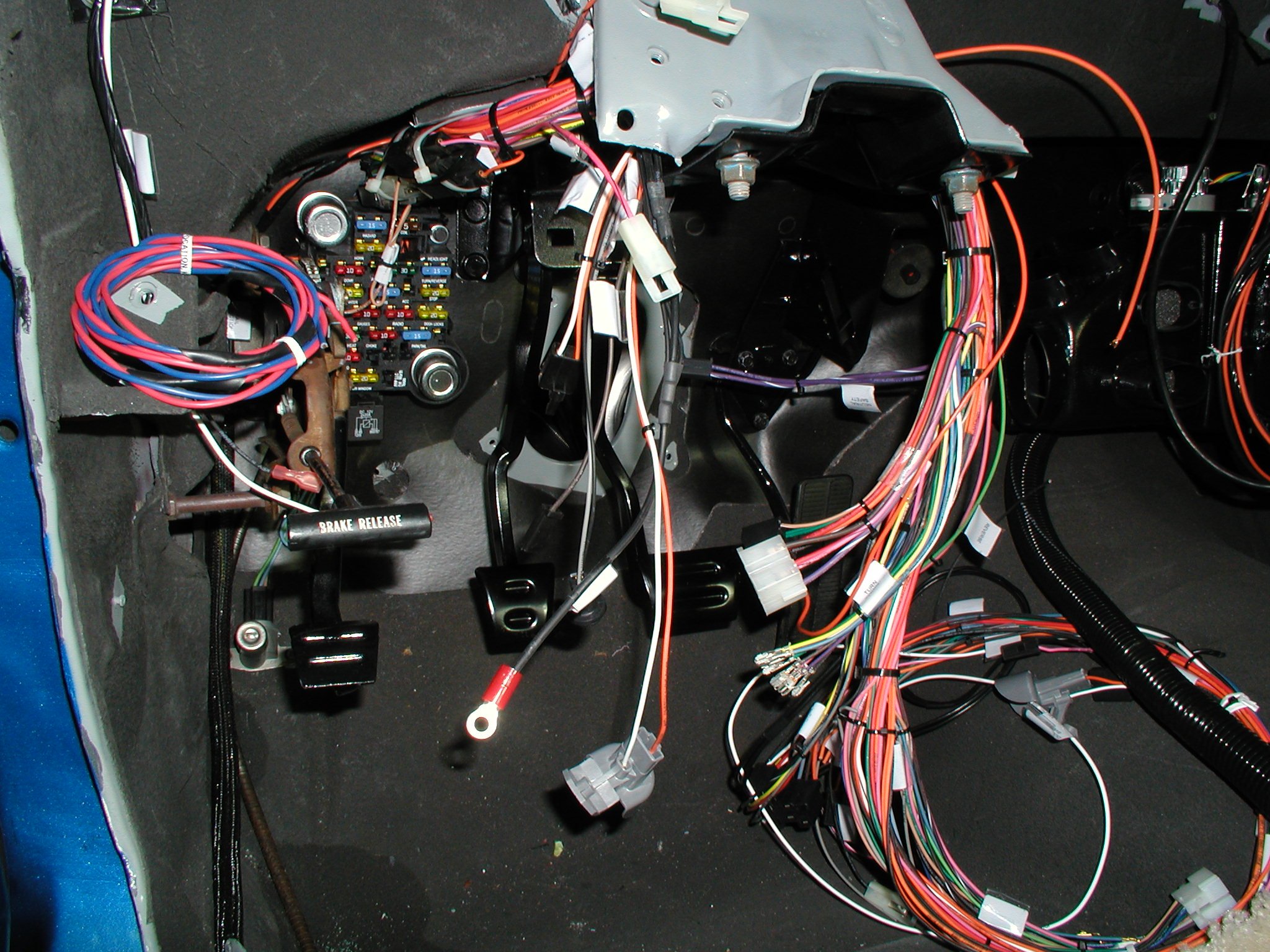

As you can see in the picture above, we also started wiring the car around this time. Ugh. The wiring. It was a really big job on this car. I learned to hate wiring. I'm ok at it. It is just tedious and time consuming to do a decent job. We started out with a Painless replacement harness kit specifically made for the 78-81 Camaro. The quality was outstanding as were the instructions. They did a great job building in flexibility into their harness. If I have any criticism, it's that they are a little stingy with supplies for what they charge. It starts out by mounting the fuse box to the firewall inside the car and then connecting the bulkhead connector to it under the hood. Then you start routing the harness to the lights and working on connections under the hood. This was a relatively easy part of the wiring. Here's a pic of the beginning....

This gets us to the beginning of December of 2013. More wiring and more progress under the hood to come...

And here it is in the car. This also gives you a good look at the Competition Engineering subframe connectors which I've hardly mentioned...

Here's a look at the rear disc brakes, traction bar, sway bar, etc. It's amazing how dirty this stuff gets just sitting around. A lot or most of the dirt is from all of the body work.....

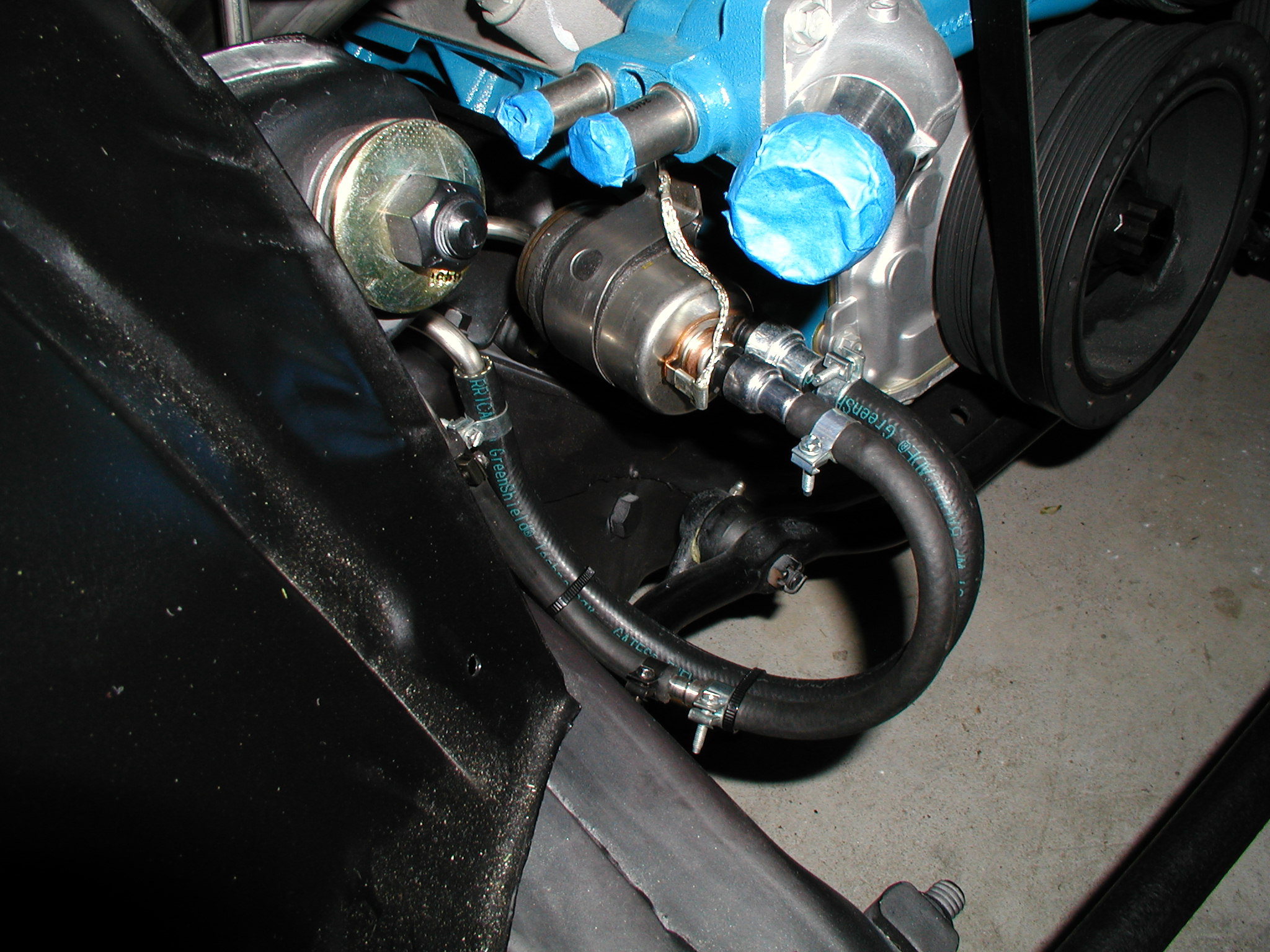

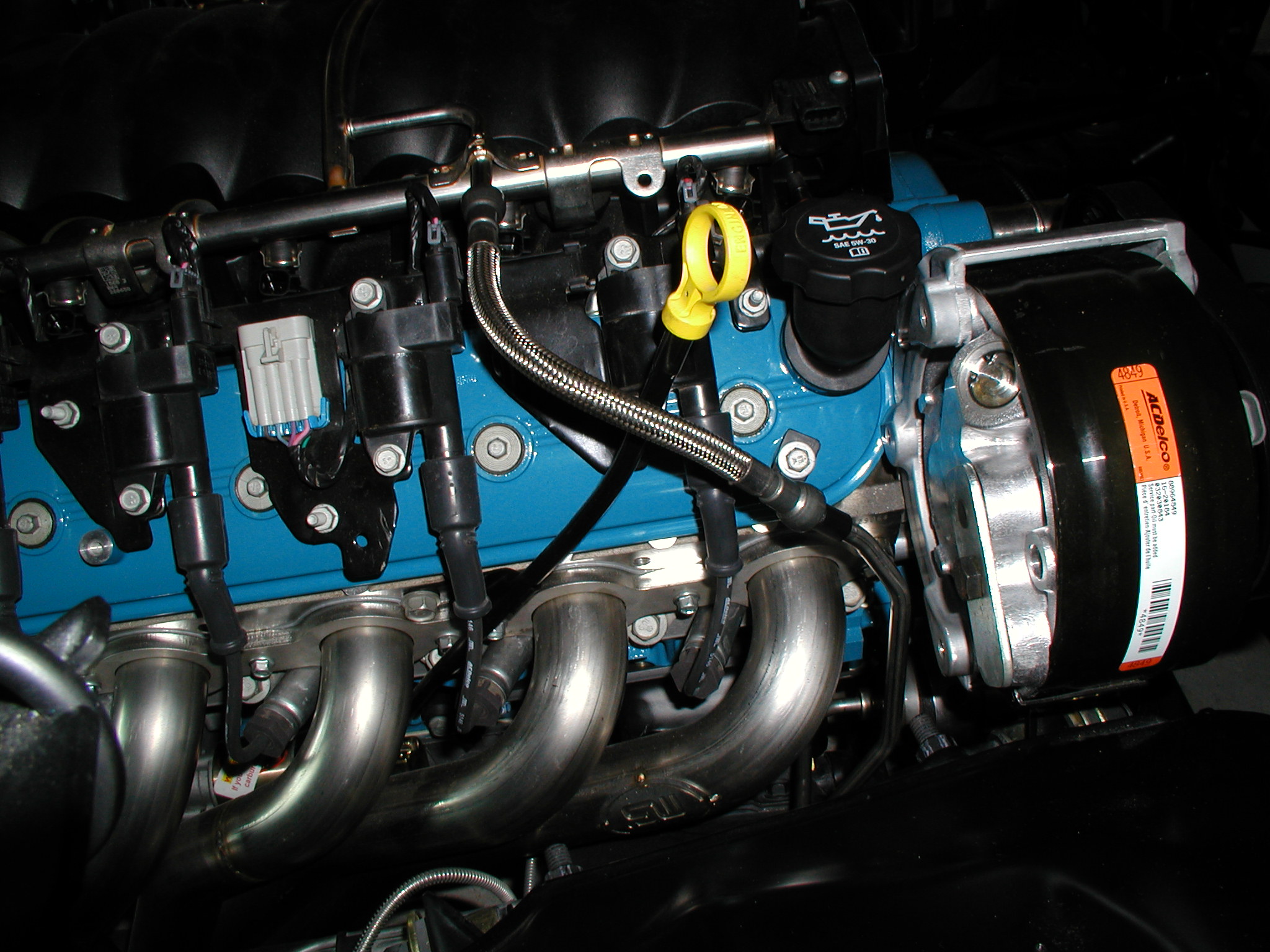

Moving into October, we started connecting the fuel lines to the engine. We used the factory configuration fuel supply/return/vent lines. When we installed all new stock style stainless lines we were still planning to go back with a Gen I small block. If we had planned an LS swap all along, we might have plumbed it differently. Since the LS3 fuel rail doesn't include a pressure regulator or a provision for a return line, we decided to use the C6 Corvette filter/regulator. we found a place to mount it on the lower front passenger side corner of the engine block, near where the factory fuel and return lines terminate, near where the stock mechanical fuel pump would be. We used fuel injection grade hose and clamps to connect the filter/regulator to the hard frame lines...

The next issue was that the LS3 fuel rail has it's inlet on the driver's side and our fuel lines were on the passenger side. What to do? It turns out it was as easy as pulling the fuel rail and swapping it around. It fit perfectly. Now all we needed to do was get from the outlet of the filter/regulator to the fuel rail. The stock fittings are GM push lock. On the inlet side of the filter regulator we used aftermarket adapter fittings to adapt the push lock barbs to the hose clamp barbs. We didn't want to use rubber hose from the outlet of the filter/regulator to the inlet on the fuel rail due to the proximity to the header on the passenger side. After doing some looking, we sourced a stock braided stainless fuel hose from I believe, a fourth gen LS1 F body. That left us a pretty long gap. I ended up fabbing up a hard line out of stainless to bridge the gap. I bought a really nice hydraulic flaring tool that had the dies to make these push lock flares. I wish I had a picture of the completed line off of the car but here it is installed. You can barely see where it turns to the front and stabs into the filter regulator deep down in the picture. You can also see the little bracket we fabbed up to tie the hard line to the passenger valve cover....

Next we installed a new coolant bottle....

Next we worked on hooking up the power steering hoses. This was a little bit of a challenge on the pressure hose since the C6 power steering pump used a metric bubble flare fitting with o-ring and the gearbox took a good old SAE inverted flare fitting. The solution was to take a new pressure hose that was stock to the car and cut the pump end off of it. Then I used a repair fitting from Edelman that included the metric bubble flare fitting and a straight section of metal pipe. We initially installed it on the car with just a hose clamp holding the two pieces together but later took it off as an assembly and had a local shop crimp it together professionally.....

Next the new windshield washer bottle went in...

Around this time we procured and installed the throttle body. We went with an Edelbrock 90mm throttle body that had the late style four bolt pattern to fit the LS3 intake but was cable driven...

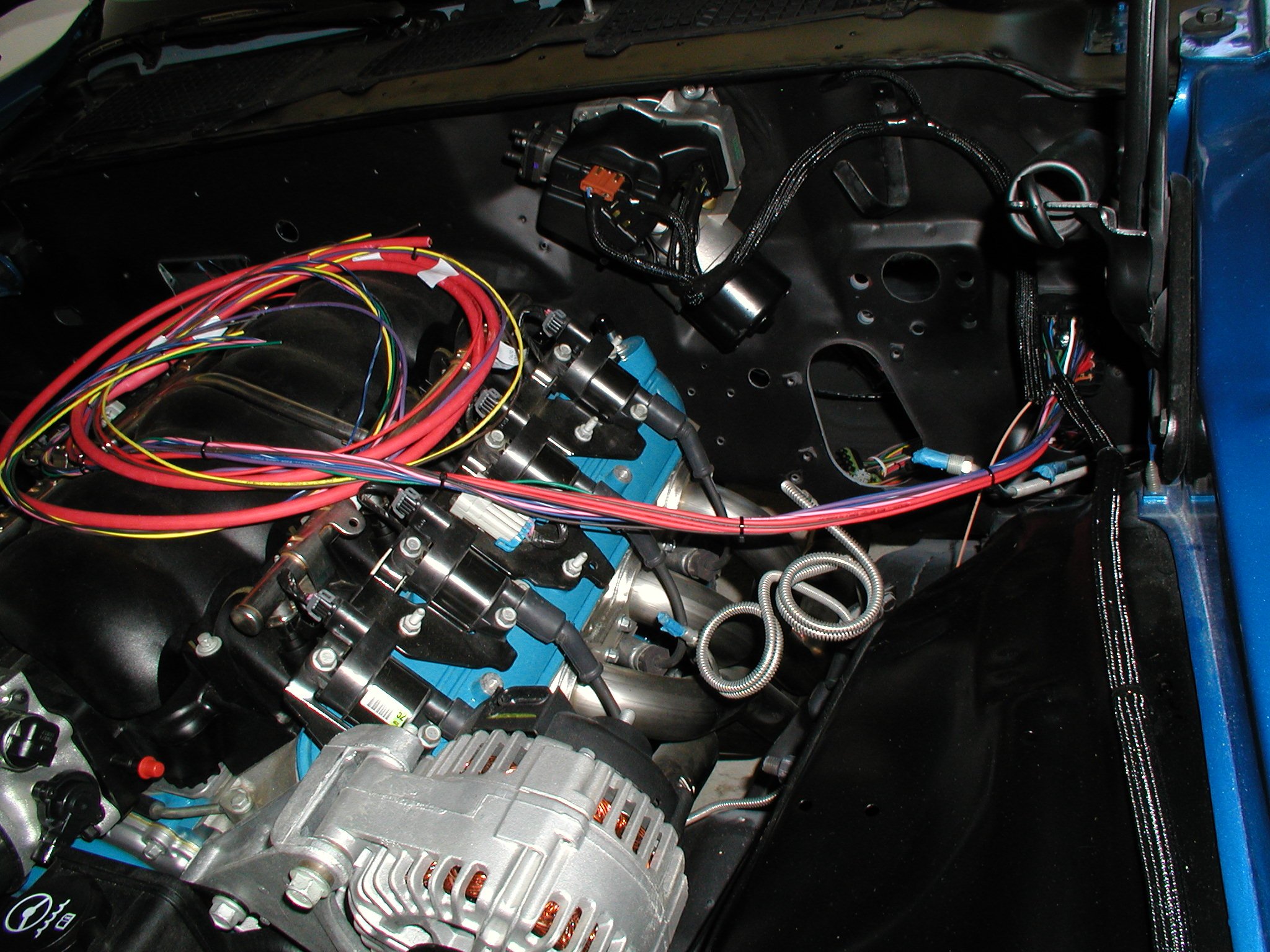

As you can see in the picture above, we also started wiring the car around this time. Ugh. The wiring. It was a really big job on this car. I learned to hate wiring. I'm ok at it. It is just tedious and time consuming to do a decent job. We started out with a Painless replacement harness kit specifically made for the 78-81 Camaro. The quality was outstanding as were the instructions. They did a great job building in flexibility into their harness. If I have any criticism, it's that they are a little stingy with supplies for what they charge. It starts out by mounting the fuse box to the firewall inside the car and then connecting the bulkhead connector to it under the hood. Then you start routing the harness to the lights and working on connections under the hood. This was a relatively easy part of the wiring. Here's a pic of the beginning....

This gets us to the beginning of December of 2013. More wiring and more progress under the hood to come...

Last edited:

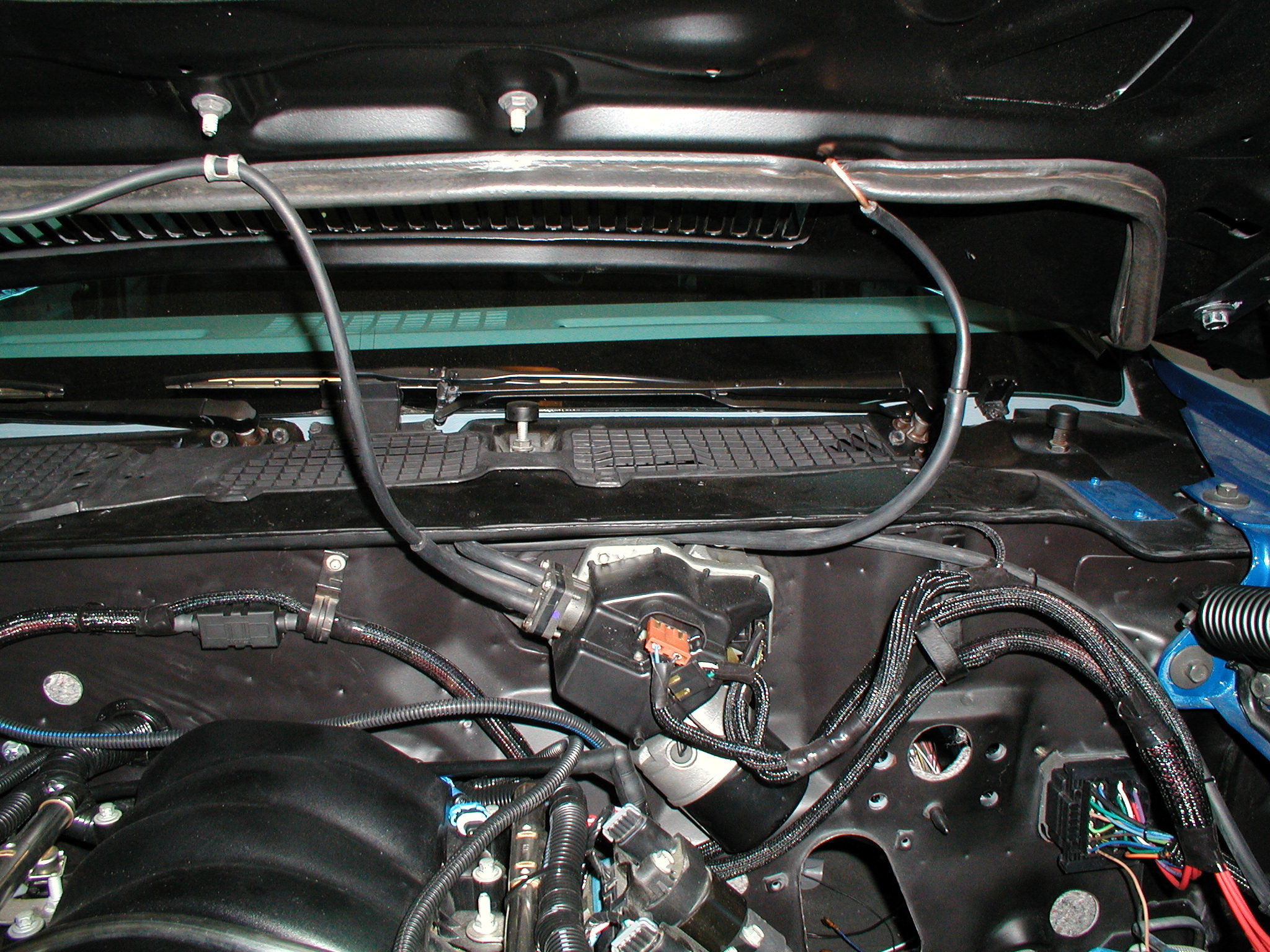

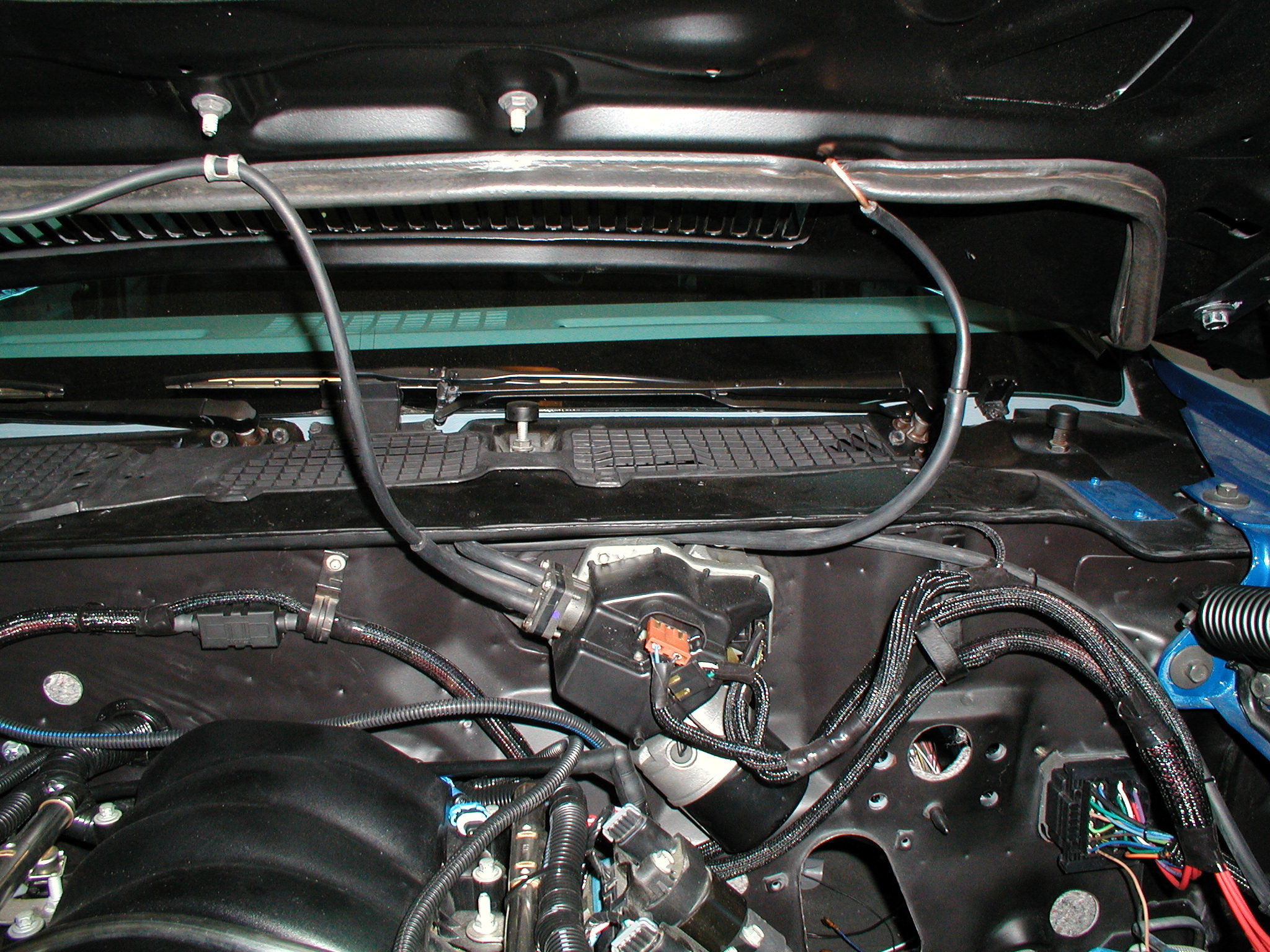

In December we kept working under the hood. We worked on finalizing most of the connections under the hood for the Painless harness. We went with their Powerbraid on all of the underhood portion of the harness. We got the wiper motor and wiper linkage/arms installed and all the connections made...

Also visible in this picture is the engine harness installed. We went with a stand alone harness from PSI conversions. It was really nice. Note the new hole in the firewall just above and behind the passenger side fuel rail where the harness goes in the car. Here's another look at the engine harness. Also visible is the throttle cable bracket. I don't completely remember but I believe this is a Holley bracket that we modified to work with our setup...

We got the throttle pedal cleaned up and installed. This gives you a look at the beginning of the fun to come in wiring everything up under the dash...

We also got the clutch and brake pedals installed along with the bracket they hang from. Part of the dash harness has to go up and over that bracket. We also got the e-brake pedal cleaned up and installed and got the e-brakes hooked up...

Visible in the picture above is the harness that goes from the fuse block to the rear of the car. This includes the taillights, fuel pump, fuel gauge, etc. Here's a look at the taillight harness routed through the tailpanel and put into position for the taillights...

We got the throttle cable routed through the firewall and hooked up at both ends. We used a Lockar throttle cable. It worked out well....

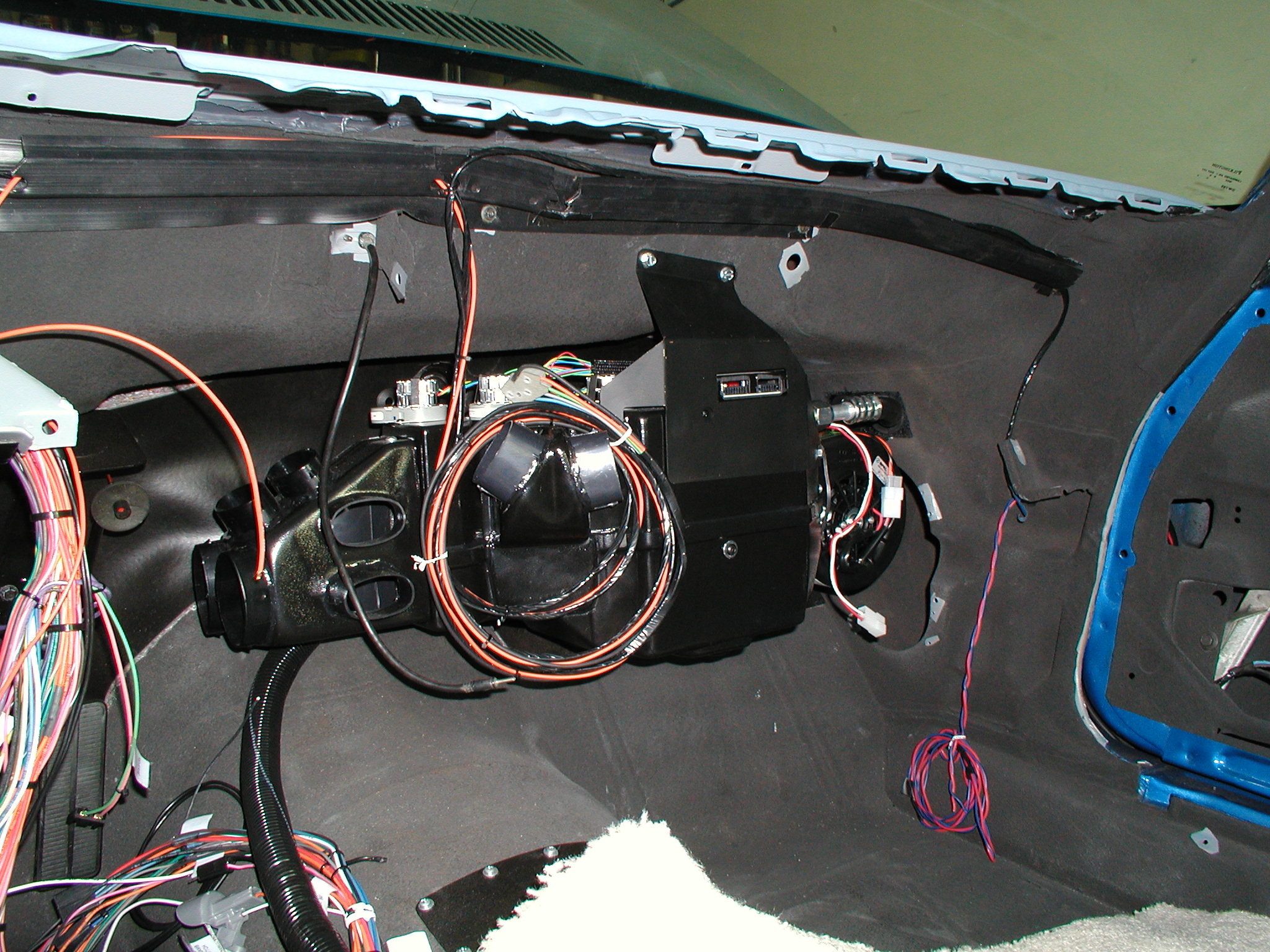

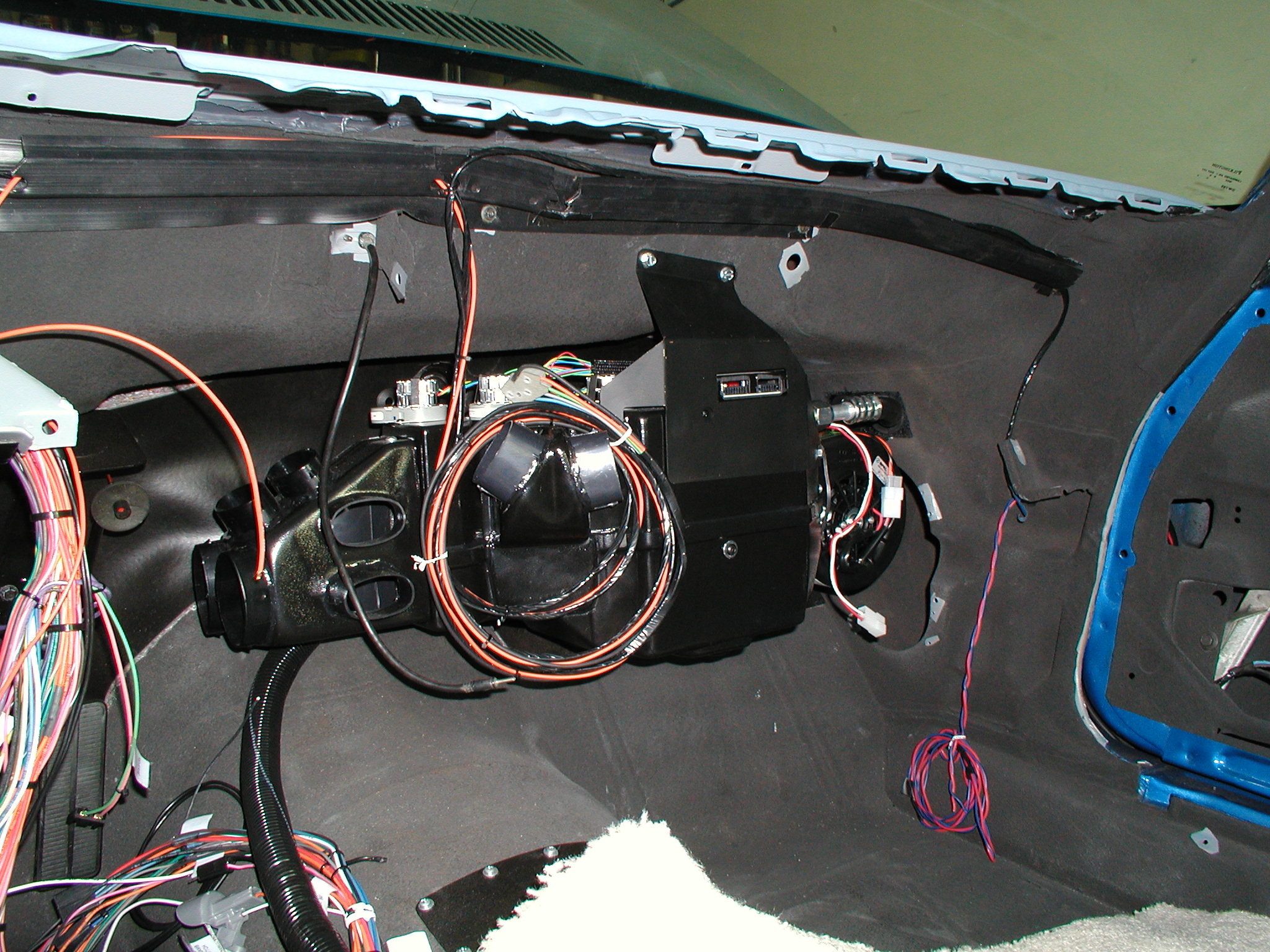

We also got going on installing the HVAC system. We went with the vintage air kit specifically for the 2nd gen Camaro. We made some modifications since we had an LS swap instead of the Gen I small block the kit was designed for. Here's a look at the under dash unit which includes the heater core and the evaporator core....

One of the modifications we made was to route the heater pipes through the firewall rather than route them through the cowl with the AC hoses. We didn't want the heater hoses running into the cabin of the car....

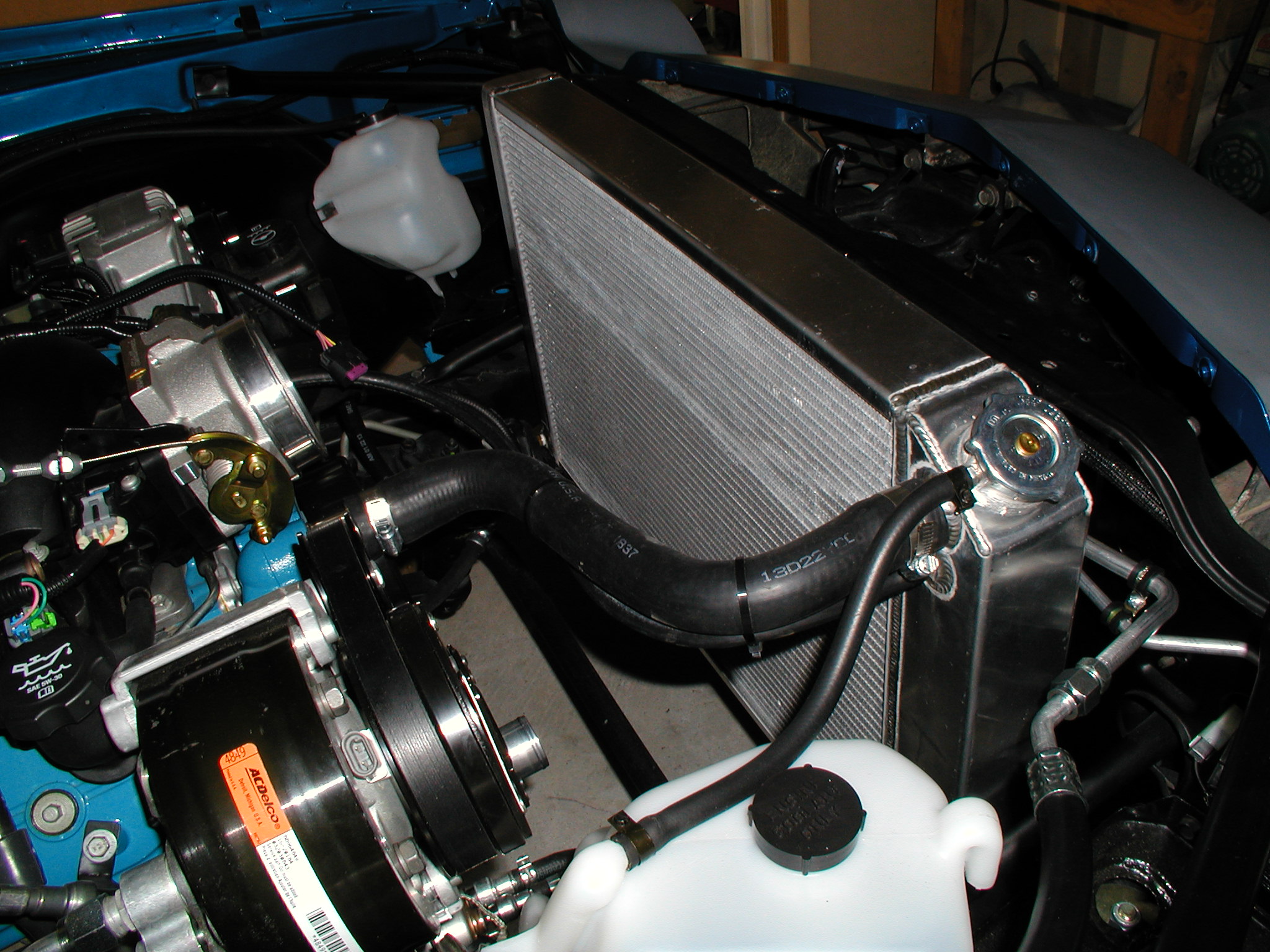

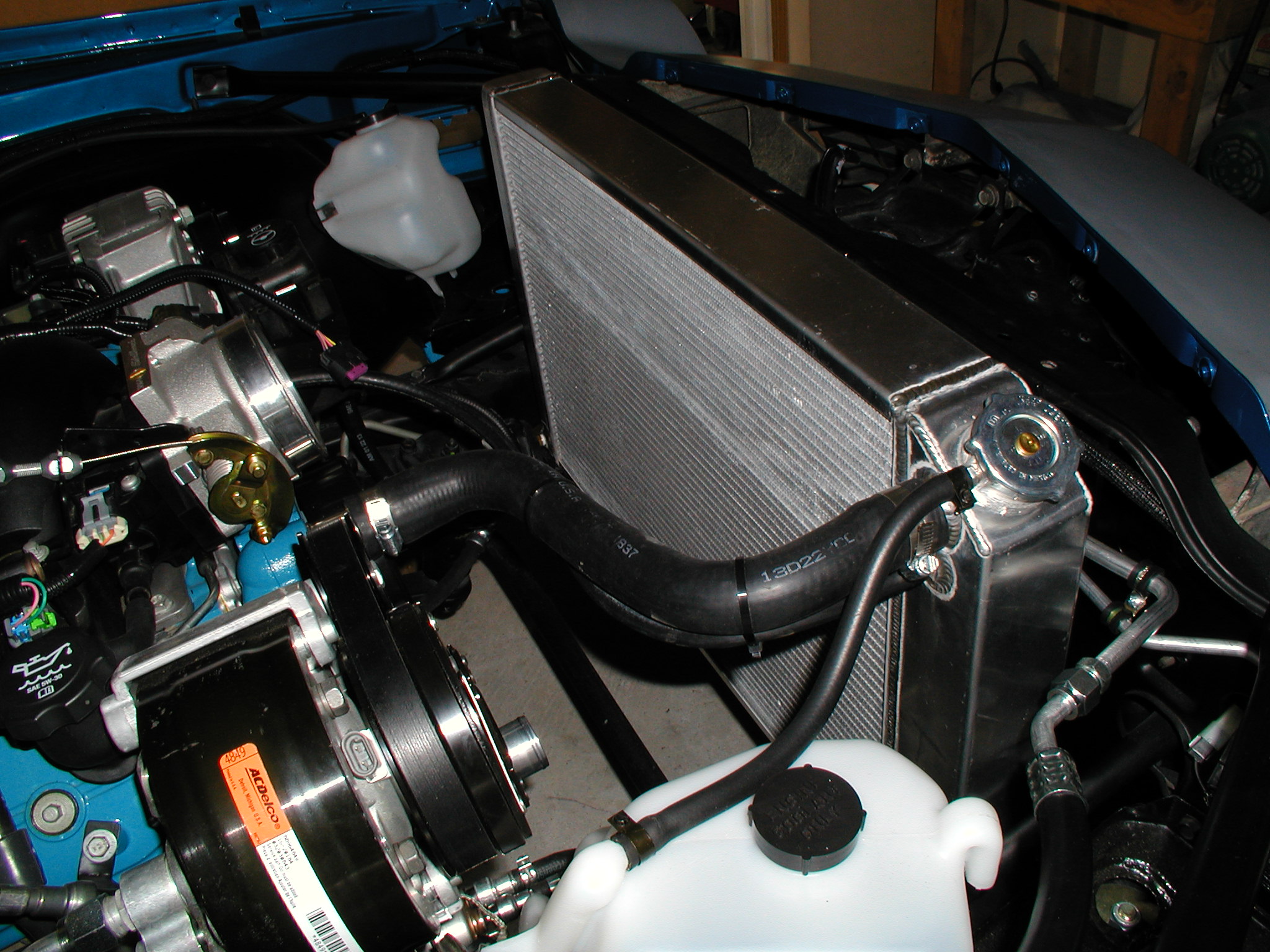

Also visible in the picture above is the plate that Vintage Air provides that closes up the big opening in the firewall between the two halves of the original HVAC case. During December we also got the radiator in the car. We went with a Griffin unit that has both the inlet and outlet on the passenger side. It makes for a clean install. On the hoses, I used some coat hanger wire to layout the desired shape. I measured the inlets and outlets on the water pump and the radiator and went to the local NAPA. They let me comb through their hoses and I just matched up something that would work for both and then we trimmed to fit...

And here's a look at the A/C hoses. they were totally custom since the Vintage Air kit assumes a Sanden compressor on the driver's side of the car. We got the hoses mocked up and marked for clocking and then I took them to a local shop to have them crimped....

That's most of what we got done in December of 2013. I'll post the rest in the next installment, which might not be tonight. Stay tuned for more updates...

Also visible in this picture is the engine harness installed. We went with a stand alone harness from PSI conversions. It was really nice. Note the new hole in the firewall just above and behind the passenger side fuel rail where the harness goes in the car. Here's another look at the engine harness. Also visible is the throttle cable bracket. I don't completely remember but I believe this is a Holley bracket that we modified to work with our setup...

We got the throttle pedal cleaned up and installed. This gives you a look at the beginning of the fun to come in wiring everything up under the dash...

We also got the clutch and brake pedals installed along with the bracket they hang from. Part of the dash harness has to go up and over that bracket. We also got the e-brake pedal cleaned up and installed and got the e-brakes hooked up...

Visible in the picture above is the harness that goes from the fuse block to the rear of the car. This includes the taillights, fuel pump, fuel gauge, etc. Here's a look at the taillight harness routed through the tailpanel and put into position for the taillights...

We got the throttle cable routed through the firewall and hooked up at both ends. We used a Lockar throttle cable. It worked out well....

We also got going on installing the HVAC system. We went with the vintage air kit specifically for the 2nd gen Camaro. We made some modifications since we had an LS swap instead of the Gen I small block the kit was designed for. Here's a look at the under dash unit which includes the heater core and the evaporator core....

One of the modifications we made was to route the heater pipes through the firewall rather than route them through the cowl with the AC hoses. We didn't want the heater hoses running into the cabin of the car....

Also visible in the picture above is the plate that Vintage Air provides that closes up the big opening in the firewall between the two halves of the original HVAC case. During December we also got the radiator in the car. We went with a Griffin unit that has both the inlet and outlet on the passenger side. It makes for a clean install. On the hoses, I used some coat hanger wire to layout the desired shape. I measured the inlets and outlets on the water pump and the radiator and went to the local NAPA. They let me comb through their hoses and I just matched up something that would work for both and then we trimmed to fit...

And here's a look at the A/C hoses. they were totally custom since the Vintage Air kit assumes a Sanden compressor on the driver's side of the car. We got the hoses mocked up and marked for clocking and then I took them to a local shop to have them crimped....

That's most of what we got done in December of 2013. I'll post the rest in the next installment, which might not be tonight. Stay tuned for more updates...

Similar threads

- Replies

- 1

- Views

- 110

- Replies

- 8

- Views

- 453

- Replies

- 35

- Views

- 1K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.