Just a few shots of the progress on adding a lifting winch for the movable press deck on my press

View attachment 235578

View attachment 235579

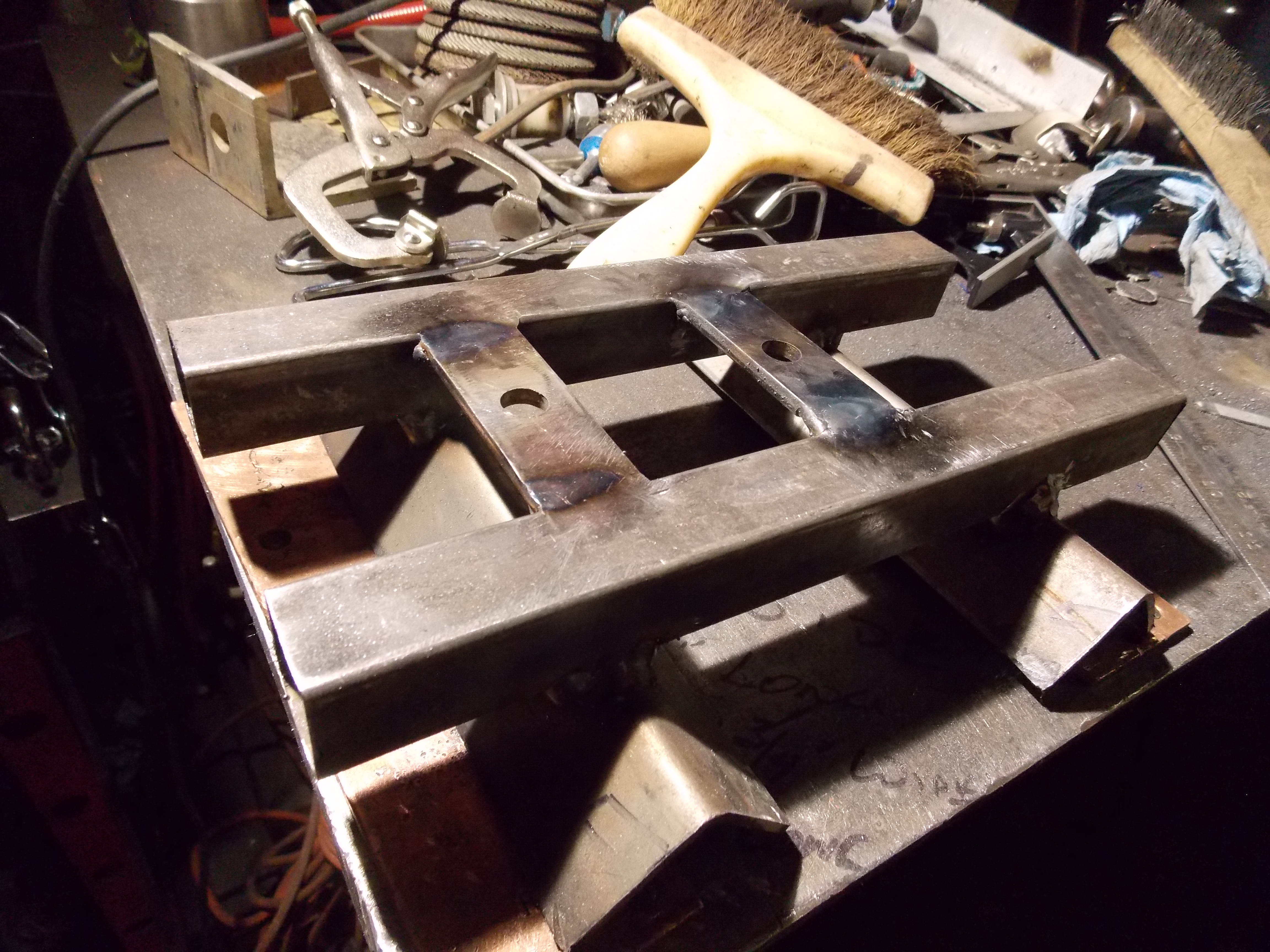

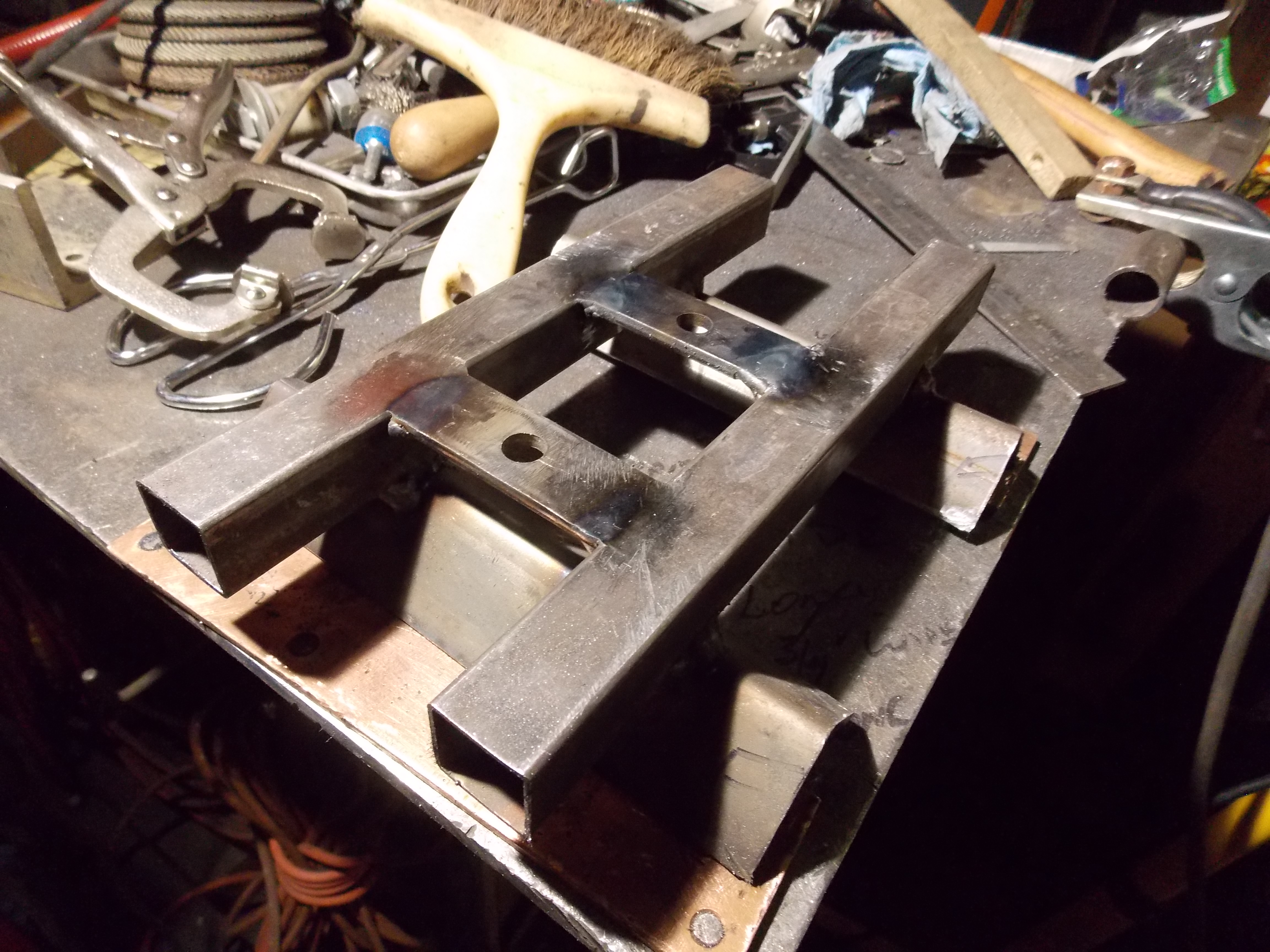

So the feet, you can call them trunnions if you want, were made from 1.5 inch pressed angle iron. Unlike the extruded stuff, you get a round corner instead of a sharp one. On top of them I welded two sections of light wall square tube and bridged them with the two straps that have the mounting holed for the winch chassis drilled into them. Like I mentioned sometime else, being bolted on lets me drop the winch off if I have to work on it or replace it.

View attachment 235580

View attachment 235581

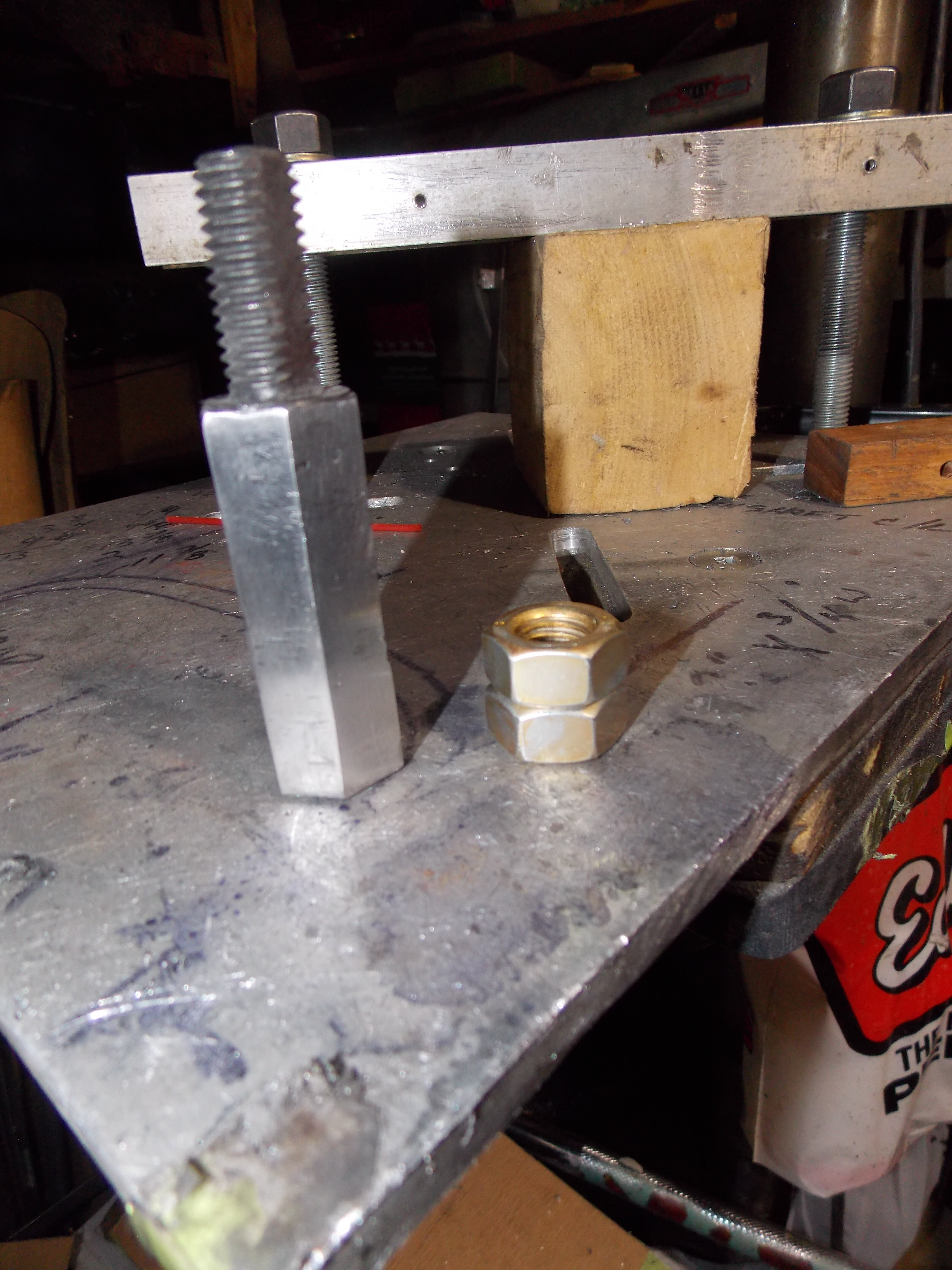

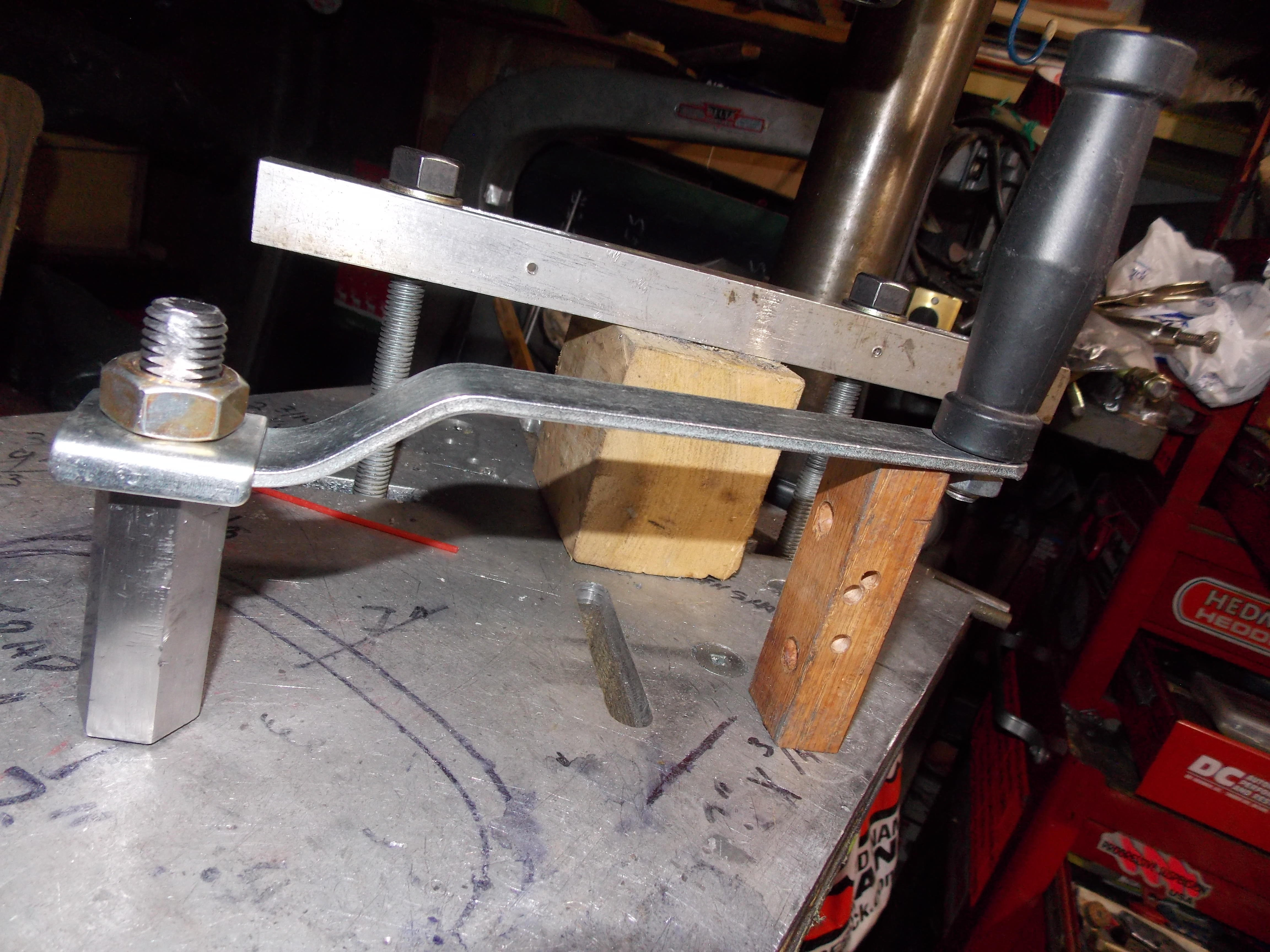

And how it all goes together. In these pictures the subframe is ready to be burned in permanently. The winch is positioned atop it to give a better sense of how it all come together. It also lets you see how the crank arm has been extended out and away from the top frame of the press so that it can be swung without smashing knuckles on it.

View attachment 235583

This is the basic crank assembly that, as delivered, bolts directly to the crankshaft on the winch that turns the cable reel.

View attachment 235584

And here is the extension that i dreamed up to gain the clearance for the crank once the winch was mounted on top of it. Not so oddly enough, the thread on the crankshaft turned out to be metric, 14mm. And, of course, no one local carries 14mm coupling nuts, which is wanted I originally wanted to work with. (They are available on line) So I decided to make a coupling nut, using 14mm nuts like the two sitting beside the finished item and used a 14mm bolt as a spindle on which to stack the nuts so I could line up the flats and tack them together while still being able to turn the bolt; meaning that the threads had lined up and not gone into bind. To faciliate the welds, I chamferred the edges of the nuts where they met each other to get a deeper pass and a stronger joint. That also let me finish the welded faces down to smooth for a better final look.

View attachment 235585

And this is how the crank arm assembly all goes together. To keep the arm from just sitting there and slipping when turns are applied, the stud section showing, has flats carefully ground into it to accept the squared off hole in the crank mounting tab.

Still to be done: Lacing on the lifting cable and fabricating rollers for each end to allow the cable to roll and slide as it transitions from being on the winch reel to meeting the chain yokes that were attached to the press deck lifting points made from 3/16ths angle that I welded to the rails of the press deck (Not sure if I posted pics of them; maybe when I show how the cable gets strung.)

Nick