So I've taken some time away from the car, been busy with a lot of other things and needed a break after the mad rush to get the car done for Power Tour. I'm hoping to get the car ready for some cruising before the year ends though now.

Power tour went pretty well for my car at least.

Did the trip this year with a supercharged Montana van and the

Lesabre in this picture that has a turbo and a supercharger.

Hotel shenanigans were really disappointing this year, but it was still cool to hang out with people at them

I did end up putting the car on the dyno finally but was pretty disappointed with the numbers it put down. I had a lot of trouble with my boost controller being inconsistent and not putting out the 20 psi I was trying to get out of it. It made about 350 at the tire on 15 psi but it the power peak was way lower in the RPM range than it should've been.

I blame that on my cam timing experiment I did a while back. Basically I had the cam timing retarded 4* to try and take more advantage of my ported heads and ported intake.

Or at least that's what I think the issue was.

One of the biggest issues I was fighting was my clutch though the whole trip. The clutch I used here was one I had from a few years ago when the car had a T5 in it. It's a spec stage 3+ clutch and I guess it wasn't ready for the task or it was already destroyed. The clutch might have been out of balance or something, but it really had a hard time getting the car out of the hole.

So trans is back out and I'm waiting for my next clutch that is going to be way better for this thing than the spec clutch was.

In the meantime I'm going to be addressing the power issue I had with it and I have a few things I'm going to do to it to try and get the most out of the stock camshaft for now.

First fix is a new timing set. I'm reverting back to the stock L67 cam timing instead of the modified L36 cam timing. No more cam timing retard for this one.

Second fix is an upgraded turbo!

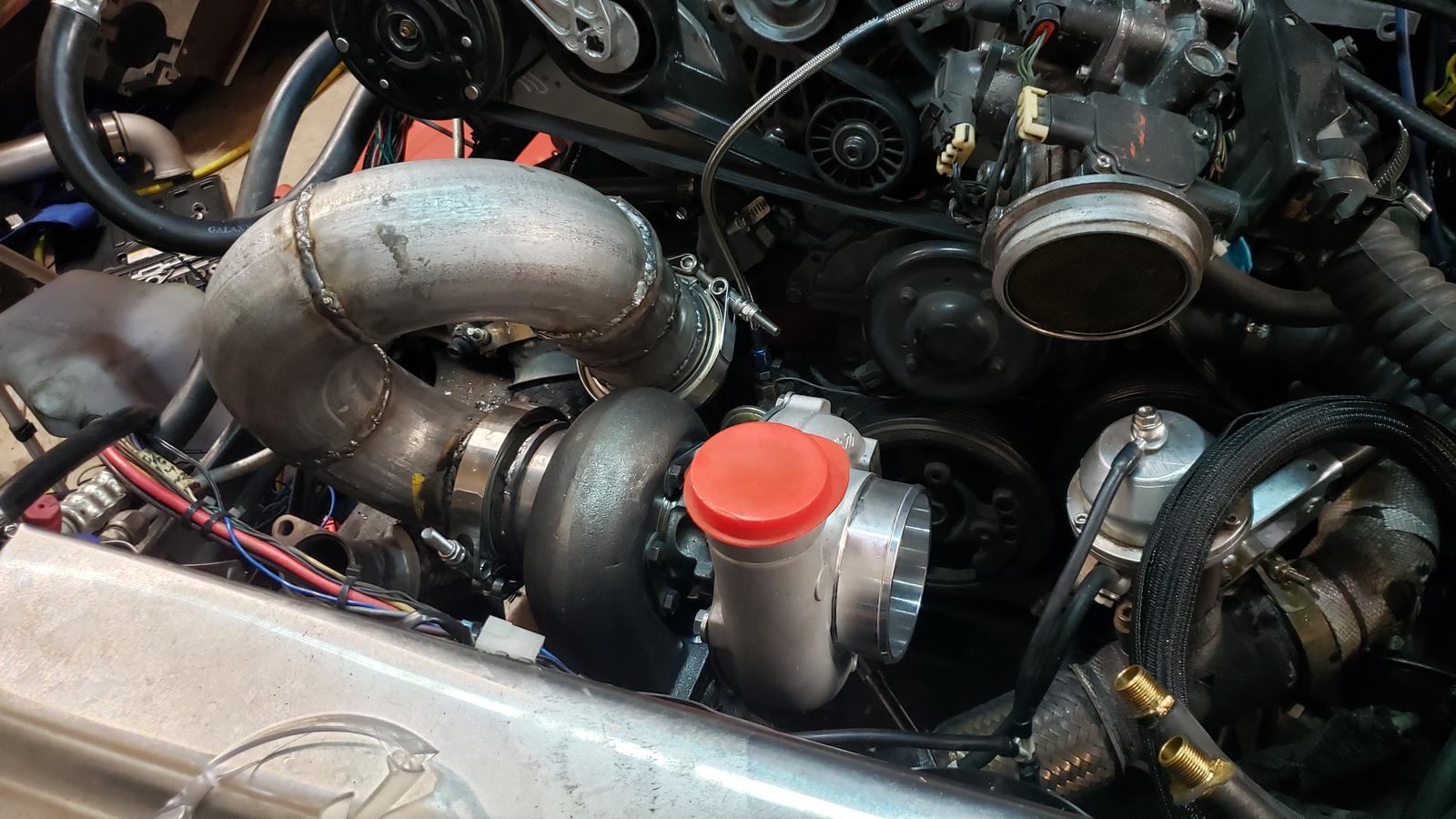

On the left is the old Holset HX35. The HX35 I have here is a 54mm turbo on the compressor side and has a twin scroll T3 housing. I'm thinking that I'm really hitting the limit of what this turbo can do when it hits 20 psi (400 WHP) on this engine and a few other people have told me that 400 is really the limit of this on a 3800.

The new turbo has a 62mm billet compressor wheel, twin scroll T4 exhaust housing which has a 3.5" outlet for the downpipe. It's a little larger on the exhaust side but a lot larger on the compressor side. This one should be able to hang with the car hopefully past 500 WHP. With the billet compressor wheel and the twin scroll T4 housing it should also spool pretty fast still.

I have two more things I'm working on too to make this thing come alive a little more but I'll save those for another post once I start working on them.

For now I'm working on getting the exhaust from the turbo all the way back done. I'm moving from a 3" downpipe to a 3.5" downpipe and I'm figuring that I need to go and just upgrade the rest of the exhaust that's currently a single 3" pipe.

So it's going to be a 3.5" pipe down up to somewhere by the trans and then it'll split into two 3" pipes all the way back. 3" should clear the axle still and give me plenty of flow for the next iteration of this car.

The challenge now is getting everything to fit in the place I have the turbo right now and it is tight! Here is the old 3" downpipe:

It was so tight that only pie cuts would give me the tight radius I needed to get the pipe where it needs to go. Really would have designed the whole thing different if I were to do it again because I don't think we even thought about the downpipe when we built it.

So with the 3.5" down pipe I had to get a little more creative. I created what I'm dubbing the Power Vortex

🤣

This really was the only way I could get the exhaust to get where it needs to go in that area without doing more pie cuts again. I wanted to stick with mandrel bends as much as possible in case that's the issue too.

Now that I have that done now I'm also going to relocate my wastegates. I've had a crazy hard time getting these things to work consistently and it's because of the angle that they're mounted at off of the exhaust.

Both of them are at 90* angles to the main tubes and the passenger side might even be a lot worse than 90*

When I built them I didn't know any better but now I'm forcing myself to fix them. Hopefully I can get that done by the end of this weekend, but drilling through stainless steel is a real PITA lol

Once this is done I'm also going to be able to run a much larger air filter in front of the turbo too so there's going to be a lot of WIN to be had with these changes!