What is that? I've never seen one. Doesn't say much, but I do appreciate the rare weird stuff that occasionally gets put out.

Malibu S3 Laguna. They have somewhat of a cult following.

What is that? I've never seen one. Doesn't say much, but I do appreciate the rare weird stuff that occasionally gets put out.

Malibu S3 Laguna. They have somewhat of a cult following.

Its a 1975 Chevelle Laguna S-3. Chevy dropped the SS model in 74 and produced these from 74 to 76. They were sold in limited numbers to the public so they could race them in NASCAR back in the day.What is that? I've never seen one. Doesn't say much, but I do appreciate the rare weird stuff that occasionally gets put out.

Thanks. I hope to see you out there sometime soon. I love those colonnade A-Bodies, especially the Laguna and the Can Am. Dad wanted to go tonight but Sean and I pushed pretty hard today and just didn't have the car show in us tonight.Yup, that was my work in progress that he saw. The guys I met up there were F body folks as well and they commented on how well done Sean's Z turned out. I'll be sure to introduce myself next time I see him up there. Hope to see you at one of the shows too. Love to see your GP in person.

Looking forward to catching up with you at the next one. You all did an amazing job on the Z. The blue paint job really stand out. Is that a factory color?Thanks. I hope to see you out there sometime soon. I love those colonnade A-Bodies, especially the Laguna and the Can Am. Dad wanted to go tonight but Sean and I pushed pretty hard today and just didn't have the car show in us tonight.

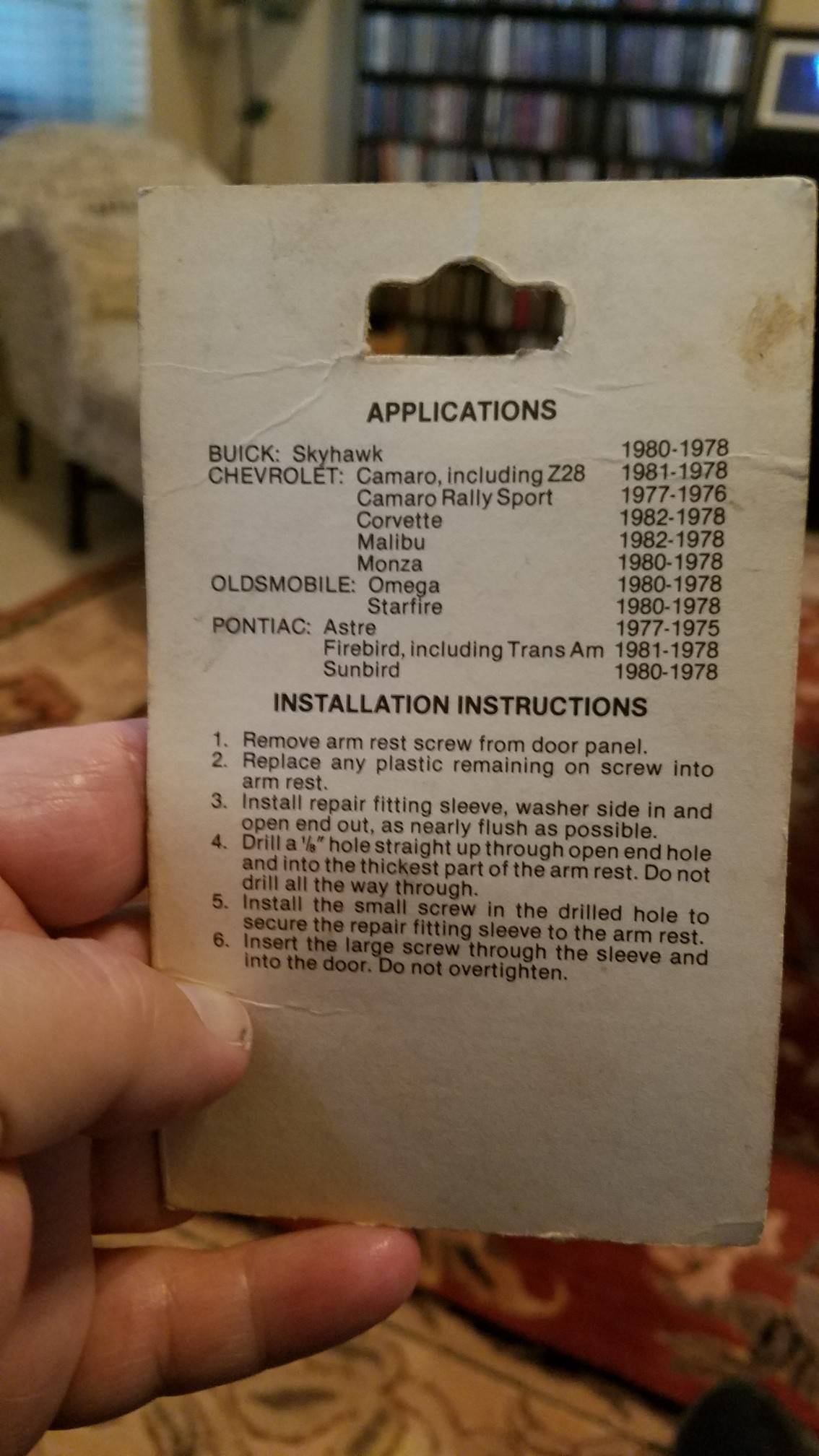

I really appreciate the kind words on my brother's Z28. It's not perfect. We just did the best we could. I'm really proud of it and love to see my brother enjoy the car he always wanted.

Yes that's the original paint color and decal package. The light blue interior with navy blue carpet is also how it was new. The bright blue in the seats is a modification. They were light blue/navy blue from the factory. It had that style of wheels stock, but they were 15's and were body color, originally.Looking forward to catching up with you at the next one. You all did an amazing job on the Z. The blue paint job really stand out. Is that a factory color?

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.