So this didn't start as a G-Body day in the shop, it was more of a surprise, the new transformer came in for the picnic cooler so let's see if the fossil works.

But that went so well and my energy level was up there so i spur-of-the-moment decided that I ought to do another in the ongoing series of engine oil primes that I periodically engage in. The theory is that if I can't remember the last time that I did one then it is time to do it again.

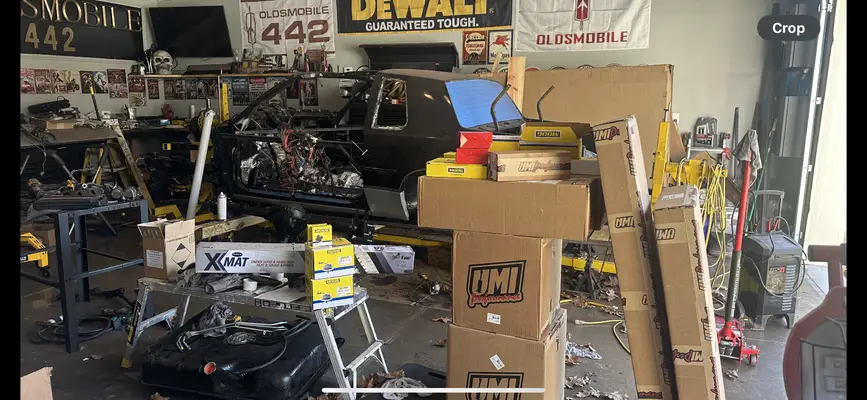

So that in mind, I barked up the compressor and used a long want to blow off all the dust and fallout and minor debris that had accumulated during the summer; actually not all that much and then removed the covers, then did the same thing for the engine and adjacent assemblies. Took that opportunity to shut the compressor off at the breaker box and then emptied both the tank and the water trap for winter.

For purposes of doing an engine pre-oil I have a special oil pump drive that I built and it sits in the engine in place of the timer so no need to lift the distributor. I also bring out my 1/2 drive drill motor as it has the needed torque to rotate the pump gears and drive the oil through the galleries and up into the rockers. The rocker tins are just an old set that I leave in place. They were the ones that were on the engine when it was dropped into place and bear the scars of being banged around.

It took about 10 minutes, maybe less, but at the end I had all 16 rockers showing oil flow and had the oil moving to the point it was oozing out of the rockers and down onto the springs. Counted that a success and re-installed the covers. Detached the drill from the pump drive and covered everything back up again. Did think and decide to set a strip of masking tape on the one rocker cover with the date of this pre-oil written on it. Memory? who needs a memory, ya have to have a mind for that and I don't mind at all. 😆

Looked at the clock and decided I had just enough obstinacy, stubbornness, and initiatve left to go after all the plug welds that hold the outer skin on the lower A-pillar door post assembly. I had, I think, identified all the dents and used a center punch and hammer to prep them so the 1/2 inch got fitted with a plug weld cutter and the fun began. Three cutters later, I think I have all the holes deep enough that the skin ought to pop free but it thinks otherwise. The thought now is to locate a panel separator and see if that can bring some daylight onto the subjject. Alos have to find some 5/64ths hex keys as that is the size of the allen screws that hold the drill bits in the shank and those bits commit suicide about every other weld.

Oh, yeah, The cooler? Well it did get cool inside but the transformer was quite warm to the touch. Shut the whole thing down and unplugged it. Now have to wonder if there is a thermostat in there that has decided to self destruct? Good thing the initial buy in on this was nada, zero,zilch, bupkus. Nothing substantial invested means I am out nothing if I decide to to turn the whole thing into a storage bin instead.

Nick

But that went so well and my energy level was up there so i spur-of-the-moment decided that I ought to do another in the ongoing series of engine oil primes that I periodically engage in. The theory is that if I can't remember the last time that I did one then it is time to do it again.

So that in mind, I barked up the compressor and used a long want to blow off all the dust and fallout and minor debris that had accumulated during the summer; actually not all that much and then removed the covers, then did the same thing for the engine and adjacent assemblies. Took that opportunity to shut the compressor off at the breaker box and then emptied both the tank and the water trap for winter.

For purposes of doing an engine pre-oil I have a special oil pump drive that I built and it sits in the engine in place of the timer so no need to lift the distributor. I also bring out my 1/2 drive drill motor as it has the needed torque to rotate the pump gears and drive the oil through the galleries and up into the rockers. The rocker tins are just an old set that I leave in place. They were the ones that were on the engine when it was dropped into place and bear the scars of being banged around.

It took about 10 minutes, maybe less, but at the end I had all 16 rockers showing oil flow and had the oil moving to the point it was oozing out of the rockers and down onto the springs. Counted that a success and re-installed the covers. Detached the drill from the pump drive and covered everything back up again. Did think and decide to set a strip of masking tape on the one rocker cover with the date of this pre-oil written on it. Memory? who needs a memory, ya have to have a mind for that and I don't mind at all. 😆

Looked at the clock and decided I had just enough obstinacy, stubbornness, and initiatve left to go after all the plug welds that hold the outer skin on the lower A-pillar door post assembly. I had, I think, identified all the dents and used a center punch and hammer to prep them so the 1/2 inch got fitted with a plug weld cutter and the fun began. Three cutters later, I think I have all the holes deep enough that the skin ought to pop free but it thinks otherwise. The thought now is to locate a panel separator and see if that can bring some daylight onto the subjject. Alos have to find some 5/64ths hex keys as that is the size of the allen screws that hold the drill bits in the shank and those bits commit suicide about every other weld.

Oh, yeah, The cooler? Well it did get cool inside but the transformer was quite warm to the touch. Shut the whole thing down and unplugged it. Now have to wonder if there is a thermostat in there that has decided to self destruct? Good thing the initial buy in on this was nada, zero,zilch, bupkus. Nothing substantial invested means I am out nothing if I decide to to turn the whole thing into a storage bin instead.

Nick