It should be the bottom one on sender but hopefully someone else will verify. White thing has to be a vent maybe with built-in rollover valve???

BUILD THREAD Tomeal's Elky Build

- Thread starter Tomeal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

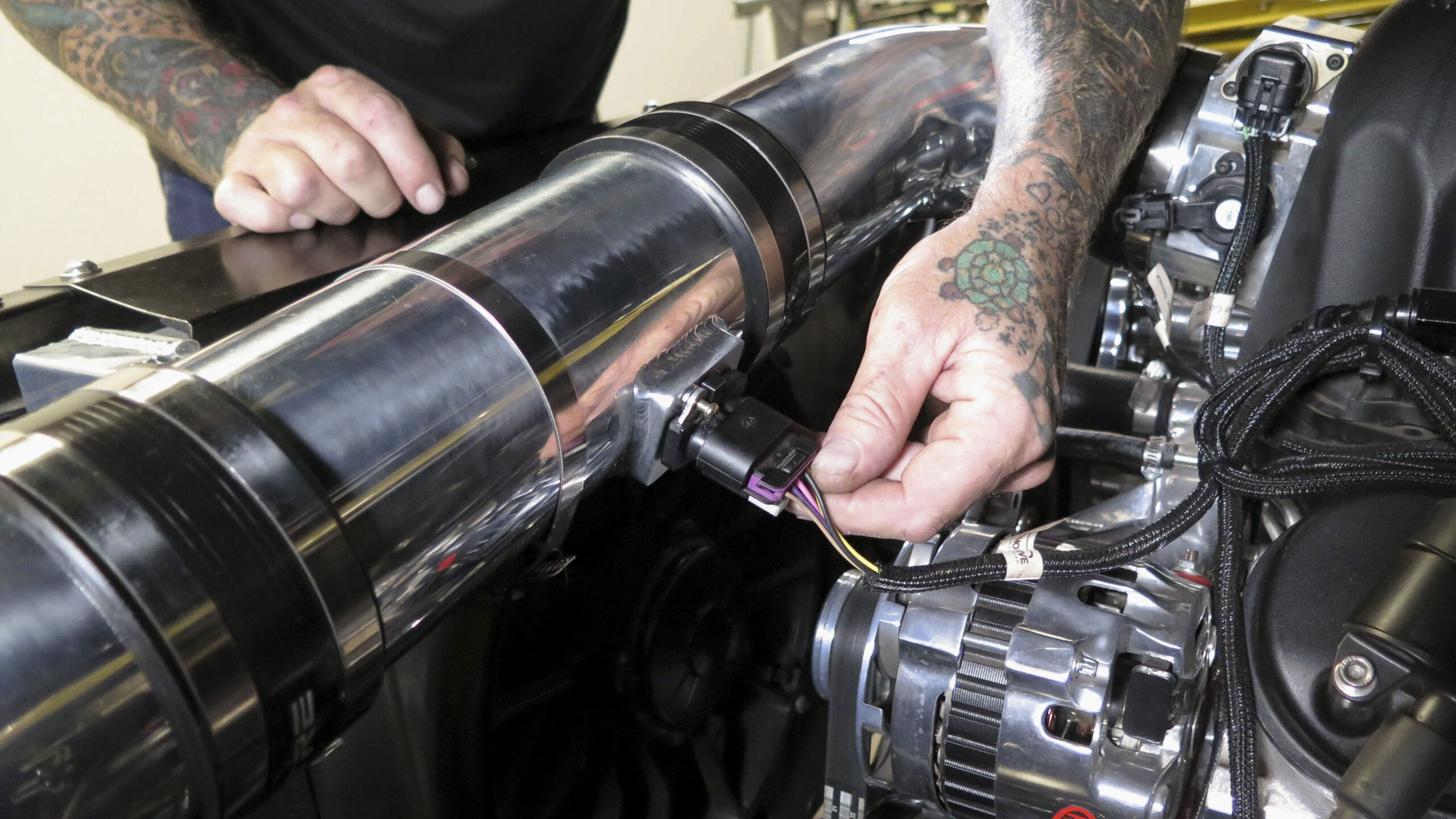

Started putting the harness back on the engine. Should have taken more before pictures. Need to pick up some larger loom to finish running it.

Got a little high on paint fumes from the chassis paint. Should've paint the underside of the body before I put it on the frame, but oh well.

Paint can dry then I'll run the fuel system.

Got a little high on paint fumes from the chassis paint. Should've paint the underside of the body before I put it on the frame, but oh well.

Paint can dry then I'll run the fuel system.

Fuel system day!

Was hoping to get farther today, but I apparently needed to learn how to do AN fittings. Started with not having anything that would cut through the stainless braid. Then figuring out how to spread the braid right so the furrel would seat right. I think I figured it out.

Tomorrow is another day. I'll finish the lines tomorrow and hopefully pressure test them to find out if I need to re-do any fittings.

After that then it's back to wiring. In cab wiring and finishing the engine wiring.

Was hoping to get farther today, but I apparently needed to learn how to do AN fittings. Started with not having anything that would cut through the stainless braid. Then figuring out how to spread the braid right so the furrel would seat right. I think I figured it out.

Tomorrow is another day. I'll finish the lines tomorrow and hopefully pressure test them to find out if I need to re-do any fittings.

After that then it's back to wiring. In cab wiring and finishing the engine wiring.

Tape areas to be cut to stop fraying. Use a hacksaw, cut off wheel, or large wire/cable cutter.Fuel system day!

Was hoping to get farther today, but I apparently needed to learn how to do AN fittings. Started with not having anything that would cut through the stainless braid. Then figuring out how to spread the braid right so the furrel would seat right. I think I figured it out.

Tomorrow is another day. I'll finish the lines tomorrow and hopefully pressure test them to find out if I need to re-do any fittings.

After that then it's back to wiring. In cab wiring and finishing the engine wiring.

Tried a hacksaw, none of the blades I have wanted to cut it worth a sh*t. All my blades are loose and laying around, so I'm not sure what they are intended to cut. Was going to try the cut off wheel, but it looked like it could be messy going through the liner. The videos I watched I liked the cable cutter.

Ran and got one. It works really smooth. Oblongs the pipe slightly,but is easy to fix.

Tape works so freaking good I was fighting getting it to expand open that little bit to get the furrel to seat right on the liner.

I'm using fragola line and fittings. Found I can slip the fitting in the liner and use a small flat screwdriver that I bent the tip to work around the braid to open it up.

Ran and got one. It works really smooth. Oblongs the pipe slightly,but is easy to fix.

Tape works so freaking good I was fighting getting it to expand open that little bit to get the furrel to seat right on the liner.

I'm using fragola line and fittings. Found I can slip the fitting in the liner and use a small flat screwdriver that I bent the tip to work around the braid to open it up.

Well spent a lot of the holiday working with my boy on his truck. We bought him things he wanted for it so we worked on it together!

Anyways got some time while he was doing some things on his own. I ran the rest of my fuel lines.

I was sweating this part a little cause I've never done AN lines before. Finished up and hooked up a battery to the pump to pressure my lines and check for leaks. Purged the air from the fuel rails and let it pressure for a minute. NO LEAKS!

This feels like a good step. Got to dress the lines, but a little closer.

Now to work on the dash and the gauge wiring.

Anyways got some time while he was doing some things on his own. I ran the rest of my fuel lines.

I was sweating this part a little cause I've never done AN lines before. Finished up and hooked up a battery to the pump to pressure my lines and check for leaks. Purged the air from the fuel rails and let it pressure for a minute. NO LEAKS!

This feels like a good step. Got to dress the lines, but a little closer.

Now to work on the dash and the gauge wiring.

Mass air flow sensor MUST be in the air inlet of you're using the stock computer. Usually everyone just connects it with silicone couplings

The best way is to duplicate the basic layout of the factory set-up.Right up against the intake using couplers, then run the rest out to the filter?

Thanks, my brain would not think of that.

The MAF part of the tune is set for the factory location.

Might make a difference, might not.

Most crate engine kits I've seen say "x" number of inches from the throttle body in a straight piece of pipe at least "y" inches long.

Try this. It explains it better than I can.

Optimal LS MAF Sensor Placement for Best Performance

Learn about GM's guidelines for LS MAF sensor placement to enhance performance. Ideal distances and positions for accurate airflow readings.

teamcpp.com

teamcpp.com

Similar threads

- Replies

- 2

- Views

- 145

- Replies

- 38

- Views

- 978

- Replies

- 35

- Views

- 1K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.