Update time guys!

Sean and I are three days into what we are calling "The Camaro Thrash". We've planned this for most of this year. Sean and I both took vacation this week and we are working on the punch list on the Camaro. We both believe these cars are never technically 'done' but we want to get the Camaro a lot closer.

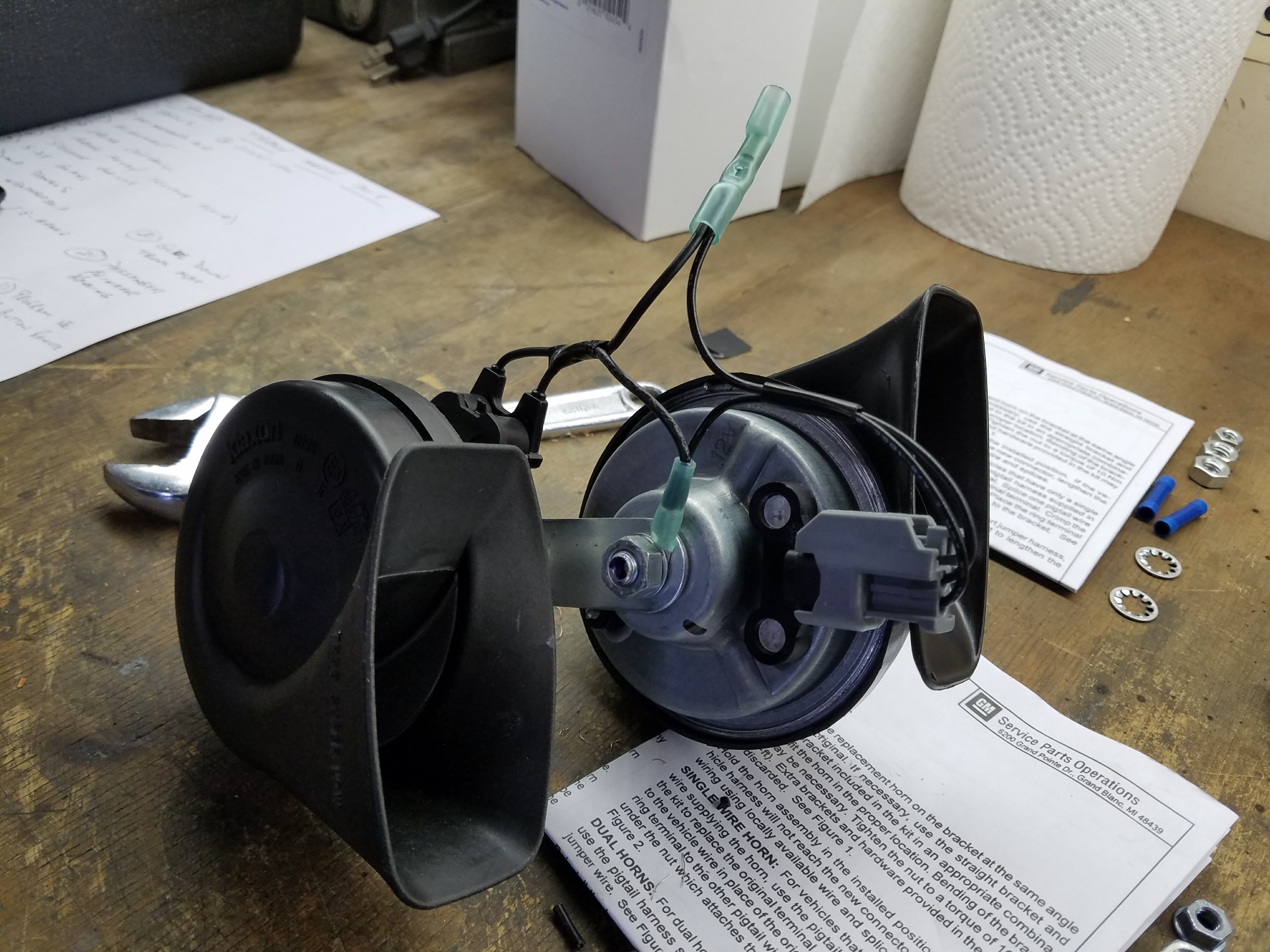

We started out Saturday morning. I started on replacing the horns and Sean started on the passenger front park/turn signal. When we put the car together, we put new AC Delco horns on it. It had one horn when we took it apart, and it didn't work. The horn(s) are mounted to the hood latch on these cars. The Delco horns were China and evidently no good because they didn't last very long. The car has been 'alive' since late 2013 I guess and has right at 4,000 miles on it right now.

We replaced the defective horns with another pair of AC Delco horns, that cost substantially more than the initial pair of horns. The new horns were made in India.

Still, I'm much happier with the new horns. The old set were plastic and stamped sheet metal. This new set is partly cast metal, is lager in size and just seems to be of better quality. We'll see how they hold up. Here is a look at a new horn (right) up against an old one (left)....

When we put the car back together, we mounted the horns similar to how the stock one was mounted, which was horizontal. I decided I wanted the horns mounted vertical so the opening was pointed down. I came up with this arrangement using the brackets that came with each horn 'kit'....

And here is a look at the horns in place. I'm really pleased with how it turned out....

Story on the front right park/turn signal....

When we got the car back from paint, we were having trouble with the right front park/turn signal not working. It turned out we had a problem in a connector in the front (Painless) harness where the park/turn bulb socket plugs in. It took awhile to figure out where the problem was though. Unfortunately, in the process, we ended up with the bulb installed in the socket backwards, which I didn't know was possible. Sean drove the car to work a few times like that (in the early morning dark, running the park lights) and having the bulb run all the time on the 'high side' resulted in melting of the plastic park/turn signal housing. Sean had bought a good used housing in the past few months to fix it with. He took the old housing apart and cleaned it up. He sprayed the inside of it with some 'chrome' spray paint we had on hand from a previous non-automotive project. It turned out looking great....

He cleaned up and reused the lens and bezel from the assembly that we melted the housing to. It had been a brand new assembly. It sucked that we burned up that new housing. Here's a glance at his cleaned up parts...

While we waited for the paint inside the new/used housing to dry, we turned our attention to the next issue: a coolant leak that had sprung up in the past few weeks. Unfortunately the radiator we put in the car has failed. When we put the car back together, we went with a Griffin aluminum radiator specifically for LS swaps in second gen Camaros. It has both the inlet and outlet on the passenger side. It has two rows of 1-1/4" tubes. It was made in the USA. I was pretty proud of it until this failure. I was even less proud when I realized it only has a two year warranty. I realize it has had coolant in it for about four years, but it only has 4,000 miles on it and it has not been abused. It still looks new....

Unfortunately, it has failed where the tubes meet the bulkhead for the core. I looked on Summit's website and other folks are having the same trouble. Some are even saying they have had these radiators fixed, only to have them spring leaks on other tubes. I also saw a guy on Summit who had gone through three units during the warranty period. My advice to folks considering buying a Griffin radiator: don't.

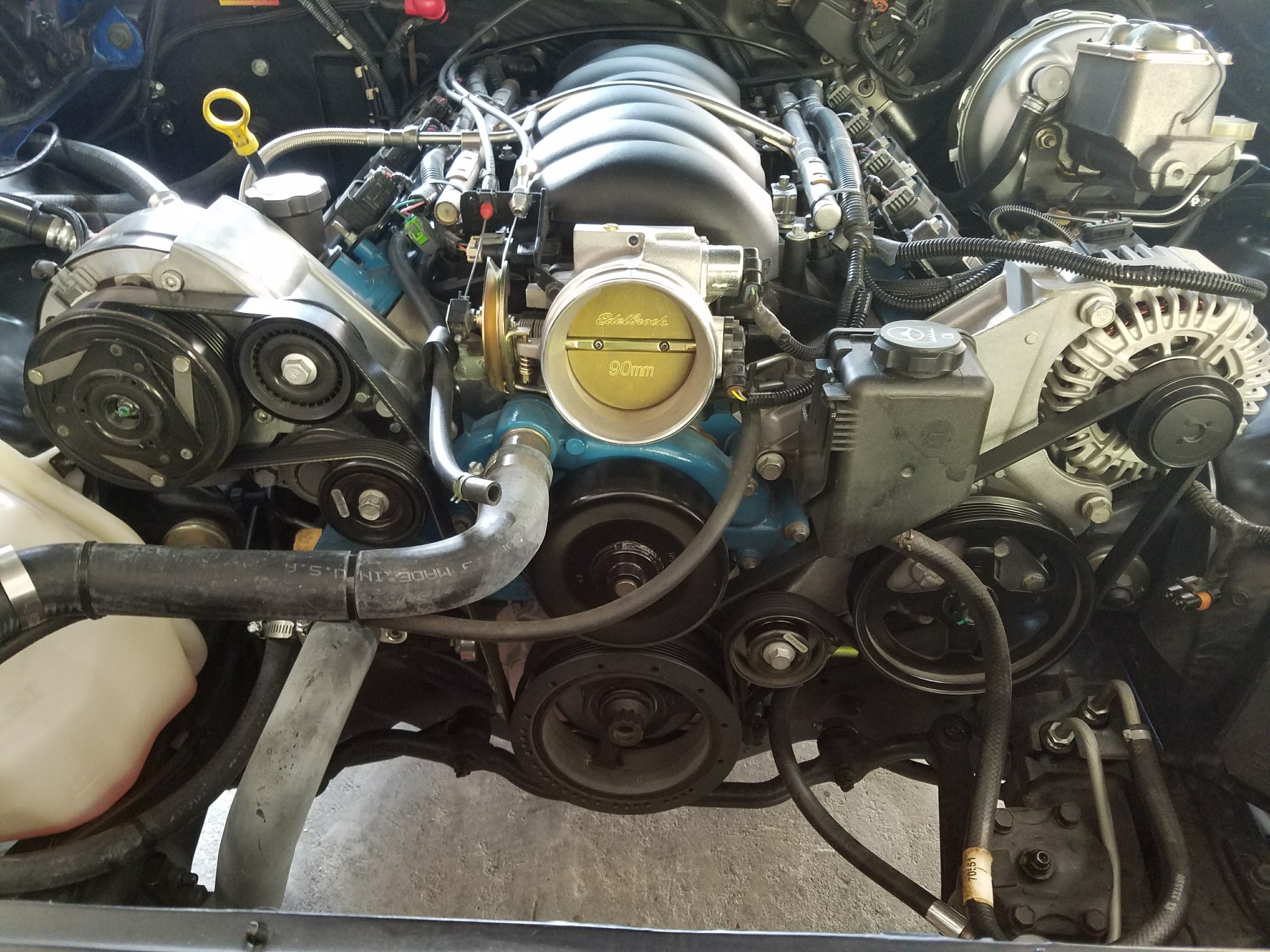

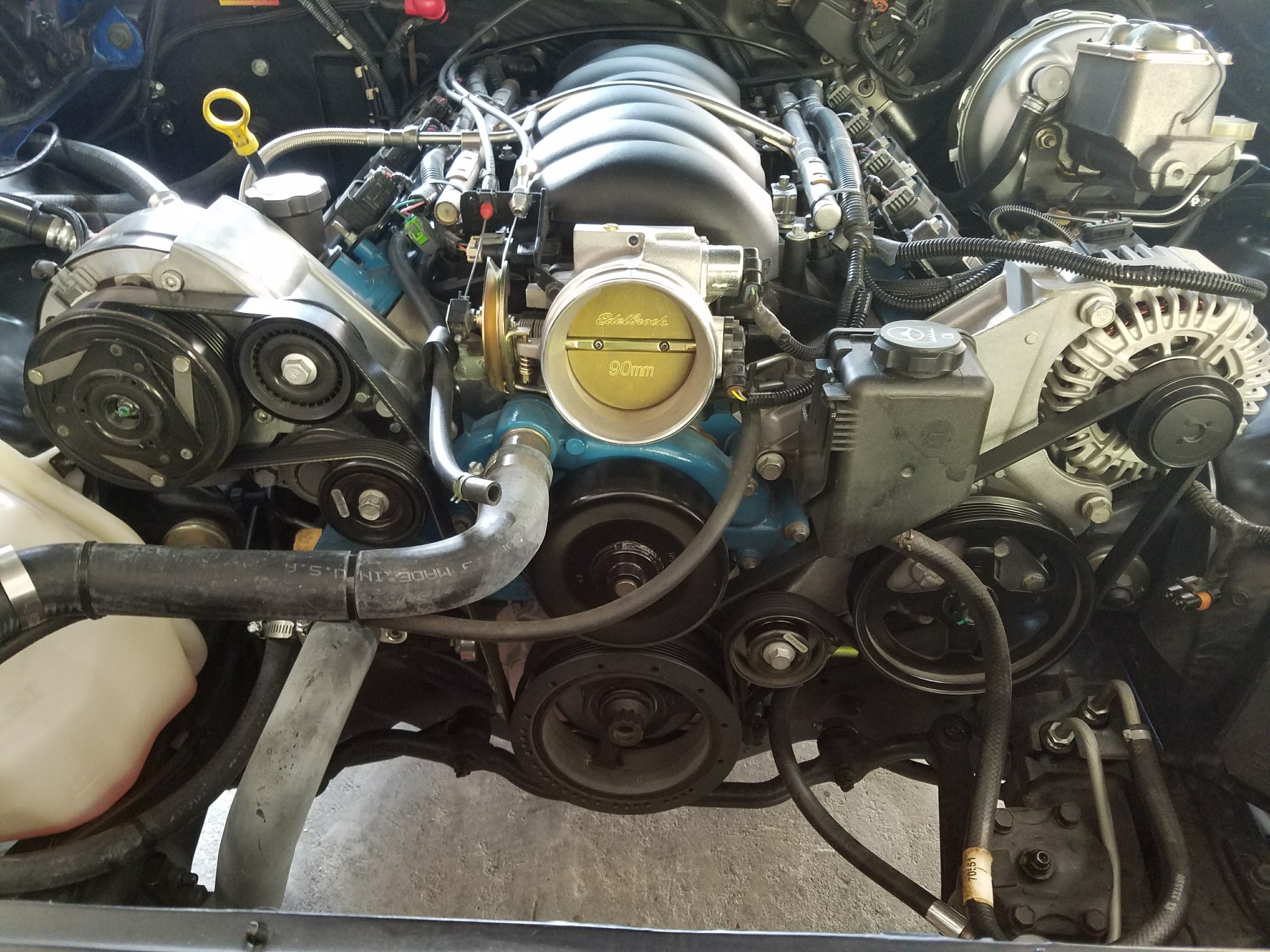

Saturday evening I did a lot of research on what to replace this expensive piece of scrap metal with. We wanted to stay with a swap radiator because we didn't want to re-engineer our air intake. In the end we went with a Champion 3-row aluminum LS swap radiator. Neither of us is crazy about the fact that it is made in China, but it comes with a Lifetime warranty. It was about $100 more expensive than the Griffin. We're hoping to have it towards the end of the week. Here's a look at the engine bay with no radiator and fans...

Saturday morning we jumped on the next item on the list: un-metered air. We've been experiencing a tuning issue where if you start the car cold and drive it, it acts one way but if you cut it off hot, like when you go into a store and come back out, it runs a different way. After a lot of work logging data, our tuner notified us that when we are restarting hot, there is significantly less air flow. In other words, the theory is that we are leaking vacuum on a cold start and after the engine warms up and everything under the hood takes a good heat soak, something is swelling up and sealing itself and we are getting less airflow.

Based on this theory, we attacked the problem head on. We pulled the intake to replace the intake gaskets. While it was out Sean replaced all of the injector O-rings. I pulled the throttle body and inspected its O-ring. I also pulled the idle air control valve and looked at its O-ring. Sean worked on tightening up our plumbing for the PCV. I looked at how our LS1 map sensor was sealing in our LS3 intake and replaced our first solution with a short length of 1/4" fuel hose which seems to fit really nice and tight. Here is a look at the engine without the intake...

We got the intake installed back on the car yesterday afternoon. We pulled the battery and the alternator for testing. More on that later. Next we moved on to front end alignment. In one of the last posts in this thread, Sean and I were working on getting the steering wheel straight and setting the toe. The last time we worked on it, we got the wheel a lot straighter, but it still wasn't quite straight. Inspired by the YouTube video Steve posted above, we set up string lines on jack stands and took another stab at getting the wheel straight...

A look at way too much human being jammed under a low slung car...

The trash bags are a tip from a YouTube video. They make getting the wheels to move much easier. Anyways, by the end of Saturday, I felt good about the toe setting and I felt like the steering wheel was straight. Sean was able to get the passenger side park/turn signal buttoned up and crossed off the list.

To be continued ==>

Still, I'm much happier with the new horns. The old set were plastic and stamped sheet metal. This new set is partly cast metal, is lager in size and just seems to be of better quality. We'll see how they hold up. Here is a look at a new horn (right) up against an old one (left)....

Still, I'm much happier with the new horns. The old set were plastic and stamped sheet metal. This new set is partly cast metal, is lager in size and just seems to be of better quality. We'll see how they hold up. Here is a look at a new horn (right) up against an old one (left)....